It is the front suspension that most often “takes the blows of fate”, being the most loaded component of the car’s chassis. That is why care and timely inspection of its main components, their repair and replacement will be the key to successful driving of the VAZ 2107.

The entire front suspension of the “classic” is more reliable than subsequent front-wheel drive modifications of the VAZ, since a car with rear-wheel drive has fewer parts in the front suspension, its design is more “economical”.

The design of the front suspension has important components, without which a smooth ride of the car is impossible.

Let us describe the design of the front suspension on the VAZ 2107:

- double wishbone suspension, there are upper and lower arms that exist independently; the upper one is secured through the mudguard strut with a long bolt, the lower one is bolted to the suspension cross member, which, in turn, is connected to the front side members.

- silent - blocks, or rubber-metal hinges of quiet running. They are needed for the levers to turn. When worn out, replacement is required.

- ball joints, or simply “ball” joints - the wheel hub is ultimately installed to them through a steering knuckle system with a pin.

- The shock absorption device includes a spring installed in the cups and a hydraulic shock absorber installed inside the spring.

- The list of main devices is completed by a lateral stability bar (stabilizer).

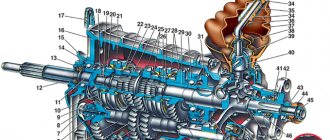

The structure and most important parts of the VAZ 2107 suspension:

5 — knuckle axle; 9 — ball pin of the upper support; 10 — steering knuckle; 13, 36 — upper and lower arms; 17 — support glass; 18 — shock absorber mounting pads; 21 — upper spring support cup; 22 — axis of the upper arm; 29 — bracket for fastening the cross member to the spar; 30 — cross member of the front suspension; 33 — stabilizer bar; 34 — body spar; 37 — bolts for securing the lower arm axis; 40 — shock absorber;

This is what the pendant looks like from below. All structural elements are clearly visible (levers, spring, shock absorber, stability bar, balls, etc.).

What can be determined when inspecting the suspension?

- The state of wear, crumbling, dryness of all rubber parts;

- It is determined how dry the shock absorber is and whether there is any oil leakage from it, as well as evaluate its performance. The test scheme is simple: you need to sharply press on the surface of the car's wing and remove the load, that is, “release sharply”. A working shock absorber returns the wing up in one pass, without additional vibration.

- The integrity of all coils of springs on the right and left sides;

- The gap in the ball joints is determined.

Replacing ball joints

The work scheme (like all others) begins with cleaning the parts from dried dirt. You need to make it a rule to clean all the elements at the bottom of the machine before starting diagnostics and repairs. The most convenient way to do this is to first use a stream of water from the nozzle of a portable car wash, and then dry it with compressed air.

To replace the ball joints, first remove the wheels of the VAZ 2107.

The jack for loading the lower part of the suspension rests on the lower arm, simulating a “load” on the suspension.

- Unscrew the ball pin nut (for example, the top one).

- A special pressing tool is used to separate the steering knuckle and the support pin;

- Unscrew the ball joint and remove it in its protective case.

- A new support is installed and assembly occurs in the reverse order.

The lower support is also replaced. After this, the car is jacked up on the other side and the ball joints on the other side of the suspension are replaced.

After this, it is necessary to adjust the wheel alignment; this must be done at a service station on a special stand.

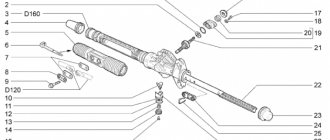

Let us recall that the silent block is a connecting element in the suspension of the VAZ 2107, and any other “classic”, which has an elastic liner made of polyurethane or rubber in order to soften the shocks of the suspension and vibrations. These parts take on large shock loads.

The figure shows the mounting diagram for the silent block of the lower arm.

Because of this, silent blocks are susceptible to wear, as a result of which the alignment is disrupted. It is advisable to change silent blocks every 50-100 thousand km. Mileage.

Steering knuckle repair

Repair of the steering knuckle is possible with minor wear or minor damage. As a rule, if a unit is seriously damaged after an accident, car enthusiasts simply replace it with a new one.

Repair work is only possible after the steering knuckle has been completely removed from the vehicle. The repair schedule looks like this:

- Clean the surfaces of the fist from dirt and dust, wipe it with a clean cloth, and blow with compressed air.

- Clean the grooves for the retaining rings.

- Inspect the steering knuckle after dismantling for signs of deformation and wear.

- Install a new retaining ring and press the new bearing in until it stops.

- If it is necessary to replace the trunnion, replace it. If the axle and kingpin are severely worn, it is recommended to replace the steering knuckle assembly.

Repairing the steering knuckle involves replacing the retaining rings and bearing. In case of extensive damage, only replacement is recommended.

If the pin wears out and the threads are “eaten”, there is only one way out - replacement

Replacing shock absorbers

The shock absorber is a non-separable paired part. That is, if one of them fails, then both change.

In order to replace the shock absorber, you need to carry out the following steps:

- Unscrew the fastening nut on the rod;

- Remove the washers along with the upper cushion made of rubber;

- We unscrew the bracket with which the shock absorber is connected to the lower arm;

- The broken shock absorber can be removed through the slot in the lever housing;

- The bracket is removed from the shock absorber and a new shock absorber is installed in the reverse order.

A few words about the hub

Why am I talking about the hub, although we are talking about the axle? Because some beginners cannot understand the differences between these two mechanisms. We need to clarify a little on this issue. Without a hub, a car will not be able to receive torque and transmit it to the wheel so that the vehicle can move. The wheel rim is also attached to it. In general, it is a blank of metal. I would like to dwell in more detail on its constituent elements:

- A housing in which studs of various numbers, diameters and lengths are installed. They depend on the weight and size of the machine. Due to the heavy load on the road surface, which is transmitted to the suspension through the wheel, the body of the part consists of high-strength steel with thickened walls.

- The bearing is inside the housing, completely reducing friction when the wheel rotates.

- Splines installed in the inside of the bearing. The CV joint elements pass through the hole and transmit torque from the engine. This is how the wheels are set in motion.

- Fixing and fastening devices for cables and wires that lead to the on-board system (if various pressure sensors and ABS are present).

Product added to bookmarks!

- Description

- Reviews

APPLICABILITY: VAZ 2101, 2102, 2103, 2104, 2105, 2106, 2107.

DIMENSIONS: shortened by 30 mm

.

MATERIAL: forged cast iron.

INSTALLATION: shortened bipods are designed to increase the maximum turning of the front wheels. It may be necessary to modify or replace the steering “strains” (depending on the front suspension arms you have installed).

ADVANTAGES:

suitable for those who want to increase their wheel alignment, but are not ready for major changes. When using these steering bipods, you can drive a car every day (there will be no increased wear of tires and instability in control during normal driving). Also, this is an excellent option for winter competitions: circuit racing or drifting.

ADDITIONAL INFORMATION:

The Ackerman angle relative to the standard bipod has been changed.

Repair of VAZ 2101, 2106, 2107 hub

Maintenance-free front hubs on VAZ 2107 (bushing drawing)

This time we will talk about maintenance-free front hub bearings. Having changed 3 bearings over the winter (sometimes they didn’t last, sometimes they overtightened them, sometimes they fell apart during maintenance), I got tired of all this, surfing the Internet and DRIVE came across articles about maintenance-free bearings on the front. There are several options: 1. Buy a ready-made kit. There are people who sharpen hubs and axles for them. 2. hub with axle from Izh od (also suitable) - I couldn’t find it 3. Rear hub from 08 VAZ + bearing also rear and + adapter sleeve - that’s what you need and in terms of cost.

Since I didn't look carefully at the bearings? and bought an extra stopper, but they were in the box. Next, we will need classic wheel nuts, 08 ones will not fit, and the ring that presses the bearing is also classic.

1

2

3,1

The first time I did it according to the first one, I’ll say right away it was in vain, the size 22 was not the topic and during installation the bushing swelled while I was inserting it. but more on that later.

here is my modified drawing

So we collect all this and happily go to the garage (well, that’s how it was for me), we begin to take everything apart

Having unscrewed the nut and the caliper, I had the first problem: I bent the brake disc (I don’t know how, but I did, I realized this when I was putting everything back together after the second problem), so I knocked over the old hub with the dead bearings, we start assembling it and now it’s not a problem, there’s an error in size, no Well, it’s okay and you can knock it out, and in the end I put everything back in the car in the garage and we’re waiting for it to be re-sharpened...

this is how it was inflated due to the wrong size, after measuring the axle, I changed the dimensions

Finally, they machined the bushings for me, and I, happy, flew to the garage to finish it... Since everything was put back in place temporarily, we disassemble everything: we remove the caliper, peel off the brake disc, knock off the hub (I’ll tell you right away that everything came off quickly on the left side, but on the right I had to suffer.) When everything was removed and wiped clean of fuel oil and grease, we put it back together.

We put the bushing on the axle, now everything is easy to install

Install the second part of the bushing

Well, a washer with a nut (the nut and washer are original - classic)

Now everything needs to be tightened. I pulled it with a ratchet and then, using a piece of a meter-long pipe, tightened it with force. I don't have a torque wrench, and I don't need one yet.

I bought these on occasion for only 1500 for 2, and they look better, and are not much more expensive than the original 600 rubles pieces. I assembled the left side - let's move on to the right. There was a little dance with a tambourine, a vdshka, a sledgehammer, and everything flew off (of course, I removed the caliper). In general, the hub, together with the disk, flew off.

We assemble it, tighten it in the same way, and test drive... Result: it steers better, rolls better, less noise. I really don’t know what’s causing it, maybe I just haven’t driven for a long time, the controls are somehow better. These are my impressions.

this is what the front looks like now

Replacing front wheel bearings VAZ 2101-07

Problem: less than 2 years later, the bearing on one wheel began to hum, and on the second there was a slight crunching sound when braking. I will try to explain in detail but briefly and in pictures what and how. First, remove the wheel.

We unscrew the caliper, not forgetting to bend the fixing plates of the bolts highlighted in yellow (and, by the way, be prepared to replace them - they often break).

And remove the hub assembly. It came off without any problems, but sometimes it gets stuck. It is better to knock it out through a block. In this photo, the working surface of the shaft is highlighted in yellow where the oil seal actually sits. I had a decent amount of wear in this place, as a result of which the oil seal quickly failed and water got inside during the season as a result and the bearing did not pass for a long time. By the way, this is also noticeable in the lubricant - it is brownish in color (the presence of rust).

The axis is relative, the road is 700 - 800 rubles. Therefore, I take a new oil seal, remove the spring and cut it about a centimeter from the side where it is widely highlighted in yellow in the photo. I screw the spring into the spring and put it on the oil seal. I think with such an oil seal it will be enough for a longer mileage.

We pry out the old oil seal with a large screwdriver or wrench, remove the spacer ring and pull out the inner race.

And using a mandrel or an unnecessary shaft, we knock out the outer race on one side and the other.

We clean out the old grease and use the old clip to drive in a new one. We only knock out the old one back.

We install the inner race and spacer washer and carefully hammer in the oil seal.

And fill it with lubricant. The ABC says Litol 24 Front wheel bearings 0.4 l Front wheel hub cap 0.25 l. We naturally wipe off the old grease from the axle and put on the hub, install the washer and tighten the nut with a little force.

We fasten the caliper without forgetting to bend the locking plates. We put the cap on lightly to prevent debris from getting in and screw the wheel on. Since the nut is tightened with little effort, we turn the wheel 90 degrees in one direction or the other so that the rollers find their place. Then loosen the nut until the wheel spins freely. We lower the car to the ground and, shaking the wheel, see if there is any play, i.e. We are trying to catch the moment so that the wheel rotates relatively freely and there is no play in the bearing. And we tighten the nut so that it does not unscrew.

We hammer in the cap and tighten the wheel completely. After a short break-in, we check again for the presence of play and, if necessary, make adjustments. In one bearing there were shells on the rollers, on the other, on the outer race, there was a scratch on the mirror, apparently some piece of metal had gotten into it. shavings. And the fastening of the hood pillar also broke, so we had to improvise. I cut out a metal plate, drilled holes and screwed it on.

I screwed the nuts from below in such a simple way.

Video about replacing wheel bearings for a VAZ classic

https://www.drive2.ru/l/6919354/, https://www.drive2.ru/l/7087225/, https://www.drive2.ru/l/4993033/

FRONT SUSPENSION VAZ 2107: DEVICE, FAULTS AND MODERNIZATION

The most loaded element of the VAZ 2107 car is the front suspension. Indeed, it takes on almost all mechanical loads that arise during movement. For this reason, it is important to pay careful attention to this unit, carry out timely repairs and modify it, whenever possible installing more durable and functional elements.

PURPOSE AND DEVICE OF THE FRONT SUSPENSION

Suspension is usually called a system of mechanisms that provide an elastic connection between the chassis and wheels of a car. The main purpose of the unit is to reduce the intensity of vibrations, shocks and jolts that occur during movement. The vehicle constantly experiences dynamic loads, especially when traveling on poor quality roads and when transporting cargo, i.e. in extreme conditions.

It is at the front that the suspension most often takes impacts and shocks. It is rightfully the most loaded part of the entire car. On the “seven” the front suspension is made better and more reliable than the rear - the manufacturer, of course, took into account the high load on the unit, but this is not the only reason. On rear-wheel drive cars, the front suspension has fewer parts than the rear, so its design is less expensive.

The front suspension diagram of the VAZ 2107 includes important parts, without which the smooth movement of the car would be impossible.

- Stabilizer or lateral stability beam.

When cornering, the anti-roll bar redistributes the load on the wheels and keeps the car parallel to the road.

- Double wishbone suspension is the main chassis unit at the front, consisting of an upper and lower independent link. One of them is fixed with a long bolt through the mudguard strut, the other is bolted to the suspension cross member.

The upper arm (item 1) is attached to the mudguard strut, and the lower arm is attached to the suspension cross member

- Ball joints are connected to the wheel hubs through axle-mounted knuckle systems.

- Wheel hubs.

- Silent blocks or bushings - designed for free movement of levers. They have an elastic polyurethane (rubber) liner that significantly softens the shock of the suspension.

The silent block serves to soften impacts transmitted by front suspension elements

- Shock absorption system - includes springs, cups, hydraulic shock absorbers. On VAZ 2107 models of the last years of production and on tuned “sevens”, struts are used.

FRONT BEAM

The task of the front beam is to stabilize the car when cornering. As you know, during a maneuver a centrifugal force arises, which can cause the car to roll over. To prevent this from happening, the designers came up with a transverse stability beam.

The main purpose of the part is to twist the opposite wheels of the VAZ 2107 using a torsion elastic element. The stabilizer is attached using clamps and rotating rubber bushings directly to the body. The rod is connected to the suspension elements through double levers and shock absorber struts or, as they are also called, bones.

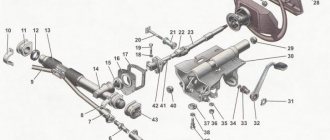

LEVERS

The front levers are the guiding components of the VAZ 2107 chassis. They provide a flexible connection and transmission of vibrations to the body.

The levers are directly connected to the wheels and body of the car. It is customary to distinguish between both suspension arms of the “seven”, since their replacement and repair are carried out in different ways:

- the upper arms are bolted, making them easier to remove;

- The lower arms are screwed to a cross member connected to the spar; they are also connected to a ball joint and a spring - replacing them is somewhat more difficult.

The upper and lower arms are directly connected to the wheels and body of the car

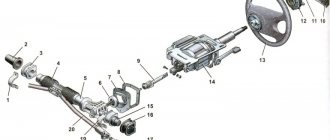

FRONT SHOCK ABSORBER STRUT

The owners of the VAZ 2107 learned about the existence of racks when the VAZ 2108 model appeared. From that time on, the manufacturer began to gradually install new mechanisms on the “sevens”. In addition, the racks were chosen by specialists modernizing a classic car.

The strut is part of the shock-absorbing system, the task of which is to dampen vertical vibrations of the body, taking on some of the impacts. The stability of the car on the road depends on the technical condition of the rack.

Symptoms of a problem

As all owners of the VAZ 2107 note, the most common malfunction of the steering knuckle is its deformation - during long years of driving or after an accident. The driver can quickly identify this problem by the following “symptoms”

- the car “pulls” to the left or right when driving;

- The tires on the front pair of wheels wear out very quickly;

- hub bearing play as a result of wear on the entire axle.

However, the car leaving the given trajectory and rapid wear of the tires may also indicate an imbalance in the wheel alignment. Therefore, you will need to turn to specialists to find out for sure the root of all evil: is the steering knuckle deformed or is it simply an imbalance in the alignment angle.