When choosing a new car from official dealers or on the used car market, each buyer pays attention to a number of characteristics and features of the vehicle.

16 valve engine

Everyone's selection criteria are different. But almost everyone first looks at the technical aspects in the form of the engine. Car enthusiasts take into account volume, power and specify the number of valves.

The operation of the engine directly affects the capabilities of the vehicle in terms of acceleration, maximum speed, efficiency, dynamics, etc. Because of this, there is a huge amount of controversy regarding engines. Experts and car enthusiasts are trying to figure out what is best to choose.

One of the pressing issues regarding engine characteristics is the number of valves used. There are engines with 8 and 16 valves. But how do they differ from each other, what advantages do they have, and which option should you choose when buying a car?

8 valve engine design

Such engines are used mainly on models in the entry-level price segment. Here there are 2 valves per cylinder: 1 for intake and 1 for exhaust.

Another important feature of such power plants is that only 1 camshaft is needed, which controls the gasoline injection and exhaust gas exhaust system. To operate it, a simple belt or chain mechanism is sufficient. Such a system is much easier to maintain and repair compared to complex timing belts of more expensive cars. And such an elementary design significantly affects the final cost of the car.

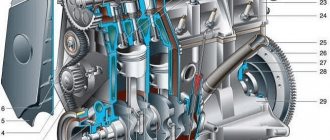

As an example, we give a diagram of the design of an 8-valve VAZ-2114 engine.

1) generator drive pulley; 2) oil pump; 3) timing belt; 4) coolant pump timing belt; 5) front cover of the timing mechanism drive; 6) tension roller; 7) camshaft toothed pulley; camshaft drive rear cover; 9) camshaft oil seal; 10) cylinder head cover; 11) camshaft; 12) front camshaft bearing cover;

2) oil pump; 3) timing belt; 4) coolant pump timing belt; 5) front cover of the timing mechanism drive; 6) tension roller; 7) camshaft toothed pulley; camshaft drive rear cover; 9) camshaft oil seal; 10) cylinder head cover; 11) camshaft; 12) front camshaft bearing cover;

13) pusher; 14) valve guide; 15) oil separator mesh for the crankcase ventilation system; 16) exhaust valve; 17) inlet valve; 18) rear camshaft bearing cover; 19) fuel pump; 20) housing of auxiliary units; 21) ignition distributor sensor; 22) cooling jacket outlet pipe; 23) cylinder head; 24) spark plug; 25) crankcase ventilation hose;

26) flywheel; 26) flywheel; 27) crankshaft rear oil seal holder; 28) rear crankshaft oil seal; 29) cylinder block; 30) oil pan; 31) oil level indicator (oil dipstick); 32) crankshaft; 33) piston; 34) connecting rod cover; 35) connecting rod; 36) crankshaft main bearing cover; 37) front crankshaft oil seal; 38) crankshaft toothed pulley.

Pros and cons of an 8 valve engine

This engine design, despite its venerable age, has many advantages:

- simplicity of design - an 8-valve engine has significantly fewer wearing parts, and accordingly, its repair will be easier and cheaper;

- lack of hydraulic compensators - motors of this type simply do not need them, so the design is further simplified and cheaper;

- less demanding on oil characteristics - 8-valve engines allow the use of lower quality lubricant, which is noticeably cheaper;

- less sensitivity to the quality of gasoline - most of the 8-valve valves used today were developed at a time when there was no better fuel than 92;

- small size - one camshaft takes up much less space, so such engines are more compact than their 16-valve counterparts, and this makes access to attachments easier.

However, there are also many significant disadvantages:

- less power - intake and exhaust through 2 valves significantly limits the amount of fuel supplied to the cylinders and the total engine power;

- slightly higher fuel consumption - the reduced throughput of 1 pair of valves forces the engine to put more effort into pushing exhaust gases into the manifold, and accordingly more energy is spent on this;

- noise at high speeds - the pushers wear out during engine operation, gaps form, which is why the engine begins to make noticeable noise;

- the need for more frequent valve adjustments - if this is ignored, engine performance will drop, and fuel consumption, on the contrary, will increase.

What should you choose?

We bring to your attention 5 engines that we consider the best:

Ford 1.0 EcoBoost

The 1.0 EcoBoost engine was introduced in 2012 and found its way into most Ford models, from Fiesta to Mondeo.

Customers could choose from versions developing 100, 120, 125 and 140 hp. Despite considerable effort, the device turned out to be durable. Before 2013, the cooling system was a problem. In some vehicles, leaks were found in the pump and water channels. The subject of the service action was a hose susceptible to cracking between the expansion tank and the turbocharger.

Mercedes 2.0 CGI

Mercedes had a lot of supercharged engines. Due to characteristics and historical events, the concern used compressors more readily than turbochargers.

After all, even in Stuttgart, turbo was considered the only true way. The new four-cylinder engine was not built from scratch. Engine code M271 (2002-2011) with direct injection was used and the compressor was replaced with an exhaust gas turbocharger. As a result, the engine became economical during quiet driving and developed 156-204 hp.

The change in supercharger concept also solved one of the main problems of the old engine, namely the compressor problem. However, with high mileage, it is worth preparing to replace a worn timing chain - a single-strand chain that is not very durable.

Opel 1.4 Turbo

For many years, Opel offered supercharged petrol engines that could cope with the need to drive a poorly regulated gas setup without the need for frequent oil changes.

To keep up with competitors, Opel had to update its engine range. One of the new era engines is the 1.4 Turbo, introduced in 2010 (also found in Chevrolet). It produces 120-140bhp and in some models it has been fitted with an LPG unit from the factory which works very well thanks to indirect fuel injection and hydraulically compensated valve timing which is not available on naturally aspirated 1.6 engines for example.

Fiat 1.4 T-Jet

The 1.4 T-Jet series engine is designed for long-term operation. With proper maintenance more than 300,000 km.

Properly installed LPG and even tuning attempts, which Fiat often used when creating subsequent versions of the Abarth 500 / Punto, do not harm it. In top versions, the 1.4 T-Jet developed 190 hp. Its base variants produce 105 hp, which proves how versatile the engine is.

Renault 2.0 Turbo

Depending on the version, the engine offers 165-275 hp.

Thanks to its high torque (at least 270 Nm), it allows you to enjoy smooth driving even in basic versions. To keep the engine running for a long time, the driver must remember to change the oil and timing belt.

Petr Alekseev

Regular author of articles for the magazine rating cars.

16 valve engine design

In such 4-cylinder engines, each cylinder already has 2 pairs of intake and exhaust valves. To operate such a system, 2 camshafts are required. And for their coordinated work, a much more complex gas distribution mechanism is used. At the same time, 2 intake valves allow more fuel to be supplied to the cylinders per stroke - and hence a significant increase in power and efficiency. At the same time, fuel consumption is reduced thanks to the presence of 2 exhaust valves.

Hydraulic compensators are often used to press the valves against the shaft in such engines. Unlike 8-valve valves with mechanical pushrods, this system operates smoother and quieter. It also provides an additional increase in power and additional fuel economy.

Another specific feature of 16-valve engines, which becomes especially relevant against the backdrop of ever-tightening environmental requirements, such engines, due to more precise operation of the gas distribution mechanism, are safer for the environment.

For example, here is a diagram of the design of a 16 valve VAZ 2112 engine.

1) engine oil pan; 2) front crankshaft oil seal; 3) crankshaft; 4) crankshaft pulley; 5) oil pump; 6) generator drive pulley; 7) timing belt; front cover of the timing mechanism drive; 9) coolant pump pulley (pump); 10) tension roller; 11) camshaft toothed pulley; 12) rear cover of the timing mechanism drive; 13) camshaft oil seal;

2) front crankshaft oil seal; 3) crankshaft; 4) crankshaft pulley; 5) oil pump; 6) generator drive pulley; 7) timing belt; front cover of the timing mechanism drive; 9) coolant pump pulley (pump); 10) tension roller; 11) camshaft toothed pulley; 12) rear cover of the timing mechanism drive; 13) camshaft oil seal;

14) exhaust camshaft; 15) hydraulic pusher; 16) valve spring; 17) valve guide; 18) exhaust valve; 19) receiver; 20) camshaft bearing cover; 21) guide pipe; 22) cylinder head cover; 23) plastic cover; 24) spark plug; 25) intake camshaft; 26) inlet valve; 27) cylinder head; 28) coupling;

29) fuel rail; 30) crankcase ventilation hose; 31) nozzle; 32) intake manifold; 33) flywheel; 34) crankshaft rear oil seal holder; 35) rear crankshaft oil seal; 36) cylinder block; 37) oil dipstick; 38) piston; 39) connecting rod; 40) connecting rod cover; 41) crankshaft main bearing cover.

Pros and cons of a 16 valve engine

So, here are the main advantages of 4-cylinder engines with 16 valves:

- significant increase in power, increased maximum speed and dynamics;

- lower fuel consumption and environmental friendliness;

- much lower noise level;

As you can see, the advantages of such engines are significant. But they also have significant disadvantages:

- hydraulic compensators are very sensitive to oil quality, it is recommended to use only synthetic oil;

- for efficient operation of the “four” with 16 valves, you need high-quality gasoline, ideally not lower than AI-95;

- Structurally, such engines are much more complex, in particular, replacing the timing belt here, as a rule, costs several tens of thousands of rubles;

- The motor itself is larger, which makes access to attachments more difficult.

Knock during operation

The main malfunction of the valves (not counting burnout) is considered to be a knocking sound on a cold or hot engine. The knocking noise on a cold engine disappears after the temperature rises. When they heat up and expand, the thermal gap closes. Another reason may be the viscosity of the oil, which does not enter the hydraulic compensators in the required volume. Contamination of the oil passages of the compensator can also cause a characteristic knocking noise.

On a hot engine, valves may knock due to low oil pressure in the lubrication system, dirty oil filter or incorrect thermal clearance. Natural wear and tear of parts should also be taken into account. Malfunctions may be in the valve mechanism itself (wear of the spring, guide bushing, hydraulic pushers, etc.).

Main differences between 16 and 8 valve engines

We have figured out the features of these types of engines, now we will specify the differences between them.

8-valve engines are much simpler in design, which has a positive effect on the price of the entire car, its maintenance and repairs. However, they are significantly inferior in power to 16-valve analogues with the same displacement - on average, the difference in power here is 15-25 hp. Because of this, engine response, acceleration dynamics, and maximum speed suffer.

At the same time, 4-cylinder engines with 8 valves are much simpler and more affordable to repair. There are significantly fewer elements that can break, and if something does break down, the breakdown can be repaired with less effort. And spare parts for such engines are usually cheaper.

With efficiency, everything is not so clear. Yes, 8-valve engines consume more fuel - but at the same time, they can be filled with lower quality, inexpensive gasoline. Oil may not be the most expensive either. Another controversial point is the use of hydraulic compensators. They are installed on 16-valve engines and eliminate the need for systematic valve adjustment. At the same time, they sometimes fail, and replacing them will cost a pretty penny.

One more important point should also be noted: in 16-valve engines, the piston and valves can jam together - and this inevitably leads to costly repairs, and sometimes to a complete replacement of the engine. In principle, 8-valve patients do not have such a disease. However, such jamming occurs, as a rule, on Russian and Chinese cars, which by default are inferior to the Western and Japanese automobile industry.

Technical specifications

Let's consider the technical characteristics of 8 and 16 valve engines using the example of VAZ models.

Technical specifications

VAZ 21126

What is better, an 8 or 16 valve engine? According to technical indicators, the 16-valve engine wins in power and efficiency, but it is worth taking into account the costs that will have to be incurred for using dynamics and comfort.

When buying a car aftermarket, you can distinguish a 16-valve engine by its appearance. The engine's wide intake manifold resembles a snail, and is usually covered by a shroud with the company logo and the inscription 16Valve.

Which is better 16 valves or 8

So, let's try to determine which option and in which situation will still be preferable. New cars with 4-cylinder engines offered in showrooms are almost always equipped exclusively with 16-valve engines; such engines have already displaced the outdated 8-valve design from the market. However, some manufacturers, usually from the lower price segment, still have such simplified options. Their main advantage is just a more affordable price.

But, if you have the opportunity to pay extra, the car is chosen for personal, not commercial use, and you are not going to service it yourself, then it would be more reasonable to buy a car with a 16-valve engine. It will delight you with higher power and dynamics, as well as efficiency and reduced noise.

In a situation where the car is taken from hand, 8-valve options may be preferable. The fact is that they are structurally simpler and more unpretentious in the choice of fuel and oil, respectively, here the chance of getting a car with a “live” and peppy engine will be higher than in the case of more sensitive 16-valve engines.

It is impossible to say unequivocally which option is better. It is necessary, first of all, to take into account your own goals and objectives, financial capabilities, and the conditions in which the car will be operated. If your primary requirements are reliability and unpretentiousness, then it makes sense to take a closer look at the 8-valve modifications. If speed and power are important to you, then it is better to choose 16-valve engines.