Recently, SUVs and crossovers with all-wheel drive have become very popular.

If previously preference was given only to cars with high ground clearance, now the presence of a 4x4 transmission is a priority. But such technology can be implemented in completely different ways; let’s look at the structural features of the center lock and clutch on a Chevrolet Niva car.

Niva drive device

The chassis of the car is made on the principle of permanent all-wheel drive - torque from the power unit is transmitted to all 4 wheels. This scheme improves the performance of the car when driving in off-road conditions, while simultaneously reducing the load on transmission parts.

The Chevrolet Niva drive consists of the following components:

- Gearbox.

- Transfer case.

- A pair of drive and cardan shafts.

- Front and rear axle gearboxes.

The transfer case is designed to distribute torque between the drive axles of the vehicle. The car is equipped with a two-speed transfer case, which provides:

- stable running of the machine when driving at low speed and at high engine speeds;

- power distribution between drive axles, depending on road grip.

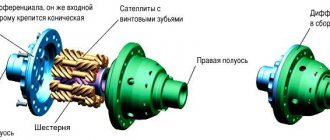

The differential is one of the most important elements of the transmission. Its main purpose is to distribute traction force, and, if necessary, ensure rotation of two consumers at different angular speeds. The Chevrolet Niva drive transmission has three differentials:

- One for each axle (inter-wheel) - they allow the wheels of the same axle to rotate at different speeds.

- The third (interaxle action) - transmits power from the power unit to both axles of the vehicle. It also allows the shafts to operate at different angular speeds, depending on operating conditions, which significantly improves controllability.

A pair of cardan shafts (CV joint or cross design) provide connection between the transfer case and the drive axle gearboxes. Both car shafts have the same design - they are interchangeable.

The front and rear axles transmit force from the transfer case to the drive wheels through external and internal angular velocity joints.

Advantages of Lada 4×4 and Chevrolet Niva cars

Why have these inconspicuously designed cars remained so popular over the years? The secret is the relatively low cost, which is combined with good maneuverability, reliability and simplicity of design. Many people appreciated this vehicle during trips to hunting, fishing, and off-road travel.

Of course, Lada4×4 and Chevrolet Niva have many disadvantages. They are inferior in many respects to modern SUVs, which are distinguished by increased comfort and the presence of many additional options, but for those who are looking for an inexpensive, easy-to-repair car with high cross-country capability, the Niva is a pretty good option.

Lada 4×4

Chevrolet Niva

Location of levers on Lada 4×4

Transmission units

Differential locations

edit this post

The principle of operation of all-wheel drive on a Chevrolet Niva

In normal mode, the Chevrolet Niva operates in high gear with the differential unlocked. Torque is transmitted from the power unit, through the gearbox and intermediate shaft, to a two-stage transfer case gearbox. A center differential is installed in the transfer case housing. It links the front and rear axles, allowing them to rotate at different speeds, depending on road conditions and direction of travel.

How does all-wheel drive work on a Niva with a locked differential?

When all-wheel drive is engaged, both cardan shafts are secured with a locking clutch. This promotes uniform transmission of traction force to both axles of the vehicle. Due to this, the vehicle's cross-country ability increases, but controllability deteriorates.

Advice: It is not recommended to use the lock mode on roads with good grip, as this will lead to accelerated tire wear, increased load on transmission parts and components, and will also increase fuel consumption.

Differential locking

Sometimes you can come across a misconception about why a small handle is needed next to the shift lever on a Niva. Some car owners believe that it is needed to connect front-wheel drive. However, the front-wheel drive of this car is permanently connected. As is the rear one. Cars of the Niva family have permanent all-wheel drive. The handle actually serves to switch the operating modes of the differential of the transfer mechanism.

In the “forward” position, the differential operates as usual, but if you move it back, the differential is locked, and the forces from the motor are applied to the differentials of the axles, which makes the drive more rigid. It is worth noting that there are also special types of locks for front and rear axles.

In theory, when used in conditions where the car is stuck, it will be able to overcome the obstacle if there is sufficient traction on at least one wheel. In this case, it is better to lock the differential before overcoming an obstacle, but never after entering an area that is difficult to overcome. This application of locking will avoid wear and damage to the transmission.

Transmission of Chevrolet Niva and Lada 4x4: what is the difference

The first thing that catches the eye of the average user is that the Lada’s transmission is controlled by two levers, while the Chevrolet Niva has only one, not counting the gearbox control lever. This is due to the fact that Chevrolet’s upshift and downshift ranges, as well as the center differential lock, are implemented using a single-lever design. In addition, the Niva's front axle gearbox is not attached directly to the engine cylinder block, and the transfer case has three mounting points, unlike the Lada, which has two.

Nevertheless, both cars are absolutely identical in transmission design, have one engine for two, but due to the transfer case set back, the Niva’s intermediate shaft is longer than that of the Lada 4x4 by exactly 250 mm. Moreover, both cardan shafts driving the front and rear axles are completely interchangeable.

Tips for owners

To make driving your car comfortable, read some important points:

- The usual, standard arrangement of the front and rear handles is forward and backward, respectively. Movement in this mode can and should be carried out in areas characterized by even and smooth surfaces.

- Locking the differential by switching the front handle to the rear position is best on roads characterized by increased slipperiness. This measure will give Niva stability. It is worth understanding that after overcoming the problem area, the handle will need to be returned to its original position.

- As noted earlier, downshift should be activated before a potential obstacle, but not while the car is already stuck.

- It is worth understanding that activating the lock when the vehicle is stationary is sometimes impossible, even if the clutch is depressed. This may be caused by the clutch teeth hitting the gear teeth. In this case, you can try to activate the lock by starting to drive slowly and make a slight turn. If problems arise with disabling the lock, it is recommended to perform the same procedure with the clutch depressed and the steering wheel slightly rocked.

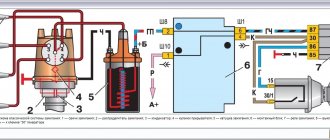

Design and diagram of the Chevrolet Niva transmission

The Chevrolet Niva transmission, in terms of operating principle and architecture, completely replicates the donor car, the VAZ 2121 and its modification, the VAZ 21213. This means that the drive is carried out to all four wheels constantly, without the possibility of disabling the front axle. The design provides a number of reduction gears, as well as a manually lockable center differential.

The main elements of the transmission are as follows:

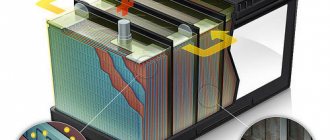

- dry single-plate clutch;

- five-speed gearbox;

- intermediate shaft;

- transfer case;

- 2 cardan shafts driving the front and rear axles;

- front split axle with a gearbox separately mounted on the load-bearing frame;

- continuous, solid rear axle with integrated gearbox and differential, as in classic Tolyatti models.

The transmission structure is shown in the drawing and it is no different from most SUVs with permanent all-wheel drive, as well as the operating principle.

Torque is transmitted from the engine crankshaft through a dry single-plate clutch to the gearbox input shaft. Next, the torque enters through the reduction gears in the box and is transmitted through the output shaft to the transfer case, where it is evenly distributed between the drive axles. The stock Chevrolet Niva does not have a power take-off shaft, which can be used to transmit rotation to the winch.

Modified versions

This approach has already been applied in VAZ-21213 cars; as a result, even at a speed of 100 km/h you don’t feel any unpleasant noise, you can talk calmly and hear your interlocutor without effort. For these purposes, a number of modernization methods have been used: from unloading the floor near the transfer case and manual transmission mounts, reducing the load on shaft bearings to smoothing out peak torques under conditions of increasing loads on the transmission.

The noise in the modernized Niva transmission is comparable to that of a Zhiguli. It becomes more comfortable to be in the car when driving off-road. Upgrade costs are negligible; modification requires only the master's understanding of the design itself and a little time.

Gearbox and clutch Niva Chevrolet

The Niva has virtually the same VAZ gearbox, but with minor changes designed to increase the durability of the unit. Firstly, this is the replacement of the VAZ rear bearings of the primary shafts and intermediate bearings on the secondary shafts with similar, but sealed types. This eliminates bearing malfunctions associated with contamination and premature wear. Secondly, the gear shift control drive has been changed. It is easy to notice that in a Chevrolet the gearbox control lever is closer to the driver, which makes control more convenient. This was achieved through the use of an extension with a 250 mm horizontal rod. Gear ratios remain the same, as does the gear shift pattern.

The clutch device in the Chevrolet Niva transmission has undergone some changes and received a number of improvements and more progressive parts from front-wheel drive VAZ cars.

Features and malfunctions of the transfer case

The Chevrolet Niva transfer case not only moved back by 250 mm, but also changed the installation angle by 4 degrees. Chevrolet engineers calculated that this angle would be optimal for the operation of driveshaft joints. The design of the transfer case uses small-module, low-noise gears, so the howling of the transfer case, as on the old Niva, is now completely eliminated.

Another common malfunction of the transfer case on old Nivas was vibration. On Chevrolet, this issue has been practically resolved by installing new pillows and the appearance of a third attachment point. This will eliminate not only operational vibrations and noise, but also the likelihood of incorrect installation of the transfer case after repair, prevention or troubleshooting.

There is another malfunction that few people think about, however, this problem is related to the resource and endurance of constant velocity joints. The fact is that a cermet valve is installed directly under the CV joint boot mounting clamp. Its task is to compensate for excess pressure inside the cover, thereby protecting it from rupture, and the CV joint itself from water and dirt. If you monitor the performance of the cermet valve during repairs or replacement of hinges, the boot will last a long time and will reliably protect the CV joint.

Even such a complex system as the Chevrolet Niva transmission can be succinctly described in an accessible way. Each owner is required to know the basic principles of operation of the systems of his car.

Grenade replacement

This unit consists of parts that are constantly in motion. As a result, they may burst or wear out, requiring replacement.

The device can only be repaired if the owner of the car has identified damage to the boot in time, and therefore foreign substances have not yet managed to get inside the mechanism.

But this happens quite rarely, since it is almost impossible to detect damage to the boot in time. It should also be said that the cost of the CV joint is not high, and therefore it can be purchased if necessary.

Troubleshooting

You can determine the malfunction of the grenade yourself. To do this, while the car is moving, turn the steering wheel in any direction until it stops. In this case, the driver will hear a crunching sound in the area of the front wheel. In this case, you need to replace the hinge.

During the repair process, it is important to determine whether it is necessary to change both hinges or one, because such work is recommended to be carried out only in a comprehensive manner

Video on how to determine if a grenade is faulty

Changing a grenade on a Niva Chevrolet with your own hands

To replace a grenade, you must first remove the old one. In the process, you will have to dismantle the axle shaft along with the CV joint (you can find a disassembly video on the Internet). Then the car owner must perform the following actions:

- Clamp the removed assembly in a vice.

- Remove the old boot.

- Knock the CV joint off the axle using a hammer and a socket.

- Clean all teeth on the axle gear.

- Install the new joint on the axle.

- Place the boot and secure it with clamps.

- Install the axle with CV joint on the car.

Chevrolet Niva transmission device

Transmission is a purely technical concept and does not relate exclusively to a car. Literally, it is a power transmission that ensures the integral functioning of the mechanisms. Applicable to a specific car model, we can conclude that the Chevrolet Niva transmission is represented by mechanisms that implement the transfer of torque from the engine to the wheels with the possibility of changing it. We have another video on the topic of Chevrolet Niva transmission.

The VAZ-2123 transmission includes the following units:

- Variable gearbox;

- Transfer case;

- Intermediate shaft;

- Drive and cardan shafts;

- Rear axle;

- Front axle.

The transmission provides permanent drive. This means that it is impossible to disable the front axle of a Chevrolet Niva. This scheme increases fuel consumption and also reduces noise and vibration insulation characteristics, but is considered the most optimal in off-road conditions.

The torque transmission diagram can be represented as follows: engine – clutch – gearbox – intermediate shaft – transfer case. The drive is transmitted to the axles via cardan shafts. The Chevrolet Niva transfer case has a center differential. In operation, it provides different angular displacement of the front and rear wheels. The differential lock allows you to equalize the angular speeds of rotation of both cardans. (you can see it more clearly in the video)

Important. The operation of the transmission with a locked differential is intended only for overcoming obstacles. Driving along a straight section of the road at high speed leads not only to excessive vibration of the car, but also to increased loads on the transfer case, which can cause its early failure.

The transfer case can operate in two modes. When you turn on the reduction mode, the torque increases. The features that the Chevrolet Niva gearbox has in conjunction with the transfer case allow you to control the torque and engage the center differential lock with one lever, and not two, like the predecessor VAZ-2121.

Possible problems

Harsh operation and insufficient attention to how to use the transfer case on the Niva 2121 lead to the appearance of:

Experience shows that the culprits are: insufficient oil level, incorrect centering of the steering wheel, loosening of the support fastenings and damage to the rubber bands. An additional influence is exerted by the condition of the cardan and the engine itself.

Video distribution control Sources used:

- https://motoran.ru/transmisii/niva-polnyj-privod

- https://expertniva.ru/hodovaya/kak-rabotaet-polnyj-privod-na-nive-shevrole.html

- https://akppwiki.ru/polnyj-privod-lada-4×4-i-chevrolet-niva-ustrojstvo-i-princip-raboty.html

- https://nivaexpert.ru/transmissiya/kak-polzovatsya-razdatkoj-na-nive-ustrojstvo-korobki/

Transmission

The Chevrolet Niva gearbox has no structural differences compared to the Lada 4x4 box, and they are identical in design. The difference can only be noticed in the mounting and length of the gear shift drive. Another important feature is the presence of 5th gear.

The main parameter of the gearbox is the gear ratio. By trivial definition, this is the ratio of the number of teeth of the driven shaft to the number of teeth of the drive shaft. Naturally, we talk about the gear ratio when there is actually a transfer of torque from one shaft to another. If the specified parameter is greater than 1, then such a mechanism works to increase torque. The gear ratio for IV gear is 1, and for V – 0.82. That is, in V gear there will be an increase in the number of revolutions of the secondary shaft with a parallel decrease in torque. It is more convenient to imagine the value of the gear ratio using the sprockets of a high-speed bicycle.

Transfer case

The transfer case and differential control lever (multiplier) allows you to combine one of two modes with turning on or off the center lock. Together with neutral, there are 5 lever positions.

- Neutral position. There is no engagement in the main pair. The car cannot move.

- Differential unlocked, reduction disabled. Essentially, this is normal mode for everyday driving. The distribution of the moment of force occurs in a ratio of 1:2.

- Differential locked, reduction disabled. The distribution of the moment of force between the axles occurs in equal shares, but due to the operation of the cross-axle differential, the force on each wheel depends on the road surface.

- Differential is unlocked and reduction is engaged. The torque has been increased, but its distribution between the axles is 1:2.

- Differential locked, reduction enabled. Bridges work in a rigid connection. The car has the most increased cross-country ability.

Resource of transmission elements

With proper maintenance, all transmission elements have service lives that comply with the regulations. The existing stereotype about unreliability is not confirmed either documentary or practically. Until now, the Chevrolet Niva remains one of the most popular cars on the market. The owners claim that the car is taking care of its 200,000 km, which the plant lays down as a resource. This means that the transmission resource is determined by the manufacturer and cannot be less than 200,000 km.

Once again, emphasis should be placed on timely maintenance as a guarantee of flawless operation of the system.