From the secondary winding of the ignition coil, a high voltage is supplied to the central electrode of the distributor, which is transmitted using a slider to the side electrodes of the distributor. The speed of rotation of the slider is equal to the speed of rotation of the camshaft and relates to crankshaft revolutions in a ratio of 1:2. The side electrodes of the distributor cover are connected to the spark plugs via high-voltage wires. The main disadvantage of this system is the difficulty in ensuring timely supply of voltage to the spark plugs at different engine speeds and operating modes. This problem was partially solved by the use of a centrifugal and vacuum ignition timing regulator, and subsequently by the use of electronic units, but did not completely solve the problem. In addition, the system has many connections and wearing contacts, which significantly reduces reliability.

Ignition system

A car's ignition system is a complex of instruments and devices that work to ensure the timely appearance of an electrical discharge that ignites the mixture in the cylinder. It is an integral part of electronic equipment and for the most part depends on the operation of the mechanical components of the motor. This process is inherent in all engines that do not use highly heated air for ignition (diesel, compression carburetor engines). Spark ignition of the mixture is also used in hybrid engines running on gasoline and gas.

The principle of operation of the ignition system depends on its type, but if we summarize its operation, we can distinguish the following stages:

- process of high-voltage pulse accumulation;

- charge passage through a step-up transformer;

- synchronization and pulse distribution;

- the appearance of a spark at the spark plug contacts;

- arson of the fuel mixture.

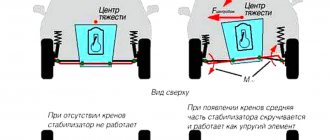

An important parameter is the advance angle or moment - this is the time at which the air-fuel mixture is ignited. The torque is selected so that the maximum pressure occurs when the piston hits the top point. In the case of mechanical systems, it will have to be set manually, but in electronically controlled systems, the setting occurs automatically. The optimal advance angle is influenced by driving speed, gasoline quality, mixture composition and other parameters.

Car with HBO

The main reason for installing gas equipment is to save on fuel. Practice shows that gas costs are approximately half that of gasoline, which is a compelling argument for many. However, you cannot completely switch to this type of fuel, since the need for gasoline remains for warming up and working at high loads.

HBO cylinder in spare tire

Plus, gas is consumed much faster and has a fairly high octane number, so the fuel-air mixture burns out even at the exhaust stage, which has a negative thermal effect on the exhaust tract.

Adjusting the ignition and combustion of the mixture on cars with LPG is the main task; good tuning allows you to save even more money on fuel.

Classification of ignition systems

Based on the ignition synchronization method, a distinction is made between contact and non-contact circuits. Based on the technology for forming the ignition timing, systems with mechanical adjustment and fully automatic or electronic systems can be distinguished.

Based on the type of charge accumulation, to break through the spark gap, devices with accumulation in inductance and with accumulation in capacitance are considered. According to the method of switching the primary circuit, the coils are of mechanical, thyristor and transistor varieties.

Ignition system components

All existing types of ignition systems differ in the way they create a control pulse; otherwise, their design is practically the same. Therefore, it is possible to indicate common elements that are an integral part of any variation of the system.

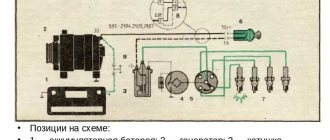

The primary power supply is the battery (used during startup), and during operation the voltage produced by the generator is used.

A switch is a device that is necessary to supply power to the entire system or turn it off. The switch is the ignition switch or control unit.

A charge accumulator is an element necessary to concentrate energy in the required volume to ignite the mixture. There are two types of components for accumulation:

- Inductive - a coil, inside of which there is a step-up transformer that creates a sufficient impulse for high-quality arson. The primary winding of the device is powered from the positive side of the battery and goes through a breaker to its negative side. When the primary circuit is opened by a breaker, a high-voltage charge is created on the secondary circuit, which is transferred to the spark plug.

- Capacitive - a capacitor that is charged with increased voltage. At the right time, the accumulated charge is transmitted to the coil via a signal.

Operation scheme depending on the type of energy storage

Candles are a product consisting of an insulator (the base of the candle), a contact terminal for connecting a high-voltage wire, a metal frame for fastening the part and two electrodes, between which a spark is formed.

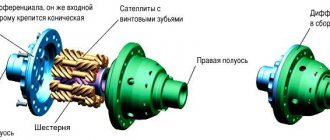

The distribution system is a subsystem designed to direct the spark to the desired cylinder. Consists of several components:

- A distributor or distributor is a device that compares the crankshaft speed and, accordingly, the working position of the cylinders with the cam mechanism. The component may be mechanical or electronic. The first one transmits the rotation of the motor and, using a special slider, distributes the voltage from the drive. The second (static) excludes the presence of rotating parts; distribution occurs due to the operation of the control unit.

- A commutator is a device that generates coil charge pulses. The part is connected to the primary winding and breaks the power supply, generating a self-induction voltage.

- The control unit is a microprocessor-based device that determines the moment of current transmission to the coil based on sensor readings.

The wire is a single-core high-voltage conductor in insulation that connects the coil to the distributor, as well as the switch contacts to the spark plugs.

What does the BSZ consist of?

Contactless ignition includes a small number of parts, thereby reducing the likelihood of failure of each of them. The system consists of:

- Power supply. In all cars it is the battery.

- Ignition and starter switch. The part is necessary for the correct distribution of operating time of the device.

- Ignition coil. Converts low-voltage current from the battery into high-voltage, which ensures stable operation of the car.

- Transistor switch. Responsible for interrupting the flow of electrical current to the coil.

- Ignition sensor. Detects changes in the magnetic field.

- Distribution sensor. The sensor is combined with a pulse sensor, which comes in several types. The pulse sensor is most often represented by a Hall sensor, but there are also two more varieties - inductive and optical.

- Candles.

Magneto

One of the first ignition systems is a magneto. It consists of a current generator that creates a discharge solely for sparking. The system consists of a permanent magnet, which is driven by the crankshaft and an inductor. A spark capable of breaking through the spark gap is generated by a step-up transformer, one part of which is the rough winding of the inductor. To increase the voltage, a part of the generator winding is used, which is connected to the spark plug electrode.

Magneto ignition system

Control over the supply of a spark can be contact, made in the form of a breaker, or non-contact. With the non-contact spark supply method, capacitors are used to improve the quality of the spark. Unlike the ignition circuits presented below, a magneto does not require a battery, it is lightweight and is actively used in compact equipment - brush cutters, chainsaws, generators, etc.

FakeHeader

Comments 21

For many years I have had a BSZ switch like in the video, Ukrainian 0529.3734, a Bosch coil, an Oskol distributor. I bought everything separately. I'm very pleased with how it works. No complaints. In reality, you just need to occasionally check the wire contacts on the switch and the Hall sensor. I treat them with hi-gear to protect the high-voltage part of the ignition.

what kind of sonar is this?

From contact ignition it turns into non-contact ignition. You pull out the breaker and in its place in the old contact distributor you put Sonar ik) and voila you have 800 rubles without contact ignition.

The five had the same dilemma, the question was either to pay 3.5 kilo rubles for a contactless distributor or 500 rubles for a sonar. I bought a sonar, installed it in my original distributor in five minutes, and forgot what ignition problems were! The only thing was that I put the old contacts in the trunk and took them with me just in case of fire. I didn’t remove the capacitor, I just threw the wire away... I drove the Sonarik for 3.5 years and it never let me down! My opinion is definitely to take it and put it! And of course it’s up to you...

The Sonarians are definitely not. They work on IR rays (luminous flux). It gets clogged with dirt and you get up, the spark is gone. About increasing the voltage on the staggered coil from such a stray to 400 V (I read it from the instructions for Sonar) - complete heresy, there is about 16,000 V on contact ignition. In general, there are only disadvantages, except for one plus - the price.

Non-contact kit 1. Hall sensor installed in the distributor is essentially eternal and is not afraid of dirt. 2. The voltage on the coil (discharge voltage on the spark plugs) is already about 40,000 V. 3. The ignition pulls out normal sparking at another 8 volts on the switch. 4. Spare parts are available in all stores. 5. I gave everyone five years and everyone was just happy, forgetting about hemorrhoids with contacts and connectors.

And advice - buy a ready-made set, not individually. What if it doesn’t work (I haven’t had this happen, but suddenly. After all, we live in Russia :)) I always handed it in as a set and took another one, but individually, first you have to find what doesn’t work, etc.

Wow! Now I fully understand what's what. Thank you very much for the clarification. Well, I looked in our city and didn’t find the kit. And there is one store where they can change it for me without any problems if something is wrong. Because I’m not afraid to take it in bulk if) I’ll take the ignition completely decided!)

Well good luck. You will not regret. Even savings should appear. Don’t forget - you also need spark plugs for explosive ignition and explosive wires designed for 40 kV.

I want to make the wires zero. The central one is already there. And the difference between them is in the rubber bands on the tips. Spark plugs, if you don’t go deep into the quantity, the gap can be increased and it should be normal) thank you.

The Sonarians are definitely not. They work on IR rays (luminous flux). It gets clogged with dirt and you get up, the spark is gone. About increasing the voltage on the staggered coil from such a stray to 400 V (I read it from the instructions for Sonar) - complete heresy, there is about 16,000 V on contact ignition. In general, there are only disadvantages, except for one plus - the price.

Non-contact kit 1. Hall sensor installed in the distributor is essentially eternal and is not afraid of dirt. 2. The voltage on the coil (discharge voltage on the spark plugs) is already about 40,000 V. 3. The ignition pulls out normal sparking at another 8 volts on the switch. 4. Spare parts are available in all stores. 5. I gave everyone five years and everyone was just happy, forgetting about hemorrhoids with contacts and connectors.

And advice - buy a ready-made set, not individually. What if it doesn’t work (I haven’t had this happen, but suddenly. After all, we live in Russia :)) I always handed it in as a set and took another one, but individually, first you have to find what doesn’t work, etc.

Will it become clogged with dirt? Where will the dirt come from under the distributor cap? I have been using it for more than 3 years and nothing has clogged once. As for the pros, the most important plus is reliability and price. And even if it fails, you can install the old contacts in 15 minutes and move on. But if the hall sensor fails, then you will be on the road... And by the way, with a sonar, the Conder also reclines, and this is the most common hemorrhoids...

The same coal, condensation in the lid, dust - there are 2 ventilation holes in the lid through which there is access from the outside with all factors. . It is easier to block the light emission and the photodetector than the magnetic field. Do you carry contacts and a capacitor with you, as well as a probe or an UZSK device? Why not just carry a Hall sensor in this case? It’s even simpler - you unscrew the bolt and tighten it, and the best part is that there’s no need to adjust the contacts. And by the way, in 15 minutes you can install the condenser + contacts + adjust the contacts, but somehow, since it is impossible to carry out all the procedures efficiently in 15 minutes. Sorry, but as they say, “I’ve been married for several years and I know first-hand what to do and what not to do.”

I don’t force anyone to do as I do, if you have a lot of money, of course you can buy a contactless ignition kit and not reinvent the wheel! But the essence of the question, as I understood it, was how to get away from the contact ignition system at a lower cost, I answered the question. Moreover, he answered not from theory, but from the practice of using this device for more than three years in his car and installing it on a VAZ2106 for his father for more than two years, and not a single problem arose. And as I understand it, you install contactless kits for everyone (that’s understandable, it’s the client’s money, and you can charge more for installation) but you yourself used a sonar? If you have used it and there are cases when it REALLY got clogged with dirt and did not work, please share your experience. And there are a lot of experts who can talk theoretically while sitting on the couch... By the way, in my memory, my friends’ hall sensors died a couple of times for no apparent reason, and 99.9% of people in their cars don’t have a spare sensor, everyone came as they say... I also read (personally, none I haven’t seen a case, I’m just writing facts) that sonars can die suddenly, nothing happens forever, there is a thyristor there as far as I remember, BUT in the event of such a breakdown, I repeat, you can put contacts and get to the place without problems (and contacts are put when presence of direct hands without probes and instruments, and the Conder is in its normal place, just the wire is disconnected). The PRICE of the issue speaks in favor of such a modification, and there is no need to buy additional contacts, you carry the old ones. And you need to buy a hall sensor as a spare, and the high-voltage wires need to be changed, if I’m not mistaken, that’s also money... So if you have facts, write, but theoretically you can crap anything...

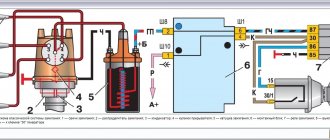

Contact ignition system

An outdated, common scheme for igniting the fuel mixture. A distinctive feature of the system is the creation of high voltage, up to 30 thousand V per spark plug. This high voltage is created by a coil that is connected to the distribution mechanism. The pulse is transmitted to the coil thanks to special wires connected to the contact group. When the cams open, a discharge and spark are formed. The device also acts as a synchronizer, since the moment of spark formation must coincide with the desired moment of the compression stroke. This parameter is set by mechanical adjustment and shifting the spark to an earlier or later point.

The simplest scheme

The vulnerable part of this option is natural mechanical wear. Because of it, the moment of spark formation changes, it is unstable for different positions of the slider. As a result, engine vibrations appear, its dynamics decrease, and the uniformity of operation deteriorates. Fine adjustments can get rid of obvious faults, but the problem may reoccur.

The advantage of contact ignition is its reliability. Even with serious wear, the part will work flawlessly, allowing the motor to work. The circuit is not picky about temperature conditions and is practically not afraid of moisture or water. This type of ignition is common on older cars and is still used on a number of production models today.

Differences in testing methods for carburetor and injection internal combustion engines

To determine the malfunction, you need to check all the spark plugs individually. Often, an improvement in the spark occurs when replacing a set of spark plugs. But sometimes the reason may be different. At the same time, all SZs break down at the same time infrequently.

Checking these elements for cars with carburetor and injection engines is different. For the first type of car, it is enough to unscrew the spark plug, connect the wire and touch the ground with the metal part. Turn on the car ignition.

Checking the spark plug using wires, typical for cars with a carburetor engine

This method is not suitable for vehicles with fuel injection engines. These cars are equipped with many electronic devices. They may fail during such a test. Therefore, it is recommended to use a multimeter to diagnose the condition of the spark plugs. It will allow you to safely and accurately identify a faulty SZ.

Checking the spark plug with a multimeter, typical for cars with an injection engine

Contactless ignition

The principle diagram of the contactless system is somewhat different. It retains the distributor as a structural element, but it only performs the function of synchronizing the cylinders and sends an impulse to the switch. In turn, the transistor element is synchronized with the sensor indicator and determines the ignition angle, as well as other settings, automatically.

The advantage of the system is the stability of sparking quality, which does not depend on manual settings or the preservation of the contact surface. If we consider the superiority of this option over the contact circuit, we can highlight:

- the system generates a high quality spark constantly;

- the design of the ignition system prevents deterioration of its operation due to wear or contamination;

- there is no need to fine-tune the ignition angle;

- there is no need to monitor the state of the contacts, control their closure angle and other settings.

As a result of using a contactless system, one can observe a decrease in fuel consumption, improved dynamic characteristics, the absence of strong engine vibrations, and a stable spark makes cold starts easier.

Electronic ignition

A modern, most advanced design that completely eliminates the presence of moving parts. To obtain the necessary data on the position of the crankshaft and others, special sensors are used. Next, the electronic control unit makes calculations and sends appropriate impulses to the working components. This approach allows you to determine the moment of spark supply as accurately as possible, so that the mixture is ignited in a timely manner. This allows you to get more power, improve cylinder purging and reduce harmful emissions due to better fuel combustion.

Electronic system diagram

The electronic ignition system of a car is highly stable and is installed on most modern cars. This popularity is determined by the advantages of this scheme:

- Reduced fuel consumption in all engine operating modes.

- Improved dynamic performance – response to the gas pedal, acceleration speed, etc.

- Smoother motor operation.

- The graph of torque and horsepower is aligned.

- Power loss at low speeds is minimized.

- Compatible with gas equipment.

- A programmable electronic unit allows you to configure the engine to save fuel or, conversely, to increase dynamic performance.

The purpose of the ignition system is quite simple; it is an integral part of a gasoline engine, as well as engines equipped with gas equipment. This component is constantly changing and acquiring new forms that meet modern requirements. Despite this, even the simplest ignition models are still used on various equipment, successfully doing their job, just like decades ago.