Diagnostics of speedometer operation at fourteenth

Troubleshooting begins by disconnecting the wiring block from the speed sensor harness and checking them using a test light.

To make a control light bulb, you need any car lamp that can operate at a voltage of 12 V, and two wires about 1 meter long each. One of the wires is attached to the positive terminal, the second - to the negative terminal of the lamp. The resulting device also includes a Krona battery.

To carry out the test, one wire of the warning lamp is attached to the ground of the body or battery, and the second is made with short, frequent touches to the middle contact of the DC connector. If there are no faults in the connector-speedometer section, the speedometer needle will slightly tremble or rise. If the needle shakes, the answer to the question why the speedometer does not work can be considered found - the speed sensor requires replacement.

In cases where the needle’s response to tapping on the central contact of the block cannot be detected, it is necessary to “test” the speedometer power circuit. The procedure is carried out using a multimeter (multitester), or by using the same light bulb - a control.

The wiring harness is first disconnected not only from the speed sensor block, but also from the speedometer itself. One terminal of the tester or warning lamp is connected to the end of the wire located under the hood, the other to the interior end of the speed meter current supply circuit. If the tester in the “continuity” mode indicates a violation of the integrity of the circuit, further troubleshooting is carried out in this direction. It is necessary to check the fuses, the connection points of the wires, and their integrity inside the insulating braid.

The search area can be reduced by gradually “ringing” individual sections of the circuit. On model 2114 and other VAZ products, the cause of speedometer failure is often oxidation of the “mass” contacts attached to the car body.

In cases where the speedometer needle does not work, but there is no evidence of malfunctions in the electrical supply circuit, a logical conclusion is drawn about the malfunction of the device itself. Additional testing can be done by temporarily installing a known good instrument panel.

Speed sensor problem

In order to understand the question of why the speedometer needle twitches, it is necessary to become more familiar with the design of the car. For example, domestic classics did not have a speed sensor. The system worked approximately as follows. The gearbox contained a motor (drive), which, while the car was moving, turned a cable going to the speedometer.

If the motor failed, then the arrow on the instrument panel completely “died” and always showed “0”. But most modern cars are equipped with a speed sensor that is installed in the gearbox. It determines the speed limit practically without error and transmits data to the speedometer via wires. From the same wire and sensor, data also comes from the distance traveled, that is, to the odometer.

The main reasons why the VAZ 2114 speedometer does not work

Let's now look at the main reasons why the speedometer on the VAZ 2114 does not work and see the solution to these problems.

Speedometer sensor VAZ 2114 - failed

VAZ 2114 speedometer sensor

Unlike older AvtoVAZ models, the VAZ 2114 speedometer is not mechanical, but electronic, whose readings depend on the sensor that is installed on the car’s gearbox. It is this electronic device that most often fails, which can be caused by various factors:

- lack of contact on the connector block (for example, due to water getting there);

- break in the wire supplying the sensor;

- lack of current in the supply contact.

Since the VAZ 2114 is equipped with an on-board computer, the first thing you can do is try to detect a breakdown with its help: having turned on the self-diagnosis process, you need to wait until it ends. If the result of the test is the displayed error P0500, it means that the on-board computer does not receive the corresponding signal from the speed sensor.

How to check the speedometer sensor of a VAZ 2114

Speed sensor VAZ 2114

To check the status of the speedometer sensor, you need to do the following:

- Open the hood of the VAZ-2114.

- Get rid of the adsorber, it will be more comfortable to work.

- Determine where the wire to the sensor is located in the CV joint area.

- Locate the tool located under the throttle assembly.

Finally, you get to the sensor itself. Take a look at what it looks like and check the functionality of the device. What is it?

Look at the stem, it is made of plastic, this material often breaks and deteriorates. Failures also occur with the plastic rod. Pay attention to the plastic drive gear - ideally all the teeth should be in place. If they are cut off, then the sensor’s performance leaves much to be desired.

That is why, even at the stage of absence of breakdowns, service station specialists recommend replacing plastic parts with metal ones. If the rod and gears are made of metal, the speedometer is unlikely to break soon. When changing the mechanism, take into account the following features: the VAZ-2114 can be equipped with units with different volumes.

Speed sensor VAZ 2114 - faulty

The gears are not the same color. The numerical values of the speedometer drive change in accordance with the different gear ratios of the main combination of pairs. This means that the shade of the gears must match and remain the same.

When checking the device is completed, it will not be superfluous to ring the contacts located in the block - this way you can fix the location of the break in the electrical circuit, then record the voltage of all contacts. In order for testing to be completed effectively, arm yourself with a multimeter, available for sale in car dealerships, to carry out diagnostics, set the operating mode to “voltmeter”. Next, determine the condition of the controller; if you don’t know how, it’s better to contact a specialist.

Troubleshooting Methods

Usually, the functionality of control devices can be restored by replacing the speed sensor. As an example, consider the Hyundai Accent car. The speedometer needle twitches - we go to the store to buy a new speed sensor. With a high mileage of this brand of car, this is a completely typical problem that many motorists encounter. If the gearbox is mechanical, then the problem is most often solved by replacing the cable. Lubrication with WD-40 also helps, but this is more of a temporary solution, so the problem may return in the future.

As for automatic transmissions, there are sensors installed there that often fail. Changing them won't be difficult. Let's see exactly how to do this and what we need to complete the work.

Wear or breakage of the VAZ 2114 speedometer cable

Speedometer cable VAZ 2114 - is responsible for transmitting speed from the box to the instrument panel of the car’s speedometer. One end of this cable is connected to the drive gearbox, which is located on the gearbox, and the other end is connected to the speedometer mechanism itself, which in turn is located on the instrument panel.

The speedometer cable of the VAZ 2114 is located near the bottom of the gearbox housing and is attached to the gearbox, for clarity, so that you have at least the slightest idea of where the cable is located, look at the photo below in which the arrow indicates the cable:

The speedometer cable is replaced in 2 cases:

Failure, and therefore the speedometer will not show any values on the instrument panel. And also when it is deformed and when the nut that secures it to the gearbox or to the speedometer mechanism breaks. It is important to know: If you have a nut securing the cable to the gearbox, or to the speedometer, it is broken, then when driving you will experience sharp jumps in the speedometer needle!

Engine operating temperature on a VAZ-2112 16 valves: parameters

The engine cooling system has many components that are interconnected, and if one fails, the entire system will not be able to function. So, let's look at the location diagram and decoding of the indicators for the cooling system of a 16-valve engine.

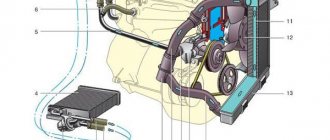

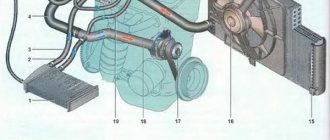

Diagram of the cooling system operation

1 – heater radiator; 2 – steam removal hose of the heater radiator; 3 – outlet hose; 4 – supply hose; 5 – coolant temperature sensor (in the block head); 6 – pump supply pipe hose; 7 – thermostat; 8 – filling hose; 9 – expansion tank plug; 10 – coolant level indicator sensor; 11 – expansion tank; 12 – exhaust pipe; 13 – liquid chamber of the carburetor starting device; 14 – radiator outlet hose; 15 – radiator supply hose; 16 – radiator steam outlet hose; 17 – left radiator tank; 18 – sensor for turning on the electric fan; 19 – fan electric motor; 20 – electric fan impeller; 21 – right radiator tank; 22 – drain plug; 23 – electric fan casing; 24 – timing belt; 25 – coolant pump impeller; 26 – supply pipe of the coolant pump; 27 – coolant supply hose to the throttle pipe; 28 – coolant drain hose from the throttle pipe; 29 – coolant temperature sensor in the outlet pipe; 30 – radiator tubes; 31 – radiator core.

Replacing the speedometer cable of a VAZ 2114

In order to replace the speedometer cable on a VAZ 2114, you must perform the following procedure:

- At the beginning of the operation, you will need to remove the instrument panel from the car.

- Next, using pliers, completely unscrew the nut that secures the cable to the mechanism, and after unscrewing, disconnect the cable.

- Then move to the bottom of the car, and there, unscrew the nut that secures the cable to the gearbox (it is indicated by the arrow), and after unscrewing the nut, disconnect the cable.

- Now take the cable in your hands and pull it out of the car.

- Finally, untie the wire from the nut.

- Do the entire cable installation in the reverse order of removal.

What do you need to know?

Often, problems with the speedometer are related to electronic problems. Although a lot depends on the car. For example, if the speedometer needle of a VAZ-2107 twitches, then it is not necessarily a matter of wiring. The speedometer in this car is of a mechanical type, there are a minimum of wires. Therefore, very often the problem is a cable that has lost tension.

At the same time, the issue may be a faulty speed sensor. Many motorists check its performance first. After all, it’s much easier than disassembling the dashboard, fixing the problem and putting it back together. Let's look in more detail at the main malfunctions of speedometers on some car brands and consider methods for eliminating them.

Mechanical drive VAZ 2114 - checking functionality

Another common reason is the malfunction of the mechanical drive, and in particular, the one that is installed when the car is assembled at the car factory has an unreliable plastic rod on which the drive gear is located. There are cases of breakage of this rod and cutting of teeth on the gear. When replacing them, pay attention to the color of the gears, since the VAZ-2114 is equipped with engines with different displacements and due to different gear ratios of the main pair, the gear ratios of the speedometer drive change. Therefore, the color of these gears must be the same. If the speedometer drive fails, replace it with one that has a metal rod.

Video: VAZ 2114 speedometer does not work - the main reasons

https://www.youtube.com/watch?v=qiDmZLUuTMI

Didn't find the information you are looking for? on our forum.

Typical faults

There is no need to talk about the reliability or unreliability of this sensor. On some cars it works throughout its entire service life, while on others it often fails. However, there are a number of typical problems that motorists face:

- Failure due to old age. Each electronic device, regardless of quality, has its own resource. Therefore, it can fail at any time.

- Mechanical impact. Simply put, damage to the sensor housing or wiring. If any work has been done to remove and install the sensor, it is likely to be damaged.

- Oxidized, dried out or broken wires. Also, the wiring simply wears out its own life if it has not been changed for a long time.

- The sensor does not fit this car model. In this case, you should not count on correct speedometer readings.

If the instrument panel is faulty

Very often, in addition to a broken speed sensor, a blown fuse designated F1, or poor wire contact, the speedometer installed on the Lada Kalina refuses to work because the instrument panel has failed. It can only be replaced as an assembly. The spare parts store does not sell individual parts of the instrument panel.

However, before proceeding with the replacement, you first need to make sure that the wire going to ground is securely fastened. Perhaps this is the reason for the breakdown. Of course, the design of the speedometer is based only on electronics, but motorists can cope with some of its malfunctions on their own. To locate the sensor under the hood and replace it, you must first perform several operations.

It is necessary to remove the inlet pipe connecting the air filter to the throttle assembly. To do this, you need to release three clamps. After which the pipe can be easily removed. The gearbox housing is now visible. The speed sensor will be attached to it together with a suitable plug with wires. In order to replace it, you need to have a small supply of tools:

- flat screwdriver;

- Phillips screwdriver;

- spanners;

- head;

- ratchet.

First, the wires supplying power to the sensor are disconnected. For this purpose, use a flat screwdriver to pry off the plastic retainer that secures the plug. Without releasing the latch, it is slowly pulled up. The plug does not offer much resistance and can be easily removed.

Then the nut that secures the sensor we are interested in is unscrewed. This work is best done with a ratchet wrench. Due to the fact that the sensor seat is made very tightly, it needs to be pryed off with a thin flat screwdriver. After which it can be easily removed from the gearbox of the Lada Kalina.

The new part is mounted in its original place. Before installation, all free spaces in front of the hole must be thoroughly wiped and free of dirt. In this case, you can be sure that no debris has entered the gearbox. The new sensor is inserted all the way until there is a loud click. Only then can you tighten the nut.

The cost of a Lada Kalina speed sensor in spare parts stores reaches a maximum of 400 rubles. Almost every car enthusiast can afford to purchase a new sensor. Replacing the device does not cause any particular difficulties, so such repairs are usually done independently.

Signs

A speedometer malfunction will manifest itself almost identically not only for Lada cars, but also for other cars. The main signs by which you can almost unmistakably recognize a device breakdown:

- The speedometer needle constantly points to zero, jerks erratically or freezes;

- the same thing can happen with the arrow showing the fuel level;

- the speed of the car cannot be changed;

- the device turns off while driving;

- cravings have disappeared or decreased significantly;

- the power steering indicator lights up for no reason (in this case the steering wheel becomes too heavy or, on the contrary, light);

- fuel consumption has increased;

- the odometer gives incorrect information about the kilometers traveled;

- the light is on indicating the need to check the engine;

- reduction in power, as well as uneven idling until the engine switches itself off (while poor performance in other modes often has a different reason).

Repair

Repair of the speed measurement system directly depends on the identified malfunction:

Speed sensor

- Clean from dirt;

- Clean the pad contacts from corrosion and oxides;

- If the above measures do not help, the sensor is replaced.

Wiring

- Check and clean “mass” contacts;

- Solder or secure with twists the places where the wires are broken, due to which the speedometer stopped working;

- Cover areas where the braid is damaged with insulating tape;

- Replace failed fuses;

- Clean the pad contacts from oxides and corrosion.

Speedometer

If the speedometer stops working, it must be replaced. On domestic cars assembled using an electronic type of speed meter, the speedometer changes along with the instrument panel. You can carry out this operation yourself. To do this, you only need a Phillips screwdriver and pliers.

Repairing an old speedometer can be much more expensive than completely replacing the old instrument cluster with a new one.

Wiring fault

As noted above, the wires oxidize over time, become bent and simply dry out. Ultimately, this leads to the complete loss of contact, which previously appeared and disappeared, which led to the incorrect operation of the speedometer.

This problem can be solved in several ways. The simplest is to re-solder the wires and heat-shrink them. The problem may arise somewhere else, but it may not happen. The second method is to replace the entire braid. A more labor-intensive and complex method, but the result is normal wiring operation for a long time. You also need to understand that if the wire is exposed, it can short to ground. There is nothing good about this either, so if you notice this, then you should try to fix the problem as soon as possible.

Priora engine tuning

To improve the power performance of the Priora power unit, they resort to the following modifications:

- The receiver is installed.

- Exhaust pattern: 4-2-1.

- Throttle valve: 54 -56 mm.

- Sports camshaft.

- Modification of the cylinder head (cylinder head) by sawing.

- Lightweight valves.

- 440cc type injectors.

In addition to the considered method of transforming the power unit to increase dynamic performance, there are several more ways to tune a car of this model.

Atypical breakdowns

If the speedometer needle twitches (2109 is a VAZ or another model - it doesn’t matter, this type of breakdown is common to many cars), and the above method did not help, then there are several more options. One of them is wedging the arrow in a certain position. Therefore, when picking up speed, the instruments may show normally, but at some point there will be a jump. The problem can be solved by disassembling the dashboard and repairing the speedometer. It is likely that you will need to remove the arrow and lubricate it or replace it with a new one.

Another atypical failure is the failure of gears after turning off the mileage on a mechanical speedometer. It is quite rare and suggests that the technicians who corrected the mileage did not take too much pride in the car. But on the electronic speedometer, when the mileage is increased, the system may be blocked, and the “Check Engine” error will appear on the dashboard. The last thing you should look at is the on-board computer, but this only applies to electronic systems.

Insufficient coolant level

In the expansion tank of your car, the level of coolant should be almost equal to the half of the tank. If you look at the mark, it turns out to be the top mark on the tank body with the MAX mark. If there is no such mark, then most likely it will be located along the upper edge of the clamp.

If necessary, add antifreeze or antifreeze to the required level. It is worth noting another fact that in winter, if its level is insufficient, the stove may not work efficiently, that is, the air will not blow as hot as during normal operation of the heater.

Driver signals

A specially equipped sensor in each vehicle will currently help to systematically monitor or monitor the temperature of the liquid in the cooling system. In more modern cars it can be slightly modified and display indicators using LEDs, but the essence does not change, the purpose remains the same - to help the driver in signaling the readings.

If you blinked and sent the sensor needle into the red zone, then expect a column of steam from under the hood of your friend in a few seconds. Believe me, there is nothing good here, and no one knows how it will all end.

The concept and principle of operation of a thermostat

Now the physical side of the “coin”. Even from driving school, we know that an automobile cooling system consists of large and small circles through which some liquid or water circulates. When starting the engine and up to 90°C

the liquid flows in a small circle, from 90°C and above the thermostat opens and allows flow in a large circle to reduce the overall temperature by lengthening the flow chain.

Accordingly, breakdowns in the thermostat can lead to its failure to open in a timely manner and the coolant to boiling. This means expect a “hello” from the piston rings.

You can check the functionality of the thermostat as follows:

start and heat the engine to 90°C and feel the radiator pipe; if it is hot, then the thermostat is working, otherwise look for an urgent replacement. If it happens that the thermostat is unusable, then we buy its working analogue in any auto shop or on the market and get ready to replace it yourself.

A few important nuances

So we, in fact, figured out why the speedometer needle may twitch. As you can see, there can be a lot of reasons. But, when faced with such a problem, it is not at all necessary to immediately go to the service station. The malfunction can often be fixed on your own, of course, if you have the time and desire.

Oddly enough, with electronic systems in this case everything is much simpler. In most cases, it all ends with a banal replacement of the speed sensor or wiring. Another thing is that this sensor costs a lot of money for some cars. In this case, you can try to find a worthy analogue using online catalogs. But it is better to avoid openly Chinese products, which attract with their low cost. After all, such a sensor can please the owner of the car with correct operation for a short period of time, or even not work at all immediately after installation.