When the rear of the car begins to sag significantly, the suspension springs need to be replaced. The “fatigue” of this part creates many inconveniences:

- the car's ground clearance decreases, which is why the muffler and rear end hit bumps on the roads and cling to the asphalt;

- Rubber friction occurs in the rear wheel arches;

- shock absorbers wear out more, which leads to damage to other parts of the suspension and body;

- the machine warps to one side (usually due to broken coils);

- the car sways, often violently.

The quality of the springs determines the smoothness of the ride, its softness, and the handling characteristics.

Replacing this part is necessary when car owners want to transport a heavier load; some increase the speed characteristics of the car in this way. Typically, the service life of springs is 5–10 years. However, on Russian off-road conditions they “get tired” quite quickly, reducing the period of their high-quality functioning to 3 years.

In addition, the springs are constantly exposed to impacts from small stones, the surface is damaged, moisture gets there and, naturally, corrosion begins. Therefore, it is better to replace them regularly. For example, on the VAZ 2107 it is recommended to change them every 30 thousand kilometers.

Removing the rear suspension strut module on a VAZ 2110-2112

So, when the car is still standing on the ground, you need to slightly loosen the nut securing the rear drain from above, which can be reached from the inside of the car or the trunk. This is what the nut looks like:

While unscrewing the nut, the strut rod must be held so that it does not turn. This can be done using a regular 6 key, or you can use a special one - which is designed for this work.

After this, we tear off the rear wheel mounting bolts, lift the car with a jack or lift and completely remove the wheel from the car. Now we have free access to the lower rear shock absorber mounting bolts. Unscrew the nut with a 19mm wrench, while simultaneously holding the bolt on the reverse side from turning:

And then remove the bolt from the reverse side. It is not always possible to do all this by hand, so you can use either a thin punch and a hammer so as not to damage the thread, or using a wooden block and again a hammer.

Then use a pry bar to pry the stand from below to disengage it. This step of the procedure is shown more clearly in the photo below:

Then you can completely unscrew the upper rack mount. Personally, I got by with a regular open-end wrench and held the rod with a 6 wrench. Although, it is more convenient to do this with a special one:

After which you can remove the entire VAZ 2110-2112 rear suspension module assembly, as shown in the photo:

Reinforced front stabilizer

The front stabilizer of increased rigidity is a means designed to significantly improve the quality of vehicle handling.

Its main difference from the standard part is the harder rubber bushings located at the attachment points.

The nuance of using such an element is that it improves the ride on smooth asphalt areas, but if you have to drive along a bumpy country road, vibrations in the steering wheel will become a real punishment.

Even the slightest impact will be completely transmitted to the steering wheel, which will significantly complicate the driver’s life.

A reinforced stabilizer is quite expensive, and we consider the need for its installation doubtful.

Perhaps only sports car models participating in road competitions need it. The average car enthusiast does not need this modification, especially when tuning the VAZ suspension.

Removal and installation of springs, boots and bumpers (compression buffers) on VAZ 2110-2112

The spring can now be removed without any problems, since there is nothing holding it in place.

The boot is also easy to remove, just pull it up:

The bump stop, or as it is also called, the compression buffer, is also pulled off the rod without unnecessary difficulties. If necessary, replace all removed parts and install everything in the reverse order.

Prices for struts, rear springs and compression buffers using the example of SS20

Unfortunately, I no longer remember the exact prices, but I can roughly name the range of what costs and how much:

- a pair of rear struts - price about 4500 rubles

- classic springs around 2500 rubles

- compression buffers from SS20 can be purchased for 400 rubles

It is possible that there are some deviations from the above prices, but a little time has passed since I personally bought all this for my car.

Almost every driver, even those far from mechanics and repairs, knows that replacing the rear struts on a VAZ 2110 is carried out when the car unsuccessfully runs into potholes. At the same time, replacing the rear struts on a VAZ 2110 must be carried out competently and using special equipment.

Auxiliary powertrain support

The purpose of supplementing the standard motor mounts with another auxiliary module is to minimize the amplitude vibrations of the engine during sudden braking, acceleration and overcoming road hills or potholes.

Its presence eliminates the so-called “pecking” - inertial phenomena that occur during vehicle operation.

The presence of an auxiliary support also prevents spontaneous disengagement of the transmission gears.

This significantly reduces the risk of unpleasant incidents that directly affect safety.

Typically, it is difficult to install this component yourself.

A certain skill is required, which the average car enthusiast does not always have.

Separately, we will say that some engine models require the installation of a fourth support only after moving the ignition unit.

This, on the one hand, is an additional difficulty, but, on the other hand, it significantly improves the operating conditions of the electronic module, moving it away from the road, thereby reducing the amount of dirt that gets on it.

An additional support for the power unit is often installed during tuning of the suspension of VAZ 2109, 2110 cars.

What problem does the rear pillar solve?

A car's pillars, including the front ones, are car components that are designed to absorb body energy transmitted from driving on the road surface. If the road is uneven, then a double load sits on the racks. In fact, not only the comfort of movement, but in many cases also safety depends on the operation of the racks. So:

- In particular, they are responsible for the wear of the car’s chassis, help, together with shock absorbers, to resolve issues with body bouncing, and much more. As is known, at the moment of bouncing, the wheels of the car lose contact with the road surface and temporarily become suspended from transmitting the brake, driving and exerting lateral forces. As a result, all this affects driving safety.

- As for driving comfort, it is lost without high-quality shock absorption, especially if the direction of movement changes when moving over bumps. In addition, when braking or sharply accelerating, every pebble on the road, or rather its energy, is transferred to the cabin, so to speak, without filtering.

Note. The rear pillars, like the front ones, effectively solve the above problems, absorbing all the shocks and shocks from the road surface. They are designed to take care of the comfort and safety of the driver and passengers inside the car.

- In addition, poorly performing shock absorbers increase braking distances and allow the vehicle to bounce on the road, causing severe body vibration. It swings from side to side, which contributes to rapid wear of tires and other parts of the car's chassis.

Front strut

The most popular element, widely used by many owners of Russian cars, is the front cross brace.

Its installation is carried out in the area of the upper shock absorber supports, by securing it between the strut cups.

The main purpose of this part is to increase the angular rigidity of the body and improve the handling quality of the vehicle.

In addition, the presence of a spacer helps eliminate the “floating” geometry of the suspension arms, which occurs as a result of strong impacts on road potholes or uneven surfaces.

The main reason why many car enthusiasts, in particular owners of VAZ cars, make such modifications is due to insufficient body rigidity, which contributes to deterioration of handling, a feeling of “sluggish” steering and excessive roll that occurs when performing maneuvers.

This is detected only when driving at high speeds, mainly associated with trips on country roads.

Those drivers who spend most of their time within the city and are accustomed to a calm, leisurely drive may not notice these shortcomings.

The spacer is a fairly thick metal rod, either of a fixed length, intended for specific car models, or endowed with the possibility of spatial adjustment, facilitating the installation of the element on different cars.

Its installation is carried out when the machine is placed on a flat surface by screwing several nuts onto the upper studs of the shock absorber mounts.

If for some reason there is a mismatch between the mounting holes, the car body must be slightly “pulled” in the desired direction.

Installing a crossbar makes a certain amount of sense. You will not only significantly improve the car’s handling, but also extend the “life” of its body, thanks to improved torsional resistance.

Knock or it's time for replacement

This often happens. The car runs about 30 thousand km and nothing, and then suddenly the wheel bearings start knocking at the rear. So it becomes necessary to replace the rear struts. In fact, the knocking sound of the rear suspension is a kind of signal indicating the need for replacement. At the same time, it is still unknown which part should be replaced. After all, a knock does not necessarily indicate a breakdown of the rear suspension, but can only indicate defects. Therefore, it will be relevant to touch upon the topic of determining the cause experimentally and professionally. Therefore, let’s look at the main causes of knocking from behind, so that you know what’s what:

- If the car is moving on an uneven road and a knocking sound is heard, then the cause is most likely faulty shock absorbers that need to be replaced with new ones;

- If it is clearly visible that the rubber bushings of the suspension arms are worn out, then the problem is in the suspensions themselves, which need to be replaced;

- If the spring has settled, then it also needs to be replaced;

- A knock may indicate weak fastening of the shock absorber itself or wear of the rubber bushings of the eyes (all worn elements are replaced with new ones, and the nuts and bolts are properly tightened);

- A knock may also appear when the rear suspension is overloaded or due to its breakdown, which is possible due to the destruction of the compression stroke buffer;

- Sediment or breakage of one of the suspension springs also requires replacement;

- A knock can also occur when the rear axle of the VAZ 2110 moves due to destruction of the suspension arm bushings;

- If the knocking comes from the suspension arms, then they simply need to be replaced with new ones;

- The knocking can also be determined by unloading the trunk (passengers are not seated behind the car and thus the cause of the knocking is determined, which most likely lies in the shock absorbers or springs).

Some important tips when choosing the right products

There are several questions from domestic car enthusiasts that I would like to answer at the end of this material:

- Which option is most suitable for the VAZ “seven”? In this particular option, experienced craftsmen do not advise choosing original products specifically for this particular car brand. It is better to take the springs for a VAZ 2104 and cut off one turn of the circle to give the products optimal rigidity for this car.

- Will Niva products fit the “seven”? Yes. And this gives a good result, since the level of comfort while driving does not change, but at the same time the controllability of the car improves.

- What is better to choose for the “ten”? Experts recommend installing products marked 2110 on the rear, and 2108 on the front suspension. The consequence of such actions is to increase the stability of the car when cornering.

- VAZ 2114 – what to buy? It all depends on where the car is used. If it is used more often off-road, then it is better to take the 2112 model, as it can increase the ground clearance by several centimeters.

Actually, when it comes to springs for car suspension, there are a very large number of different options. Therefore, it is always recommended to first seek advice from a reputable and experienced technician before starting any replacement.

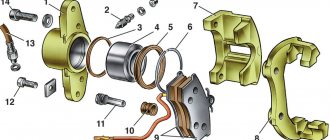

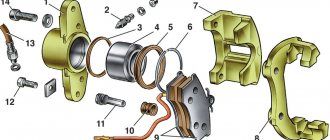

Rear suspension design for VAZ 2110

On the VAZ 2110, the rear suspension is a dependent structure with coil springs and double-acting telescopic shock absorbers. The main load-bearing element is the beam, which, in turn, consists of:

- trailing arms;

- connector;

- brackets with lugs;

- silent blocks, etc.

We select springs according to markings

So, a man came to the store to buy new springs. Which option should I choose? The decoding of the markings presented below will help with this:

- 2101. Ideal for all sedans equipped with rear-wheel drive;

- 21012. A very rigid product, which is usually used on special vehicles;

- 2102. First of all, intended for domestic station wagons. When installing this option, the vehicle's ground clearance increases, which is very important if the vehicle is used off-road;

- 2018. Usually installed on any variant with front-wheel drive, except for Oka and those cars that have a 16-valve power unit under the hood;

- 2110. Designed for expert versions of domestic models from VAZ;

- 2111. Used on models such as VAZ 2111 and 2113. Only on rear suspensions;

- 2112. Similar to the previous version, only for the front suspension;

- 2121. Typically used on four-wheel drive vehicles only. First of all, this is a domestic Niva.

We've decided on the labeling. What else should you pay attention to, for example, if a spring has flown on your beloved Priora? Of course, to the manufacturer.

Replacement

If a problem is discovered and it becomes necessary to change the rear struts, then you need to carry out a number of operations. To begin, you will need to arm yourself with the following tools:

- Key to 6;

- Key to 17;

- Key for racks

- Key to 19.

Dismantling

- we dismantle the luggage compartment in the area of the rear arches;

- Next, remove the rear belts, as well as the brackets that secure the rear seat;

- take a special wrench designed for struts and unscrew the rear strut rod nut;

- Now you will need to lift the car, or rather its rear part;

- Next, unscrew the nuts securing the lower part of the rack;

- remove the stand from its place.

At this stage, the removal of the rear pillar of the VAZ 2110 ends.

Installation

In the process, the new strut will need to be fitted with a compression stroke buffer, a special spacer-type bushing, a casing with an upper cover, a shock absorber pad, a support-type washer and a spring. Let's get started:

- insert the shock absorber rod into the upper hole;

- we press the rack with a beam, using a crowbar or a reliable lift;

- Now you will need to insert the lower mount of the rear pillar into the beam;

- after this you need to carefully fasten the nuts securing the stand;

- install wheels;

- we lower the car.

A rear strut is nothing without a good shock absorber

After replacing the racks on a VAZ 2110, the following situation may occur. The wheels began to hold the road normally over bumps and uneven surfaces, but before, before the replacement, the rear of the car would bounce even on small bumps. But, although road stability became normal, driving comfort suddenly disappeared. In other words, now the bumps hit the driver’s back through the seat, and the car really shakes on the road. What's the matter? Maybe it's all a matter of grinding in the new struts or is this how it should be? It turns out that the whole problem may actually lie in the shock absorbers or in the bearings, but then the knocking should not disappear. Therefore, correct replacement of racks implies knowledge of its design, so to speak, an integrated approach must be applied.

- Shock absorbers in this case can play a very important role. As you know, today there are a lot of different shock absorbers of gas and oil type. Some of them are specially made rigid and when driving on uneven roads, you will definitely feel all the bumps. But driving in this case will be simply superb. Typically, such shock absorbers include products from expensive manufacturers intended for sports driving on highways and even surfaces.

- As for off-road driving, most experts agree that oil shock absorbers are no better in this case. In particular, they are cheaper and do not have too high rigidity. That is why, if after replacing the rear struts you feel stiffness and discomfort in the ride, the problem may lie in the shock absorbers. They will have to be replaced.

- Today, in addition to oil-type shock absorbers, there are also those equipped with special stiffness adjustment. But they are very expensive and not every VAZ 2110 owner can afford to buy them.

Choice depending on manufacturer

Often, when parts break down, drivers try to buy original factory parts as replacements, not wanting to experiment. However, there is a decent choice from other manufacturers, whose products are sometimes no worse than the original ones.

Sirius

There is a large assortment for different brands of cars, and parts are also manufactured in any configuration according to customer drawings.

Phobos

The quality is satisfactory, but, according to some car enthusiasts, after 2 years they begin to sag, losing rigidity. In total, about 500 types of springs are manufactured under this brand for any brand of car; there are standard, reinforced and lowered springs. Clearance kits with increased ground clearance are also available.

Technospring

Good quality for little money. They lose rigidity over time, but do not sag. Quite good as a budget option.

Koni

Very durable, no sagging. They have a stiffness adjustment directly on the car, done with a special thumb under the hood.

Eibach

High-quality, very durable, practically do not “age” - do not sag, do not lose rigidity. There is no roll when turning. But they cost one and a half times more than Koni.\

SS20

Products of the SS20 brand undergo mandatory testing at test benches, after which they are selected in pairs with similar characteristics. This check ensures, according to the manufacturer, 100 percent product quality. A large assortment allows you to choose the right characteristics depending on your driving style and operating conditions. There are 3 options available:

- hot coiling of standard height with linear compression characteristic;

- cold coiling of standard height with linear and progressive compression characteristics;

- cold coils are lowered, with a progressive compression characteristic.

Kilen

Alternative original springs from Kilen are of the highest quality. The service life, as the manufacturers claim, is twice as long as the original VAZ products.

Asomi

Excellent springs made from special alloys, coated with epoxy coating to increase service life.