Solution methods

Once the main reasons why the VAZ 2109 engine fails are identified, you can proceed directly to methods of diagnosing and troubleshooting problems.

It is worth recalling that for a complete diagnosis you will need certain tools, as well as design knowledge of the power unit. So, what tools will you need: a set of keys, heads and screwdrivers, a hammer, WD-40, a multimeter, as well as new spare parts that have become unusable. Now that everything is at hand, you can proceed directly to the repair process.

Poor quality fuel

The engine often jerks and tripping occurs because low-quality fuel enters the combustion chambers. This is typical for the CIS countries, especially Russia and Ukraine, since most gas stations dilute gasoline or sell it of low quality.

So, low-quality fuel, in addition to clogging the fuel lines, also, when it gets into the combustion chambers, does not form a normal air-fuel mixture, and therefore the car begins to twitch and jerk, in the worst case, black smoke and shots will come from the exhaust pipe. This means that the gasoline is not the best and should be replaced.

To eliminate the malfunction at this stage, you will have to clean the fuel supply elements, such as the fuel tank, gas lines, injectors and the fuel filter element (which is most likely clogged).

Fuel pump and gasoline filter element

Even if the fuel that enters the engine and its systems is of fairly good quality, you do not need to be sure that the fuel supply elements will not fail. The second reason why a car starts to run poorly is a malfunction of the fuel pump.

To be more precise, interruptions in the operation of such an important element lead to an uneven supply of fuel to the engine

Let's sum it up

Fine cars with carburetor engines have become industrial history, but they are still widely represented on the roads. That is why you can use the ideas presented in this publication, since there are still a lot of carburetor masters, and you can find the necessary spare parts in stores. If your car has problems with the quality of the fuel supply system, it’s time to fix all these problems. You can quite easily obtain high quality operation of the power unit and fuel system if you simply take care of all the important components of the car.

For the carburetor to work properly, it simply needs to be cleaned occasionally. This point is quite important for every car operating in Russia. Fuel quality, atmospheric pollution - all this affects the normal operation of the engine. It is enough to carry out a high-quality cleaning of the fuel supply system every few years by performing certain maintenance processes to ensure long-term and high-quality operation of all engine systems. How did you maintain a carburetor car?

A hot engine stalls while driving or idling

Let's start with the fact that the symptoms and signs of this problem can manifest themselves in different ways. Quite often, the power unit may stall in idle mode, and unstable operation and complete stop of the internal combustion engine often occurs after the engine has warmed up.

First of all, diagnostics should begin with checking the spark plugs and their condition. At the same time, high-voltage armored wires should also be checked. This must be done because there may be weak sparking or no spark at all on the spark plug electrodes. Interruptions in the spark lead to serious malfunctions in the operation of the engine, as a result of which both the cold unit and the engine stalls after warming up. Replacing spark plugs and high-voltage wires often helps solve the problem.

Another common situation is when the engine stalls hot or cold immediately after starting it. In this case, on many modern cars with an injection power system, you should check the idle speed sensor. The failure of this element of the electronic engine control system often leads to the fact that the engine is simply unable to operate at idle speed.

In some cases, cleaning the XX regulator helps, in others the device should be replaced. On cars with a carburetor, the idle jets may become clogged and other carburetor malfunctions may occur. Injection engines also require additional checking of the synchronization sensor (DSPS), and possible problems with the fuel pump should not be ruled out. One way or another, if the engine stalls when hot or this constantly happens with a cold unit, then in-depth diagnostics will be required.

On carburetor cars with a mechanical ignition distributor, a situation arises when the slider stops performing its functions. Quite often, after the engine has warmed up, the central wire on the ignition coil may come off, problems with the ignition unit capacitor, etc. may occur. A known problem with cars with a mechanical fuel pump is that the engine stalls in hot weather. This occurs due to overheating, since the high temperature outside and significant heating of the engine compartment do not allow the pump to cool properly.

At the same time, attention should be paid to the condition of the fuel filters. If the filter element becomes clogged, then as the load increases and the speed increases, the required amount of fuel does not flow into the engine through the dirty filter and the engine stalls.

We add that usually before a significant decrease in the filter capacity and a complete stop of the motor, the malfunction progresses. At first, the car may not pick up speed, starts poorly, dips appear when you press the gas pedal, the engine is unstable or jerks when you press the accelerator, in transition modes, etc.

Modern cars with an injector have an electronic control unit (ECU). This unit is quite rare, but still fails. In this case, the engine may stall while driving, and the problem itself manifests itself in various situations, including after the internal combustion engine has warmed up. In this case, as well as if it is necessary to check individual ECM sensors, it is necessary to carry out computer diagnostics of the vehicle. The system will display existing errors in the form of codes, after decoding which it is possible to localize the fault. If the problem is “floating”, that is, it occurs periodically, then it is recommended to purchase a compact device that allows you to read information about engine operation via the OBD connector. Thanks to the subsequent display of data on the screen of a smartphone, tablet or laptop with a pre-installed program, this solution will allow you to record failures in real time.

Troubleshooting options

It is clear that if any emergency situations arise with the motor, it is advisable to contact a specialized service. However, this procedure is not always possible. Therefore, it is worth knowing how to independently diagnose the main systems and key parts.

Throttle valve and assembly

When the speed drops at idle and the car stalls, you need to pay close attention to the details of the throttle assembly. Long-term operation of the car on low-quality fuel, untimely maintenance of the air filter can lead to malfunctions of the throttle valve

It periodically jams if debris gets into the equipment.

Throttle valve VAZ 2112

The problem can be solved by cleaning the system. The throttle is cleaned using carburetor cleaners. Using a compressor, you need to blow out the damper under the pressure of compressed air. It is not recommended to touch the screws located inside and on the side. If cleaning does not correct the situation, the device must be replaced. This operation is not particularly difficult.

Crankcase malfunction

There is an oil trap in the crankcase ventilation system of the engine. Its contamination can also lead to interruptions in engine operation. Crankcase gases do not allow the engine to function normally, the speed fluctuates, the internal combustion engine stalls.

Sensors

If a gasoline car stalls at idle, then one of the sensors is likely to break. In injection cars with an electronic engine control system, the engine usually starts normally, but then it stops working. It's worth checking here:

- Electronic car indicators;

- DRХХ – device that regulates idle speed;

- Air flow meter (air intake in the carburetor);

- Sensor indicating the position of the throttle curtain.

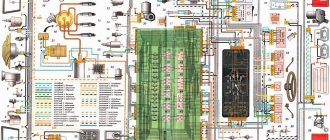

Electronic control unit in VAZ 2114

Interruptions in the operation of any sensors immediately affect the behavior of the electronics - errors appear in the car control unit. The “brains” of the machine receive unreliable information. It is not transmitted correctly to the engine. It starts working with parameters that do not correspond to reality. Self-testing of this device is not possible. You need to contact a professional for service.

Diagnostics of mass air flow sensor

The idle air control device is usually to blame for engine malfunction when the car idles poorly. But you pressed the gas pedal and the engine started. In the latest VAZ modifications, error information appears on the instrument panel.

When diagnosing, you must use a multimeter. If a part is faulty, it is recommended to replace it with a new one. All sensors are reasonably priced. It is better to start checking with parts that have a simpler design. Then gradually move on to complex devices. We must not forget that the problem may lie not only in the sensors themselves. It is also necessary to check the wiring to them and the presence of stable contact.

Carburetor

If the VAZ carburetor stalls at idle speed, then the jets may become clogged. Low-quality gasoline, deposits from the gas tank, contain small particles of debris. They can easily disrupt the operation of the fuel injection system. It is worth replacing the filter in front of the carburetor and cleaning the device itself. The dispensing part is cleaned using a cleaning solvent, which is sold in aerosol cans. Another reason is often a prolonged lack of carburetor adjustment.

In a mechanical fuel pump of carburetor cars, the filter mesh may be clogged with dirt. This reduces the performance of the device. Wear of the membrane and its destruction often leads to clogged carburetor channels.

Injector

A situation that often arises is that various Lada models, as well as the VAZ 2110 injector stalls at idle. It is necessary to check the fuel pump strainer for clogging. This is a common problem with injection machines. It is better to immediately replace the part with a working one.

Filter problem

If the VAZ 2112 stalls at idle, then the fuel filter may be dirty. This also applies to other models of the concern. Generally, it is not practical to clean it. The part must be replaced. The same should be done with a dirty air filter. Low throughput leads to the fact that the air-fuel mixture simply floods the spark plugs.

Self-checking will not always lead to a positive result. It is often more practical to identify the cause of unstable operation of the internal combustion engine at a car service center. It will cost more, but specialized diagnostics will prevent more serious damage to the car.

Causes of the problem

When a car jerks, it is accompanied by some associated problems. Particularly characteristic of this malfunction is the tripping of the power unit, as well as loss of traction. This problem is identical for the entire family of cars, but is most typical for its younger brother - VAZ 21099.

So, let’s look at the main reasons why the VAZ 2109 injector misfires, the engine does not pull and jerks:

- Poor quality fuel.

- Fuel pump and gasoline filter element.

- Injectors.

- Spark plugs and high-voltage wires.

- Burnout of valves.

- Air filter and throttle.

- Sensors and ECU.

How to help the engine work

Sometimes the VAZ 21099 carburetor does not start well. To help a cold engine work, you need to perform the following steps.

- Press the handle of the fuel pump to pump gasoline into the carburetor float chamber.

- Place the gearshift lever in neutral position.

- Pull the choke toward you, closing the throttle valve, and with the ignition on, try to crank the starter. If unsuccessful, repeat the action after some time.

- If the car starts, let it idle, release the throttle and take your foot off the clutch pedal.

- In the cold season, try to turn the crankshaft several times, turn the headlights on and off, pull out the choke handle, squeeze the clutch and turn the starter. In winter, to keep warm and improve engine performance, it is recommended to wrap the radiator grille. When the engine starts, the pressure control and battery charging lights on the operating panel should go out.

The driver starts the car

When the car is warmed up, its engine should start running immediately. Other situations arise when the machine does not. Starting a hot engine should take place with the throttle valve open and the gas pedal depressed to one third of its full travel. As soon as the engine starts, you need to release the accelerator pedal. If the start is unsuccessful, repeating the described steps may lead to difficulty starting the engine and flooding the spark plugs with gasoline. If this does happen, the turned out candles must be dried with air.

The engine stalls when switching to neutral

The reasons that the engine stalls at idle may be identical to those when the car is moving. But there are also problems inherent only in idling engine operation.

A common problem is a malfunction of the idle speed sensor, which is directly related to the operation of the power unit in this mode. You can check the status of the sensor yourself as follows. If the engine does not start at the moment of starting, you need to pump the gas pedal several times. When the unit has started, you should take your foot off the pedal and check the engine speed. If they are unstable and “float” chaotically, the likelihood that the problem lies in the sensor is very high. This type of malfunction can be solved by washing the sensor with regular WD-40 or installing a new one.

The second reason is a clogged throttle valve, which simply needs to be washed.

Particular attention should be paid to the throttle position sensor. This can also cause the car to stall while driving and then start

Fixing this breakdown is quite simple; you just need to replace the sensor, which you can do yourself.

Determining the quality of the spark

At this stage, you need to understand whether there is voltage on the spark plugs. To do this, just unscrew one spark plug and connect the central electrode to the high-voltage wire. Next, ensure that the threads are in contact with the ground of the car and turn on the ignition. A stable spark of blue (white-blue) color indicates that everything is fine with the ignition.

Check the remaining spark plugs in the same way. Because a common reason for an engine to fail to start is the failure of one of these parts.

After working for a while in this mode, the engine will stall.

Cylinders with non-functioning spark plugs are simply filled with too much gasoline and the situation will repeat itself when the engine is restarted. If there is a spark on all spark plugs, evaluate their color and size. Yellow/red color and small size also indicate that the car will start and subsequently stop working.

At this stage it is enough to replace the failed spark plugs

When purchasing parts, pay attention to the manufacturer’s recommendations regarding clearance and heat rating parameters

Non-carburetor causes of engine failure

Car owners usually refer to failures as unpredictable short-term interruptions in the operation of a car’s internal combustion engine. Failures belong to the category of so-called “unreasonable”, or, more precisely, multi-cause failures. It is impossible to say unequivocally about such breakdowns: failures appear - change the spark plugs. More precisely, it is possible to say, but it is not a fact that after replacement the failures will disappear. Although this also happens.

So failures in the operation of a carburetor engine are not necessarily related to the device itself. And before you start working on such a complex unit, you should exclude the influence of other reasons.

- Mechanical failure of the drive.

- Ignition system malfunctions.

- Failures of the power system located outside the carburetor.

These groups of negative factors stand out among others. Let's look at them in detail.

| Malfunctions | Your actions |

| Mechanical failures of the drive include, first of all, a faulty throttle cable. | It simply needs to be replaced. |

| In the ignition system, spark plugs most often fail. | Excessive carbon must be cleaned, faulty spark plugs must be replaced. |

| High-voltage wires fail a little less often. | It is not recommended to check the spark “to ground”; this is dangerous. You should measure the resistance of the wires using an ohmmeter and make sure that it corresponds to the nominal value. |

| Excessive wear of the carbon contact in the distributor cover. | Rule out this reason. |

| If everything is in order with the ignition system, and the engine still fails when you press the pedal sharply, move on to the power system. | Most often the fuel pump fails. Start with an inspection of this particular unit. |

Remove the outlet pipe from the fitting. Press the fuel pump manual drive lever vigorously. There should be an intense stream of fuel coming out of the hose. If not, the pump is faulty and must be repaired or replaced. Clean the fuel line filters from the tank to the carburetor, and blow out the pipelines themselves.

If everything is in order with the power and ignition systems, move on to the carburetor itself.

Idle speed VAZ 2109 carburetor

Recently I encountered the following problem: Lada cars with a carburetor power system stopped idling. The car starts on choke and runs. Everything is fine, you can drive, but as soon as you remove the choke and take your foot off the gas pedal, the engine stalls. Of course, the car is running, but it is very difficult, especially at traffic lights when driving around the city, when you constantly need to either accelerate or slow down and drive without idling. When the car warms up to operating temperature, it may not stall at idle, but shake terribly at idle, the engine speed being about 500-600 rpm. We urgently need to restore the car's normal idle operation, let's look at how. There are many articles on the Internet explaining the reason why the idle speed does not work on nine. 90% of such articles only consider manipulation of the idle air solenoid valve. Indeed, problems with the valve are very often the cause of idle loss, but there are other reasons. I’m sharing my experience because I myself spent many hours searching for normal material, but I only came across hundreds of articles that dealt with EPHH in one go. So, let's go in order: your VAZ 2109 has lost idle speed, with the gas pedal pressed the car works, as soon as you release it it stalls. The reason for this phenomenon is as follows. The carburetor has a special idle system: an idle fuel passage with a jet, an idle air passage and a solenoid valve. When the car is idling, the combustible mixture enters the engine through the idle passage. The throttle valve is closed, and therefore the vacuum in the engine is huge and it sucks the combustible mixture into the engine through the idle channel. The fuel and air nozzles have special holes of a certain diameter, which are selected for stable engine operation at idle. Why does the idle speed disappear? It's simple: either fuel does not flow through the idle fuel channel, or there is an air leak somewhere in the system and the fuel/air ratio in the combustible mixture is maintained incorrectly. The idle speed solenoid valve (hereinafter referred to as ESV) is responsible for the fuel supply. If the valve is not working, fuel will not flow into the space behind the carburetor throttle plate at idle.

Remove the air filter cover from the carburetor.

Removing the air filter

Removing the air filter cover

Checking the valve is simple: turn on the ignition and remove and put the chip on the valve. Clear clicks should be heard.

Removing and putting on the valve chip

If the valve clicks perfectly, this indicates that the electromagnetic coil inside the valve is working properly, but to check the jet, the valve still needs to be unscrewed with a 13mm wrench.

Unscrew the EPHH

Remove the jet from the valve body and check if it is clogged. We check with our mouth how the air passes through it.

EPHH VAZ 2109

Idle fuel jet

Next, we do the following thing: plug the EPHH hole in the carburetor body with your finger and start the car.

We start a VAZ 2109 without EPHH

We do this so that if there is any debris in front of the fuel nozzle, then we drive it out of the idle channel

We pay attention to the EPHH sealing rubber; if it is cracked, skewed, or does not press tightly against the carburetor, then air will leak through it and the idle speed will accordingly not work. If your EPHH does not click when you bring a chip to it, check if there is voltage on it

If there is no voltage, check the economizer and carburetor end throttle valve. If there is voltage, but the valve does not click and there is nothing to replace it with (for example, you are on the road), do the following: remove the jet from the valve body and break off the plastic needle,

Break off the EPHH locking needle

We put the nozzle in place and that’s it, now there is no need to put the wire on the EPHH. This is fraught with detonation when you turn off a hot engine, but on the road or if you urgently need to repair it, it’s a completely acceptable option. If manipulations with EPHH did not help, we move on. The search circle narrowed - there was an air leak somewhere. It's easy to say, but hard to find, but we have no choice. We check in order: 1. How the carburetor cover is pressed to the carburetor body, the integrity of the paper gasket between them.

The influence of the accelerator pump on the operation of the VAZ-2109 internal combustion engine

Unstable engine operation, stalls, sluggish acceleration, etc. can also occur due to malfunctions in the Solex accelerator pump system. Here are the main causes of problems on the “nine”:

- incorrect dosage of the sprayer (“spout” or “elephant”), as well as clogging of this channel;

- torn or dried out diaphragm;

- incorrectly selected accelerator pump drive (“flag”).

Factory nozzles for the “nine” usually have two “spouts”, which are distributed among the chambers, but in the “secondary” fuel injection turns out to be completely unnecessary, at least that’s what many craftsmen think. The modernization of this part is the transfer of both “spouts” to the “primary chamber” (primary chamber), another option is the installation of a single sprayer from the KU for the Niva.

When bending the tubes, it is important to install them so that the injection passes exactly between the carburetor body and the damper, without hitting these parts, otherwise there will be no effect from such tuning.

The injection is checked, of course, with the carburetor removed, without the top cover, with the float chamber filled with gasoline. When you open the throttle (simulating pressing the gas pedal), you should get two even jets that pass through the lower part of the body without hitting it.

Carburetor power units are actually a thing of the past. But many cars on the roads of our country still use this option for supplying fuel to the engine. For many, a carburetor turns out to be a fairly convenient means of replacing an injector, since the car becomes easier to repair and cheaper to operate. In most cases, the owner of a carburetor car can independently carry out basic maintenance work on the fuel supply system. In the case of an injector, this task should only be performed by specialists. For simple carburetor repairs, you do not need special equipment, but to work with an injector, such devices are simply necessary. Therefore, such a part of the engine power system has certain advantages. Interestingly, these advantages force many to change the injector to a carburetor, which is not difficult at all.

Problems that arise with the carburetor can be very different. One of the common problems is that the engine stops working after the car has completely warmed up. The driver has to increase the speed with the help of a choke, but this trick will not work on carburetors with auto-choke. Eventually, the engine will stall as soon as you release the gas pedal. At every traffic light, intersection and pedestrian crossing, the driver begins to curse fate, red lights and innocent pedestrians, and the carburetor continues to stall and refuses to work normally, despite very expensive gasoline. Let's figure out the nature of this trouble.

Idling VAZ 2109

On cars of the VAZ 2109 family, Solex-type carburetors are used.

| Automobile model | Engine displacement, cm3 | Carburetor model |

| 2109 | 1295 | DAAZ–2108 |

| 21091 | 1100 | DAAZ–21081 |

| 21093 | 1499 | DAAZ–21083 |

There are three most common reasons for the disappearance of idle on a VAZ 2109: clogging of the idle jet of the solenoid valve, burnout of the EMC, lack of power to the EMC.

To adjust the idle speed of the VAZ 2109, you need wrenches for “8”, “10”, “12”, “13”, “14”, a 12 V probe or test lamp with wires, a piece of wire with stripped ends, a compressor or an air pump .

All of the listed carburetors have an electromagnetic valve (EMV) with an idle jet in the idle system. The valve is controlled by the electronic forced idle unit

Remove the air filter housing cover by unscrewing the nut with a “10” wrench and unfastening the spring clips and remove the air filter. Unscrew the four nuts with a key “8”, use a screwdriver to loosen the clamp of the crankcase ventilation hose at the connection point to the valve cover and remove the air filter housing

Turn on the ignition. Remove the power cord from the EMC. Try touching the power wire terminal to the EMC terminal several times

Using a key set to “13” (to “12” or “14” depending on the version), unscrew the EMC from the carburetor cover. Using two fingers, remove the idle fuel jet

Pay attention to the central hole: remove debris from it using a compressor or air pump, and make sure the hole is clear and clear. Reinstall the fuel jet

Place the EMC in place and screw it in by hand until it stops. Connect the power cord and start the engine

Using a key set to “13” (“12” or “14”, depending on the version), unscrew the EMC from the carburetor cover. Using an additional piece of wire, feed the “ ” from the battery to the terminal of the EMC; with its body, touch the “–” terminal of the battery several times.

The EMC burned out. Replace with a working one after checking it first. To get to the nearest auto shop, you can convert a faulty EMC into a forced open one. To do this, remove the idle fuel jet of the VAZ 2109 with two fingers, break off the plastic tip of the valve and put the jet in place. Place the EMC in place and screw it in by hand until it stops. Connect the power cord and start the engine. Keep in mind that using such a valve may cause problems with engine shutdown: it will try to run after the ignition is turned off. In such a situation, try not to turn off the engine immediately, but let it idle for at least 5 minutes, and after turning off the ignition, smoothly press the gas pedal all the way

Place the EHR in place. Turn on the ignition and check with a tester or test lamp for the presence of “+” at the terminal of the EMC power wire. If there is no power, the electronic control unit for forced idling of the VAZ 2109 has failed

The electronic forced idle control unit cannot be repaired. Replacing it is not difficult, but in order to get to the nearest auto shop, you can temporarily, using an additional wire, supply power to the EMC at least from terminal “B” of the ignition coil. As an option, you can first bend the rubber cover from the connector of the wire bundle of the forced idle block and connect the wires at terminals “4” and “6” with a jumper. The numbering order of the terminals is indicated on the cover of the electronic unit to the right and left of the connector - numbers “1” and “7”

A frequent malfunction of the VAZ 2109 engine associated with the forced idle block is a significant decrease in rotation speed (up to a complete stop) when the clutch is depressed, for example, when changing gears or stopping at a traffic light. In this case, in order to safely get to a car shop or service center, it is enough to disconnect the connector of the control circuit of the forced idle unit, located near the mixture amount adjusting screw.

remocars.ru

Troubleshooting

In order to fix this problem, you need to determine the culprit. Once you have located the location where the problem occurred, you can begin preparing for the repair work. First of all, check whether the carburetor is set correctly. To do this, tighten the quality screw and the quantity screw until it stops, and then unscrew it as indicated in the factory settings of the carburetor (often, the carburetor settings are as follows: quality screw - 2.5 turns, quantity screw - 4 turns). If there are no changes, and the engine still does not idle, or even stalls, then you need to look for the reason, choosing from the above. To determine the cause, the carburetor of the VAZ 2109 will need to be disassembled. By removing its upper part, the float chamber will open in front of you. Check the gasoline level in it. It should be approximately 25 mm. If everything is in order with the level, then we will move directly to the jets.

The idle jet located in the float chamber must be removed and checked for debris or debris. If debris is found in the nozzle hole, it must be blown out and washed with gasoline. If there is no debris in the hole, then we continue to look for the cause further.

We have examined the carburetor, now we can move on to the fine filter. Look at the condition of the gasoline in the filter sump. If there is no sediment at the bottom, the filter is still in good condition. If there are at least some particles at the bottom, it needs to be urgently replaced.

Old and new filter

After you have cleaned the carburetor and changed the fine filter, start the VAZ 2109 and check its operation at idle. If the speed still fluctuates or the engine stalls, the idle speed sensor may be the cause.

You can check the sensor in the following way: disconnect the wires from it and check it with a voltmeter. We put the negative wire to ground, and the positive wire to the block connector. Turn on the ignition and monitor the instrument readings. The sensor should produce a voltage of 12 volts. If there is no such current, then the sensor is most likely faulty.

If, after the procedure, it turns out that the sensor is in normal condition, but there are still no changes (the speed floats and the engine stalls), then the last option remains - the solenoid valve. It is quite difficult to check it, therefore, it is easier to install a new one.

Now, your VAZ 2109 car should work stably, both at idle and while driving. If the engine still stalls, although the speed no longer fluctuates, then the reason is much more serious, and most likely, special diagnostics and specialist intervention will be required.

Sometimes such a nuisance happens on the way, the driver finds himself in a situation where the engine of a VAZ 2109 stalls in the middle of the road and it is impossible to start the car further. The most interesting thing in such a situation is that there were no traces of any signs warning (foreshadowing) these problems, the car drove as usual, there was no “sneezing” or “shooting in the muffler.” Since the problem is common, our instructions will tell you what to do in a situation such as a sudden stop of the engine and poor starting. We will consider in detail all the main reasons that cause the engine to stop at idle and while driving. And also the reasons why it does not start when warm and how to solve this kind of problem.

Lost idle speed VAZ 2109 1987+

Cars of the VAZ-21099 family use Solex-type carburetors from the Dimitrovgrad Automotive Unit Plant.

| Automobile model | Engine displacement, cm3 | Carburetor model |

| 2108 | 1295 | DAAZ–2108 |

| 21081 | 1100 | DAAZ–21081 |

| 21083 | 1499 | DAAZ–21083 |

There are three most common causes of idle speed disappearance:

— clogging of the EMC idle jet; — EMC burnout; — lack of power supply to the EMC.

For work you need: wrenches “8”, “10”, “12”, “13”, “14”, a 12 V probe or test lamp with wires, a piece of wire with stripped ends, a compressor or air pump.

| All of the listed carburetors have an electromagnetic valve (EMV) with an idle jet in the idle system. The valve is controlled by the electronic forced idle unit. |

| EXECUTION ORDER mashintop.ru |

The car stalls at idle: reasons

Drivers often encounter problems with idle speed. It happens that the driver begins to warm up the engine before driving and notices that at first the idle speed fluctuates, and then the car completely stalls. Why does the engine stall at idle? For a carburetor, these are some reasons, but for an injector, due to design differences, these can be completely different reasons.

If the carburetor stalls at idle

There are only 3 possible reasons:

1. There is no power to the solenoid valve - check the power.

2. The magnetic valve has become unusable, its winding has burned out - replace the valve with a new one.

3. The idle jet is clogged - clean it.

Carburetor solenoid valve

After eliminating the cause, adjust the idle speed. On a carburetor engine, the driver will be able to do this on his own - nothing complicated. If the idle speed of a carburetor engine fluctuates, then you need to look at the reasons, and then also proceed to adjustment.

If the injector stalls at idle

With injection engines the situation is more complicated, since the fuel supply and the quality of the combustible mixture in them are regulated electronically. Unlike a carburetor, adjusting the idle speed by rotating the quality screw on the injector is a pointless and even dangerous task, as it can only harm the car. But an injector is not electronics in its pure form, but a complex of mechanical and electronic systems, therefore, if an injection engine stalls at idle, then the whole issue can be in both electronics and mechanics. The driver can find and eliminate the mechanical cause himself.

If the injector does not hold idle speed due to failure of the electronics - for example, one of the sensors or a malfunction of the on-board computer, then only car service specialists can solve this problem.

Idle speed can float if an unequal amount of air enters the system each time, sometimes there is a lot of it, sometimes not enough. If there is a lot, it means that air is leaking from outside. The task is to determine the place through which air is leaking into the system.

The engine may idle unstably and stall if:

1. The mass air flow sensor (MAF) is faulty. How to check the mass air flow sensor

2. Rubber air supply tubes are damaged. To find a damaged tube, you need to turn on the engine and begin, in turn, to pinch all the tubes, observing the operation of the engine. If the nature of the engine operation changes while pressing on one of the tubes, then this tube should be disconnected, hold the air inlet hole on it with your finger and find the place of damage through which air is leaking. If the tube turns out to be intact, then you need to check all the other tubes.

This is interesting: At what distance do radars record the speed of a car?

3. There is a malfunction in the starter blocks (how to check the ignition module), or the valves are not adjusted (how to adjust the valves). If all air supply tubes are intact, then you need to check the air vent - close its hole. If the idle speed returns to normal, then the valve may be dirty and sticking due to this. If the problem is in the valve, then you can try injecting a special cleaning fluid into the air vent hole (do not start the engine), after 15 minutes make another injection, and after another 15 minutes start the car.

If the problem with idle speed remains, then perhaps the valve is no longer working, and all that remains is to change it.

This simplest manipulation of cleaning the air vent, in fact, exhausts the driver’s ability to independently repair his car with an injection engine. Electronics require competent diagnostics and full adjustment, and if the car stalls at idle, then let the specialists at the service station sort it out. If the car starts and immediately stalls

Step-by-step instruction

By following a certain sequence in your actions, you will eventually be able to determine on your own why the engine does not start or problems arise with it.

| Repair stage | Your actions |

| Turn the ignition key, check the starter | If the key turns and the starter turns, then this is definitely not the reason. Even if the engine doesn't start. A failure of the starter indicates the need to replace it. |

| Check the fuel level in the tank | You should not rely only on the sensor readings. He sometimes cheats. More than once it happened that a car owner went through almost the entire car, rebuilt the carburetor, and in the end it turned out that the fuel had simply run out. It may be funny, but it’s still worth checking for yourself that there is fuel in the gas tank. |

| Make sure there is spark | Remove any of the spark plugs, connect to the high voltage wire and touch ground (engine). You will need a partner to sit behind the wheel and turn the starter. If a spark appears at the tip, everything is fine. Is she not there? Blame the switching unit and replace the switch with a new one. |

| Check for spark on the center wire from the coil | A test method similar to the spark plug is used. If no spark is detected, most likely the coil has failed. Replace element |

| If it's freezing outside, there may be water in the gasoline, which eventually turns into ice. To check this, open the air valve and press the fuel pump button several times. The sound of gurgling sounds indicates that gasoline is flowing to the carburetor. The absence of rolls will not allow starting the carburetor when cold, since the fuel is partially frozen. You'll have to change the fuel pump here. | |

| Fine filter | Look at the condition of the filter. If cracks, damage and other visible defects appear on it, the element will have to be replaced |

| Gasoline supply hoses | Make sure that the hoses supplying gasoline from the pump to the engine are intact. In case of defects, damage, cracks, they must be replaced with new ones. |

| Spark plug | We've already checked the spark. Now unscrew all the spark plugs and inspect them for traces of carbon deposits. If the spark plugs turn out to be black from soot or filled with gasoline, there is no point in cleaning the units with ordinary sandpaper. You will not achieve the desired effect. The only recovery solution is to heat them on a gas stove. If you don't want to try this method, just install a new set of quality spark plugs |

| Distributor high voltage wires | Remove them and check for integrity and absence of damage. If there are any, buy a new set and install it on the car |

| Distributor cover | The presence of chips and scorched contacts inside it indicates wear and loss of functionality. There is only one way out - change devices. It is worth changing the slider at the same time as the lid. |

| Hall Sensor | Quite often the carburetor does not start precisely because of a faulty Hall sensor. It is held on the distributor with two bolts. Unscrew the fasteners, disconnect the wires and replace the old sensor with a new one. Put everything back together, check the carburetor's functionality |

| Location of distributor high voltages | It is not uncommon for inattentive craftsmen or inexperienced craftsmen who repair their car themselves to make mistakes when reassembling the distributor. High voltage wires must have a specific connection. The wire marked on the cover with the number 1 comes from the leftmost (first) cylinder, then clockwise goes cylinder 2, then 4, and only then 3. If you mix up the location, the car will start to shake wildly or you will not be able to start the carburetor at all |

| You can find the timing belt on the left under the casing. Remove it and evaluate the condition of the belt teeth. If they are partially loose or fall off, it is better to replace the belt with a new one. It is also possible that the valves on the 1.3-liter engine were bent. It is strongly not recommended to resolve this issue on your own. |

If a step-by-step check of each component of the VAZ 2109 car did not allow you to find the answer to why the carburetor cannot start properly, you will have to go to a service station.

Practice shows that a detailed inspection of the machine’s components and replacement of worn-out, damaged elements immediately returns the carburetor to its previous functionality; it starts without problems both cold and hot.

Good day.

So, introductory: a VAZ 2109 car, it’s already 15 years old, carburetor, electronic ignition. At first it started badly, then it didn’t start at all. The owner is a girl and knows a lot about cars, which is rare. All this happens in the field, the car is on the side of the road, I am pulled out of the wedding after a couple of glasses of wine. We arrived, tried to start it, and suddenly after parking for several hours everything went away. Don't start. The starter turns vigorously - that's good! The car doesn’t grip at all, doesn’t even try to start: either the gas isn’t pumping, or there’s no spark, maybe the alternator belt has jumped (if there had been a break, it would have stalled once and that’s it, but we gradually got worse). Next, open the hood... The engine is old, everything under the hood is covered in oil, but oh well. Inspection of all those fluids - everything is fine. I pulled all the caps of the high-voltage wires - no miracle happened. We look at the fuel supply - the filter is visually normal, the fuel pump is pumping - the problem is not here. We check the spark plugs, I unscrewed them from one cylinder - the spark plug was clean (they turned out to be four-electrode ones - apparently they got it in the store...). I put a cap on the spark plug and leaned it against the engine - we turned it with the starter - there was a spark and it was stable, the output here was also fine. I have no particular desire to look at the timing belt... I open the lid of the “pan” (air filter housing): the air filter is covered in oil, the carburetor is also pretty clogged. It wouldn't start with the pot open. We remove the hose after the gas pump and pump a little gasoline into a small container (I cut off the bottom of a 0.5 bottle). We spray a couple of grams into the first chamber (the one closer to the cabin - there is a damper), try to start it - it catches a little! I add a little more and add a little to the bottom of the pan. Let's try it - it started! The diagnosis is that the jets are clogged and the entire carburetor needs to be cleaned. The girl is happy. I revved it up a bit and turned it off. Then it started up a couple more times. He gave the girl a TsU and sent her home (from Serpukhov to Moscow). He also ordered (yes, this is how I command people) to change the engine oil (it was too black), the air filter and clean the carburetor.

I’ll summarize where to look: — inspect all the liquids (takes 2-3 minutes, but it’s calmer later). — battery condition. — starter. — serviceability of the fuel pump and fuel filter. - condition of spark plugs and spark. — timing belt marks. — carburetor (as in this case). — ignition sensor.

The girl wrote back: she drove normally to the Moscow Ring Road, and there, in a traffic jam, she had to periodically spray gasoline into the carb. As a result, she was dragged the rest of the way on a tie. The girl is very good with cars, better than some of the guys I know...

That's all. I didn’t take a photo - there was no time, and it was already twilight.

Why does the VAZ 2109 injector not start? Let's find out together. We will look at the most common cases that owners of nines with injection engines have encountered, and tell us how they got out of them.

The engine stalls periodically

This phenomenon may be due to problems with the ignition system. When driving, chaotic interruptions with sparking on the spark plugs are possible, both on a specific one and on all of them at the same time. The lack of a spark will most likely lead to the unit stopping.

If a car stalls while driving and then starts (including the 2112 VAZ), the most common reasons include the following: malfunction and moisture in the ignition coil, damage to the crankshaft position sensor and ignition module, failure of safety elements of control systems sensors

In this case, you should pay attention to the condition of electrical wires and their connections, which may contribute to power outages

It is very rare for a car to stall while driving and then start again due to a faulty vehicle speed sensor.

Optional equipment

As a rule, the stable engine speed of most cars is affected by turning on the air conditioning compressor. Very often this happens at low and idle speeds. Since the air conditioner consumes a considerable amount of energy, the control unit sends a signal to the power system to increase the volume of fuel mixture supplied to increase idle speed to compensate for the loss of power consumed by the air conditioner.

But when the impulse to turn on the air conditioner does not arrive at the electronic unit due to a communication failure between the computer and the device module, the control unit is not able to assess the situation and add fuel. As a result, the stability of idle speed is disrupted until the moment when the engine completely stalls.

Causes of the problem

When a car jerks, it is accompanied by some associated problems. Particularly characteristic of this malfunction is the tripping of the power unit, as well as loss of traction. This problem is identical for the entire family of cars, but is most typical for its younger brother - VAZ 21099.

So, let’s look at the main reasons why the VAZ 2109 injector misfires, the engine does not pull and jerks:

- Poor quality fuel.

- Fuel pump and gasoline filter element.

- Injectors.

- Spark plugs and high-voltage wires.

- Burnout of valves.

- Air filter and throttle.

- Sensors and ECU.

Option

The VAZ 2109 injector started only after you directed hot air from the hair dryer into the air duct. We rode fine all day. The car sat overnight and the problem came again. Everything turns, but it doesn’t catch, there is a spark, and there is a strange exhaust.

You checked the fuel pump - it buzzes and floods the spark plugs. We are sure that the ignition module is ok because we recently installed a new one. What to do?

Check the timing belt. Most likely he slipped by a tooth.

If not, check the labels. If everything matches, give it a few turns to make sure the marks always line up.

Also check the belt tension. It could have become loose or the belt might have stretched.

Idle speed for VAZ 2109

One of the reasons that the VAZ-2109 starts and stalls is problems with idling. The VAZ-2109 is equipped with Solex carburetors. It is almost impossible to distinguish carburetor components by appearance; there are differences in internal parts. The idle system in carburetor units regulates the minimum engine speed and is responsible for fuel consumption.

"Solex" consists of the following elements:

- Air jet.

- Channels through which air and fuel are supplied.

- Solenoid valve with fuel jet.

- Speed screw.

- A needle that sets the quality of the fuel-air mixture.

The speed screw adjusts the throttle position. It should always be slightly open so that the fuel mixture flows through the carburetor into the engine at low speeds. The mixture is directed in portions, which occurs thanks to jets. The enrichment and unification of the mixture is ensured by the adjusting needle. The solenoid valve with the fuel nozzle is responsible for the fuel supply.

How does this relate to idle speed? Failure of the solenoid valve or clogged channels leads to the fact that the required doses of air are no longer delivered to the intake manifold.

In this regard, the engine loses the ability to fully perform its functions and breakdowns occur:

- The VAZ-2109 carburetor starts and immediately stalls due to the lack of idle speed.

- The presence of idle speed in this case does not guarantee the possibility of movement, since engine operation is unstable.

- The car loses momentum.

Actions in case of loss of idle speed

The solenoid valve should be checked first. To do this you need:

- Turn on the engine and increase the speed with the speed screw (this is done to prevent the car from stalling).

- Then, without stopping the engine, remove the solenoid valve wire.

- If there are no changes in engine operation, make sure there is power to the valve. This is done by connecting the wire to the solenoid valve. The tension will make itself felt through a small click.

The absence of voltage indicates that the economizer control unit has stopped working or there is a break in the wiring. It is likely that the idle speed disappeared for this reason.

If there are no problems with the power supply, the operation of the solenoid valve is checked directly:

- The fuel jet is removed.

- The solenoid valve housing is installed on the ground terminal of the power source and the positive is connected to the contact.

The valve works if its needle works, that is, “sinks”.

Idle speed may not appear in this case either. Then you should clean the valve jet and blow out the idle passages.

Step-by-step instruction:

- The solenoid valve and air filter housing are removed and the engine is turned on.

- The throttle must be operated by hand. At the same time, the idle channel is clamped with this finger.

- You need to apply gas several times with the throttle valve and release your hands so that the engine runs without a valve.

- Turn off the engine, install all parts in place and check for idle speed.

If a trickle of gasoline is leaking from the nozzle, visible to the naked eye, this means that there is a problem with the carburetor. This moment is noticeable when the engine is running at low speeds.

Repairing the idle speed sensor

This method of detecting faults in the VAZ 21099, such as computer diagnostics, is not suitable. Problems will be indicated by indirect signs:

- engine stops working at idle or when changing gears;

- no increase in speed for faster reaching operating temperature.

The process of replacing the sensor is not complicated; operations must be performed in this sequence.

- Remove the negative terminal from the battery.

- Press the plastic latch and remove the block with contacts from the sensor.

- Unscrew the mounting screws and remove the sensor. Very often a screw gets lost during operation, so care should be taken.

- After installing a new sensor, it is necessary to calibrate it on the VAZ 21099 engine. To do this, you need to turn on the ignition for 5-10 seconds after installing the negative wire.

Computer diagnostics will accurately figure out what's what

An important point to consider when choosing an idle speed sensor is the marking of the part. If the last digit in the number of a failed sensor is a multiple of 2 - 02 or 04, then this is the part that needs to be selected for replacement. If the number is odd, then the newly installed sensor must have the same number.

Among such regulators, the most popular are sensors with index 2112-114830, as well as KZTA RXX 2112-1148300-04. The parts are distinguished not only by their high reliability, but also by their reasonable cost, which does not exceed 400-450 rubles.

Despite the simplicity with which everyone is able to identify a malfunction of the idle speed sensor, replace it themselves and prepare it for work, some difficulties may arise. It is known that an incorrectly functioning vacuum brake booster can significantly affect the functioning of the engine as a whole. This is expressed in the supply of more air than is necessary to prepare the fuel-air mixture. In such a situation, one or two cylinders will not work properly.

VAZ injection engines

In injection engines VAZ-2110, 2112, 2114, 2115, both 8-valve and with a timing belt with 16 valves, it is more difficult to identify the cause of the decrease in power due to the more complex design of the main systems.

Supply system

Any injector consists of a mechanical executive part and an electronic control part, and problems can arise in both of them, which will lead to a drop in power.

Let's look at the mechanical part first. Here, cravings can be influenced by:

- Severely clogged mesh filter on the fuel pump;

- Decrease in fuel pump performance due to wear;

- The fine filter is dirty;

- Malfunction of the fuel rail pressure regulator;

- Clogged injectors;

- Fuel filter dirty;

- Air leak in the manifold.

In general, almost every element of the injector executive part can be the culprit for a decrease in dynamics.

The situation is approximately the same in the electronic component.

The operation of the engine with the injector is controlled by an electronic unit, which constantly monitors the parameters through sensors installed on different systems.

The number of these tracking elements is considerable and the breakdown of any of them leads to the fact that the ECU incorrectly evaluates the indicators on the basis of which it controls the executive part.

Thus, the lambda probe, DPKV, mass air flow sensor, DPZ, phase sensors, detonation sensors and coolant temperature sensors in the event of a breakdown lead to a decrease in power, so you will have to check all of them in search of the cause.

Ignition and exhaust system

As for the ignition system of injection engines VAZ-2110, 2112 and others, the reasons may be:

- Candles;

- High voltage wires;

- Ignition module.

Another possible cause could be a misalignment of the generator drive pulley (with the ring gear).

IMPORTANT TO KNOW: What is an adsorber in a car. Because of this, the DPKV readings are disrupted, as a result the operation of the ignition system is disrupted, which leads to a drop in traction

Because of this, the DPKV readings are disrupted, as a result the operation of the ignition system is disrupted, which leads to a drop in traction.

In injection engines, the exhaust gas removal system more often creates this problem than in a carburetor car, and all due to the use of a catalyst.

The element's honeycombs have a small cross-section, so they become clogged quite quickly, which leads to exhaust gases “crushing” the engine.

Also, if the engine does not pull, check the lambda probe.

Removing the device

If you nevertheless determine that the idle speed sensor is broken, then you will need to replace it with a new one. To dismantle this part, no special skills are required. The above-mentioned VAZ 2109 and 21099 sensor is installed on the throttle body body and attached to it with two bolts, for example, like a fuel pump. In order to remove this device, it is enough to unscrew the two mounting bolts and remove the bundle of wires connected to the device. Before performing this work, it is recommended to disconnect the battery by removing both terminals from it.

The simplest diagnosis of DXX

The easiest way to check the idle speed sensor of the VAZ-2109 is the following method. Need a friend's help. The sensor is disconnected from the connector, then the mounting screws are unscrewed and the device is dismantled. Next, the regulator will be plugged into the connector again, but held in your hands.

At this time, the assistant starts the power unit, and the IAC rod should at this moment retract completely and then extend to a certain distance. If the device behaves this way, then it is operational - the rod is not bent, it is not jammed inside the valve. But there is no guarantee that the device matches the ECU firmware. The rod extends, but the number of steps is unknown. There is a marking on the connector - you can use it to ensure that the ECU sensor matches.

This is the initial stage of diagnosis. Next, check the electrical part, the condition of the valve, and the degree of needle wear.