A timing belt or chain is installed as a timing drive on different types of engines. They transmit torque from the crankshaft to the camshaft, which controls the operation of the vehicle's valve system. The VAZ 2107 engines use a chain drive, which provides greater reliability compared to a belt drive. There are frequent cases of broken timing belts, which leads to damage to the valves of the gas distribution system and requires expensive, labor-intensive engine repairs. Unlike a belt, a timing chain guarantees the absence of breaks and the consequences associated with it.

During operation, the chain gradually wears out and stretches, beginning to make an unpleasant knocking noise. If the malfunction is not corrected in time, a chain that is too loose can jump one or two teeth, which will lead to a shift in valve timing, loss of power and engine performance. If the chain slips by a larger number of teeth, the timing valves may “meet” the pistons, as happens on some engines when the timing belt breaks. To prevent this from happening, it is necessary to periodically monitor the tension and, if necessary, tighten the VAZ 2107 chain.

When to check chain tension

If you need to tighten the chain, it is not necessary to check the tension. It is enough to use a chain tensioner (this will be discussed below). Checking the tension is necessary if the chain has been replaced or if the chain continues to knock after tensioning. The knock of a loose chain is easy to distinguish from other noises: when the engine speed increases, it disappears.

To check this yourself, you need to open the hood and start the car. Then ask an assistant to press the gas pedal or independently pull the cable that controls the throttle valve with your hand. If the knocking noise at the front of the engine has disappeared, the cause is low chain tension. It needs to be tightened up.

Replacing the timing chain

The material of the chains of modern engines no longer has the strength that was characteristic of the gas distribution mechanism drive parts of cars of the late 19th and very early 20th centuries, and due to the heavy load on turbocharged engines, the service life of spare parts in other cases does not exceed 100 thousand. km. If extraneous noise appears under the hood, it is necessary to immediately find out the cause of the defect; the car owner always has two options:

- figure out the problem yourself;

- contact a service station.

When diagnosing yourself, first of all you need to troubleshoot the tensioner, remove it and do an external inspection. Replacing a timing chain with your own hands is a rather difficult and time-consuming operation, and if the car has an internal combustion engine of a complex design, it is better to entrust the repair to professional craftsmen.

How to check chain tension

The VAZ 2107 timing chain is located in the front part of the engine. It is closed on top by the cylinder head cover, on the bottom by the engine sump, the middle part runs inside the block and can only be reached by removing the chain.

To check the chain tension, simply remove the cylinder head cover. To do this, you need to unscrew the 8 fastening nuts. After removing the cover, the gasket must be replaced. It is inexpensive, but if this is not done, after installing the cover with the old gasket, it is almost guaranteed that oil will begin to ooze from under it.

When the "valve cover" is removed, the top of the chain is exposed. You can check the tension with your hands, but it is better to use a large screwdriver. It must be inserted between the chain and the cylinder block body and, using it as a lever, try to bend the chain. In this case, the chain should not bend. The tension must be checked on both sides - on the left and right sides of the engine. A chain that is taut like a string and does not bend when pressed with a screwdriver or fingers is a sign of its correct tension. Otherwise, it must be tightened or replaced.

Important: Do not apply too much force by pressing the chain as hard as you can. This can lead to deformation of the chain links. Therefore, it is necessary to press “half-heartedly.”

Adjusting chain tension VAZ 2107

“How to properly tension the chain of a VAZ 2107” is a common question among novice owners of the VAZ “classic”. The chain tension is regulated by the crankshaft bolt and a special part - the chain tensioner.

To adjust the chain tension, you need a spanner for the chain tensioner nut and a special wrench to turn the engine crankshaft. The latter can be replaced with a 36 ring wrench.

Adjusting the tension begins by loosening the chain tensioner nut. In this case, if the chain has been loosened, the tensioner shoe should move slightly and tighten it.

If the shoe is stationary and the chain is not tensioned, release the tensioner plunger by lightly tapping the nut with a hammer. Sometimes it doesn't help. Then you should remove the tensioner and restore its functionality or replace the part. This malfunction (plunger jamming) is quite typical for VAZ engine chain tensioners. This is why it is advisable to remove the engine head cover and check the chain tension, rather than adjust it “blindly”.

To properly tension the VAZ 2107 chain, you need to turn the engine crankshaft with a special wrench clockwise 1-1.5 turns, stopping it at the moment when the rotation resistance is maximum.

Important: some mechanics prefer to turn the crankshaft with the starter when adjusting the chain tension. This is not recommended, since the correct tension can only be achieved by smoothly rotating the crankshaft and stopping at the moment of greatest resistance to rotation.

After completing the operation, all that remains is to firmly tighten the tensioner cap nut and replace the engine head cover.

Tensioning the VAZ 2107 chain takes about half an hour, however, if this is not done, the consequences can be very disastrous. The article contains detailed instructions with photos.

Contents of the article: Before starting work, you need to find out what the reason is. After all, incorrect diagnosis will not only force you to do unnecessary work, but will also not allow you to identify the true malfunction.

Let's sum it up

Sometimes a metallic knock in the engine turns out to be not such a terrible problem. But often it notifies the driver that one of the main units is failing. So it is very important in this situation to act thoughtfully and calmly, to use only the most worthy options for diagnosing the problem. There are various types of problems that can only be identified through professional intervention. But some problems are also visible upon personal inspection of the engine compartment. If you are convinced that the problem is with the engine, it’s time to sign up for service. This will help you find a solution to the problem.

Sometimes specialists can greatly delay diagnostics and repairs, since finding the cause of knocks and other noises can be difficult. It is best to use the repair options from a good professional service to eliminate all risks of problems. This will help to significantly improve the quality of restoration and reduce the time required for repair work. If you decide to troubleshoot the problem yourself, you will need a lot of time and a number of instructions to complete the necessary tasks. Have you ever encountered metallic sounds when starting the engine in a car?

Source

Symptoms of loose chain tension

In principle, the symptoms are quite specific, and it is very, very difficult to confuse them with something else.

- Increased engine noise, even at idle speed;

- Instant increase in noise during a sharp increase in speed;

- The roar increases proportionally with a smooth increase in speed, and decreases gradually with a sharp release of the gas pedal;

- Most often, a loose VAZ 2107 chain rattles because the damper has broken and needs to be replaced.

However, let’s say that this is not the case, and we just need some tension.

To work, we will need a special key to turn the crankshaft; on carburetor cars, you can turn it using a ratchet. Before starting work, let the engine cool down. Many people believe that it is necessary to tension the chain when it is hot in order to compensate for its thermal expansion. In fact, an automatic tensioner is installed on the car, which copes with this. In principle, there is no difference at all; you need to let the engine sit so that the oil flows from the head into the crankcase or down the line.

Now let’s look directly at how to tighten the chain on a VAZ 2107:

- Remove the valve cover. Do not forget about specific washers, which, if lost, will have to go to the store;

- Using a 10 mm socket wrench, unscrew the two bolts that hold the tensioner;

- Next, we clamp it in a yew or in a gas wrench, after which we unscrew the cap nut three or four turns with a 13 wrench;

- Remove the tensioner from the vice. We press the plunger (the thin finger on the back side of the cap) against the table or other surface until it is completely sunk into the body;

- Now tighten the nut and insert the tensioner into place. Of course, you need to check the gasket and replace it if necessary. Tighten the fastening bolts;

- Make a couple of revolutions of the crankshaft. It is advisable to do this with your hand and not with a starter. To make work easier, you can unscrew the spark plugs. As soon as you feel uniform resistance, hold the crankshaft from reverse and unscrew the cap a couple of turns. Thus, we “discharge” the plunger and tension the chain.

This completes the tensioning of the chain on the VAZ 2107.

Installing the chain by marks

If repair work has been carried out on the timing drive or the chain is highly stretched, such that the marks on the camshaft gear and crankshaft pulley do not match the corresponding marks on the bearing housing and engine block, an adjustment must be made and the chain installed correctly.

Tools you will need:

- Screwdriver Set;

- key for rotating the crankshaft;

- a set of keys.

To install the chain, follow these steps:

- Remove the cover, filter and its housing.

- We disconnect the crankcase exhaust pipe from the carburetor, and also loosen the fasteners of the choke cable to remove the cable.

- Using a 10 mm socket wrench, unscrew the valve cover fasteners.

- Remove the lever from the cover along with the carburetor rods.

- Remove the cylinder head cover.

- We turn the crankshaft using a wrench until the mark on the camshaft gear coincides with the protrusion on the body. The mark on the crankshaft pulley should match the length mark on the front engine cover.

- If, when setting the marks, it turns out that one of them does not match, unbend the lock washer under the camshaft gear mounting bolt.

- Engage first gear and unscrew the camshaft gear bolt.

- Remove the star while holding it in your hands.

- We remove the chain from the gear and change its position in the desired direction to align all the marks, as described in paragraph 6.

- We carry out assembly in reverse order.

- At the end of the procedure, do not forget to tension the chain.

Video: setting valve timing on a VAZ 2101–07

Consequences of a loose chain on a VAZ 2107

This applies to 2106 and all classics in general. First of all, the chain is manufactured with high precision and durability. This means that at the slightest jump of teeth, the engine will work at random. This is especially true for injection engines, since the crankshaft position sensor will give one reading, but in fact, the shaft will be in a completely different position. Moreover, jumping two or more teeth is fraught with the risk that the valve will punch a hole in the piston, and such a disaster will occur in all cylinders, and if, when the belt breaks, for example, the timing parts move simply by inertia, then in this situation they are still driven into movement from the crankshaft.

The next problem is wear of the head housing. It has a special part near the camshaft gear. So, aluminum wears off very easily at high speeds, and then restoring the head can be very problematic. The same goes for the tin valve covers. In general, timely tensioning of the chain on a VAZ 2107 is a mandatory procedure.

One of the most critical components in any car is the gas distribution system. The operation of the entire engine depends on its serviceability. If the phases are shifted by even one tooth, dips will begin and the speed will destabilize. The motor will run unsteadily. But how to maintain this unit in good condition? Let's look at how to properly tension a chain on a VAZ-2107 and how to identify the symptoms of a malfunction.

Whistling like the Nightingale the Robber

Some cars can frighten their owner with a sudden and strong whistle when starting to drive. The car warmed up calmly and without unnecessary sounds, but as soon as we started driving, it began to whistle all over the street. The reason most likely lies in the tension roller of the drive belt. Domestic cars especially often suffer from this disease. If you notice this behavior in your car, then you should not turn a blind eye to it, as many do. This unfortunate roller can jam at any time and cause the belt to break, which will lead to the pistons meeting the valves.

Photos from Internet resources

Signs of stretching

The symptoms of this problem are specific. And it will be very difficult to confuse them with something else.

So, the main signs of a stretched gas distribution element chain are:

- Increased engine noise. Yes, the chain itself is very noisy. But in this case, the sound will be accompanied by a characteristic clattering sound, even at idle speed. As you press the pedal, the clunking sound will increase in intensity.

- Unstable engine speed. Since we now have shifted valve timing, the engine will adjust. Excessive vibrations occur and are transmitted to the body.

In some cases, the damper breaks. In this case, only replacing it will help. How to tension a chain on a VAZ-2107 (injector)? Photos of the process are in our article.

By the way, on a VAZ-2107 with a carburetor power system, unlike injection engines, to turn the crankshaft it is enough to turn the ratchet. But let’s not get ahead of ourselves and consider several ways to tighten the motor chain on a VAZ-2107.

What happens when the timing chain breaks and is pulled out?

When the timing chain is stretched, it eventually begins to make noise not only at idle, but also at higher speeds, as a result of prolonged operation with chain noise:

- the chain jumps, which causes the marks and valve timing to go astray;

- the gas distribution mechanism drive breaks with all the ensuing consequences.

When the chain drive links jump, the engine begins to work intermittently, power is lost, and in some cases the engine may not start at all. If a break occurs, at least it bends the valves on 16-valve internal combustion engines, in the worst case, in addition to this:

- piston heads are damaged;

- the front engine cover breaks (a hole may form);

- the cylinder head seats crumble;

- scoring occurs on the surface of the cylinders.

Basically, a break in the timing chain threatens the overhaul of the power unit, often due to the high cost of parts and the work itself, it is more profitable to buy a contract engine than to repair the engine.

How to tension a chain on a VAZ-2107 without removing the valve covers?

First we need to place the car on a flat surface and secure it with anti-roll bars. Next, fix the gearshift lever in the neutral position. Then remove the drive cover. Once access to the chain is free, the tensioner should be slightly loosened. It is located next to the water pump. Next, using a 36-degree socket, rotate the crankshaft 360 degrees. After this, tighten the tensioner to the maximum. We start the engine and check the tension level. The clatter must disappear.

Why does the engine knock, what is the reason

Knocks in the engine appear both cold and hot. Engine knocking when cold appears both in winter and in summer. Today we will look at the reasons for the appearance of knocking when the power unit is running cold. Let's find out how to independently diagnose the motor.

Anything can knock in the power unit. This could be noise from the attachment. For example, the bearings of the generator or water pump are noisy. This could be noise from the connecting rod bearings or pistons.

Tightening the chain while removing the valve covers

If the chain is still noisy, perform the following operation. Using keys, we remove not only the drive, but also the valve cover from the cylinder head side. In this case, the chain tension can be checked manually as the camshaft sprocket is released.

So, loosen the tensioner a little and turn the crankshaft two turns. After this, fully tighten the timing chain tensioner. Next, we check the element manually. There should be no sagging. The chain must be elastic. If so, replace the valve cover and drive cover.

Is it possible to drive?

In short - NO NO! We immediately go to the service station and look for the causes of this malfunction. Of course, if the chain rattles for a short period of time, you have a few days, maybe even weeks. But again, I wouldn't wait. All this can end very badly!

When replacing, I also do not advise you to save money - we change the tensioners, the chain, you should not change everything separately. As a rule, the complete set is changed, especially if your mileage is really high.

Now let's watch the video version

I’ll end here, I think my article and video were useful to you. Sincerely yours, AUTOBLOGGER

Similar news

- After how many engine hours should you change the engine oil? Must know...

- Adsorber. What is it in a car, what is it for, what does it affect...

- How to unscrew the oil filter (without using a wrench). What to do if...

Add a comment Cancel reply

Adjustment Details

Sometimes the process of adjusting the tension level may be required several times. Therefore, let us consider in detail how this procedure is performed. After the cover has been removed, it is necessary to relieve the pressure in the tensioner. To do this, unscrew the corresponding lock nut.

As soon as it loosens, the tensioner shoe will make a characteristic click. If this does not happen, and the locknut is almost unscrewed, you need to knock on the tensioner. Sometimes the plunger gets stuck in it. Try not to damage this element and strike gently through the rubber layer. As a result of the operations performed, the element should snap off.

How to tension a chain on a VAZ-2107? Use a large wrench to turn the crankshaft. It should stop at the point of greatest resistance. Just turn it a couple of turns. Using a wrench, fix the shaft in this position and tighten the cap nut. How to further tighten the chain on the VAZ-2107 with your own hands?

We connect the tensioner and check how secure it is. If the chain is elastic, install all the elements in place and start the engine. When checking the operation of the timing drive, there should be no extraneous noise, which will increase with increasing crankshaft speed.

Main Causes of Circuit Failure

As the engine speeds up, the chain begins to rattle. In this case, the metallic ringing goes away as the speed decreases. A stretched timing chain contributes to a gradual shift in the valve timing, which leads to engine malfunctions.

All owners of cars of this brand should know how to tighten a chain on a VAZ 2107. This work is performed using a “13” wrench and a hammer. The chain is adjusted as follows.

- The tensioner is discharged. When performing this procedure, the shoe should snap off. If this does not happen, it means that the timing chain tensioner plunger is stuck. The problem is eliminated by tapping the unit body with a hammer.

- Using a key set to “13”, the cap nut is unscrewed.

- Using a special crankshaft wrench, the pulley is turned a couple of turns.

- The crankshaft stops at the moment of maximum rotational resistance. In this position, tension is applied.

- While holding the crankshaft from turning in the opposite direction, tighten the cap nut.

- The cylinder head cover is being installed.

In some cases, such tension is ineffective. Experienced auto mechanics know how to tighten the VAZ 2107 injector chain. To do this, you will need the following tools: 8 and 10 sockets, pliers and a ratchet with a handle. The valve cover is unscrewed and dismantled, thus providing access to the camshaft sprocket. The chain tension is checked manually.

The next step is to turn the crankshaft of the VAZ 2107 injector several turns. This work is carried out by turning on the starter for a few seconds or using a wrench that is placed on the ratchet.

The next step in solving the problem of how to tension a chain is to check the tension. To do this, it is recommended to click on the side branch of the mechanism in question. This procedure is carried out until the desired result is achieved. After this, the tensioner bolt is screwed in until it stops. To ensure that the work is completed correctly, a special scheme is used.

Why is this so important to do?

During operation, the chain is subjected to significant loads. After all, it interacts with two shafts - the crankshaft and the camshaft. Over time, the part stretches out. The chain pitch changes and the engine begins to operate unstably. As a result, the revolutions fluctuate, and the mechanism itself jumps one or more teeth. If the circuit begins to make noise, this is the first sign for diagnosis.

The tensioner may have failed. But in most cases, simple adjustments save the day.

Experts recommend tightening the chain every 15 thousand kilometers. Its resource itself is about 100 thousand. By this time the part must be replaced. The sedative also changes. Before tensioning the chain on the VAZ-2107, check its condition. All the necessary elements can be found in the VAZ-2107 timing belt repair kit.

When is stretching necessary?

The gas distribution mechanism on the VAZ 2107 injector consists of the following elements:

- intermediate and crankshaft gears;

- camshaft and intermediate shaft;

- rocker;

- sedative;

- intake and exhaust valve;

- tensioner;

- shoe;

- timing chain drive.

The photo shows timing parts.

Components of the gas distribution mechanism

Thanks to the timing belt, the air-fuel mixture is supplied and exhaust gases are removed. Its operation is carried out using a chain drive or belt. They transmit torque from the crankshaft to the camshaft.

The shafts must be in a certain position. To do this, special marks are placed on the crankshaft pulley and the camshaft sprocket, which must be set correctly. If the marks do not match, serious problems with the engine may occur, including major engine repairs.

During operation, the chain drive and belt are under constant tension, so after a while the chain gradually stretches out - its pitch increases. In this case, the engine begins to idle unstably, the speed begins to fluctuate, and the engine may stall.

If metallic sounds appear when increasing or decreasing speed, this is a sure sign of stretching of the chain drive or wear of the damper. To eliminate these sounds, you need to tighten the chain or replace the damper. Chain drive tensioning should also be done after replacing any timing parts, including the guide rail and shoe.

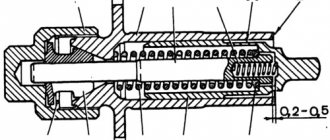

The chain drive on the VAZ 2107 injector is adjusted using a tensioner, which can be a mechanical, automatic or hydraulic tensioner. To install a hydraulic tensioner on a VAZ 2107, you need to redo the timing belt. Instead of the standard one, an automatic tensioner is often installed; it is more reliable.

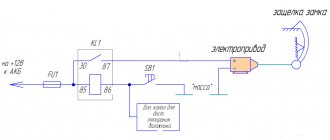

Diagram of the gas distribution mechanism

How to determine that the chain drive is knocking?

Actually, this sound is quite strong, metallic and clinking. Many call this sound similar to the operation of a diesel engine, that is, there will be a kind of “dieseling” present. Of course, I will have everything in the video version below

As I already wrote above, it can manifest itself in three stages:

- Rattles when “cold”

- Knocks on "hot"

- Sound when under load. For example, if you accelerate, no, but when you let off the gas, there is

- Constant metallic noise

Of course, it’s difficult to understand in words, so I advise you to watch the video version below

Step-by-step instruction

Before starting work on tensioning the chain, the car must be placed in a comfortable position. Place the gearshift knob in the neutral position and secure the wheels so that the car does not roll during the procedure.

Tools

To carry out the work, the following tools are required:

- set of socket wrenches;

- set of heads;

- pliers;

- screwdriver;

- hammer.

Before starting work, you should make a visual inspection of the chain drive. If mechanical damage is found to the tension roller, shoe, guide, sprockets or chain, the defective parts must be replaced.

Stages

The sequence of work when tensioning the chain both in an engine with an injector and with a carburetor consists of the following steps:

Sometimes tensioning is impossible because the chain stretches over time and the plunger is no longer long enough to make the adjustment. If you do not plan to change the product, then for temporary driving you can increase the tensioner rod, for example, by attaching a bushing to the end of the rod, with which the air filter is attached. But still, a worn-out product must be replaced in the near future.