Why does a car's steering wheel become heavy - reasons for a heavy car steering wheel

It’s worth noting right away that the article will only consider cars equipped with power steering, since cars without power steering are a rarity , if not a rarity. Most owners of such cars know all the faults by heart and can fix them right in their garage.

So, heavy steering wheel - reasons:

- The simplest reason why the steering wheel turns hard is the lack of power steering fluid in the expansion tank.

- The next reason for a heavy steering wheel is wear and sometimes failure of the power steering pump .

- If the steering wheel becomes difficult to turn, the reason may be the presence of air in the power steering system.

- It's also worth checking the drive belt. It may be very worn or loose. Both malfunctions can be the reason why the steering wheel turns hard.

- The last reason that is worth mentioning, as always, is the most unpleasant: there is a defect in the gearbox or steering rack .

Why are valves knocking? Prerequisites and methods of solution

The knocking of valves is difficult to confuse with the knocking of the crankshaft, for example, but there are plenty of circumstances for which valve knocking occurs, therefore, for the clearest “conclusion,” the most detailed “inspection” is needed.

In this article I will try to thoroughly explain the problem of valve knocking, by considering the prerequisites and methods for eliminating this malfunction.

Most often, valves begin to knock on a car with a high mileage, or on someone who, as they say, “has given up” on his own car and doesn’t know what’s in it and where it needs care. From time to time there are cases when valves knock on completely new machines that are still under warranty. But in this case, the culprit will most likely be some kind of factory “jamb” or omission.

What to do if the car’s steering wheel turns hard - instructions for action

If you notice that your steering wheel is hard to turn with the power steering, you shouldn’t rely on the simple Russian expression “it’ll ride again . Such neglect of a malfunction can result in expensive repairs.

- Stop the car and at least take the trouble to look under the hood. The first thing that should interest you is the power steering fluid reservoir . If it is empty, then we go to the nearest auto parts store or gas station.

- We buy liquid and fill the tank to the maximum allowable level.

- check the fluid level in the tank by starting the car engine.

- Please note - after stopping you do not go anywhere so as not to aggravate the problem. It is better to leave the car in the parking lot.

Knock in the VAZ 2107 carburetor engine

Unread message NikVE » Fri Nov 14, 2008 12:42:51

Unread message by DonPedro » Fri Nov 14, 2008 16:00:10

Unread message Vladimir S » Fri Nov 14, 2008 17:22:59

Unread message by VladiZlav » Fri Nov 14, 2008 20:27:42

Unread message Mr_Ice » Fri Nov 14, 2008 21:52:48

Unread message by Semavod » Sat Nov 15, 2008 5:37:26 AM

Mr_Ice I'll try it and report back

Added after 1 minute 38 seconds:

Vladimir S where can I get such a rating “I drive a car. months days”?

Added after 4 minutes 34 seconds:

Mr_Ice remembered, now he was moving specifically in this mode with the lights on, heated rear window and heater, when you step on the gas, the whistle intensifies, especially from 2nd to 3rd gear.

Unread message Mr_Ice » Sat Nov 15, 2008 7:55:04 AM

Semavod In general, you open the hood. You approach it from the battery side and look at the engine in front of you there is a generator belt (generator, pump, engine), so this belt just got loose. Look at the generator, it has an adjustable top mount, it regulates the tension of this belt (as soon as you look under the hood, you’ll immediately understand everything). It’s very easy to tighten it - (personally, to tighten it, I remove the battery, it’s just easier) Loosen the adjusting nut of the top mount of the generator, take a wrench or some kind of green pipes, insert it into the spacer between the engine and the generator and pull it back so that the belt is tensioned. Then with one hand you hold the pipe so that the belt is tensioned and with the other you tighten the adjusting nut.

PS I advise you to always carry a spare alternator belt with you; it’s not cheap, but it can be very helpful on the road.

Source: www.semerkainfo.ru

Power steering and heavy steering - how to troubleshoot?

Now let's try to figure out how to fix other power steering faults.

- Remember, if the steering wheel turns hard, but there is still fluid in the tank, this does not mean that the reason is elsewhere. Start the engine and check the level again. The liquid may either completely disappear from the tank, or its level will be catastrophically low. In this case, it is enough to simply add fluid to the maximum level and hope that the lack of the latter does not lead to other malfunctions.

- To diagnose the power steering pump, it is recommended to contact a car repair shop (Professional car repair in St. Petersburg - Autopride service station). If this is the reason, then the pump must be sent for repair, or possibly replaced with a new one. If it is not possible to visit a diagnostic station, it is recommended to check the pump control valve for blockages. If there are any, the valve must be cleaned and flushed.

- You can remove air from the power steering system by rotating the steering wheel from one extreme position to the other. As you can see, the deaeration procedure is simple, but you still need to understand where the air in the system comes from? To do this, check all connecting hoses and, if damage is found, replace them. Check the clamps at the joints, if necessary, tighten them or replace them. If the described procedures do not help, it is recommended to contact a specialist.

- This point is simple. When the belt wears out, it changes. With low tension, it tightens. If the procedure cannot be performed independently, contact a service station.

- If the problem is in the steering rack or gearbox, then they must be sent in for repair. If it is impossible to repair the damaged unit, it will require an expensive purchase followed by replacement, which is also not recommended to be done independently.

General recommendation for power steering maintenance: check the fluid level in the expansion tank at least once a month .

If the level has dropped, add fluid ; if it drops constantly and at high speed, look for the leak and do not delay repairs.

Monitor the condition of the steering rack boot , and if necessary, replace it.

To understand why the steering wheel turns tightly, you need to find out what type of steering is installed on your car - a regular one with a steering rack, in addition to a hydraulic booster (power steering) and an electric power steering (EUR), combined (EGUR), with a pre-amplifier. Let's look at the first four cases, which are the most common.

First, we will dwell on the general causes of a tight steering wheel, then we will distribute them by type of steering, focusing in more detail on the VAZ 2105, 2106 (and other models from this line), 2109, Chevrolet Lacetti, BMW e39, Mazda 3, Volvo xc90, Renault Symbol and Gazelle.

Filling oil into the steering gear

As mentioned above, the steering gear housing is sealed. Oil is poured inside, which can significantly reduce friction of parts. Any GL5 or GL4 class oil is suitable for the VAZ gearbox. The viscosity grade should be SAE80-W90. Many owners of the Six use old Soviet TAD17 oil, which also has an acceptable viscosity and is cheaper. To completely fill the gearbox, 0.22 liters of gear oil is required.

How to check the oil level in the steering gear

In order for the steering parts to work as long as possible, the driver must periodically check the oil level in this device and, if necessary, add lubricant.

- The gearbox cover has an oil filler hole closed with a plug. The cover is unscrewed with an 8 mm wrench.

Oil filling sequence

If the driver needs to add oil to the transmission or change the oil completely, he will need an empty plastic bottle, a piece of plastic tubing and a larger medical syringe. It should also be noted here that the operating instructions for the machine state: the oil in the steering mechanism should be changed at intervals of once a year.

- The oil cap on the gearbox cover can be unscrewed. A plastic tube is placed over the syringe. The other end of the tube is inserted into the drain hole of the gearbox, the oil is drawn into a syringe and drained into an empty plastic bottle.

Video: we change the oil in the steering gear of a “classic” ourselves

Therefore, the steering on the 6 is a very important part. Not only the controllability of the car, but also the safety of the driver and passengers depends on its condition. Even a novice car enthusiast can replace the gearbox. This does not require any special skills or knowledge. You just need to know how to use wrenches and follow the recommendations described above exactly.

Common reasons

There are reasons that do not depend on the type and condition of the steering elements, these include low tire pressure and incorrect wheel alignment, violation of body geometry, etc.

In the first case, due to the large contact patch between the tire and the road, not only tire wear increases, but also the load on the steering wheel increases, which begins to turn tightly. In the second case, incorrect wheel angles also lead to this malfunction. We'll talk about the influence of body geometry later.

You should also pay attention to the steering knuckle bearing, shown below in the Nissan Primera example. Due to the wear of the boot, it rusts, as a result you have to make more effort when turning.

And yet, it is important to understand that if other tires were installed on the car and they are larger and wider than the previous ones, then the steering wheel will be difficult to turn and this is natural, there is no need to panic.

It is also worth paying attention to the crosspieces (universal joints) of the steering column. There may be one or two of them (lower and upper), it all depends on the design. The crosspieces may bite or after installing new ones, the steering wheel will be difficult to rotate for some time.

Be sure to pay attention to the cardan boot, for example, on the Toyota Caldina 2.0 MT 4WD FULL it looks like this.

If it is torn, then replace it, since over time, water and dirt that gets there will lead to bad consequences. The first sign that the problem is in the crosspieces is a tight rotation of the steering wheel with cyclic jerks.

Also, different behavior of the steering wheel is possible as a result of linear expansion of the parts. As a rule, if the tolerances and fits in the parts are selected correctly, and this also applies to the crosspieces, then after they are heated or cooled, no jamming occurs, and the steering wheel turns easily and smoothly.

If these parameters are not maintained correctly, and this no longer applies to original spare parts, then the steering wheel will be difficult to turn, with jamming both when the engine is cold and when it is warm.

How to adjust the steering gear

The steering may need to be adjusted if the steering wheel becomes very difficult to turn or if you notice a slight grip when turning the steering wheel. Adjustment is made with a 19 mm wrench and a flat-head screwdriver. You will also definitely need the help of a partner for precise adjustments.

- The car is parked on flat asphalt. The steering wheels are straight.

- Open the hood and wipe the dirt off the steering wheel with a rag. The adjusting screw with lock nut is located on the gearbox cover. This screw is covered with a plastic cover, which will need to be unscrewed with a screwdriver and removed.

Video: how to adjust the classic steering gear

Power steering

Most modern cars, for example, Chevrolet Lacetti, Volvo xc90, BMW e39 (not on all models), Renault Simbol, Gazelle GAZ-3302 (not on all models, the latter have an ESD) have been and continue to be installed with power steering. It is malfunctions in its operation that can lead to the fact that you will have to make a lot of effort to drive the car.

Oil level and condition

The first thing you should pay attention to if the steering wheel starts to turn tightly is the presence and condition of oil in the power steering reservoir. Its low level is the most likely cause of the problem. But you need to take into account that the level of heated liquid may differ from cold one.

It is important to find out why this happened:

- natural consumption (you just haven’t looked into the tank for a long time);

- leakage occurred as a result of wear or damage to sealing elements, hoses, etc.

If the oil level in the tank is minimal, then it is better to refuse further operation of the car in this situation, as this may lead to pump failure. As a last resort, you can remove the power steering drive belt and thus try to get there or call a tow truck.

Also pay attention to the condition of the oil, ask yourself - “When did you change it and what kind did you fill in?” There have been cases when simply replacing it solved the problem. But here it is important to fill in the oil prescribed in the operating manual for your particular car model, and not experiment.

Air in the system

Air can get into the booster hydraulic system for various reasons, the main one being improper replacement of the working fluid (oil).

It is clear that the presence of air bubbles in the system will negatively affect the transmission of forces as a result of a decrease in pressure, which will lead to tight rotation of the steering wheel.

To solve this problem, it will be sufficient to turn the steering wheel completely to the right and left several times with the engine running. This will renew all the oil in the expansion tank and squeeze out the air.

Power steering belt tension

Check the condition of the power steering drive belt. If it slips, which is often accompanied by a whistling sound, the pump will not create the required pressure in the system. For this reason, the steering wheel will turn tighter.

An overtightened belt will create an unnecessary load on the drive shaft and, accordingly, on the engine, thereby causing rapid wear of the bearing, reducing the efficiency of the pump and motor.

If the belt is tensioned correctly, but wears out noticeably quickly, then remove it from the pulley and turn it last. It should rotate freely without grinding or jamming. Otherwise, you will have to change the bearing.

The schematic diagram of tensioning the UAZ Patriot power steering belt is shown below.

Thick oil

In winter, if the steering wheel starts to turn hard, pay attention to the condition of the oil in the tank. If it has thickened greatly, it means it is not suitable for the given operating conditions.

Make sure that the fluid has been filled according to the car manufacturer's recommendations. If necessary, replace with another after consulting with specialists.

How to disassemble the steering gear of the “six”

If the driver decides not to change the gearbox on his six, but only to replace the oil seals or bearings inside it, the gearbox will have to be almost completely disassembled. To do this you will need the following:

- a large head is taken as 30;

- bipod extractor;

- flat screwdriver;

- hammer;

- vice.

Sequence of work

It must be said right away that the extractor and vice are the main tools when disassembling the gearbox. It is better not to start disassembling without them, since these tools cannot be replaced with anything.

- There is a fastening nut on the gearshift bipod. Unscrews with a wrench. Next, the gearbox is installed in a vice, a puller is put on the bipod, as shown in the photo, and the rod is smoothly removed from the shaft with the puller.

Video: disassembling the steering gear of a “classic”

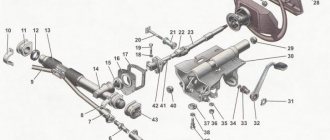

Steering rack

It is an integral part of the car's steering. It is to facilitate the movement of its elements, as well as steering rods, that power steering, electric power steering and other types of amplifiers were developed. The latter may or may not be installed on the machine.

In the latter case, the car is controlled only due to the driver’s physical impact on the steering wheel with the subsequent conversion of the rotational moment into the translational movement of the steering rods.

This transformation is carried out due to the gear rack, precisely because of the constriction of which it becomes difficult to turn the steering wheel.

The problem is easily solved by loosening the adjusting bolt, which is present on almost all steering racks or steering gears, such as, for example, in the VAZ 2105.

Let's look at specific examples.

VAZ 2105, 2106, 2107

The first thing you need to look at when on a VAZ 2105, 2106, 2107 and other cars from this model range, the steering wheel begins to turn tightly, especially with the front wheels hanging, is the steering gearbox (column).

By external inspection, make sure that there is no oil leakage through the seals in the unit. Check the transmission oil level in the gearbox through the filler (control) plug. Make sure the steering column is adjusted correctly and is not pinched.

The second thing to do is check the condition of the ball joints. There are four of them, two on each side, top and bottom. If they are worn out and there is play in them, then this can also affect the increase in effort to rotate the steering wheel.

Next, check to see if one or both ball joints are jammed. To do this, disconnect the steering tips from the column. This is done so that the steering knuckle can be rotated freely.

If it rotates heavily with a knocking noise, the ball joints are jammed and will have to be replaced.

Next, check the left and right pendulum arms for wedging; to do this, disconnect the steering rods from them and move them by hand. They should walk freely, without grinding. Otherwise, replace them. For example, they can jam due to misalignment of the nylon bushings.

It’s better to immediately replace the pendulums on bushings with an analogue with ball bearings. You will immediately feel how easier the steering wheel begins to turn.

Also check the tie rod ends for play. If new tips were installed, then it will be difficult to drive the car for some time until they develop and become easy to move.

Angle of inclination of the stand (caster).

It would seem that this has something to do with the caster and the tight steering wheel. As a rule, the angle of the strut (positive or negative) is set by the manufacturer, and it does not change during wheel alignment.

But there are situations when on VAZ classics 2101 - 2107 at the service this indicator is changed, for example, from 0 (factory) to 1. This leads to the fact that the steering wheel begins to rotate harder, but at the same time it returns to the zero position faster after completion turn.

If you drive around the city more, then cluster 0 is more preferable, since the steering wheel rotates easier with it, but it does not return to its original position as quickly.

With cluster 1, the opposite happens: the steering wheel turns hard, but returns quickly. This cluster is preferred by drivers who travel more outside the city.

Purpose of the VAZ 2106 steering gear

The steering is an integral part of the six's control system. And its goal is to ensure timely rotation of the steering wheels in the direction desired by the driver.

Thanks to the steering, the effort required by the driver to turn the front wheels is significantly reduced. And finally, the gearbox allows you to reduce the number of steering revolutions several times, which significantly increases the car's handling.

Steering gear design

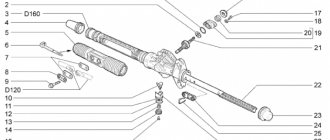

All elements of the wheelhouse are enclosed in a sealed steel case made by casting. The main parts of the gearbox are the gear and the so-called worm. These parts are under constant tension. The housing also contains a bipod shaft with bushings, several ball bearings and springs. There are also several seals and gaskets to prevent oil from leaking out of the housing. You can learn more about the “six” by looking at the picture.

Electric power steering (EGUR)

According to the principle of operation, electric power steering is not much different from conventional power steering. The main difference is that here the power steering pump is driven not by the internal combustion engine, but by an electric motor. The system also includes an electronic control unit.

The pump itself (geared motor) can be of two types: vane and gear. The second type is considered more reliable.

EPS is installed on many foreign cars, for example, Ford Focus 2, Skoda Fabia, Mazda 3. And also on some domestic cars, for example, Lada X-Ray.

Let's look at the reasons why the steering wheel turns tightly, using the Mazda 3 as an example:

- Deformation of the steering rack. The problem is solved only by replacing the latter;

- Low voltage in the on-board network. The battery is dead, the generator is malfunctioning.

- Incorrect steering wheel calibration or the ECU does not see its position at all. The previous and this problem can be easily diagnosed in the service.

- The relay has failed. On Mazda 3 it is located under the hood in the fuse box. But perhaps the relay has not failed, but the contacts under the block itself have rotted - this is a Mazda 3 disease.

- The power steering fuse has failed or the power supply circuit to the electric motor has broken. Sometimes, in order to find an open circuit, you have to remove the entire pump. The problem is diagnosed at the service.

- The steering rack is installed incorrectly after repair or replacement.

- Other causes related to power steering.

Checking operation and repairing in case of sound signal malfunctions

There are three malfunctions: it doesn’t sound when needed; works when not needed, or sounds intermittently, hoarsely, quietly. Unlike the high-voltage ignition system, which is little affected by the quality of the connection, the horn system is low-voltage. This means that the film of oxides and rust significantly impedes the passage of current. But signals are a powerful current consumer. The current in the circuit is at least 4-5 A.

The quality of all contacts must be perfect, otherwise repairs will be needed constantly. Remember that the car body itself is a “negative” contact, and in the direction of current movement, all oxides settle on the “plus”

Pay special attention to stripping the terminals of the red, “positive” wire

The “negative” part of the chain is longer. Therefore, most often this is where malfunctions occur. Therefore, it is immediately necessary to check the serviceability of the signal and look for an open circuit. To do this, you need to attach the gray-black “negative” wire from the sound signal to a cleaned place on the case, i.e., “short to ground,” and the “positive” wire directly to the battery. Then turn on the ignition. If there is sound, it means there is a break somewhere in the negative circuit. If there is no sound and the positive terminals are cleaned, then the signal itself is faulty.

Common faults:

- fuse blown (replace)

- The contacts have oxidized, or the relay has burned out (needs replacement).

- if there is a jumper, the contacts have oxidized and weakened; clean or change;

- the paddle on the switch under the steering wheel is broken, the slip ring on the steering wheel has worn out (this happens when the car wears out significantly, and also among those who like to honk constantly).

Here repair is hardly possible; the steering wheel needs to be replaced, since the slip ring is rarely found on sale.

Figures 5 and 6 show the replacement of a fuse and relay (using the example of another fuse) on a new mounting block for VAZ 2107 injection engines. Installation is carried out using plastic tweezers included in the delivery kit.

In conclusion, we will give some advice. When the radiator cooling fan is running (in the VAZ 2107 this is noticeable both by ear and by instruments), it is not advisable to use the signal! The VAZ 2107 circuit provides for the presence of a common fuse, which is not designed for such a load. Therefore, it is better to install a 25 A fuse.

Electric power steering

Compared to power steering and electric power steering, the EUR is structurally simpler and therefore more reliable. It consists of an electric motor that is mounted directly on the steering column, a set of sensors and an ECU.

EUR is installed on most modern cars. Let's include domestic models - Lada Priora, Granta, Kalina, Niva (since 2009), the latest Gazelle models (GAZ 3302, 2705, 3221, 33023).

If the steering wheel on a car with electric power steering starts to turn tightly, check:

- Is the EUR indicator on the instrument panel lit? When the ignition is turned on, the lamp should light up and go out after the engine starts.

- Whether the speed sensor and speedometer work, they work synchronously with the power steering and are interconnected. The higher the speed, the less force is transmitted to the steering rack and vice versa;

- Is the torque sensor faulty?

- What is the voltage in the on-board network;

- The contacts of the 50 A power steering fuse have burned out or burned out. For example, on a Lada Priora it is located under the hood, shown in the diagram below.

If the problem persists, check the condition of the steering rack, support bearings, cardans, etc. All this has already been described above.

If your car's steering wheel starts to turn hard and you can't find the reason, ask questions in the comments, we will try to answer.

Guys, tell me, at 14k the steering wheel became hard to turn, before I could turn it with one hand, but now it’s very hard? What should I watch?

When turning left, the heater motor seems to hit something

by Adminrive · Published 01/29/2017

Previously, the same wheel had a crunching sound when turning the steering wheel slightly to the right. VAZ

by Adminrive · Published 06/10/2015

How to change the steering gearbox on a VAZ 2106

Owners of the VAZ 2106 believe that the steering mechanisms of the “six” are practically beyond repair. An exception is made only in case of wear of ball bearings, gaskets and seals. Then the car owner disassembles the gearbox and replaces the above parts with new ones. And if a worm, gear or roller wears out, there is only one way out - to replace the entire gearbox, since it is not always possible to find on sale, for example, a worm shaft from a “six” gearbox or a cog. The reason is simple: the car has been out of production for a long time, and the number of spare parts for it is decreasing every year. To remove the gearbox we will need the following tools:

- series of sockets and handles;

- special puller for steering rods;

- set of wrenches;

- new steering mechanism;

- rags.

Sequencing

Having prepared everything necessary, the car should be driven along the overpass (or into the inspection hole). The wheels of the machine must be securely secured with skids.

- The left front wheel of the car is lifted and removed. Access to the steering rods is open.

- Using a rag, the fingers on the steering rods are thoroughly cleaned of dirt.

- The rods are disconnected from the bipod gears. To do this, remove the fastening pins on the rods, and then unscrew the nuts with a wrench. Next, using a puller, the rods are pulled out from the steering bipods.

Video: changing the steering gear on a “classic”

Let's sum it up

As you can see, there are more than enough sources of extraneous noise in the power plant.

Some of them do not cause significant harm even with prolonged use of the car without eliminating them.

Some reasons are more serious, but at least allow you to take the car for repairs.

And the causes of knocking in the engine associated with the crank mechanism and the cylinder-piston group are very serious and are a harbinger of expensive and time-consuming repairs.

By clicking on the link, you will learn about other causes of extraneous noise in a car.

In this situation, it is very important to take action in time. Good luck.

Knock at low speeds

A knocking sound in the engine at low speeds when the engine is not warmed up, if it comes from the top, indicates problems with the hydraulic compensators.

A uniform knocking sound in the upper part, which intensifies significantly when warming up, signals the beginning of destruction of the valve seat.

It is worth considering the possibility of damage to the bearings of attachments.

It is also possible that the valve timing is disrupted due to the timing belt slipping, as a result of which the piston bottoms come into contact with the valves, hence the knocking sound in the engine.

Filling with low octane gasoline can lead to detonation in the engine, which is why knocking occurs.

If you detect extraneous noise while the engine is running cold at low speeds, it is better to immediately try to determine where exactly the noise is coming from.

If the knocking sound in the engine comes from the top, the car can still be driven for a short time.

If sharp noises appear from the lower part of the engine, it is better to immediately stop the power plant and deliver the car to the repair site by tow truck or in tow.

Knock of connecting rod bearings

Typically, the knock of connecting rod bearings is sharper than the knock of the main bearings. It can be heard at idle and with the gearshift lever in neutral. The knocking noise increases with increasing crankshaft speed. To determine which of the four connecting rods turned out to be defective, it is necessary to exclude one of the cylinders from operation in turn, removing the high voltage wire from the spark plug. The reasons that cause knocking of connecting rod bearings are very similar to the previous ones: incorrect ignition timing; low quality oil; large gaps between the journals (now connecting rods) of the crankshaft and the bearings; ovality or taper of the connecting rod journals; non-parallelism of the axes of the upper and lower connecting rod heads. And again you have to go to a service station, since the engine will have to be disassembled.

Extraneous knocking noises when the engine is idling

Let's look at the causes of knocking in the engine under different operating modes.

First, let's look at the reasons for its occurrence at idle.

Here you first need to determine the behavior of the knock in the future.

Thus, a slight knocking sound in the engine at idle, emanating from the middle part of the engine, having a uniform intensity, while the sound intensity decreases somewhat with increasing speed, presumably indicates that small third-party parts or debris from parts have entered the cylinder.

This problem is eliminated by removing the block head and removing foreign objects.

The same knock, but increasing with increasing speed, signals wear of the cylinder-piston group, damage to the piston skirts due to overheating.

This malfunction can only be eliminated by replacing the cylinder-piston group.

The appearance of a similar noise, but with half the intensity, and heard in the upper part of the unit indicates a violation in the operation of the timing belt.

If a knock is present not only in idle, but also in other modes, this indicates wear on the camshaft and a violation of valve adjustment.

If the thermal gap is adjusted using hydraulic compensators, then the knocking noise as the speed increases, as a rule, decreases.

But this indicates a malfunction of the hydraulic compensators.

Problems with the cylinder head are solved by removing the valve covers, determining the source of the sound, replacing worn elements or adjusting the clearance.

A uniform knocking sound, significantly increasing with increasing speed, if it comes from below, this indicates the destruction of the balancer shaft bearings, the beginning of the destruction of the connecting rod liner, and deformation of the connecting rod itself.

These are some of the most dangerous causes of noise.

If at idle you hear an uneven sound that completely disappears as the speed increases, this is a signal of problems with the bearings of the engine attachments, for example, a malfunction of the pump bearing.

A muffled, uneven knock that appears at idle and disappears as the speed increases indicates that the permissible oil level has been exceeded due to working fluids or fuel getting into it. In this case, an internal breakdown of the cylinder head gasket occurred and antifreeze began to flow into the oil.

All of the above malfunctions, except for destruction of the connecting rod bearings and balance shafts, are generally not very dangerous; the driver has the opportunity to deliver the car under its own power to a service center or garage.

Crankshaft knock

An extraneous knock that suddenly appears in the engine causes concern for every car enthusiast - experienced or new. First of all, you need to figure out which engine mechanism is making the knocking noise. The most convenient way to determine this is with a stethoscope. The Chernigov Auto Parts Plant (GAZ branch) has developed a special technical stethoscope that allows you to determine by ear the condition of the engine and its components by the noise that occurs. To do this, just attach an acoustic probe to one or another node. Some car enthusiasts successfully diagnose the engine with homemade stethoscopes. An old oiler is soldered to a steel bar. To accurately determine the source of the noise, the end of a steel rod is alternately applied to different parts of the running engine, and an oil can is applied to the ear. Due to the fact that the thin bottom of the oil can is an excellent membrane, even the slightest sound will not be hidden from the ear.

The knock of the crankshaft is metallic and dull. Its frequency increases with increasing crankshaft speed. If the axial clearance of the crankshaft is significantly larger than the norm, the knocking becomes sharp with uneven intervals, especially noticeable during smooth acceleration and deceleration of the rotation speed.

The main causes of crankshaft knocking:

- excessively early ignition. If this is the reason, then it is no big deal. It is necessary to adjust the ignition timing and the knocking should disappear;

- the use of oil whose grade and quality does not correspond to those recommended by the factory. If the defect is not started, i.e. it is detected immediately as soon as the knocking appears, the situation can be corrected by draining the oil, flushing the system with detergent oil and filling the engine with fresh oil, as specified in the instructions;

- insufficient oil pressure. This causes malfunctions of the oil pump, pressure relief valve, and clogging of the lubrication system channels. Considering that to correct defects it is necessary to disassemble the engine (even partially), you should not undertake such work at home.

There are a number of other reasons that can cause crankshaft knocking: increased clearance between the journals and main bearing shells, misalignment and ovality of the main journals, increased clearance between the thrust half-rings and the crankshaft, loosening of the bolts securing the flywheel to the crankshaft. In all cases, engine disassembly is necessary, so the listed repair work should be performed at a service station.

Deformation of the protective shield - will pliers help?

The brake disc is protected from dirt and foreign objects by a metal shield about 0.3 mm thick. There are situations when, under mechanical stress, this part becomes deformed and begins to touch the brake caliper or disc, causing a metallic grinding noise to appear. This happens especially often when driving on gravel roads or off-road.

In such a situation, it is necessary to remove the wheel, inspect the protective part and, if deformation is detected, straighten it using pliers or a screwdriver. This procedure can be done by any car owner.

In addition, a foreign body, for example, a stone, wire, or a piece of a tree branch, can get between the protective shield and the disc. In this case, an unpleasant squeak will also appear. To remove an object, you can first try driving the car back and forth while simultaneously twisting the steering wheel in different directions. Carry out the procedure several times. In most cases, this will lead to the object removing itself and the grinding noise disappearing. If the method still does not help, you need to remove the wheel and manually remove the foreign object.

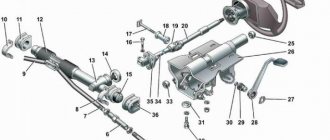

Mechanism design

To repair the steering column on a VAZ 2107, you first need to understand its structure, as well as the principle of operation.

The seven is in many ways similar to the “penny”. Therefore, the device and design received minor changes. The structure includes:

- A mechanism that transmits the driver’s force to the executive components;

- A steering drive that turns at an angle specified by the driver.