For a car to move, its wheels must rotate normally. If problems begin with the rotation of the wheels, then the driver immediately has problems controlling the car, which can cause an accident. This applies to all cars, and the VAZ 2107 is no exception. The most important element that ensures the correct rotation of the wheels of the “seven” is the hub. The driver can repair it himself. Let's figure out how to do this.

- Rounded fist

- Increased wheel turnout

- Front wheel bearing

Checking the wheel bearing

- Wheel Bearing Adjustment

- Sequencing

- Sequencing

FRONT HUB AND ITS PURPOSE

The front hub on the VAZ 2107 is a massive steel disc with a hole in the middle. This hole contains a large bushing in which the wheel bearing is mounted. Along the perimeter of the hub disk there are holes for fastening the wheel. And on the reverse side the hub is connected to the steering knuckle.

The front hub of the “seven” is a massive steel disc with a bushing and bearing in the middle

That is, the hub is an intermediate link between the moving wheel and the stationary part of the suspension. It ensures not only normal rotation of the front wheel, but also its normal turning. Therefore, any malfunction of the hub can have very sad consequences for the driver and his passengers. For example, if the wheel bearing becomes completely unusable, the wheel may jam or simply come off while driving, if the speed is high. It's not hard to guess where this will lead. That is why experienced drivers check the condition of the front hub at least once a month by grasping the top of the wheel and slightly rocking it away from and towards themselves. If even a slight play is felt when rocking, you should not drive such a car.

What bearings to put

When a wheel bearing requires replacement, the question immediately arises of which part to install. Many people advise using original components. However, today the quality of parts leaves much to be desired and the issue of choice remains quite relevant.

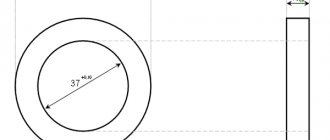

Table: type, installation location, and size of bearings

| Installation location | Bearing type | Size, mm | Quantity |

| Front wheel hub (outer support) | Roller, conical, single row | 19,5*45,3*15,5 | 2 |

| Front wheel hub (inner support) | Roller, conical, single row | 26*57,2*17,5 | 2 |

| Rear axle shaft | Ball, radial, single row | 30*72*19 | 2 |

Manufacturer's choice

When choosing a manufacturer of a wheel bearing for a VAZ “Seven”, we can recommend SKF , SNR, FAG, NTN, Koyo, INA, NSK. The companies listed have many locations around the world. These products are of high quality and meet the most stringent requirements.

Among the domestic manufacturers that supply bearings for cars of the Togliatti plant, we can highlight:

- CJSC "LADA Image" - manufactures and sells original Lada wheel bearings through secondary markets;

- Saratov plant - produces parts under the SPZ brand;

- Volzhsky Plant - uses the Volzhsky Standard brand;

- Vologda plant - sells products under the VBF brand;

- Samara plant SPZ-9.

ROUNDED FIST

The steering knuckle, mentioned above, is another important element of the VAZ 2107 suspension. Its purpose is easy to guess from the name. This part ensures smooth turning of the car's front wheels. The knuckle has two eyes with which it is attached to the paired suspension arms. On the reverse side of the knuckle there is a kingpin onto which the hub is placed along with the wheel bearing.

The steering knuckles on the "sevens" have a long kingpin for attaching the hub

The hub, placed on the knuckle pin, is secured with a nut. It should be said here that turning the wheels is not the only thing the fist is responsible for. It also has an additional function: it limits wheel rotation. For this purpose, special protrusions are provided on the fists of the “seven”. When turning too sharply, the suspension arms hit these ridges and the driver can no longer turn the steering wheel. The knuckle must have a huge margin of safety, since it bears most of the shock loads that occur when the car is moving, especially on uneven roads. However, sometimes the fist becomes deformed (as a rule, this happens after the front wheels fall into a very deep hole or after an accident). Here are the main signs that something is wrong with your fist:

- when driving, the car pulls strongly to the side, and this becomes more pronounced with increasing speed;

- the driver suddenly notices that the turning radius has become smaller, and it has become more difficult to “fit” into very sharp turns. This indicates a decrease in the angle of rotation of the wheels. And this phenomenon occurs after a serious deformation of one fist;

- turning the wheel out. There are situations when one of the knuckle eyes breaks. This is very rare, but it cannot be ignored. So, when the eye breaks, the wheel turns out almost at a right angle to the body of the “seven”. If this happens while driving, the car instantly loses control.

FRONT WHEEL BEARING

To ensure uniform rotation of the front wheels, special bearings are installed in their hubs. These are double-row roller bearings that do not require regular maintenance or lubrication.

The front hubs of the “seven” are equipped with tapered roller bearings

The reason is simple: they are pressed into the hub, so they can be destroyed when you try to remove them. Therefore, the driver removes the wheel bearings only when he decides to change them. Here are the main signs of wheel bearing failure:

- the front wheels rotate with a characteristic low hum. This indicates wear of one or more rollers in the wheel bearing. Worn rollers dangle inside the separator, and when the hub rotates, a characteristic hum occurs, which becomes louder with increasing wheel speed;

- a crackling or squeaking sound coming from behind the wheel. The driver usually hears this sound when turning. He says that one of the wheel bearing rings has collapsed. As a rule, the inner ring of the bearing breaks, and it usually breaks in two places at once. When turning, the hub carries a huge load, as does the bearing in it. At such moments, the fragments of the inner ring begin to rub against each other at the fracture points, resulting in a characteristic cracking or squeaking sound.

In all of the above cases, there is only one solution: replacing the wheel bearing.

CHECKING THE WHEEL BEARING

At the slightest suspicion of a bearing malfunction, the driver is obliged to check it, especially since there is nothing complicated about it.

- The wheel, from which characteristic sounds are heard, is jacked up. Then the driver manually spins the wheel so that it rotates as quickly as possible and listens. If the bearing is worn out, a characteristic hum will be clearly audible to anyone who does not have hearing problems. In some cases, bearing noise cannot be detected when the wheel is spinning too quickly. Then you need to spin the wheel as slowly as possible. If at least one roller in the bearing is worn out, the wheel will definitely hum.

- If manual rotation of the wheel does not reveal the problem, then you should pull the wheel without removing the car from the jack. To do this, the driver grabs the top and bottom of the tire and pulls the wheel several times, first away from himself, then toward himself. If the bearing rings are broken, then a slight play will be clearly felt on the wheel.

- If the play was not detected by pulling the wheel, then the wheel should be rocked. The driver grabs the top of the tire and begins to swing it away from him and towards him. Then he does the same with the bottom of the tire. Backlash, if any, is almost always detected. Either when the bottom of the tire rocks, or when the top rocks.

To identify play, the wheel must be rocked away from you and towards you.

ADJUSTING THE WHEEL BEARING

Once play is identified, the wheel bearing is carefully inspected. If the play is insignificant, and no signs of wear or damage were found on the bearing, then this indicates a weakening of the bearing fasteners. In this case, the driver will not have to change the bearing; it will be enough to simply adjust it.

- Using a screwdriver, remove the protective plug from the wheel bearing.

- After this, the adjusting nut located above the bearing is tightened so that the wheel cannot be turned by hand.

Sometimes, to eliminate wheel play, it is enough to adjust the hub nut - This nut is then gradually loosened two to three turns. After each loosening, the wheel is turned and checked for play. It is necessary to achieve a situation where the wheel rotates freely, but no play is observed.

- When the desired position is found, the adjusting nut should be locked in this position. Drivers usually do this with a simple chisel: hitting the side of the nut with a chisel slightly bends it, and it no longer unscrews.

Sign of a faulty VAZ classic wheel bearing.

A faulty bearing usually produces extraneous sounds in the form of a hum or grinding sound, and the wheel can also hang on such a bearing due to wear or due to a poorly tightened wheel nut.

To diagnose a bearing, it is enough to hang the wheels (or each separately) and rock the wheel in different directions. If there is play when rocking in all planes (wheel rotation left and right and tilt up and down), the wheel bearing may need to be replaced. But the backlash can also be due to tired silent blocks or ball bearings. To exclude a suspension malfunction, you need a second person who will check whether the wheel wobbles together with the steering knuckle or walks separately from it. If the wheel moves separately from the steering knuckle, then the wheel bearing is definitely faulty (in this case, tightening the wheel nut may briefly save the situation).

A sign of a malfunction may also be extraneous sounds when the wheel rotates (usually a hum, sometimes a grinding sound) or its uneven rotation.

You can also determine a faulty bearing by an excessively heated wheel (for example, if the front right wheel disc is much warmer than the front left one). But you can’t compare the temperature of the rear and front wheels because... They have brakes of different designs.

And so, let’s summarize everything we’ve read. The wheel bearing is replaced if:

- The wheel dangles separately from the steering knuckle.

- A hum and grinding noise is heard when the wheel rotates.

- The wheel does not spin evenly.

- The wheel rim gets very hot.

REAR HUB

The rear hub of the VAZ 2107 differs from the front hub both in design and purpose. There are no steering knuckles or additional suspension arms attached to the rear hub.

The rear hub of the "seven" is not as massive as the front

Because the main task of this hub is to ensure uniform rotation of the wheel, and that’s all. It does not require a huge margin of strength and resistance to mechanical loads, since it does not participate in turning the wheels, like the front hub.

The rear hub is simpler than the front, as it does not experience huge loads

The rear hub is equipped with a rolling bearing, which is covered with a special cap. On the other hand, a dirt-proof inner ring is installed in the hub to prevent clogging of the bearing. This entire structure is put on the rear axle shaft of the “seven” and secured with a 30 wheel nut.

What reasons lead to hub failure?

- dashing ride over potholes and bumps. This is typical for lovers of the VAZ 2107: everyone wants to “wipe their nose” on the Lexuses lazily diving into holes on a country road. And trimming the “puzoter” is generally a real pleasure.

- serious overload: an attempt to pick up “all the potatoes” from the dacha can result in a serious accident.

- driving style, which is called “aggressive” - with sudden changes in acceleration.

- If the hub cap is lost, corrosion and wear will occur faster.

Front hub VAZ 2107

Hi all!

One day I tightened the wheel bolts so much that one bolt decided never to be tightened again.

Nothing to do at all - there are exactly four ways out: 1) leave it on three bolts and pray; 2) tap the thread and hope; 3) weld cylinder head studs instead of bolts and be proud; 4) change the hub and calm down.

I chose the fourth option. I bought a hub assembly with bearings and boot. I decided to leave the old nut and support washer.

So let's get started. In fact, the task is not a tricky one. Let's jack it up, prop it up, remove the wheel and see what we have there. And there we have a brake disc, which is held by a caliper. Then we unscrew it by loosening the cotter washers. We don’t confuse anything and put the bolts aside with these washers.

Replacing the VAZ 2107 hub

We put the caliper on top or somewhere else so that it does not fall and the brake hose is relaxed.

Then I saw how the disk was knocked off the hub, but it was somehow inconvenient. Personally, I removed the hub from the axle, unscrewed the soldiers and knocked it out of the disk by placing two planks. In my opinion, it couldn't be simpler. The main thing is not to stain the disc.

Ready. We clean the whole thing and start assembling it, wearing cleaner gloves.

The secret to the long service life of such units is cleanliness during assembly and plenty of lubrication.

Therefore, we add as much lubricant as possible at each stage. A new boot is also needed. Don't skimp on such little things.

Once the hub with generously lubricated bearings is in place, install the support washer and tighten the nut. Personally, I tighten the nut like this: I tighten it until there is a noticeable heaviness of rotation, and then I release the nut to a sector equal to one edge. Then there remains a barely noticeable rolling resistance, and after a few meters the wheel will rotate without resistance at all, but also without the slightest play. Maybe the technology is not correct, but personally, I adjust the tapered bearings once every 30 thousand and I have never had any play or hum in any car.

That's it. We put on the brake disc. He dresses very hard. It would be nice not to skew it. To do this I use the wheel bolts as guides. I tighten the disc with bolts and lightly tap it with a hammer.

That's all. We install the caliper. We cotter its bolts. We check everything. We put the wheel on and off we go. Finally a repair without welding, chisels and grinders. I wish it would be like this more often.

Thanks everyone for your attention! I wish you limitless good luck and good health! See you on the track!

VAZ 2107

Spare parts sizes

List of suitable spare parts with nominal size:

| Manufacturer | Cat. number | Dimensions | price, rub. | |

| 1 | OberKraft | 103504 | 80*90*70 | 660 rub. |

| 2 | AVTOVAZ OJSC | 21010-3101800-86 | 700 rub. | |

| 3 | TD EPK LLC | 2101-185 | 720 rub. | |

| 4 | RUMELIA APS GROUP | ES737630 | 660 rub. | |

| 5 | PKF Niagara LLC | RG2101-3101800 | 330 rub. |

Installation of parts of other configurations is unacceptable by design.

Do-it-yourself adjustment of the clearance in the VAZ-2107 wheel bearing

Spring has arrived, and with it it’s time to change to summer tires. At the same time, it is necessary to check the clearance in the tapered bearings of the front wheel hubs and adjust it. Since a large gap leads to a decrease in the service life of both the bearings themselves and the tire tread, vibration may occur and deterioration of vehicle controllability at speeds.

So, we need:

- new hub nuts - left and right

- torque wrench (you can do without it)

- wheel wrench

- 27mm socket or open-end wrench

- hammer, flat screwdriver

- some new bearing grease

To begin, remove the wheel, decorative cap and hub cap to provide access to the nut.

Checking the presence of grease in the cap

We put the wheel back, but without the caps, fasten it with at least two bolts diagonally and hang it on a jack. Don't forget to put chocks under the wheels and put the car in gear.

Now, sharply shaking the wheel by the rim in a vertical plane with one hand (to eliminate play in the steering linkage), we apply a finger to the washer and hub with the other finger and determine the presence of noticeable axial play.

If this is inconvenient, then you can simply pump the wheel with both hands by the upper and lower rims with sharp movements, visually by the nut and by ear determining the play. It should be no more than 0.02-0.08 mm. In my case, it felt like it was about half a millimeter.

To exclude the influence of other gaps, for example, in the silent blocks of the levers, ball joints and steering linkage, you can ask an assistant to press the brake pedal. In this way we will fix the bearing and the hub - and the play should disappear. If it does not disappear, then its source is not in the bearing.

Once you are convinced of the opposite, you can begin adjusting the gap: use a socket or a 27 wrench to unlock and remove the old nut and put on a new one. But, for prevention, before tightening the new nut, let's inspect the outer bearing, to which we have free access - carefully remove the washer and take it out. We wipe off the old grease and carefully inspect - pitting, visible wear of the separators, cavities and chips on the rollers and rings are not allowed. In our case everything is fine.

Now we fill the hub cavity with new grease, lubricate the bearing and put it back, then the washer and tighten the new nut by hand. The nuts on the left and right sides of the car are different - the nut on the right side has marks on the edge, the one on the left does not.

We take a torque wrench and tighten the nut with a torque of 19.6 N m (2 kgf m), while simultaneously rotating the wheel in both directions so that the bearings self-align.

Then we loosen the nut back and tighten it with a torque of 6.8 N m (0.7 kgf m). And after that we once again finally weaken it by 25°. We check for any play - it should be almost unnoticeable.

If this method did not help us and the play is still significant, then we can use the old “old-fashioned” method - we tighten the nut until the gap completely disappears and gradually unscrew it until a very slight one appears, accordingly also rotating the wheel so that the bearings fit into their places.

We make sure that the adjustment is correct - the wheel should rotate freely, without “biting”; for a more accurate determination, you can press it with a screwdriver or remove the brake pads. That's it, lock the nut, jamming its shoulder into 2 grooves on the trunnion, using a handy tool (screwdriver, bit).

We fill the hub cap with fresh grease and hammer it into place, tighten the remaining wheel bolts. We do the same on the other side.

We carry out the final check of the correctness of the adjustment on the road, driving about 1-2 km and trying not to use the brakes. We check the heating of the hub bearings by hand - it should tolerate it. If the heating is significant and the hand can no longer tolerate it, then it is necessary to carry out the adjustment again or replace the bearings.

Preparatory activities before replacement

Regardless of the chosen replacement option, you will need a minimum set of tools:

- Large screwdriver.

- Keys: 17, 13, 10.

- Hexagon 10.

- Hammer and chisel.

- A long 30mm wrench or a 30mm socket with a knob.

- Wheel puller for VAZ (photo).

- Mandrels (or heads) for knocking out the old part from the hub.

- Torque wrench.

We prepare the car, place it on a flat surface, you will also need bright lighting. You will complete all the work faster with an assistant, and also if you use an inspection hole (overpass). Put the car in first gear, and be sure to put chocks under the rear wheels.

Advice: The first, more efficient and high-quality replacement option is recommended for work, since pressing in and out is done using a removable device, in a shock-free manner.

Tools and materials for work

- Wheel chocks;

- Socket head for nine, thirteen, fifteen, nineteen, thirty;

- Power wrench;

- Jack;

- Wheel bolt wrench;

- Car stand;

- Nineteen spanner;

- Penetrating lubricant;

- Ratchet driver;

- Kardanchik;

- Extension;

- Pliers;

- Vise;

- Torque wrench;

- Extensions for dismantling and installing bearings;

- Hammer;

- Deep head for seven;

- Slotted screwdriver;

- Rubber hammer;

- Bulgarian;

- Chisel;

- Circlip pliers;

- Lithium grease.

This is interesting: Which brake pads are better to choose?

Sequencing

- First of all, the car should be in first gear, after which the car is put on the handbrake. Wheel chocks must be placed under the rear wheels.

- The car is jacked up, the wheel, in the hub of which the bearing is damaged, is removed.

The car is on a jack, the wheel is removed, the hub is visible

- Use a 30 mm socket wrench to unscrew the wheel bearing nut.

The nut is unscrewed with a 30mm head

- Using a flat screwdriver, pry up the caliper, then it should be unscrewed from the steering knuckle (for this, use a 17 mm spanner).

- The unscrewed caliper should be tied with something (otherwise it will hang on the brake hose and this hose may come off under its weight). You should also unscrew the brake disc from the hub.

- Now you need to remove the wheel bearing itself. To get to it, you must first remove the steering knuckle, which will require unscrewing a couple of bolts that secure the knuckle to the car's ball joint.

Use a spanner to unscrew the ball joint bolts

- Using an attachment of a suitable diameter (you can use a piece of steel pipe of the required diameter as this attachment), you should knock the hub out of the bearing, after which you need to remove the retaining ring (pliers are excellent for removing the retaining ring).

It is better to knock out the hub with a pipe of suitable diameter

The best way to remove the ring is with pliers.

- Now you need to press out the bearing. This is done using a puller pre-clamped in a vice.

Pressing out the bearing with a puller

The bearing was successfully pressed out by the puller

- After pressing out the bearing, the place where it was located must be thoroughly cleaned of rust and dirt, and then lubricated.

- The new wheel bearing is pressed into the steering knuckle using a vice and a puller, and the retaining ring is installed in place.

- The knuckle with the new bearing is screwed back to the ball joint, the unit is reassembled, and the wheel is installed in place.

Self-replacement of front bearings on VAZ cars

Hubs are an important element of a car's front suspension. When the wheel bearings malfunction, the first thing that appears is a hum, and sometimes a grinding sound, in the front wheels of the car. The hub begins to heat up, which can cause problems with the brakes. Play in the front suspension hubs leads to damage to the brake discs. There is an imbalance in the suspension, resulting in increased tire wear.

In order not to bring the suspension components to such a state, it is necessary to periodically carry out technical inspection of the front hubs. If such symptoms appear, it is necessary to replace the wheel bearings on the VAZ-2107 as soon as possible.

Welcome to the website Bearings in Russia

To quickly find the information you need, use the site search in the upper right corner.

Any spare part of a modern car must be perfectly matched to fit and technological dimensions. Unfortunately, the manufacturer does not always take into account the specifics of using materials in spare parts, which affects their service life, reliability, and, ultimately, traffic safety. The chassis of a car is subject to enormous loads, so it is simply impossible not to pay attention to the correspondence of the factory dimensions with the ones being replaced.

Content:

VAZ 2108 front wheel bearing size

If we take this issue more specifically, the chassis of cars of popular models and brands most often suffers from low-quality spare parts. First, let's look at this problem using the example of a VAZ 2108 front wheel bearing.

It would seem that there is nothing complicated - the hub has its own standard dimensions, which the roller bearing must correspond to:

internal diameter - 34 mm; outer diameter - 64 mm; Bearing width - 37 mm.

Only by these parameters can you select a bearing, of which domestic factories produce thousands. Manufacturers from China actively help in this, providing products that are not of the best quality and do not stand up to any criticism. Neither the steel grade, nor the number of balls, nor the dynamic performance of such bearings meet the standards. There are bearings without any markings at all, and there are particularly zealous owners who buy them. Such bearings burn out within 1000 km and simply fall apart while driving.

Features of choosing a wheel bearing for a VAZ 2108

Naturally, we will not be able to check the dynamic load on the bearing races and on each of its balls. But you need to remember, like the Our Father, that:

- The VAZ 2108 wheel bearing is marked 25 69 07;

- according to the international marking system it is designated 53 20 66 DA;

- the bearing has a mass of 0.445 kg;

- ball diameter - 9.525 mm;

- number of balls - 28.

The difficulty in choosing bearings is that they are not consumable parts, and they are not changed as often as piston rings or silent blocks. That's why some manufacturers don't even bother making human packaging. In addition, the bearing used in the front wheel hub of the VAZ 2108 is maintenance-free, which means:

- the bearing does not require lubrication;

- does not require preload;

- does not require adjustments during installation and operation;

- must have a very high resource.

Design of wheel bearings for VAZ 2108

All VAZ cars are equipped with only three types of wheel bearings - wheel bearings for front-wheel drive VAZ cars, wheel hub bearings for rear wheels, and wheel bearings for Kalina and Grant cars, which are smaller in size.

All VAZ bearings are of the HUB-1 type, and this type is characterized by the design and installation features. The bearing has a double-row design, is a type of angular contact ball bearings with closed working surfaces and does not have flanges for attachment to the hub.

Manufacturers and prices of VAZ wheel bearings

These bearings belong to the middle price segment, so the demand for them is very high. Because of this, you can often find the fakes we mentioned. However, the transition of the VAZ plant to bearings of this type, instead of roller ones of the old type, made it possible to choose bearings not only of domestic production, but also of many other foreign factories.

The main percentage share of bearings used on VAZ cars lies with domestic manufacturers, among which several factories can be distinguished:

- Saratov Bearing Plant (SPZ) - 28%.

- "Volzhsky Standard" - 2%.

- Samara plant SPZ9 - 8%.

- "Lada Image" - 7%.

- Vologda Bearing Plant VBF - 4%.

Let us only note that Lada Image supplies products directly to the plant’s conveyor belt, and SPZ has the largest share in the spare parts market. It is impossible to say anything specific about the quality of workmanship, because there may be failures at every plant, but even if the bearing turns out to be of poor quality, the enterprise must replace it. Prices for VAZ 2108 front wheel bearings rarely exceed 250 rubles apiece, and imported models may cost a little more, but their quality is appropriate.

So, bearings from Kraft, SCT, Trialli, LGR can cost about 300-350 rubles, but these are world-famous manufacturers, and you can definitely count on the quality of the bearing. Choose the right bearings and let your figure eight roll forward with confidence!

Also, using this method, you can replace the wheel bearing on the road with a simple tool. I have a wheel bearing puller, but I will deliberately change the wheel bearing using improvised means, close to travel and close situations. Explaining and appearing in photos the details of the replacement.

Loosen the wheel mounting bolts. We hang up the front part of the car (namely both front wheels, because otherwise the anti-roll bar interferes with dismantling, pressing the suspension elements upward). We remove the wheel, the brake pad guide together with the caliper and the brake disc (see Removing parts of the front wheel brake mechanism). We tie the guide of the brake pads with the caliper so that they do not hang on the brake hose.

Checking the hub

Set the car to the handbrake and lift it with a jack, grab the top and bottom of the wheel, and rock it in different directions. There should be no backlash or knocking.

Spin the wheel; no extraneous sounds should be heard during free rotation. The wheel should rotate smoothly without difficulty. If play, knocking or irregular rotation accompanied by a crunching sound is detected, it is necessary to replace the bearings.

Before proceeding with the replacement, you need to purchase in advance the spare parts that will be needed during the repair:

- bearings, internal and external;

- stuffing box;

- new lubricant;

Instructions for replacing the wheel bearing on a VAZ-2107 with your own hands

Removal

Put the car on the handbrake. Place a shoe under the wheel to prevent the machine from rolling away. Loosen the front wheel nuts.

Raise the car and place a support under the body. Remove the wheel. Unscrew the caliper mounting bolts located on the inside and remove the caliper. To avoid damaging the brake hose, it is better to tie up the caliper.

Using a screwdriver, pry up and remove the hub cap. Unscrew the hub nut. After removing the nut and washer, pull out the outer separator. Pull the brake disc towards you and remove it together with the hub. After unscrewing the two guide pins, remove the brake disc from the hub.

Using a screwdriver, pull out the oil seal and separator, and then the spacer ring. Now you need to knock out the clips. Using a mandrel of the required diameter or a drift, knock out both clips with a hammer.

Replacement

Having selected the set of front wheel bearings required for replacement, you can get to work.

For repairs, in addition to the standard set of tools, you will need special bearing mandrels. If they are not available, you can use a pipe of suitable diameter.

Dismantling works

By following the instructions and relying on video lessons, you can replace the front wheel bearing with your own hands.

- Loosen the tension of the wheel bolts, remove the decorative plastic plug from the hub bearing and loosen the fastening nut.

- Using a socket and lever, loosen the bearing mounting nut.

- Raise the car with a jack, and then remove the wheels from the part of the front of the VAZ 2109 where you plan to replace the bearing.

- Remove anything that might prevent you from removing the hub. These objects include the brake disc, fastening to the steering knuckle, ball joint, steering knuckle mounting bolts, and front strut fasteners. Dismantle it all and move on.

- Completely unscrew the front hub nut, remove it and remove the thrust washer.

- It is necessary to remove the hubs from the front strut bracket and remove it.

- The hub has been dismantled, so you can press the damaged bearing out of it and put a serviceable unit in its place.

- Place the hub in a vise or in any other way convenient for you.

- Using a drift that fits the diameter, press the hub out of the inner race of the bearing.

- In some cases, the outer part of the inner ring may remain on the hub. In such a situation, you cannot do without a puller. In general, it is better to work with a special tool. It will probably be found among your friends or neighbors in the garage.

- Using the same drift, you need to remove the bearing from the steering knuckle. To do this work, you will have to remove the retaining rings in advance. They can be removed with any available tool, such as an awl. Although there are special clamps for such purposes.

This is interesting: Replacing lamps in Kia Sportage 3: photos, instructions

Accuracy is paramount

- That's it, you managed to remove the hub bearing.

- Carefully treat all dismantled parts using clean kerosene. Follow fire safety regulations.

- Assess the condition of the hub itself. If there are signs of damage, defects, or chips on it, it should be replaced with a new one.

- The new bearing is installed in place using a vice or press. In this case, force must be applied to the outer rings.

- Using a tool such as a hammer to drive in a bearing is strictly prohibited, as this will lead to destruction of the new part.

- After installing the front wheel bearing, perform the reassembly procedure

- Don't forget to change the hub nut.

- Once the assembly is fully assembled and the vehicle is lowered to the ground, only then should the mounting nuts be fully tightened.

Repairing the front hub when the bearing wears out or breaks is not as difficult as it might seem at first glance. Our instructions, supplemented by video tutorials, will help you complete the process yourself from start to finish.

Replacement with the rack not removed

This method will allow you to avoid subsequent collapse. Here you need to remove:

- wheel together with disk;

- caliper and the hub itself.

Replacement is carried out directly on the car, without removing the rack. Here you will have to work with a puller. The procedure is performed like this:

- unscrew the bolts from the brake drum and remove it;

- remove the ball joints;

- pull out the CV joint from the front hub, and then remove it itself using a chisel;

- the retaining ring is pulled out from the steering knuckle (it contains the outer part of the damaged bearing);

- the puller is installed directly on the fist;

- by tightening the bolt of the device, the part is pressed out;

When it completely leaves the axle, the protection is dismantled, then the hub is removed, from which the inner race is removed.

You can also remove the latter without a puller, but you will need a chisel for this. It’s also quite easy to score with a grinder and then split with a heavy hammer.

Installation

The inner surface of the fist is cleaned of dirt and lubricant (solid oil) is applied to it. The puller with the new bearing is installed in place and pressed into place. To make the process easier, it is recommended to first cool it thoroughly in the freezer.

A working unit is inserted into the fist as evenly as possible, trying to avoid distortion. After installing the bearing, put the hub back on and press it in if necessary. All other stages of work are carried out in reverse order.

The hub nut must be tightened using a torque wrench (the required force is 20 N*M).

Replacement without a puller with dismantling the rack

In this case, the entire structure must be completely removed from the car, including the steering knuckle. Replacement of a part that has become unusable is carried out directly at the rack. The advantage of this method is that there is no need to subsequently deal with wheel alignment.

All work is carried out in the following order:

- the steering tip is removed;

- the upper bolts holding the rack are unscrewed (they are located in the engine compartment);

- then it is removed from the CV joint and pulled out of the car.

The bearing is replaced and the strut is mounted in place.

Replacement without dismantling the stand and puller

In this case, it is necessary to remove the entire rotating mechanism with the hub installed.

Then she is knocked out. Upon completion of the work, you will have to check the wheel alignment. The sequence of actions here looks like this:

- the caliper is removed;

- the bolts securing the rack are screwed together;

- the rotating mechanism is removed;

- the CV joint is then removed;

- the drum is twisted from the hub;

- dismantle the protection;

- the fist, freed from other elements, is secured in a vice;

- the hub is knocked out, and then the bearing is removed.