The timing chain plays an important role in the operation of the gas distribution mechanism. Over time, it stretches and requires tension, since the quality of the engine depends on it. Therefore, you need to know when to check the tension and how to tension the chain on a VAZ 2101. This topic is covered in an article and a video that demonstrates the process of checking and tensioning the chain drive.

When is stretching necessary?

Chain tensioning is required in the following cases:

- after engine repair;

- after replacing the product;

- when stretched after prolonged use.

Timing belt VAZ 2101

In the first two cases, it is clear that checking the tension is necessary, since the chain was removed or replaced. In addition, you should also check that the alignment marks match. These marks are located on the crankshaft and camshaft. You can determine the need for tension by the sounds of the engine running. If the tension is weak, then during its operation extraneous noises are heard in the place where the chain drive is located. At the same time, timing parts wear out faster. Therefore, when checking the tension, it is necessary to pay attention to the condition of the damper and the shoe.

Timing tensioner shoe

If the tension is weak, the links can jump several teeth, then the valve timing will be disrupted. In this case, the car may stall, not start, and the speed will fluctuate. You can use a flathead screwdriver to check. It needs to be inserted and, using as a lever, pressed on the chain. It should not bend and be stretched like an arrow. Do not put too much pressure on the drive, although the part is metal, it is subject to deformation.

The video below looks at a VAZ 2101 car, in which a clattering sound is heard when the engine is running. It shows in detail how to check the condition of the damper, the shoe, and how to carry out tension.

Step-by-step instruction

Before starting troubleshooting, check that all timing components are free of mechanical defects. To do this, you need to remove the protective cover of the drive and perform a visual inspection of the parts: sprockets, damper, tensioner and shoe. If defects are found, these components should be replaced.

Tools

Before you start work, you need to prepare the necessary tools:

- keys to “13” and “38”;

- flat screwdriver;

- pliers.

To carry out work, the car should be placed on a convenient platform and supports should be placed under the wheels so that it does not roll. The gear shift lever must be set to neutral.

Engine compartment of VAZ 2101

Stages

- First you need to find the tensioning device; it is located under the pipes near the pump. Use the key to “13” to release the tensioner. Once the chain is loosened, the shoe should pop off.

- Next, you should take the key at “38” and throw it on the crankshaft pulley nut. Then you need to turn the crankshaft a couple of turns in a clockwise direction.

- Rotate the shaft until the marks on the camshaft sprocket and on the camshaft bearing housing coincide. In this case, the spring located inside the tensioning device, acting on the shoe, will automatically perform the necessary tension.

- It is advisable to additionally check the tension using a screwdriver. If everything is normal, then we return to the tensioner and tighten its head with a wrench.

Checking tension with a screwdriver

After tightening the chain drive, you should start the engine and check its operation. It should work without extraneous noise. If the noise remains after tensioning, then the reason may be in the damper. Then you need to check its serviceability and replace it if necessary. It may not be possible to tension the chain drive the first time, so this procedure will have to be repeated several times.

During the procedure, it is necessary to ensure that the marks match so that the valve timing does not go astray.

This operation should be carried out every time after any repair work. In addition, a preventive check should be performed after the 10 thousand kilometers mark. If you learn how to check and tension yourself, this will make it possible to extend its service life and save on car service costs.

Features of replacing the tensioner shoe

If a complete replacement is made, along with the shoe, then the operation becomes much more complicated.

The entire sequence of work to remove the shoe is described here.

In short, in addition to removing the tension mechanism, you will also need to dismantle the drive pulleys in the front part of the engine, the drive cover, the camshaft sprockets and the auxiliary shaft.

Only then will it be possible to remove the shoe for replacement.

Most VAZ-2107 cars were equipped with a carburetor power system.

But the latest models came with an injector. Although the sequence of replacing the timing chain tensioner does not change.

Video “Timing chain tension on classics”

This video demonstrates how to tension a chain in a classic VAZ.

Welcome! Chain tensioner - don’t know what it is? Before you start replacing, we advise you to read a short article about the tensioner, in which everything about it will be described in detail. (See “What is a chain tensioner for?”)

Note! To replace the tensioner, stock up on: A basic set of wrenches, and if you have it, you can also use a “13” spanner!

Question? Which brand of chain tensioner will you install on your car and why did you choose it? (Write your answer in the comments)

When should you change the timing chain tensioner? It must be replaced if:

- The car began to operate unstably, or if various sounds appeared in the area where the timing chain is located.

Note! If you want to know what sounds the engine will make if the chain tensioner is faulty, then in this case, start the video at the very end and watch its beginning, and you will understand everything!

- The tensioner also needs to be replaced if it no longer holds the chain in a tense state due to the fact that it has become deformed.

Note! You can also try adjusting the timing chain! (For information on how to adjust the timing chain, see the article “Adjusting the timing chain on the VAZ 2101-VAZ 2107”)

Frequency of replacing the timing belt on a VAZ 2105

Replacing the timing belt on a VAZ 2105 is necessary approximately every 60 thousand km during standard use, but in case of some damage it becomes necessary to replace the timing belt earlier than the standard period. Despite a certain motor resource set at the factory (in our case - 125), malfunctions occur quite often and their elimination is critical for continued use of the machine.

If folds, cracks, or fraying of the belt appear, it must be replaced, since when using a timing belt on a VAZ 2105 in this condition, there is a danger of rupture when the engine is running. When oiling, you should carefully wipe the belt with a cloth, after dipping it in gasoline.

Source

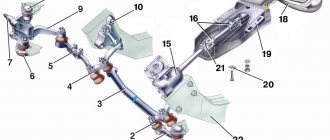

Timing belt with chain drive on VAZ 2101

The “kopek”, like all other “classic” models, has a timing chain drive. The mechanism consists of a double-row metal chain and additional elements that ensure its tension and prevent vibrations. The well-coordinated operation of the motor directly depends on the integrity and serviceability of each part of the mechanism. The chain drive connects the crankshaft and camshaft and ensures their synchronous operation. When the shafts rotate, the pistons in the engine cylinders are set in motion, and the valves in the cylinder head (cylinder head) open and close in a timely manner.

Tranquilizer

The damper performs the function of damping circuit vibrations. Without it, the chain may jump or fly off the sprockets of the timing mechanism. If the damper breaks down, the drive may simply break off. Such a nuisance is possible at high engine speeds. If the chain breaks, the pistons and valves are damaged, requiring expensive repairs. Therefore, the condition of the damper must be monitored and replaced in a timely manner. The part is a durable metal plate with special holes for fastening.

Opposite the damper there is a shoe, which is also responsible for calming and tensioning the chain. It is made of a special polymer material, which gives the part high wear resistance.

Tensioner

The “penny” chain drive tensioner prevents the chain from loosening when the motor is running. The element comes in several types:

- auto;

- mechanical;

- hydraulic.

Automatic tensioners began to be produced recently, but with regard to this part, it is already possible to note the pros and cons. The main positive point is that there is no need to make periodic adjustments, i.e. the drive is constantly in tension. The disadvantages include fairly quick failure and high cost of the part. In addition, based on reviews from car enthusiasts, the auto tensioner does not tension the chain very well.

The operation of hydraulic devices is based on the supply of oil under pressure from the engine lubrication system. With this design, the driver does not need to worry about periodically tightening the chain. However, over time, the part may malfunction, which manifests itself in the form of jamming of the mechanism.

The VAZ classic uses a mechanical tensioner. The part has a significant drawback: over time, it becomes clogged with small particles, the plunger jams and the device loses its ability to produce tension.

One of the key elements of the timing chain drive is the chain itself, made of metal and having a certain number of links: on the VAZ 2101 there are 114 of them. Compared to a belt drive, the chain is more reliable and has a longer service life.

Depending on the quality of the chain and the operating conditions of the vehicle, it is replaced every 60–100 thousand km. There are cases that a part lasts for 200 thousand km, but it’s hardly worth the risk, because a broken chain will result in a much more expensive repair than its timely replacement.

The chain is tightened every 10 thousand km, even in the absence of signs indicating sagging.

Types of chain drive

The VAZ “Seven”, like other “classics”, is equipped with a double-row timing chain. However, there is a single-row chain that, if desired, can be installed on a Zhiguli.

Single row chain

A chain drive with one row has less noise when the engine is running compared to two rows. This factor is one of the main factors in favor of choosing single-row chains. Therefore, some VAZ 2107 owners decide to replace the timing drive. The lower noise level is due to the fact that fewer links are driven. Plus, it is easier for the entire engine to rotate such a chain, which has a positive effect on the increase in power. However, due to the low noise level when such a chain is stretched, it is not always clear that the part needs tension.

Single row timing chain has lower noise levels

Double row chain

Despite the advantages of a single-row chain, a chain drive with two rows is the most common, since it is characterized by high reliability and if a link breaks, the entire chain does not break. In addition, the load on the timing drive parts is distributed evenly, as a result of which the chain and gears wear out more slowly. The life of the part in question exceeds 100 thousand km. Although recently, in order to reduce the weight of power units, automakers have been installing chains with one row.

The double-row chain, despite its higher noise level, has a long service life

Replacing a double-row chain with a single-row one

If you are thinking about replacing a double-row chain drive with a single-row one, you will need to purchase the following parts:

- crankshaft, camshaft and oil pump gears for single row chain;

- sedative;

- shoe;

- single-row chain;

- automatic tensioner.

To install a single row chain, you will need to replace the gears, chain, guide and timing chain tensioner

All of the listed parts are taken, as a rule, from the VAZ 21214. Replacing the chain should not cause difficulties. The only thing that is required is to replace the sprockets, for which you unscrew the corresponding fasteners. Otherwise, the steps are similar to the procedure for replacing a conventional double-row chain.

Chain mechanism fault detection

The timing drive, equipped with a chain, is structurally located inside the engine. To determine the condition of the parts of this mechanism, it is necessary to partially disassemble the motor. The fact that there are problems with the chain or drive elements is indicated by characteristic signs.

The chain is noisy

A circuit can have different types of noise:

- noise under load;

- knocking on a warm engine;

- extraneous sounds when cold;

- constant noise with a metallic character.

If the motor begins to make sounds that are uncharacteristic of its normal operation, it is necessary to find out as soon as possible what problems have arisen with the chain drive and eliminate them. If this is not done, wear on the timing drive elements will increase, which can lead to costly repairs.

Video: chain knocking in a VAZ “classic” engine

Timing drive components may fail prematurely for the following reasons:

- the use of oil not specified by the car factory, or its untimely replacement;

- use of low-quality parts;

- low lubricant pressure in the engine;

- failure to comply with engine maintenance regulations;

- low quality of repairs.

Often the chain is noisy due to stretching or problems with the tensioner. Attempts to tighten it turn out to be useless, and the engine sounds like a diesel engine. The sound most often appears on a cold engine when idling.

Jumped the chain

With high mileage of the vehicle, the timing chain stretches. As a result, it can simply jump to other teeth of the camshaft or crankshaft gears. This problem may occur when the timing drive parts are damaged. If the chain jumps by at least one tooth, the ignition is greatly shifted and engine operation becomes unstable (sneezes, shoots, etc.). To fix the problem, you will need to check the integrity of the parts, and if damage is detected, make repairs.

Timing chain repair VAZ 2101

On the first model Zhiguli, the timing chain drive consists of several elements, the condition of which determines the operation of the entire mechanism as a whole. If any of these parts fail, repairs must be carried out immediately. Let's look at the step-by-step steps for replacing the timing drive components on a “penny”.

Replacing the damper

Before you begin repairs, you need to take care of preparing the appropriate tools and materials. You will need:

- screwdrivers;

- a set of keys;

- new chain guide;

- wire hook.

After preparing everything necessary, we begin the repair in this order:

- After unscrewing the fasteners, remove the air filter box.

Replacing the tensioner

The chain tension device on the “classic” is located in the cylinder head below the cooling system pipe above the pump. To replace the part, use the same tools as for repair work with the damper, but you will additionally need a wrench to turn the crankshaft. Actions boil down to the following steps:

- Using a 10 mm wrench, unscrew the tensioner fastener to the cylinder head.

Replacing the shoe

The shoe is changed with the same tools as when working with the damper. Repairs are carried out as follows:

- Remove the engine sump protection plate.

Chain replacement

The chain on the “penny” is changed with the following tools:

- hammer;

- screwdrivers;

- spanners;

- mounting blade;

- a piece of wire;

- key for turning the crankshaft.

After preparation, we proceed to disassembly:

- We repeat the steps to replace the damper up to point 6 and the shoe up to point 8 inclusive.

- Rotate the crankshaft until the mark on the camshaft sprocket aligns with the protrusion on its housing. The mark on the crankshaft should be positioned opposite the mark on the timing cover.

The chain drive is installed in the following order:

- We put the chain on the crankshaft sprocket and on the gear of the auxiliary devices.

Video: how to change the chain on a “classic”

Quick replacement of timing chain and sprockets on a VAZ 2107 with an injection engine

Recently they brought us a car with a broken cylinder head gasket, and since when replacing the gasket we would have to remove the timing chain, we decided to change it along with the sprockets. We’ll talk about replacing the gasket in another article, but here we’ll look at replacing the timing chain of a VAZ 2107, as well as sprockets and a tensioner with a damper, with your own hands in an ordinary garage. In principle, the procedure is applicable to all cars of this family, because all classics were equipped with one chain motor with a slight difference in volume.

This engine is equipped with a double-row chain, which lasts a very long time; 100 thousand kilometers is not the limit for it, provided that the original Lada parts are in place. It is very simple to diagnose a stretched chain by the characteristic sound from the front of the engine; at the end of the article we will look in detail at how to diagnose and tension the timing chain.

Installing the chain by marks

The need to install marks on the timing mechanism may arise during the repair process or when the chain is severely stretched. If the marks do not match, the stable operation of the motor is disrupted due to a phase shift. In this case, an adjustment is required. The work is carried out with the following tools:

- Screwdriver Set;

- key for rotating the crankshaft;

- a set of keys.

We carry out the procedure according to the following instructions:

- We dismantle the air filter box and the valve cover with the seal by unscrewing the fasteners.

- Loosen the tensioner clamp, press the screwdriver against the shoe and tighten the nut.

- Using a 38 mm wrench or a crank, turn the crankshaft until the marks on its pulley and the timing cover match, and the mark on the camshaft sprocket should be located opposite the protrusion cast on the body.

- If any of the marks do not coincide, turn on the fourth speed and unbend the lock washer on the camshaft sprocket.

- We unscrew the bolt and remove the gear.

- Remove the chain from the sprocket and set the desired position (step 3). After installing the marks, we perform reverse assembly.

Video: how to set timing marks on classic Zhiguli cars

Preparation for service operations

Control of the tension of the chain drive of the gas distribution mechanism begins on an engine with a power system such as an injector or carburetor, similar to each other. The operation is performed in the sequence established by the manufacturer:

- We place the car on a flat area with a hard surface and fix its spontaneous movement by installing chocks under the wheels and applying the parking brake. Set the gear shift lever to the neutral position.

- Remove the cover from the cylinder head by unscrewing all the nuts along its contour using a tubular wrench. It is recommended to replace the old gasket; the use of sealants is not allowed.

- Using a key set to “38”, we turn the crankshaft of the VAZ 2107 engine in order to align the marks on the moving parts and the stationary ones. Care must be taken when performing this action, and the locations of the control points should be illuminated with a flashlight or carrying device.

- We combine two marks: the first is on the generator drive belt pulley with a special protrusion on the cover body, the second is on the upper sprocket of the gas distribution mechanism of the VAZ 2107 power unit with an injector power system.

With this relative arrangement of parts, the piston of the fourth cylinder is at the dead center at the top. Now you can begin performing service work on engine systems, in particular, timing belt and some others.

Adjusting chain tension

The need to tighten the chain may be necessary in different situations:

- engine repair;

- replacing the chain drive;

- chain stretching.

To work you will need the following tools:

- 13 and 38 mm keys;

- flat screwdriver;

- pliers.

Tensioning the chain consists of several steps:

- We place the car on a flat surface, turn on neutral, placing stops under the wheels.

- We unscrew the chain tensioner clamp, and a characteristic click will be heard.

- Use a 38 mm wrench to rotate the crankshaft, making several revolutions.

- Stop rotation at maximum force and tighten the tensioner nut.

If the valve cover is removed, you can determine the tension of the chain by pressing it with a screwdriver . If the chain is tensioned normally, it will be stiff.