Features of the device and wiper circuit

The glass cleaning system consists of the following elements:

- Electric motor or wiper drive. This device ensures the normal operation of the system by facilitating the movement of the wipers along the front and rear (for station wagons and hatchbacks) glass. If the windshield wiper gearbox fails, it will cause the wipers to not work. The rear wiper drive is also installed only in hatchback or station wagon vehicles.

- The windshield wiper blade holder, also known as the windshield wiper arm, is also known as the windshield wiper arm - brush holder. The wiper blade itself is fixed to this device and moves along the glass.

- Brush with a rubber or silicone blade. When it wears out, the quality of cleaning the windshield is significantly reduced.

- The fastening of the windshield wiper blades is a structural element of the wipers themselves.

- Expansion tank - liquid is poured into it, which is subsequently transferred to the glass through nozzles through hoses when the wipers are turned on.

- Nozzles - these elements are mounted on the hood, they perform the function of spraying water onto the glass.

- Rubber hoses connecting the expansion tank and injectors - consumables are transferred through them.

- Depending on the car, it may use a windshield wiper control unit or a windshield wiper breaker. The latter is a relay that, in accordance with the actions of the driver, determines the frequency of movement of the brushes at specified time intervals. As for the block, it allows the driver to independently set the required interval.

- The washer motor, which supplies water or washer fluid to the windows.

- Windshield wiper switch. The steering column switch is located inside the car, under the steering wheel. With its help, the driver can set the speed of the wipers, and also, if necessary, supply water to the glass.

- A rod that connects two brushes. Thanks to it, these elements can move synchronously.

Photo gallery “System elements”

Also check out

- Remove the plastic plug, unscrew the 2 nuts to “13”, then the wipers with their leads.

- Remove the frill using a TORX T20 socket. Perhaps some of the bolts will be covered with plugs.

- Using a “10” wrench, unscrew the nut on the right side and the 2 fastening bolts securing the trapezoid to the body, and then on the left side.

- Disconnect the negative terminal of the battery, disconnect the connector and the trapezoid with the wiper motor.

- Install a new trapezoid. Reassemble everything in reverse order. At the end of the work, adjust the cleaner brushes.

The principle of operation of the drive, engine and other mechanism components

If the circuit and design of the windshield wiper do not raise any questions, let’s move on to the next point - the principle of operation. The windshield wiper holder, together with the blade mounted on it, moves left and right, which allows you to almost completely clean the windshield. As stated above, using the switch, the driver can adjust the speed at which the wiper blade holder will move. Some modern cars are equipped with hidden cleaners. In this case, the windshield wiper mechanism is installed under the windshield, and when the driver needs to turn on the wipers, the device pushes up this mechanism, which, after being turned off, “hides” back.

In general, windshield and rear window cleaners are almost identical products, but there are differences in their operation. For example, the windshield wiper blade holder can only operate in one mode, without the possibility of adjustment. That is, if the front wipers are part of a whole system that includes many elements and a control unit, then the rear wiper has only one function. One of the main components of the washer is a pump designed to activate the system’s electric motor.

Let's briefly consider the principle of operation of the system:

- The driver presses the steering column switch, giving the control unit a signal to turn on the wipers and also supply water.

- Through the operation of the electric motor, the liquid begins to be transmitted through hoses through nozzles to the windshield or rear window.

- The windshield wiper blade holder begins to rotate under the influence of an electric motor, to which the control device has sent a signal - at what speed the holders should move.

- With a short-term supply of liquid, a certain volume is applied to the glass. When the water stops flowing, the wipers continue to work for some time, usually 1-3 strokes (the author of the video is the Volkswagen channel RUS-LAN center).

How to remove the trapezoid assembly

Before proceeding with the removal, it is necessary to remove the wiper arms, as well as the plastic lining at the very bottom of the windshield, which I wrote about in the instructions for replacing the Kalina cabin filter. There you will need just TORX T20.

After these pads are removed from the car, you can begin to unscrew the bolts and nuts securing the trapezium itself. First, unscrew the bolt on the left, as shown in the photo below:

Then in the center:

And you also need to unscrew one nut on the right side, it’s best to use an open-end wrench there:

Now there is nothing holding the trapezoid and now you can tilt it slightly forward:

To remove it from its seat:

And in order to finally remove it, all that remains is to disconnect the power plug of the motor. It was not possible to photograph everything in its original form, but there is nothing complicated there - bend the latch and pull the plug towards you. You will also need to remove it from the hole in the body in which it is mounted on a latch (clip). Here it is after removal:

Selection of brushes

When choosing wipers, you must be guided by the following criteria:

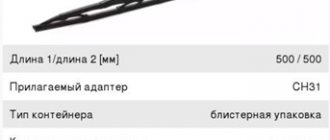

- Length. One of the main indicators - length - is selected in accordance with the car model or taking into account the size of the already installed product.

- Method of fastening products. If the fixing brackets do not match, you simply will not be able to install the products.

- Quality is an equally important criterion. The better quality the products are, the longer they can last.

As practice shows, high-quality products always cost more, and experts advise not to skimp on purchasing products, since they directly affect visibility. We recommend selecting wipers according to the make of the car, as this will allow you to most accurately select the required size.

In addition, it is best to choose products in accordance with the season - they can be both summer and winter. It should be taken into account that winter versions are equipped with special blades that do not freeze or freeze in the cold. Depending on the situation, you can not completely replace the product, but only one blade, of course, if the remaining elements of the leash are in good condition.

Recommendations for selection

Let's consider several product manufacturers:

- Frameless Bosch Aerotwin. Belgian-made products are equipped with native fastenings; the main advantage is a long service life, as well as aerodynamics and the absence of extraneous sounds during operation.

- SWF VisioNext - also of the frameless type, equipped with a hook type mount. The products are manufactured by Valeo, which also produces many other types of components and parts for cars.

- Bosch Twin Spoiler frame brushes. Dimensions fit standard Granta windshield wipers. Despite the fact that the products are frame, they are quite reliable and have a long service life.

- Champion Aerovantage. This manufacturer has been on the market for quite a long time, during which time it has been able to win the trust of many of our compatriots. The products belong to the premium segment of the market and are equipped with a steel frame.

Video “Features of replacement”

How to replace cleaners without a puller and what you need to take into account - learn from the video (author - AssistanceTV channel).

Windshield wipers, better known as windshield wipers, are not vital vehicle systems. But their breakdown causes serious inconvenience in bad weather and threatens traffic safety due to poor visibility. Fortunately, most windshield wiper malfunctions can be fixed fairly quickly with your own hands; repairing them is much easier than, say, repairing an automatic transmission.

Windshield wipers, better known as windshield wipers, are not vital vehicle systems. But their breakdown causes serious inconvenience in bad weather and threatens traffic safety due to poor visibility. Fortunately, most windshield wiper malfunctions can be fixed fairly quickly with your own hands; repairing them is much easier than, say, repairing an automatic transmission.

When do windshield wiper blades need to be replaced?

There are several signs that indicate that the purifiers need replacing:

- The primary and most important is poor windshield cleaning quality, the appearance of streaks and streaks when fluid is supplied from the washer reservoir. As a result of wear of the blades themselves installed on the wipers, the quality of glass cleaning is reduced to a minimum. Poor cleaning results in obstructed visibility.

- The appearance of noise and squeaking when the wipers operate. As a rule, extraneous noise appears after the brushes begin to wear out and the glass is poorly cleaned. But there are also cases when the sound appears first, and only then the ineffectiveness of the brushes. So if you notice squeaking or noise, keep in mind that you will have to change your wipers soon.

- The glass began to darken. As a rule, darkening of the glass is caused by the use of a low-quality washer, but the reason may also lie in damage to the rubber blade. This will cause the angle of the wiper edge to be offset.

- The windshield wipers seem to “jump”. As a result of an increase in lifting force, the following problem appears - the wipers begin to work faster, and accordingly, they can jump over some areas of the glass surface.

How do wipers work?

The windshield cleaner consists of several elements:

- electric motor with gearbox (gearmotor);

- relay with switching contacts for changing operating modes;

- lever drive;

- hinged fastenings;

- pairs of pendulum arms to which brushes are attached;

- brushes that clean glass.

The windshield wiper motor can be powered by a battery or generator, and is switched to an available power source by a relay. The power supply circuit of the gearmotor varies depending on the car model.

In modern cars, the operation of the gearmotor is controlled by an on-board computer, so it is better to repair or replace it at a car service center, and limit independent work to replacing the brushes.

Thanks to the purifier relay, the motor can operate in several modes:

- intermittent (after making one double stroke, the brushes remain in the lower position, and after 3–5 seconds they repeat the movement);

- constant, with low or high brush speed;

- Some models have a separate washing mode (with the washer on).

The gearmotor is the most complex component of a windshield wiper. It consists of an armature with a winding, blocks, wires, gears, a limit switch with a spring plate and a stand. It may also include a reusable thermobimetallic fuse for overload protection.

Through the lever drive system, the rotational energy of the motor is converted into pendulum-like movements of the levers, and the brushes move with them. Each describes a semicircle, and the rubber or silicone tape, pressing against the glass, removes moisture and dirt. Sometimes the cleaner must be used in combination with glass washer. The design of the front and rear window wipers is generally similar, but the rear does not use a relay, so the set of operating modes is different.

Brushes have different designs. They are:

- frame, with movable rocker arms, ensuring the tightest possible pressing of the cleaning tape to the glass;

- frameless, in which the cleaning edge is attached to a rigid metal base, and the curvature of the edge bend is provided by a spring mechanism.

Let's sum it up

Such an important process as replacing wipers, or when changing the windshield wiper trapezoid on a LADA Kalina car, is a very simple undertaking. There is no need for special devices or fancy tools. The brushes are removed by opening the locks.

Repairing or replacing a part such as a windshield wiper trapezium appears as a more responsible job, but it is not capable of causing difficulties for an inexperienced owner of a Lada Kalina. In such situations, do not hesitate to take action.

Typical glass cleaner malfunctions

Malfunctions in the operation of the windshield wiper may be associated with a breakdown of the gear motor, relay, switch, as well as wear or deformation of mechanical parts. The most common problems that arise are:

- the electric motor does not turn on (the characteristic noise accompanying its operation is not heard);

- the operation of the electric motor stops due to the fuse tripping;

- the engine does not go into intermittent or wash mode;

- in intermittent mode, the brushes move without stopping;

- pendulum arms and brushes do not move when the gearmotor is running;

- wipers move too slowly, with difficulty;

- brushes do not return to their original position;

- The brushes move, but the cleaning is unsatisfactory.

When is it necessary to replace windshield wipers in Kalina?

Over time, owners of practical Lada Kalinas notice the appearance of brush marks on the surface of the windshield. Such “artifacts” create an obstacle to good visibility. In this situation, the designated components will need to be replaced, and the trapezoid will likely need to be replaced. Many experienced owners advise purchasing frameless brushes, which, in their opinion, are able to “bravely” withstand temperature changes and can demonstrate a relatively longer service life of approximately 1.5 million cycles.

Before replacing, you should understand the required size of the products. For Lada Kalina, you should purchase a driver's side brush with a length of 600 mm, and for the glass area opposite the passenger - 400 mm. For stern glass, the brush has a standard parameter of 360 mm. This wiper needs to be replaced much less frequently, since the intensity of its work is significantly lower compared to the front components.

Trouble-shooting

Poor quality of glass cleaning is usually associated with wear of the cleaning tape, as well as contamination of the hinges in the frame brushes and limited mobility of the rocker arms. The easiest way to solve this problem is:

- In frame brushes, the cleaning tape is changed. The brushes must first be dismantled, the worn element removed, a new one installed in its place, secured with steel plates and the brush secured to the lever.

- Frameless brushes are replaced entirely.

Sometimes the tape is in good condition, but the brushes leave streaks because the grooves that hold the tape are clogged. In this case, they should simply be cleaned. If the metal frame is covered with rust and the rocker arms have lost their mobility, it is better to replace the brushes entirely.

Cleaning tape is inexpensive, but some motorists are in no hurry to change it. You can restore the elasticity of the tape by dipping it in gasoline and washing it with a warm soapy solution; after this procedure, it is useful to coat the tape with silicone grease. Traces of grease are easily removed with white spirit. A worn, rounded edge can be smoothed out using fine-grit sandpaper glued to a hard base.

Slow movement of the wipers may be due to:

- With wear of the gear motor. It must be disassembled, cleaned, lubricated, and if critical wear occurs, replaced.

- With corrosion, contamination, insufficient lubrication of moving joints. The entire mechanical part is dismantled, disassembled, cleaned, and lubricated.

- With an error made during the installation process that needs to be identified and corrected.

Incorrect assembly can also cause the wipers to not return to the park position. Another reason for this problem is wear or breakage of the drive splines, in which case they need to be replaced.

Problems in the operation of the electric motor can be associated with both its breakdown and mechanical problems. If the gearmotor itself is damaged, it is best to replace it entirely. But if the problem can be fixed by replacing the damaged gear, cleaning the dirty manifold, and adjusting the limit switch, replacement can be avoided.

If the engine does not turn on, you need to inspect the power wires, winding wires, commutator, brushes, as well as the steering column switch, which includes a wiper switch.

- Damaged power wires are replaced with intact ones, oxidized tips are cleaned.

- A failed switch is replaced.

- A dirty collector can be cleaned, the internal cavities can be blown out and the surface can be sanded.

- If the collector burns out, it is better to replace the gearmotor.

- Replacing the gearmotor is also recommended if the winding wires are broken, although only the armature can be replaced.

The engine shutdown due to the fuse tripping may be caused by a short circuit in the winding; in this case, the gearmotor must be replaced. But quite often, an emergency shutdown is associated with the locking of the brushes due to their freezing to the glass, deformation of the levers, or the entry of a foreign object into the mechanism. In this case, the cause must be eliminated. Frozen brushes are carefully separated from the glass using a scraper so as not to damage the cleaning edge, but it is better to wait until it thaws. The mechanism is cleaned of dirt and foreign objects that hinder its operation. Deformed drive elements are leveled, and if the deformation is severe, they are replaced with new ones. After eliminating the cause of the fuse tripping, the blown disposable fuse is replaced with a new one, and the thermobimetallic fuse can be used again.

Intermittent purifier problems are most often caused by a damaged relay or switch. If the brushes move intermittently without pauses, and everything is in order with the relay, the limit switch may not operate. In this case, you need to adjust it, bend the contacts or the spring plate, which the gear cam bends. It is also possible that the limit switch contacts are dirty and need cleaning.

Dismantling the device

In rare cases, the front or rear windshield wiper motor stops working due to some manufacturing defect. The problem is extremely rare, however, if you become a victim of it, there is nothing left to do but start special repairs.

To complete the procedure successfully, perform a complete dismantling. It is no secret that such a process is quite troublesome and time-consuming. Especially if you have to repair a part from old cars, such as Tavria, KAMAZ, Priora, and so on. In this case, you will have to use several separate steps, including unscrewing the nuts that act as fasteners for the levers.

In the future, you can begin to remove the levers themselves from the tapered splines of the drive. If you have any difficulties at this stage, the splines can be treated with penetrating lubricant. Next, the lever drives are dismantled by unscrewing the nuts, as well as removing the rubber gaskets and plastic bushings.

In the harness, the wiring block is disconnected and pulled out using the raised edge of the seal, through a special slot in the partition of the engine compartment. The next step is to remove the windshield wiper.

Now you will have to unscrew the washer from the removed device and remove the spring retainer. And also you can’t do without disconnecting the rod. As a result, all you have to do is dismantle three bolts and remove the engine. After a full visual inspection, begin replacing any faulty parts.

If this does not give any results, the only way out of the situation will be to buy a new motor. If the problem is resolved, the glass cleaning system must be reassembled in the reverse order.

Replacement features and diagram

If, after a thorough diagnosis, you were able to determine that the motor is faulty, think about replacing the failed unit. At this stage there are no special difficulties, so even an inexperienced beginner can easily solve the problem.

True, you must understand that the features of the procedure vary depending on the model of a particular vehicle.

Therefore, before performing a series of any actions, pay attention to the technical features of the system, read the service manual for the car.

- First of all, you must unscrew the nuts securing the brush arm. The help of a wrench will come in handy here. Then remove them from their installation location. If difficulties arise, use a penetrating lubricant.

- Then you need to remove the lever drives by unscrewing the nuts that secure them.

- The next step is to disconnect the connector with the wires in the harness and lift one part of the seal through the hole formed.

- As a result, all that remains is to dismantle the wiper itself. Then remove the washer and spring mount. After successfully achieving such goals, all that remains is to disconnect the pull rod, unscrew the three screws and remove the motor. Unit repair is characterized by particular simplicity and speed of execution.

I hope the developer of this wiring harness hiccups every day...

This store-bought tourniquet just won’t leave me alone. If only I knew what adventures I was signing up for when I bought it. But there is progress, having gone through 5 connection diagrams, working contacts have been identified and connected.

Task: connect the windshield wiper gear motor according to the diagram or diagrams. Schemes used:

Let me remind you once again of the wiring diagram:

What was done and invented: 1) Both schemes for connecting the gear motor and the steering columns with the gearbox are absolutely working. Or, more simply put, identical. 2) In order to save time, the wiring harness from the gear motor was crimped onto the existing 4 wires of the chip from the steering columns and, in accordance with the diagram, 2 missing wires were added - ground and straight to 31b of the gearbox. 3) But not everything is so simple. The wires going to the relay at terminals 15 and 31b turn out to come from one contact 53a of the steering column, and power is not supplied to the relay and, accordingly, to the geared motor in principle. I had a good word for this electrical engineer who made the harness. 4) The 31b coming from the steering column was disconnected from the relay terminal and the wire from the gearmotor was connected directly to it in accordance with the diagram. On the steering column with 53ah, the wire is routed to 53a. After these manipulations everything worked!

But can it really be that simple? 3 days of torment with electrics, just the windshield wiper motor, and? And it turns out that the trapezoid is laid in such a way that it touches the stove damper lever - “infection”... . How I wanted to destroy this stove with a sledgehammer... .

Bottom line. The steering column harness from the store is not of high quality. The wires are thin, the harness going to the windshield wiper is not working (in relation to gearmotors of new releases). There are wires making incorrect contacts, there are empty wires (“snot”)! One terminal is not even marked on the diagram. I had to call each wire and re-learn the circuits.

The motor is connected and operates in 3 modes (fast, slow and intermittent). Among the newly identified problems, the trapezium of the left driver's wiper rests on the heater flap lever. The gear motor mount bends and prevents the trapezoid from working properly.

But I defeated the main electrician, and only the mechanics remained.

I would be grateful for tips on how to make sure that the trapezoid of the driver's wiper does not rest against the damper lever!

Rear window wipers

Malfunctions in the operation of rear window wipers are usually associated with the steering column switch, gear motor, power wires, broken drive teeth, and worn brushes. The relay does not affect the operation of the rear wipers, so its malfunction can be ruled out. The methods for eliminating other breakdowns are the same as for the front wipers.

Repair of windshield wipers mainly comes down to replacing damaged components, cleaning electric motor parts, cleaning and lubricating moving joints, and straightening deformed levers. Repair costs are low, and using contract spare parts from JapZap will keep them to a minimum. The procedure for dismantling and installing different components of this assembly may differ in different cars, but the general principles for troubleshooting are the same.

Size

If you do not know which windshield wiper blades are best to choose, then first of all you need to consider the size of the wipers. Today, the domestic market offers many different variations of purifiers. Moreover, the size of the windshield wiper blades determines how well and efficiently the glass will be cleaned. Front wipers should always be larger than the rear ones, since the view of the situation on the road is mainly through the mirrors, not the glass.

Set of frame brushes

When choosing wipers for Kalina, you should be guided by the following dimensions:

- The longer wiper (facing the driver) should be 24 inches long;

- The passenger windshield wiper should be about 16 inches;

- As for the rear window, you can also choose a 24-inch wiper, but for better cleaning it should be rounded.

How do windshield wipers work on a car? Let's disassemble the system

Such a simple design as windshield wipers on a car, but who knew that even they could present structural surprises? Let's look at the operation diagram and design of a conventional windshield wiper.

There are many spare parts in a car that we incorrectly consider to be secondary. This is a given, which we consider as such, which means that we often do not notice how fascinating the design of this or that part of the machine can be. These things work well, and why know the structure of these “gray mice”? By the way, this is an extremely fascinating and diverse world. It also includes an element without which it is impossible to imagine safe and comfortable movement during various types of precipitation - car windshield wipers.

We lift the lever and the wipers start moving across the windshield due to the action of the electric motor. Indeed, this is how they work, but the description is extremely basic; in reality, everything is much more varied and fun.

Operations for removing the gearmotor from a Lada Granta car

1. Disconnect the wire from the negative terminal of the battery.2. Remove the windshield wiper mechanism (“Removing and installing the windshield wiper mechanism for Lada Granta”).

3. Check the position of the trapezoid rods: they should be located on the same line. If this is not the case, set the rods to the required position, otherwise after removing and then installing the gearmotor, the trapezoid crank will take an incorrect position on the axis of the gearmotor.

4. Mark the relative position of the gearmotor shaft and crank.

5. Loosen the crank nut with a wrench and unscrew...

6. Remove the crank from the gearbox shaft

7. Remove the three bolts securing the gear motor to the windshield wiper...

8. ...and remove the gearmotor.

9. Install the windshield wiper motor in the reverse order of removal, aligning the marks made during removal. Lubricate the linkage joints with grease before assembling. Before installing a new gearmotor, it is necessary to adjust it (set it to the end position). To do this, do the following: - connect the wiring harness block to the gearmotor; - place the gearmotor in the opening of the air intake duct; - connect the wire to the negative terminal of the battery; - close the hood; - turn on the ignition; - turn the windshield wiper to the operating position for 10-20 seconds and then turn it off - the gear motor will be installed in its extreme limit position.

Removal of the windshield wiper mechanism on a Lada Granta car is carried out for its disassembly and repair, as well as complete replacement in case of failure. The mechanism is also removed if its presence will interfere with the progress of various works in which the presence of the mechanism will interfere.

Prepare a standard set of tools, de-energize the car by disconnecting the minus terminal from the battery and perform the following sequence of actions:

- First of all, it is necessary to remove the decorative trims of the air supply box.

- Then press out the plastic clips and disconnect the connector of the windshield wiper wiring harness from the air supply box wires.

- We squeeze the antennae of the wire harness holder and disconnect it from the box.

- Now unscrew two bolts and one nut securing the windshield wiper mechanism.

- Turn the mechanism slightly upward and remove it from its place.

- Make any necessary repairs or replacements, then perform installation in reverse order.

Some owners of budget Lada Kalina models have problems with the windshield wiper trapezoid due to its unexpected failure. This type of malfunction has become widespread, so we cannot ignore this issue, because the situation when the wipers stop functioning in the rain is not the most pleasant. And the windshield wiper needs repair.

Methods for connecting windshield wipers.

The connection diagram for windshield wipers can be divided into two types, depending on the method of connecting the operating mode switch.

In the first connection method, a constant plus is supplied to the wiper drive electric motor, and the mode switch connects the motor elements to the minus. This method is widely used in foreign and domestic cars.

The second method is completely opposite to the first, that is, power is supplied to the electric motor through the mode switch, and the minus in this case is taken from the drive housing.

I propose to consider the principle of operation of a car windshield wiper circuit using an example, where plus is supplied to the electric motor through a mode switch, since this is the more common connection method.

The diagram shows the connection of a windshield wiper drive with an electric motor powered by permanent magnets and having two operating speeds. The difference in speed in this circuit is ensured by the displacement of one of the positive brushes relative to the physical center of the electric motor armature.