The gear shift knob is definitely an important element of the car. It interacts intensively with the driver, so it quickly wears out, wears out, and becomes unusable.

However, it is not at all necessary to go to a car dealership every time or order a handle for your model via the Internet. Surely many people have noticed the variety of handle models in other cars. It turns out that it is easy to make yourself. To do this, you need to buy a two-component epoxy compound or get it from your supplies, provide yourself with a workspace, decide on an idea and be ready to experiment.

First you need to decide on the shape of the handle. The epoxy resin gear knob can be varied. You can take any vessel you like, buy a mold in a store, or make it yourself from plastic or papier-mâché. In this review, we use an ordinary light bulb as a form. This choice is due to accessibility, because it is inexpensive, and maybe you even have an extra light bulb at home, and convenience. The shape of the light bulb is very comfortable for the hand.

Material

It was no coincidence that epoxy was chosen as the material for the gearshift knob. It is used both in households and industrial production. Every year there are more and more possibilities for its use.

The resin exhibits all its wonderful and useful qualities only after it is mixed with a hardener and the hardening process itself is completed.

If these two substances are mixed in the right proportions, it is possible to obtain a material that is almost as strong as steel. He is not afraid of falls from different heights or blows of varying severity. Cured epoxy resin is also not prone to deformation and practically does not wear out. Products made from it will be truly strong and durable. Despite its some toxicity in the liquid state, hardened epoxy does not emit any harmful substances and is absolutely safe. Cured resin is absolutely moisture-proof.

Useful to know > Types of tables made of epoxy resin and wood, features of their production

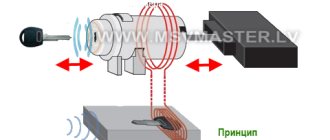

DIY illuminated gear knob

Tuning a car is wonderful; customizing a car, as they say, is the dream of every true car enthusiast, and you get even more pleasure when you do this tuning yourself, that is, with your own hands. Today I want to tell you about how to make tuning of the gear knob, or rather, how to make your own backlit gear knob.

I had the desire to make such beauty for my iron friend quite a long time ago, but there was no opportunity to realize it, but recently, as they say, the possibilities coincided with the desires and I finally brought my idea to life.

In order to make LED illumination of the gear knob, I needed the following:

- LED (its color is a personal matter);

- 1 kOhm resistor.

- A very sharp knife, preferably a stationery knife;

- Soldering iron and everything needed for soldering;

- Printer (preferably laser);

- Glue in a gun with a transparent rod.

So, in order.

The first thing you need to do is remove the gear knob itself . To do this, take your time and carefully remove the glass that is located on top of the handle (depending on the car model).

Next, you should clean it of paint, that is, so that it becomes transparent, then thoroughly polish it using GOI paste and a felt wheel.

Preparatory stage

Using a screwdriver, tweezers or any other suitable means, you need to remove its contents from the light bulb so that only the glass form remains. Also at this stage you need to think about the design of your future pen. You can prepare glitter or dyes in advance that will make the product more beautiful and unique. The dye can be matched to the interior design of the car. The handle may contain a car brand badge or other small objects, for example, cartridges, bolts, balls, stones, it all depends on the imagination of the manufacturer.

After cleaning the light bulb, secure it with tape or tape to something that can serve as a stand.

Preparation of the composition

Two-part epoxy can be purchased at any hardware store. In the box you will find two vials. One will contain the resin itself, and the second will contain the hardener. The resin must be prepared immediately before use. Manufacturers advise doing this in a ratio of 10-14 parts of hardener to 100 parts of resin, that is, 1 to 10. To measure the components, it is convenient to use two syringes.

Life hack: use a twenty-cc syringe for resin and a two-cc syringe for hardener so as not to get confused in the proportions.

It is important to measure the components carefully and correctly, otherwise the resin may not harden or, on the contrary, harden ahead of time. There is a very common misconception that if you add more hardener to the resin than required in the instructions, then curing will happen faster, but this is a misconception. Epoxy resin removal is an extremely capricious process that is influenced by many factors. But we will talk about this later, but now place the resin and hardener in a container and mix thoroughly.

Freezing

We have reached the most difficult stage, where it is very easy to mess everything up. Pour the resin and hardener mixture into the mold. Epoxy hardens very capriciously; this process is affected by any external influence, for example, room temperature, humidity, wind, sun. When such a volume of epoxy resin hardens, a large amount of heat is generated. Under no circumstances should you leave it unattended as it may start to boil.

Useful to know > What products are currently made from epoxy resin

It’s easy to come across advice on the Internet that if you heat the resin a little, there won’t be as many bubbles in it, and the mixture itself will turn out more transparent. The fact is that even after heating the epoxy resin in the microwave at room temperature, it begins to rapidly heat up, flow out of the mold in the form of foam and emit smoke, and the container in which it is located may crack or burst. The resin will indeed become more transparent, but its color will also darken. It will be difficult to get rid of frozen foam that spreads everywhere, and the light bulb itself will be damaged.

To avoid starting all over again, do not follow such advice. If you do the opposite and leave the resin to harden not in the heat, but in the cold, then you may encounter the following problem: the resin will not lag behind the mold into which it was poured, and you will not be able to pull it out. There is also a high probability of finding the resin not yellow, brown, amber or transparent, but white. One of the reasons why motorists and other inventors love to use epoxy resin for their products is the beautiful effect of transparency and as if illuminated from within. Therefore, it is better not to rack your brains and just leave the resin to harden on its own.

Check every 30 minutes to make sure it is not overheating. Once the top layers have hardened, place the bulb with the resin in the water. The resin should be transparent and a beautiful amber color. If at some point you were not careful and the temperature of the resin became too high, minor cracks may appear here and there on the vessel.

In order to get rid of the light bulb, you need some improvised object, for example, a wooden block. By tapping the light bulb with a block, we will get rid of the already unnecessary shape. Small pieces of glass will break off, so you need to be patient and careful. The handle is ready, the hardened resin is very strong, the product is not afraid of impacts or falls.

Useful to know > Types of self-leveling floors made of epoxy resin and features of their use

Do-it-yourself gear knob reupholstery

Such minor tuning of the interior can be carried out both by the car enthusiast himself and in special workshops. If the car owner is not sure that he can handle it on his own, then he can turn to specialists who will do all the work quickly and efficiently.

Required Tools

It is impossible to reupholster the gear shift lever without the following materials and tools:

- pencil, marker or pen;

- scissors;

- scalpel or stationery knife;

- cling film;

- scotch;

- sewing machine;

- glue;

- nylon or silk thread;

- thimble - to avoid damaging your hands;

- hot sewing needles;

- leather, suede or any other covering material.

Tools and materials required for upholstering the gearshift knob

The optimal material for upholstering the handle is high-quality genuine leather. All work must be done carefully and carefully so as not to damage the skin and not to redo everything several times. To create an attractive case, you can combine smooth and perforated leather.

Step-by-step reupholstery

The first stage of reupholstery is removing the lever itself along with the cover. An old case is used to create a new one: it is carefully ripped into pieces and patterns are made from them. The new cover is sewn either by hand or using a sewing machine only from the wrong side. In the case of handmade work, the parts are pierced with an awl in advance to facilitate the sewing process, because the needle may not pierce the skin. The finished case is attached to the frame using superglue.

Preparation for use

Now the handle needs to be attached to the lever. To do this, use a drill to drill a hole in its lower part. Drilling is difficult due to the strength of the hardened mixture. To make this work easier, you can insert a bolt into the mold with resin during the hardening stage. When drilling, the handle and drill heat up, which can lead to the appearance of new cracks, so at this stage you need to be careful so that all the work done is not in vain.

The drilling process is accompanied by the appearance of entire layers of dust on the work table and a dust cloud in the air, as well as an unpleasant odor, so it is advisable to do all this in a respirator. Also, be sure to wear gloves; there may be small shards of glass left on the handle, and the drill does not always obey and may slip. You need to start drilling with the smallest drill you can find, and then gradually increase the diameter to the desired size. A suitable hole would be such that the handle can be pressed onto the stem with force. Then it will not dangle and fall off.

Leather-covered protective cover and lever knob

A fairly popular type of improvement of the gear shift knob is replacing the protective cover and knob with a leather one. What will it take? Leather or high-quality leatherette, thread, scissors, needle, awl and preferably a thimble.

First of all, remove the cover and handle. As a rule, the handle is unscrewed or removed with a slight upward force. The protective cover itself is secured with four latches.

First you need to make a pattern. To do this, you can use your old case. Considering the hardness of the leather, you can pierce holes for the seams with an awl or use a large needle. Also, in order for everything to turn out beautifully, when stitching, you need to make sure that the stitches are even. The fastening plastic at the bottom of the case can simply be glued. After this, the protective cover is installed back and secured using the same 4 latches.

Next, move on to the handle trim. Before cutting out leather blanks for stitching, it is advisable to make patterns. To do this, you can wrap the handle with something, for example, regular film, and then cover it with adhesive tape. Next, make markings with a regular felt-tip pen and cut into 2 parts. This will give you the shape for the pattern. Next, transfer the entire paper, tracing the shape along the contour, cut it out, and only after that transfer everything to the skin. After cutting out the leather workpiece, use an awl to make holes for the stitches and sew them on the handle.

Grinding

The handle is sanded to obtain a more transparent surface. You can grind it on a machine, drill or sandpaper. You can grind on a machine manually, or you can attach the handle to a drill. The better the polishing is done, the better and more transparent the result. After polishing, put the handle on the lever and try to ride with it.

Making the perfect gear knob from epoxy resin the first time is not easy, but the first results will please you. Using epoxy resin, you can turn any idea into reality, even inserting an LED. But it’s especially nice that this gear knob is made by hand.

WHERE CAN YOU BUY A CAR TRANSMISSION KNOB CHEAP?

VODOOL gear knob (8.5 cm, 6 colors)

Tuning the gear shift knob

Customer reviews:

Review #1: Excellent quality for reasonable money! I recommend it to everyone! Fits Toyota Noah/Voxy 2010 perfectly! Much more convenient than the traditional one. Practical. Doesn't get dirty like traditional ones. Satisfied.

Review #2: The order arrived quickly. I recommend. Auto Kia Cerato mechanics. The quality is good, but the universal adapters did not fit.

Review No. 3: Ordered 07/20, received training on 08/24 in Moscow Region. Long delivery for me, I was really looking forward to it. I changed it without any problems, the adapter fits the Lanser X, the only thing is that there is a gap between the tip and the leather pad

Thin, ATTENTION!!! I'm fine with it, I'm very comfortable with thin

Universal gear lever La MaxZa

Customer reviews:

Review No. 1: The handle is not bad, but a little thin, it looks bigger in the picture. Overall, it's ok for the money.

Review #2: Arrived quickly. The kit included only 2 adapter bushings, but the one needed was there. I installed it, nothing fell apart - the seams are even, we'll see how quickly it wipes out.

Review No. 3: I installed it, of course it fits well in my hand, so far I like it. I was very pleased with the price and fast delivery. I recommend taking it.

Gearbox shift knob in Auzan car

Customer reviews:

Review No. 1: Thanks to the seller, the order arrived very quickly, in fact, in a week to the Vologda region. Good quality. The set contains three adapters. With one of them I approached the Hyundai matrix. The item itself is convenient. I recommend.

Review No. 2: After three months of use, there are no complaints, the paint has not worn off, it’s convenient. So take it without hesitation.

Review No. 3: Excellent quality, fits on the Subaru Forester SH without any problems, just like a native one! The post office tried to deliver and not spoil the order. Special respect to her.

IZTOSS gear knob with backlight (for BMW Toyota VW Honda)

Customer reviews:

Review #1: Everything arrived intact. Adapters and keys included, eyes glow. I didn't order for myself. It was not installed on the car. It arrived in a month.

Review #2: Very beautiful! I took it as a gift, so I won’t try it. THANK YOU! I’ll also order one for myself.. By the way, the subgrid is LED. Effective in the dark.

Review No. 3: Ordered 06/18/18, received 07/17/18 (Volgograd). The seller sent the order 4 days after payment. The track was fully tracked. The envelope was without bubble wrap, so the contents were somewhat wrinkled. There is a button on the cobra's neck that switches 3 modes of eye blinking - fast, slow, static. The material itself is plastic. We recommend reading more about the WebMoney online casino at https://games-two.su/igrovye-avtomaty/vebmani-kazino/ Wallets for withdrawal of WM Casino.

Stylish POSSBAY gear lever (for BMW Audi Mazda Ford)

Customer reviews:

Review #1: The pen arrived quickly. Thanks to the seller, I bought a Hyundai Sonata-5 Tagaz, 2008, I have not changed the handle yet. I'll change it soon. Looks like good quality.

Review No. 2: Not a bad gear knob, everything is trimmed and done as it should. The installation is not complicated, but I’ll explain just in case. First you need to unscrew the bottom ring, there will be holes on the sides for small things on the thread, they should be in a small separate bag, when you put the handle on, screw these things into the holes all the way, it’s better to have a 10 star screwdriver bit with you and screw it in carefully, like that's all.

Review No. 3: I installed it on a Mercedes w211 after some minor modifications. Looks ok. I took it under a tree. Screws onto the thread. Approximately 10. Corresponds to the description.