One day, all VAZ 2110 owners are faced with the need to repair, or even completely replace the muffler of their car. Although this part of the machine is not the most flimsy, it can also be damaged mechanically or simply rust. If this happens, then you cannot operate a car with a faulty exhaust system. Needs immediate repairs.

Before changing or repairing any part of the exhaust system, it is worth finding out the location of the breakdown.

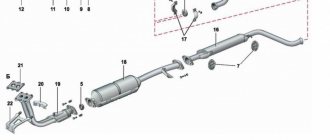

The exhaust system of the VAZ 2110 consists of four parts:

- Downpipe (often colloquially called "pants").

- Neutralizer. It is here that the fuel is burned and sparks are eliminated.

- Resonator (also called an additional muffler).

- Main muffler.

How to reduce exhaust noise

A sound wave can travel in space much faster than gases, therefore, in the design of a muffler, its noise reduction circuit is of great importance.

Physical vibrations from sound waves are transmitted to the walls of the exhaust system, and its design is made in such a way that it converts the sound wave into thermal energy, which the exhaust pipe, like a radiator, releases to the atmosphere. Reducing the noise level of a muffler cannot be achieved without creating some kind of resistance to the exhaust gases, as a result of which part of the engine power, quite insignificant, is spent on overcoming this resistance. To minimize the power loss that noise reduction inevitably leads to, a direct-flow muffler has been developed.

It has a minimum of partitions, does not interfere so much with the passage of exhaust gases and reduce their speed, which is why it sounds completely different.

How to determine whether a muffler is faulty

Where is it located and how to change the oxygen sensor on a VAZ 2110?

All original mechanisms on the VAZ 2110–2112 are adjusted at the factory to ensure a minimum noise level while driving. At the same time, engineers take into account not only the design of the engine itself, but also the car body. Therefore, after tuning the car, the noise level of the muffler increases sharply.

The main malfunctions of the muffler are those factors that interfere with its correct operation:

formation of holes in the body;

The use of such an element is unsafe for the driver

The most common problem with silencers on VAZ 2110–2112 can be considered the occurrence of knocking noises while driving. Even new and original products can cling to the bottom of the car and make loud noises:

Kkiss

https://www.autolada.ru/viewtopic.php?t=142153

Problems with the operation of the device on the VAZ 2110–2112 can be determined visually. To do this, it is recommended to drive the car into a viewing hole or lift the rear of the body on a jack:

Inspect the entire exhaust system pipe. The presence of holes can be noticed immediately. In addition, rust spots will indicate that there is clearly damage inside the muffler housing.

Rock the mechanism with your hand - if it sways too much, then it’s time to change the fixation rubber bands and the reinforced gasket between the parts of the muffler.

After leaving the inspection hole, start the engine and sharply press the gas pedal several times - black exhaust smoke indicates severe burnout of the product.

Why do you need a gasket?

The gasket is an essential element between the main muffler and the resonator. Since all parts of the exhaust system become very hot, the gasket is made of heat-resistant materials.

If, when replacing a resonator or muffler, a gasket is not inserted between them, then the joint will not be as tight as possible. In addition, when driving on uneven roads, the two elements will rub against each other and quickly fail.

There is no need to worry about the procedure for replacing the gasket: it has a convenient shape and is placed on the element pipe with one movement of the hand:

- Attach the gasket to the resonator flange.

- Tighten 4 bolts.

- Make sure the insert is kept level.

- Tighten the bolts until they stop, without overtightening them.

The product prevents heating of muffler parts

Replacing rubber bands

The VAZ 2110–2112 muffler is attached to the bottom of the car with special rubber hangers. The elastic bands have minimal elasticity, so they can ensure reliable fixation of the mechanism. Usually two rubber bands are used - one is placed at the exhaust port, the other at the compartment with the resonator.

To change the suspension rubber bands, you need to place some kind of support (boards or bricks) under the device to fix its position at the maximum height. After this, the old rubber bands are removed. If necessary, the hooks on the bottom, on which new rubber bands are put on, can be cleaned of dirt and carbon deposits. After which the muffler is easily attached with hooks to the new rubber hangers. The suspensions are removed one by one from the front of the car to the rear.

The special rubber composition allows you to keep the muffler in the desired position for many years

What to do if the muffler is knocking

Knocking is one of the most common problems with silencers on the VAZ of the tenth family. Mufflers can knock only in two cases: when, while driving, they touch the body of the gas tank or swing so that they hit the body.

The knocking can be eliminated by simply replacing the rubber suspensions: during operation they can stretch, so the muffler no longer has a reliable fixation to the bottom. In addition, the “silencer” can often knock because it was installed incorrectly during installation: for example, the flange is not fully tightened or the bolts do not match the length of the bracket. Therefore, the replacement procedure must take into account all the nuances of the correct installation of exhaust system elements.

Features of operation and types of mufflers

How to change pipes on a VAZ-2110 stove

There are two types of mufflers used in modern cars: resonant and direct-flow. Both can be installed in conjunction with a resonator (pre-silencer). In some cases, a straight-through design can replace a front muffler.

Resonator device

Structurally, the muffler resonator, which is also called a flame arrester, is a perforated pipe located in a sealed housing, divided into several chambers. It consists of the following elements:

- body (has a cylindrical shape);

- thermal insulation layer (exhaust gases have a very high temperature);

- blind partition (to turn the flow of gases);

- perforated pipe;

- throttle (allows you to change the cross-section of the exhaust gas flow).

Resonant muffler design

Unlike the preliminary muffler, the main resonant muffler is more complex. It consists of several perforated pipes installed in a common housing, which are separated by partitions and located on different axes (see Fig. Silencer in section):

- front tube with perforation;

- rear tube with perforation;

- inlet pipe;

- anterior partition;

- middle septum;

- posterior septum;

- exhaust pipe;

- body (oval section).

Thus, a resonant muffler uses all types of transformation of sound waves of various frequencies.

Features of a direct-flow muffler

The main disadvantage of a resonant muffler is the effect of creating back pressure, which occurs as a result of redirecting the flow of exhaust gases (when it collides with partitions). In this regard, many motorists tune the exhaust system by installing a direct-flow muffler.

Direct flow muffler

Structurally, the direct-flow muffler consists of the following elements:

- sealed housing;

- exhaust and inlet pipe;

- perforated pipe;

- soundproofing material - fiberglass is most often used, which is resistant to high temperatures and has good sound-absorbing properties.

In practice, a straight-through muffler has the following operating principle: one perforated pipe passes through all chambers. Thus, there is no noise suppression by changing the direction and cross-section of the gas flow, and noise suppression is realized solely through interference and absorption.

Due to the unhindered passage of the exhaust through the direct-flow muffler, the resulting back pressure is very low. However, in practice this does not provide a large increase in power (from 3% to 7%). On the other hand, the car has a characteristic sports car sound, since the noise-absorbing technology present in it only eliminates high frequencies.

The comfort of the driver, passengers and pedestrians depends on how the muffler works. So, during prolonged use, increased noise can cause serious inconvenience. Today, installing a direct-flow muffler in a structure for a car moving within city limits is an administrative violation that threatens with fines and an order to dismantle the device. This is due to exceeding the noise limits specified by the standards.

The operation of the engine in vehicles, if we talk about internal combustion engines, is associated with the production of quite loud noise. But the driver, his passengers, and people on the street practically do not hear this noise effect.

This was not always the case. The first cars running on internal combustion engines were very noisy and created a lot of smoke, and therefore this became a real problem. But after some time they came up with a solution.

Every modern car is necessarily equipped with a muffler. Already from the name it becomes obvious that the main function of mufflers is to dampen and suppress noise and sounds arising from a running engine.

The exhaust system is quite complex, despite the apparent simplicity of its functions. It consists of several elements, one of which is a resonator. Car enthusiasts have questions regarding it. They are interested in what it is, why it is installed and what tasks it performs in the operation of the exhaust system and the entire car.

basic information

The muffler of a VAZ car always receives increased attention, because its main task is to reduce the noise level, which is important.

First, let's look at how the pre-muffler, or as it is also called the resonator, works in a VAZ car. The resonator is considered to be a medium type of muffler, which is located in the middle of the exhaust system. So, the pre-muffler consists of the following main elements:

- Throttle;

- Frame;

- Blind barrier;

- Thermal insulation;

- Perforated tube.

Now let's look at the design of this part of the transport:

- Frame;

- Rear barrier;

- Middle obstacle;

- Front perforated tube;

- Rear perforated tube;

- Inlet pipe;

- Exhaust pipe.

VAZ muffler design

What are the design features of a direct-flow muffler? The main element of this type of muffler is a perforated tube. With the help of perforation, the combustion products that enter the muffler expand quite effectively in its body. Thanks to these actions, the removal of combustion products is accelerated

It is worth paying attention to the fact that high-quality tuning can account for more than eighty percent of a straight tube. This means that when using the presented type of muffler, the level of exhaust system resistance will be about ten percent, and this is much more than without it.

Independent replacement of the main and additional muffler

The exhaust system of every vehicle regularly suffers from the accumulation of dirt, dust, moisture, corrosive and hot gases, as well as impacts. Moreover, applying patches to through holes will help solve the problem only for a certain period of time, and in the end, one way or another, a complete replacement will have to be made.

The exhaust system of a VAZ car can be subject to such main factors of destruction as:

- Heating the structure to high temperatures;

- Internal corrosion;

- External corrosion;

- Beats;

- Various damages and deformations;

- Constant vibration;

- Frequent changes in temperature conditions, from the heating process to rapid cooling;

- There are no effective means of protecting metal structural elements;

- Pollution;

- The influence of abrasive particles falling from the roadway;

The most vulnerable point of the exhaust system, which requires regular monitoring, is the muffler. Let's try to figure out how to replace the main muffler. The main signs that indicate the need to replace the housing of this device:

- Areas of through corrosion;

- Pipe fractures;

- Fractures of the hull;

- Deformation.

So, the replacement algorithm:

- Unscrew the bolts that hold the clamp halves together;

- Remove the graphite O-rings;

- Remove the part from the hanging rubber bands. If such a need arises, you need to replace the hanging rubber bands.

- Hang a new one;

- Install a graphite seal at the junction of the pipes;

- Put on the clamp;

- Tighten the clamp halves using bolts.

Now we move on to considering the replacement of the additional muffler. Additional mufflers are not attached to the underbody of the vehicle. They are connected to the inlet pipes using clamps.

So, the replacement algorithm:

- Remove the main muffler;

- Loosen the clamp nut slightly;

- Using a screwdriver, spread the clamp and move it along the tube;

- Unscrew and remove them from the drain manifold tube.

The car should not only drive well, but also sound great. A good car is beautiful in all respects, and its beauty partly depends on the sounds that the equipment makes. The spectacular sound of a closed door, with a noble low overtone, the muffled clicking of the turn relay, the dense rustle of the headwind at a speed of 180 km/h. And, of course, the exhaust sound. It is the muffler that forms the first impression of the car and we will talk about the muffler today.

Malfunctions on VAZ cars of the tenth family

How to change the brake vacuum on a VAZ 2110

AvtoVAZ specialists conducted research, the results of which revealed that the car body, being a closed structure, has its own peak harmonics and can resonate at a certain frequency. To suppress spurious frequencies emitted by both the vehicle engine and those shielded by the body, it is necessary to use the range from 60 to 400 Hz, corresponding to medium and high engine speeds. A change in noise characteristics can be caused by making minimal changes to its design.

The most difficult noise to deal with is at low frequencies. From a technical point of view, it is impossible to combine tuning the exhaust system of a car and combating noise. You can maintain maximum power with a direct-flow muffler, and reduce the sound to a comfortable volume with a factory one.

Owners of VAZ 2110–2112 most often encounter breakdowns, burnouts and leaks in the exhaust system. Incorrectly set ignition, excessively rich mixture and pipe corrosion are the main causes of burnt out exhaust pipes. This defect is accompanied by knocks and pops, which indicate burnout of metal parts. A sign of burnout may be smoke from the exhaust pipe, indicating an overly enriched fuel mixture that is burning in the exhaust pipe.

Car muffler malfunctions can be caused by various reasons - pipe burnout, system leakage, breakdowns

The appearance of knocks on the body in the area where the muffler is located indicates mechanical defects in the part - changes in geometry, destruction of the rubber band, suspension or damper cushion. Eliminated by identifying the location of the breakdown and troubleshooting. Worn parts are replaced with new ones.

Muffler gaskets

The gas junction formed between the rear and additional mufflers is insulated using a rubber gasket or O-ring. In addition to the main function of closing the gap, it is also used to eliminate the movement of the pipes of the part relative to each other.

Rubber O-ring located between the car muffler flanges

The appearance of carbon deposits under the bottom of the car at the joints of the exhaust pipe sections indicates damage to the gasket. Ruptures of the sealing ring are accompanied by the appearance of an unpleasant smell of exhaust gases in the vehicle interior and a sharp grinding noise that occurs during operation of the power unit.

Their replacement

A damaged exhaust system sealing ring cannot be restored - it can only be replaced with a new one. The gasket can be replaced manually in a few minutes.

- The exhaust pipe flanges are secured with small bolts. Due to prolonged use, they can become covered with dirt and rust, which makes them difficult to unscrew. You can unscrew the bolts using a special tool or a grinder.

- After unscrewing the bolts, the resonator tube is carefully retracted to the left.

- The old O-ring is located on the resonator pipe. The rubber product is easily pryed off with a flat screwdriver and removed.

- Carbon deposits are removed from the flanges with a wire brush and sandpaper.

- A new O-ring is installed on the resonator tube flange. The exhaust pipe flanges are connected with a clamp, and the main muffler pipes are also connected to each other.

Description of individual components

To make the structure of such an element as the discharge system clearer, it is necessary to give a detailed description of all components:

- Neutralizer. A unit designed for effective purification and suppression of emissions of harmful substances into the environment. When driving, a car produces substances such as non-combustible hydrocarbons, oxide compounds of nitrogen and carbon. The work of this system is aimed at eliminating them. The design itself is a combination of two ceramic-type components. The surface of these components is coated with special afterburning catalysts, which include rhodium, palladium and platinum. These substances make it possible to purify exhaust gases emitted into the environment by almost 100%;

- Lambda probe. It is a special sensor whose task is to control the composition and amount of fuel that enters the engine. The lambda probe thereby controls the purifier. If the lambda probe does not work properly, then the entire output assembly will quickly become unusable, after which it will have to be replaced;

- Reception pipe. Designed for forced removal of exhaust gases from the cylinders of a power unit. The pipe is made of stainless steel, and its fastening to the collector is carried out using special pins, of which there are four in total. The studs guarantee reliable fastening of the two outlet pipes and the element. In order to combine the exhaust pipe and the neutralizer, as well as an additional muffler, hinged fasteners are used;

- An exhaust manifold. A component that is cast from pure cast iron. The manifold is secured with four studs in the exhaust pipe. Heat-resistant gaskets reinforced with metal are installed between the manifold and cylinder heads.

- Silencers. Necessary for effectively suppressing the exhaust rate of burnt gases. This is necessary in order to significantly reduce the noise level in a type of transport such as the VAZ 2110. The distribution device in this part of the unit is carried out as follows: the additional one is followed by the main one. These two components are connected to each other by clamps and sealing rings and are covered with a special casing on top.

Replacing the neutralizer

Attaching the neutralizer to the resonator

- This connection dampens engine vibrations and prevents them from reaching the exhaust system.

Attaching the converter to the exhaust pipe (pants)

- When replacing the neutralizer, we leave the old springs and bolts, provided they are intact.

- We definitely need to change the ring - gases escaping through it will quickly damage the flaring of the exhaust pipe and the converter

- Having installed the neutralizer, tighten the fastening bolts, then tighten them, first tighten the bolts securing the resonator.

You can also watch the video.

Problems with the resonator

Like any part, a car resonator periodically fails. After all, it passes through exhaust gases having a temperature of several hundred degrees Celsius. And in combination with the aggressive chemical elements contained in the escaping gas mixture, this leads to gradual burning of the metal parts of the system.

The main signs of resonator failure are:

- Deterioration of the muffler and exhaust system. This is manifested by increased sound coming from the exhaust pipe, especially low frequency sounds (roar).

- The appearance of exhaust gases from under the bottom of the car. This is a clear sign of depressurization of the resonator or other parts of the gas exhaust system.

- The presence of a characteristic rattling metallic sound from the resonator. It appears due to the fact that one (or more) of the internal components of the device burns out. Usually in such cases he “hangs out” or breaks away and rumbles in one of the cells.

- Significant drop in engine power. Due to a malfunction, the throughput of the resonator decreases significantly, so it dampens uneven pulsations of exhaust gases worse or not at all. And this gives feedback on the deterioration of the power unit.

If you encounter one or more of the above signs of a resonator malfunction, you need to inspect its operation as quickly as possible.

How to check the catalyst?

Engine power depends on the condition of the catalyst. If there are characteristic symptoms of a breakdown, you should definitely check it. This can be done in light (by dismantling) and for back pressure or CO content without removing Read more

Shoots the silencer

Does your car engine need to shoot at the muffler? Then it’s worth checking the ignition system, fuel supply or timing marks. Find out the reasons and how to get rid of popping sounds from the muffler Read more

Replacing the VAZ 2110 resonator

Repairing the exhaust system or replacing the muffler on a VAZ 2110 most often involves replacing the resonator, since welding does not take long to solve the problem of burnout. The main task is to quickly remove the resonator Read more

Installing a new muffler

The cost of these rubber bands is small, they are available in any store. Next you need to do the following:

- Install the new main muffler onto the rubber hangers.

- Insert a graphite O-ring between the pipe flares.

- Place the clamp in place and tighten the nuts using 13mm wrenches.

At this point, the repair of the main muffler of the VAZ-2110 exhaust system (8 valves) is completed. Start the engine and check the muffler operation. There should be virtually no sound from the exhaust pipe. The motor will run clean and smooth.

Repair of exhaust system parts

So:

- It is possible to weld parts of the exhaust system only if they have been damaged as a result of mechanical impact

- In the event that a pipe breaks, or a weld seam or tank burns out, you need to replace the entire element, it has already become unusable

- The only part to which this does not apply are metal expansion joints. They change regardless of the exhaust system itself

- The cost of the neutralizer in comparison with other elements of the system is decent. Therefore, many people change it to a stronger (flame arrester)

- The neutralizer is cut off, leaving only the connecting flanges, as well as a fist with flaring, and a flame arrester is welded in

- The cost of a flame arrester is much lower than a neutralizer. However, there is no afterburning of fuel residues. Therefore, its installation is permissible on cars with one lambda sensor. In addition, the flame arrester increases fuel consumption by about 10-15%.

Replacing plugs for VAZ 2110

Car owners often encounter the problem of fluid leaking from the cooling system. Often the reason lies in rusted or squeezed out plugs in the engine cylinder block. To fix the problem, just replace them with new ones.

Plug locations

So:

- There are plugs on the sides and ends of the cylinder block that are squeezed out of the block when the coolant freezes in it.

- Two plugs with a diameter of 34 mm are located on the cylinder block on the side of the coolant drain plug, and two more on the oil filter side

- There is another plug with a diameter of 17 millimeters on the rear end side of the crankcase

- The last plug with a diameter of 34 mm is located at the front end of the cylinder block

These plugs are changed if the coolant in the cylinder block is frozen. The plugs can be changed without removing the engine. On a VAZ 2110, replacing the cylinder block plugs is done using a special tool. To do this you will need:

- beard or chisel

- hammer

- pliers

- durable screwdriver

- telescopic magnetic pointer (purchased at any automotive store)

- new plug

- sealant

- skin

Replacing plugs for a VAZ 2110 engine block

- Remove the negative terminal from the battery

- Drain the antifreeze from the cylinder block and radiator

- Remove the air filter along with the hose

- We disconnect the exhaust pipe together with the bracket and lower it down a little so that the flange is removed from the manifold studs

- Turn the movable sector of the throttle valve drive all the way and disconnect the throttle valve drive rod

- We unscrew the bolts securing the throttle valve drive bracket. We move the bracket without disconnecting the rod to the side so that it does not interfere with us.

- Remove the belt protective cover and cylinder head cover

- We unscrew the nut securing the tension roller and remove the roller along with the axle and a special spacer ring, then remove the timing belt from the camshaft roller

- We unscrew the bolt securing the pulley and remove the pulley along with the key.

- Unscrew the nut securing the timing belt to the block head itself

- If necessary, unscrew the bolts securing the head and remove the block head.

Now that we have access to the plugs, we begin replacing the plug of the VAZ 2110 engine block.

- We take a beard or chisel in one hand, and a hammer in the other

- Place the chisel on the edge of the plug

- Gently tap the hammer on the striking part of the chisel. The plug turns (Photo below)

We tap with a hammer on the striking part of the chisel, the plug rotates

- We pry it up and pull it out using pliers

- If the plug does not turn, drill a small hole in it, screw a knob into it and remove the plug.

- We use a telescopic pointer with a magnet if it is necessary to remove a plug that has fallen inside. We pull the failed plug to its hole and remove it with pliers

- Clean the edges of the plug hole from rust using sandpaper

- To increase the tightness, coat the edges of the installed plug with sealant

- Attach the plug to the hole

- We press it in using a suitable mandrel and a hammer.

Press in the plug using a mandrel and a hammer

- Reinstalling the block head

- Fill the cooling system with antifreeze (antifreeze) or water

- Connect the negative terminal to the battery.

- Checking the engine operation

If everything is not clear when replacing the plug, this video will help you - replacing the plug for the VAZ 2110 cylinder block.

Replacing pants

So:

- The receiving pipe (pants) is attached to the manifold by means of studs with nuts, and to the converter by means of a spring-loaded connection

- When removing the exhaust pipe, we pay special attention to attaching it to the manifold. Instead of bolts, there are studs screwed into the manifold, with nuts screwed onto them. Replacing a damaged stud is not easy, so it is very important to preserve them

Nuts securing the pants to the manifold

- The nuts should be sprayed with WD-40 so as not to use excessive force, and save the studs;

- Otherwise, you will have to drill out the stud if it breaks; this requires experience and considerable effort;

- We replace the gaskets between the pants and the manifold. We also install a new o-ring for the neutralizer;

- Then we firmly press the exhaust pipe using nuts to the manifold (squeezing the gasket);

- Tighten the bolts of the spring-loaded joint with the neutralizer.

Now replacing the muffler on a VAZ 2110 yourself is not a problem for you. If anything in our article remains unclear to you, watch the VAZ 2110 muffler replacement video.

Replacing the muffler on a VAZ 2110

VAZ 2110 owners are quite lucky, since replacing the muffler is quite simple and does not require special skills or extensive experience. But you definitely need an inspection hole.

The replacement procedure sequence is as follows:

- The muffler is connected to the resonator through an O-ring on the pipe flare. Plus, the connection is compressed with a clamp, which consists of two parts.

- The clamp must be dismantled, so remove the ring. Since the O-rings used here are graphite, they should not stick to the metal.

- Now the old muffler can be dismantled quite easily.

- Be sure to check the condition of the suspension rubber bands located on different sides of the muffler body. They often end up stretched or covered with cracks. Rubber bands are quite cheap, so buy new ones and replace the old ones with them.

- The new muffler is first mounted on rubber bands, after which it is inserted into the same new graphite sealing ring between the flares. Use a clamp to compress the connection. Ready!

Replacing the resonator

Resonator VAZ 2110

So:

- The resonator is attached to the muffler using a crimp clamp with an O-ring;

- It is attached to the neutralizer by means of a floating flange (two bolts) and flaring;

- On the opposite side of the neutralizer there is a “fist”;

- It is often problematic to unscrew the knuckle mounting bolts; they are simply cut off with a grinder and replaced with new ones;

- If suddenly you don’t have a tool at hand, we clean the places where the bolts are attached and treat them with a “liquid wrench” (WD-40 or its equivalent);

- Unscrew the bolts and remove the muffler clamp;

- We remove the resonator from the suspension rubber bands, change the rubber bands if necessary;

- Then we hook a new resonator onto rubber bands and attach it to the muffler so that the pipe running from the resonator to the muffler is parallel to the ground;

- When there is wear on the neutralizer fist or there are burrs, grooves or rust on it, it is necessary to lubricate the connection with a special high-temperature sealant;

- Using new bolts and nuts, tighten the flanges of the catalyst and resonator;

- The neutralizer is attached to the resonator by means of a flange connection (two bolts), to the receiving pipe (pants) by means of a spring-loaded connection and a pair of flares, between which there is a graphite or metal-asbestos ring.

Downpipe, catalytic converter and resonator

The downpipe is painted with heat-resistant paint to prevent corrosion

Next in the exhaust diagram is the exhaust pipe. In carburetor engines it is just a pipe, but in injection engines a terrible part is integrated into it - a catalytic converter. The exhaust pipe on stock tens is attached to the exhaust manifold through a flange, a heat-resistant reinforced gasket using four or six bolts. The connection between the exhaust pipe and the catalyst is made in the form of a corrugated nozzle with a ferrule. The pipe must be made of heat-resistant steel of a certain grade, and in most cases this is the case on conveyor vehicles. If the car is more than ten years old, most likely the middle part has already been replaced, so you can only guess about the quality of the steel from which it is made.

Ideally, a steel pipe is painted with heat-resistant protective paint to prevent inevitable corrosion at least for a while. Often, the paint on pipes that come in spare parts kits is more decorative than protective. Therefore, when replacing, many people tend to install a stainless steel pipe. There is no point in changing its diameter, and stainless steel will extend the life of the part quite significantly. If it is easier with carburetor engines, then in later engines with an injection system you need to take into account the catalyst, which is worth saying a few words about separately.

Catalysts began to be installed not to make life more difficult for motorists, but to reduce the level of harmful components in exhaust gases. The main task of a working catalyst is to burn fuel that did not burn during engine operation. By and large, it is designed in the same way as any resonator type muffler. The gases pass through a fine mesh or set of plates on which a thin layer of platinum-containing substance is deposited. By reacting with the exhaust gas, the surface of the working parts of the catalyst heats up to a temperature of 500-600 degrees, helping to ensure that the remaining fuel burns out as it passes through it. The average response threshold of catalytic plates or grids is 300°C.

And here the most uninteresting part begins. The catalytic layer of the device cannot process an endless amount of unburned fuel, bringing it to Euro standards. Therefore, to control the situation, an oxygen sensor was installed on the exhaust. The lambda probe measures the amount of oxygen in the exhaust gases, and if the catalyst is not able to process the required amount of gases, the probe sends a signal to the electronic control unit. The ECU, in turn, adjusts the composition of the mixture so that the amount of CO output corresponds to the norm.

When replacing the exhaust pipe, it is better to use a stainless steel spare part.

But this correction does not always benefit the dynamic performance of the engine. More precisely, it prevents the motor from working correctly. If the catalytic layer is completely burnt out, the lambda probe shouts “guard”, and the ECU turns on the “Check Engine” light. In this case, it is necessary to replace the catalyst completely, since it is a non-separable unit and cannot be repaired. It costs as much as the entire exhaust system combined.

An exhaust manifold

The exhaust manifold is attached to the cylinder head directly with studs through a heat-resistant reinforced gasket. It is made of heat-resistant cast iron according to scheme 4-2. The collector is constantly subject to alterations from tuning studios, which replace the factory circuit with a wide variety of configurations and mounting options. It must be said that replacing the standard circuit, and especially replacing cast iron with steel, cannot bring anything good to the car.

The exhaust manifold is made of heat-resistant cast iron

Unless you are designing a narrow-profile car for competition. Moreover, for each discipline of motor sports, the exhaust manifold is configured separately and has some nuances in the design, which 90% of tuning studios have no idea about. Especially their customers. In most cases, the main focus is on the appearance of the pipe, but how it will work there is, by and large, all the same.

It must be said that the exhaust manifold is a rather important part and making it from steel, even the most heat-resistant, is a very questionable undertaking if the car will be used under normal conditions, and not just on the track or in rally raids. The collector temperature in operating mode can reach 1000 degrees. The cast iron is there for good reason and not at all to weigh down the engine structure. Any steel will burn out quite quickly under high load conditions, so before you buy an upgraded exhaust manifold made of super-Japanese steel, it would be worth thinking about the feasibility of such a replacement. Most of the top ten, thank God, do not participate in the world circuit racing championships; they simply have nothing to do there. Therefore, it would be more logical to correlate the rather modest capabilities of the VAZ 2110 engine with the level and quality of exhaust system tuning.

The exhaust manifold lasts almost forever and burns out in rare cases, and then due to a manufacturing defect. As part of improving the manifold with more effective methods, we would recommend that instead of installing thin-walled beautiful pipes of space configurations, simply pay attention to the mating of the exhaust ports of the cylinder head and the manifold holes. The fact is that the whole essence of tuning the exhaust system comes down, of course, to an amazing increase in power by reducing the resistance to exhaust gases. So it is precisely at this interface that the first additional power losses occur - at the junction of the manifold and the cylinder head. If the exhaust window and the manifold opening have even the slightest difference in size or level, parasitic vortices are formed that prevent the exhaust gases from escaping. If this is the case, after the collector you can even hang platinum direct flows with Swarovski diamonds, there will be no sense. If we are, of course, talking about saving power.

Typical exhaust system faults

Be sure to verify that there are any problems with the exhaust system before starting any repairs. And identify the node that has become unusable. Any breakdown reveals itself with the following signs:

- Broken connecting pipes. As a result, the integrity of the entire system is compromised and exhaust gases are not properly purified.

- Burnouts on the elements of the main muffler and resonator. This leads to the fact that the exhaust gases are not cleaned, and an extraneous sound appears when the engine is running.

- Strong noises appear from the exhaust system and the main muffler, indicating that there is damage.

If small cracks appear in the VAZ-2110 exhaust system (8-valve injector), then in the early stages they can be healed using sealants. This measure will increase the service life of the elements slightly, by no more than one year.

How can I fix the problem?

So, the place of gas breakthrough through the muffler has been detected, you just need to make a decision about replacement or try to repair the unit.

Often the holes in the body are small, and in this case it is not always advisable to buy a new muffler. It is necessary to remove the unit from the car and show it to a welding specialist, who will tell you whether it can be repaired. The craftsman will cut out the rotten part of the body, shake out the remains of the burnt partitions from the inside and apply a patch of new metal. Fistulas that occur at the points where the pipe is connected to the body must also be eliminated by welding. The only caveat is that these repairs solve the problem only temporarily. Such a muffler will not serve for a long time, and it may perform its function poorly; due to the lack of partitions, the sound will break through.

If it is decided that the muffler needs to be replaced, then you need to select and purchase it. New elements are made of black or stainless steel, so the choice is limited. The latter last much longer than black ones, but their cost is higher. In addition, welding work in case of repair of a stainless steel body will be more expensive. When purchasing a new muffler, it is worth purchasing a new set of suspension rubber bands, as well as a graphite O-ring. It is installed at the junction of the resonator and muffler pipes.

The exhaust system of the VAZ-2110 is designed for cleaning exhaust gases. The components included in it have a fairly long service life. But since the entire system is constantly experiencing temperature overloads, the metal gets tired, cracks and burnouts appear. Repairing the exhaust system yourself is quite simple. This allows owners of the “ten” to significantly save on maintenance. The design of the exhaust system includes: the main muffler, neutralizer, exhaust pipe and resonator.

Car muffler diagrams

A cross-section of a car muffler allows you to see exactly how the sound reduction function is implemented in each specific muffler. In direct-flow mufflers, for example, the method of changing the direction of gas movement is never used, and a standard muffler uses turns from 90 to 360 degrees. The change in the amplitude of sound wave oscillations is realized by perforating the internal pipes. It is these internal pipes, their diameter, diameter and frequency of holes that can drown out noise in almost the entire frequency spectrum.

But only the integrated use of these methods can guarantee high efficiency of the entire exhaust system as a whole. Therefore, modern cars use from one to six different mufflers. The main ones are the resonator and the main muffler.

Typical malfunctions of the VAZ 2110 exhaust system

The VAZ 2110 muffler was configured in factory and laboratory conditions so as to suppress the maximum amount of noise that the engine produces. In this case, not only the frequencies emitted by the engine itself are taken into account. A car body is a closed volume that responds to a certain frequency of a sound wave and has its own peak harmonics. As a result of research, it was found that to suppress most of the parasitic frequencies of the 2110 engine and its body, it is necessary to use the range from 60 to 400 Hz. This corresponds to medium and high engine speeds - 2500 and 4200 rpm. If at least some changes are made to the geometry of the 2110 muffler compared to the stock one, the noise characteristics will definitely change.

Moreover, the main low-frequency noise is the most difficult to remove. Therefore, if we talk about combating noise and tuning the exhaust system at the same time, then technically it is almost impossible to implement this. The maximum retained power is direct flow, and the most comfortable sound is a factory muffler. All other options are compromises.

Burnouts, breakdowns and violation of system tightness are the main malfunctions that VAZ 2110 owners encounter. Most often, the cause of exhaust pipe burnout is corrosion, too rich a mixture and incorrectly set ignition. Smoke from the muffler may indicate that the mixture is too rich and is burning out in the exhaust pipe or resonator. In this case, the muffler often fires, popping noises are heard, as a result of which the resonators and mufflers burn out. A knock on the body in the area of the resonator or muffler may indicate that, as a result of mechanical damage, the geometry of the muffler has changed, the suspension, cushion or damper rubber has collapsed, and the pipe is knocking on the body. In this case, you need to accurately determine the location of the impacts and put the geometry of the system in order. If this is impossible to achieve due to the dilapidation of the elements, only replacement or strong repairs will solve this problem.

To repair mufflers, you can buy hundreds of types of sealants, bandages and thermal putties that will temporarily insulate damaged areas even without welding. Their quality is different, as is their price, but if the question is to make it through the season, then this restoration option has a right to life.