Because You are not logged in. To come in.

Because The topic is archived.

Maybe someone will think of it))))

Or he can do it. )))) ¶

The triangular lever is a light, rigid and at the same time non-deformable front suspension unit. It is installed instead of a standard part, which consists of a suspension arm and a brace, which are connected by rubber hinges (silent blocks).

The triangular lever on the VAZ can significantly improve handling and reduce the drift of suspension angles.

Installing a triangular lever allows you to change the direction of the load, on the front panel for VAZ 2108-2109-21099 and on the beam for VAZ 2110-2112, from longitudinal to transverse. This provides an additional rigid connection between the front panel and the place where the spar is attached to the body. Wishbones increase the rigidity of the front part of the car body and increase the stability of the suspension geometry of the VAZ 2108 ¶

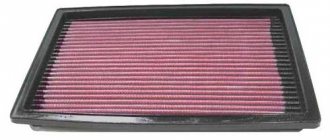

Visual difference between standard levers and wishbones of the VAZ suspension:

Purpose of triangular levers on a VAZ

Stories from our readers

“Fucking basin. "

Hi all! My name is Mikhail, now I’ll tell you a story about how I managed to exchange my two-wheeler for a 2010 Camry. It all started with the fact that I began to be wildly irritated by the breakdowns of the two-wheeler, it seemed like nothing serious was broken, but damn it, there were so many little things that really started to irritate me. This is where the idea arose that it was time to change the car to a foreign car. The choice fell on the melting Camry of the tenth years.

Yes, I had matured morally, but financially I just couldn’t handle it. I’ll say right away that I am against loans and taking a car, especially not a new one, on credit is unreasonable. My salary is 24k a month, so collecting 600-700 thousand is almost impossible for me. I started looking for different ways to make money on the Internet. You can’t imagine how many scams there are, what I haven’t tried: sports betting, network marketing, and even the volcano casino, where I successfully lost about 10 thousand ((The only direction in which it seemed to me that I could make money was currency trading on the stock exchange, they call it Forex. But when I started delving into it, I realized that it was very difficult for me. I continued to dig further and came across binary options. The essence is the same as in Forex, but it’s much easier to understand. I started reading forums, studying trading strategies. I tried it on a demo account, then opened a real account. To be honest, I didn’t manage to start earning money right away, until I understood all the mechanics of options, I lost about 3,000 rubles, but as it turned out, it was a precious experience. Now I earn 5-7 thousand rubles a day. I managed to get the car buy after half a year, but in my opinion this is a good result, and it’s not about the car, my life has changed, I naturally quit my job, I have more free time for myself and my family. You’ll laugh, but I work directly on the phone)) If If you want to change your life like me, then here’s what I advise you to do right now: 1. Register on the site 2. Practice on a Demo account (it’s free). 3. As soon as you get something on the Demo account, top up your REAL ACCOUNT and go to REAL MONEY! I also advise you to download the application to your phone, it’s much more convenient to work from your phone. Download here.

Wishbones on Priora - disassembly

- We drive into a pit or lift the car on a lift. If you have a hole, jack up the front end and start disassembling it. We remove the wheels to provide access to the levers.

Note: To avoid problems during assembly, I recommend taking measurements of the control points (between the levers) and writing them down on paper. This will avoid confusion with setting gaps, castor and camber.

- In order for the fastening nuts to unscrew without problems, we treat the threaded connections with WD-40 penetrating fluid or an equivalent.

- One by one, unscrew the nuts securing the lever (ball, stabilizer link, etc.), marked in the photo.

- Once the lever has been successfully removed, assembly can begin.

Wishbone front suspension VAZ PP

Every day the popularity of tuning Russian cars is growing, especially VAZ cars as the most popular ones on the market. I have long been fond of doing all kinds of “improvement”, so my thoughts came to replacing the standard elements of the front suspension with wishbones to improve the car’s handling, extend the life of the body and increase the rigidity of the structure as a whole, because I love dynamic driving and have a very strong attraction to motorsports, then the strength of the suspension and handling are perhaps the key factors in preparing the car. Thanks to a bunch of pointless purchases and other financial mistakes I have made in my life, I have become much more rational in choosing every part installed on my car. I began to read more forums and reviews from real users of each product, delving into all the technical features and nuances. Today I came across very interesting cases related to triangular levers: Here is a case from Drive2.ru: SPORT triangular levers lightweight FORS AUTO on polyurethane. Further from the author of the recording on the drive: https://www.drive2.ru/l/1077128/

Not even a year has passed and the lever just broke out of the blue. 27,000 km and the whole wheel stupidly turned out to be a replacement wing. the whole reason is that some smart guy during manufacturing thought of loosening the lever pipe in order to insert a mount under the ball joint. It was at this thin place that it tore. and what’s most interesting is that at the site of the explosion it is clear that it was torn a long time ago, some of it was fresh metal, some of it was rusty.

(follow the link for more photos)

Well, I thought that the previous author got bad levers and was simply unlucky. As they say, any cut leads to failure and the key to success in these matters is purchasing products from eminent and trusted manufacturers, such as Avtoprodukt, for example, but after searching a little (5 - 10 minutes)... Autoproduct has also shamefully leaked... The case of Avtoprodukt: From the author of the entry on the drive: https://www.drive2.ru/l/2858033/ I didn’t think that I would have to write part 4 about the suspension, but I think this event should not go unnoticed. So, from the previous 3 parts we know that some changes have taken place in the suspension of my car, and now I’m driving through the city in a dense stream, suddenly I hear the sound of an impact from below, the car suddenly begins to shake, somehow I leveled it out. At first I thought it was the stabilizer eggs that had broken, but it turned out not to be the case. After stopping the car and a quick inspection, it was discovered that the left lever in the place where the castor is adjusted had been torn out. I got home and called a specialist from Autoproduct to explain the situation. A meeting was scheduled for Monday at the KRUMB service in the sports hall. We raised the car on a lift and looked at it, it turned out that the lever was held on by three threads, which of course is not enough for a suspension. This threaded connection was replaced with a new one, castor and camber were reinstalled. Now we are going to test it, now I will take better care of this suspension unit.

The adventures did not end there and then part 5 appeared: https://www.drive2.ru/l/3121139/ Hello everyone, dear friends! We continue to work on the suspension. This time my story will be about the problems of operating the front suspension arms from the Avtoproduct company. Those who follow my BZ know that these levers are on my car. I described one of the problems of operating these levers in part 4, “Tin Suspension Cases,” anyone interested can see what happened. But this happened with the left lever, and now a similar situation almost happened with the right lever, fortunately the already familiar knock on the left lever was heard in time and the lever flying out of the mounting location was avoided. Representatives were informed about this “pleasant surprise”. Then, as usual, a meeting was scheduled for the lift

etc. and this is what we have. After raising the car, we saw that the lock nut of the right lever was freely unscrewed with a slight movement of a finger. Experts proposed a solution to this problem in the form of installing new nuts and additional washers, which it was decided to lock. This is what the lever looks like with new nuts and washers. Then the wheel alignment again. Well, everything is ready, let's summarize. 1. For myself, I definitely decided that this would be my last visit to the service regarding these levers, since I believe that if a company offers any product for a car, then at least it should work, especially since this is a suspension unit and not some other a plastic interior part that does not affect the driving performance and safety of the vehicle and the people in it. 2. The second point is that the nuts that were screwed in place of the old ones are painted with silver, I believe that they are raw, simply machined from metal without any coating. In this case, it would be a good idea for specialists to study the “NATIONAL STANDARD OF THE RUSSIAN FEDERATION GOST R 52643-2006 HIGH-STRENGTH BOLTS AND NUTS AND WASHERS FOR METAL STRUCTURES” or find ready-made nuts and washers that comply with the above GOST. 3. Well, thirdly, I’m just tired of being a testing machine and putting my life in danger because of an unfinished design. That's all! Good luck to everyone on the roads, take care of yourself! ________________________________________________________________________________________

Somehow, after looking at the information, I personally want to drive a stock design, or if I bother, then do it myself and with an unrealistic margin of safety, and somehow I don’t want to trust purchased products from a store with my own, and most importantly, someone else’s life...

Installation of wishbones on Lada Priora

- If the ball is “live”, you can fill it with new grease and install it in place; if not, be sure to replace it.

- We install the new lever in the following sequence: “halve” the lever (separate the two halves of the lever), install the part that acts as a stretcher, then into the beam, after that we assemble the lever, and at the end we insert the lever into the ear of the body.

- The right lever is more difficult to install, since the wheel drive interferes. In addition, installing the lever bolt required the help of a jack, which had to be used to jack up the steering knuckle.

- Many people have great problems installing stabilizer links, there are problems with the bolts, which is why I initially indicated that new longer bolts would be required. Also, often, due to the design of the levers, the bolts in the lever mount are skewed; a slight distortion is allowed, but if it is too large, you will have to think about something (adjust, add washers, etc.).

- Before tightening, all bolts must be lubricated with copper grease, “Litol”, or preferably worked off, this will simplify the disassembly process in the future. After everything is assembled, we check the distances between the control points with a tape measure, as you remember, we first took measurements. If everything matches everywhere, then most likely you won’t even have to do a wheel alignment. We tighten all the bolts and check that nothing is loose anywhere.

Now you can check the operation of the levers in practice. We go out onto the road, preferably where there are fewer cars, and enjoy the work done.

Results: the car responds better to the steering wheel, you can now take turns at a higher speed than before, and overall stability and controllability have improved.

That's all for me, I wish you good luck and see you again.

Triangular suspension arms (purpose, installation, reviews)

| The triangular front suspension arm (in simple terms - triangular arms) is a single, rigid and non-deformable front suspension unit, which is installed instead of the standard structure, consisting of two parts (suspension arm and braces, connected rubber hinges (silent blocks)). What benefits do they provide and is it worth installing them? |

Visual difference between standard wishbones and wishbones on a VAZ suspension:

Purpose of wishbones on a VAZ What are wishbones needed for? They significantly improve vehicle handling and reduce suspension angle drift during operation. The design changes the direction of load on the front panel (beam for VAZ 2110-12) from longitudinal to transverse. By providing an additional rigid connection between the front panel (beam) and the place where the spar is attached to the body, the levers help increase the rigidity of the front part of the body and increase the stability of the suspension geometry.

In simpler terms: imagine that the front arch is a bell inside which weighs a strut and a wheel, which behave in the wheel well like a “tongue on a bell,” roughly speaking, dangling. This suspension design for VAZ and many foreign cars is a significant drawback.

If you pay attention to the Mercedes-Benz W124 suspension, its design is somewhat different from ours. The top of the fastening is one to one, like that of a VAZ 2110, but the bottom is rigidly fixed to the body or front axle beam through a triangular lever with two silent blocks, approximately like on a Zhiguli 2106. And the third end is attached to the rack with a ball joint. We all remember from school that a triangle is the most durable figure.

Thus, such a lower arm prevents the suspension from moving back and forth relative to the arch. By reducing the number of such parasitic amplitudes of the suspension, the strut clearly fulfills its task and work - the move is strictly up and down. Thanks to these two silent blocks, there is additional vibration damping from the suspension.

Installation of triangular arms on a VAZ 2110, VAZ 2112 Along with the installation of triangular arms, it is recommended to immediately replace the set of stabilizer struts and gas supports. If the levers are of high quality, then there will be no problems with their installation.

The procedure for installing triangular levers with your own hands is approximately as follows:

- Raise the car on a jack.

- Unscrew the ball joints.

- Remove the 'crabs' and sabers with levers.

- For triangular levers, the castor is adjusted using clutches, so when installing (using adjusting washers), you need to make sure that the levers fit into the space between the crab and the house on the body. There should be no body tension.

- The washers must be placed between the crab's silent block and the lever so that the lever's silent block rests against the back wall of the house, and not against the front.

- Make a wheel alignment.

- Improved handling.

- Reducing wheel slip.

- Increased rigidity and strength of the front suspension.

- Eliminate the backlash that exists between standard parts.

- Increases the stability of wheel geometry.

- Allows you to set caster to more than 2 degrees

- It's easier to set the castor

Buy wishbones

| There are triangular levers with rubber silent block bushings and polyurethane bushings. The second reviews are characterized by durability. The approximate price of triangular levers Autoproduct is 4000-5500 rubles. You can buy them in online stores. |

Towbar UA Sale of towbars (TSU). Super prices from 250 UAH. Address and telephone farkop.tatet.ua Reviews about wishbones Advantages:

No deficiencies identified.

Review No. 1 : The bumps on the steering wheel when you get into treacherous potholes are gone, the car almost never strays from the trajectory (depending on the depth of the pit). Now you finally feel like a driver who controls the car and does not correct its movement =) The reaction of the car to any movement by the steering wheel, taking turns is not as scary as before, especially if the roads are uneven. The front became softer and improved handling. I advise everyone.

Review #2 : The effect is excellent. The steering wheel vibration disappeared, especially at high speeds, the steering became much more precise and what was most pleasing was that the suspension began to work more pleasantly! Overall, I really liked it and recommend it to everyone!

Review No. 3 : The difference in the behavior of the car became obvious. The car holds a straight line better at speed, I feel more comfortable driving at high speeds on the highway, it stands like a glove on a straight line.

An attempt to show the effectiveness of triangular levers on the Lada Priora (these levers are the same as the VAZ of the tenth family):

By the way, the softness of the suspension is affected by the presence or absence of front strut bracing. If it is, then the car steers a little better. If not, the car is a little more comfortable, since the engine shield of the VAZ 2110 has very high torsional compliance.