VAZ-2114 ignition module and its features

The passenger car ignition module is specially designed to improve the starting of a car engine.

Since two high-voltage coils operate as the main components of the module, it is often called the “ignition coil”. Let's look at the structure of this part:

The main operating elements of the ignition module are high-voltage coils that distribute the igniting spark to the spark plugs. This is possible thanks to the following design:

The mechanism of operation of the ignition coil is as follows:

Even an inexperienced car enthusiast can find this part: just trace the path of one of the high-voltage wires - from the spark plug to the plastic case.

This housing houses the ignition module.

How to check the malfunction of the VAZ 2114 ignition module on your own?

The easiest way to check the device without removing it is to diagnose it at the moment the power unit is tripped. When the motor begins to operate unstably, it is necessary to disconnect the connector elements from each component of the module one by one. If the connector is disconnected from a functioning device, the operation of the engine will change. Dips will appear, and the unstable operation of the unit will increase. When the non-working element of the MH is disconnected, the motor will operate in the same way.

There is another simple diagnostic method, its principle is as follows:

- You will need an assistant to check. The spark plug is removed from the seat. The high-voltage cable is disconnected from the device.

- Then the disconnected wire is connected to a spark plug, which is applied to the body of the power unit.

- The machine motor is starting, you need to make sure that a spark hits the spark plug. If it passes, a blue light will appear between the device and the surface of the power unit, its formation is accompanied by a crackling sound. If there is no spark, then the spark plugs, high-voltage cable and module must be diagnosed.

How to diagnose the ignition coil on a VAZ-2114

As already mentioned, when the first signs of malfunctions appear in the VAZ-2114 ignition module, the vehicle owner should diagnose it. You can perform a similar procedure yourself at home using the following algorithm:

At home, all stages of the checks can be performed independently. The first stage is checking the spark plugs. It is carried out in the following sequence:

If the spark plugs are in good condition, you can proceed to the next stage of checking for faults in the ignition module.

The second step is to check the crankshaft sensor. This test is carried out using a multimeter, thanks to which two characteristics are checked - voltage and resistance. To do this proceed as follows:

Otherwise, the faulty sensor will have to be replaced with a new one, because it also affects the operation of the VAZ-2114 ignition module. If after this there are still signs of coil malfunction, then you should proceed to the third stage of the test.

The third stage is checking the ignition coil itself. This part is checked as follows:

What to do if you don’t have a multimeter, but you need to check the electrical circuit? Experts recommend using a twelve-volt light bulb. To do this, one of the wires coming from it should be connected to the terminal, and the second wire should be shorted to the motor housing. If the control light flickers when the starter starts, then everything is in working order.

If the car owner has problems performing such diagnostics himself, he can always turn to qualified specialists at a service station.

Analogues of the VAZ 2114 ignition coil type 2111-3705010-02

Analogs of the ignition coil VAZ 2114 injector 8 valves, model 2111-3705010-02 , based on the M7.9.7 controller or its analogues are the following electrical devices:

| Bosch ignition coil model F000 ZS0 211; |

| Ignition coil model 2111-3705010 from Baker. |

Important ! Temperature sensor VAZ 2114

Ignition module (Ignition coil)

The ignition module is a complex electrical device designed to generate high voltage current (up to 30,000 V) and transmit it to the spark plugs. The connecting component between the ignition module and the spark plugs are high-voltage wires. It is worth noting that many car owners also call the ignition module the ignition coil, which is not entirely correct because the coil is part of the ignition module, but in this case it is not important.

Operating principle of the ignition module

The operating principle of the module corresponds to the operating principle of any ignition coil:

Signs of a malfunctioning ignition module (coil)

The main signs of a malfunctioning ignition coil are:

Where is the ignition module located?

The ignition module is located in the engine compartment. The easiest way to find it is to find high voltage wires. One end of the high-voltage wires goes to the spark plugs, the other end of the wires goes to the ignition module.

Connection diagram of explosive wires to the ignition module

High-voltage wires must be connected to the module strictly in a certain order:

If you hold the module strictly in front of you, you need to connect it as follows:

But this pinout is typical when you hold the module in front of you. If you want to install high-voltage wires on a module already installed on the machine, then the pinout is slightly different, because the module is installed at an angle (diamond):

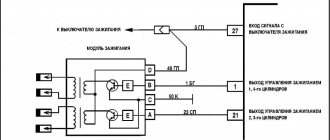

Ignition module diagram

Ignition module pinout.

How much does an ignition module cost?

The approximate cost of an ignition module in a store is from 700 to 1000 rubles.

How to check the ignition module (coil)?

To check the module, you need to measure the resistance between the terminals (1 and 4 cylinders; and between 2 and 3 cylinders). The resistance on the ohmmeter should be approximately 5.4 kOhm. For a more detailed description of verification steps, read the article: How to check the ignition module?

Ignition module errors

The following errors are associated with malfunctioning ignition module:

A common cause of this error can be both spark plugs and high-voltage wires - they need to be replaced (How to replace high-voltage wires? How to replace spark plugs?).

CarFrance.ru » Lada » 2114 » Engine and its systems » Checking the ignition coil on a VAZ-2114 with an 8-valve injection engine using a multimeter

Checking the ignition module (coil) of injection VAZ 21083, 21093, 21099

Due to a malfunction of the ignition module, the following malfunctions may occur in the operation of the injection engine 2111 of VAZ 21083, 21093, 21099 cars: the engine “triples”, “doubles” (works or tries to start on two cylinders), unstable idling, “dips”, “jerks” ", "twitching", etc.

Required Tools

— Multimeter, autotester or other device with ohmmeter and voltmeter modes

— Socket wrenches or heads for “13” and “17”

Preparatory work

— Remove the ignition module from the engine

Disconnect the ends of the high-voltage wires. Use a key set to “13” to unscrew the two upper fastening bolts, and use a key set to “17” to loosen the tightening of the bottom bolt. Remove the module along with its bracket.

— Cleaning from pollution

Wipe with a dry cloth.

Checking the ignition module (coil) of VAZ 21083, 21093, 21099 cars with injection engine 2111

In garage conditions, you can check the secondary windings of the ignition module for an open circuit and the primary windings for a short circuit, as well as the voltage supply to the module from the ECU. This is quite enough to diagnose its malfunction.

Short circuit test

The positive probe of the multimeter in ohmmeter mode to terminal “D” of the ignition module connecting block, the negative probe to the bracket (“ground”). If there is no short circuit, the device readings tend to infinity.

Checking the ignition module for a short circuit

Check for "break"

Using a multimeter in ohmmeter mode, we alternately measure the resistance between terminals “1” and “4”, “2” and “3” of the ignition module.

Checking the secondary winding of the ignition module for an open circuit

The resistance for each measurement should be within 4 kOhm. If it is different or does not correspond to the required indicator, the module should be replaced.

Checking the secondary winding of the ignition module 2-3 for an open circuit

Checking the voltage supply to the ignition module

If previous checks did not reveal a malfunction, you need to check the voltage supply to the ignition module. Turn on the ignition. Using a multimeter in voltmeter mode, measure the voltage between terminals “C” and “D” of the block of the wiring harness going to the module (the terminals are marked on the block itself). The voltage must be within the vehicle's on-board voltage (12V). If it is smaller or absent, then the battery may be discharged, the wires from the computer to the ignition module are faulty, or the control unit (ECU) is faulty.

VAZ 2115 how to check the ignition module

We have already learned what the ignition module is and what are the signs of its malfunction (unstable idling, failures during acceleration, engine twinkling). In this article we will talk about how to check the ignition module with your own hands. From personal experience: on the Internet, while reading various forums on this topic, I came across a post that punched ones do not affect the ignition module in any way. In fact, faulty HV wires can lead to the fact that a spark, in search of the shortest direction, can be sent to an adjacent relay, which contributes to module burnout. Let's move on directly to checking the ignition module. In order to correctly and accurately check the ignition module, you need a device such as an oscilloscope.

But, as a rule, the average driver does not have anything like this, except for the usual warning light and tester, so our task is to use only these devices that are available to everyone. Before checking the module itself, we need to check the block of wires coming to it. To do this, first of all, disconnect the wire block, berm tester and connect one probe of the tester to the block on contact A, connect the other probe to engine ground.

Turn on the ignition and look at the tester readings: the voltage should be around 12V. If there is no voltage, then you need to check what goes to the ignition module. The next step is to take a 12V control light and connect it to contacts A and B. Turn on the starter and look: the light should blink, if it doesn’t blink, then there is an open circuit on contact A.

We perform this operation similarly with contact B. There are several ways to check the ignition module, and we will consider some of them. 1) PPPPP The first and easiest way to check a module is to replace the module with a known working one. Everything is simple here: take the module from the donor car and change it. But there are certain disadvantages here: - the donor car may not be available, buying a new module does not suit our task - the ignition module will not work for every car: of course! You say, from SAMAR it will do. But not everything is so simple: as a rule, the first Samaras with a 1.5 liter engine are equipped with an ignition module.

New Samaras with 1.5 and 1.6 liter engines are often equipped with ignition coils. Let me remind you that the ignition module consists of a switch and an ignition coil. In new Samaras, the switch is located in, so the module is eliminated as unnecessary, only the coil remains. Take this fact into account and look for a new donor. — you must make sure that the high-voltage wires are in good condition: Otherwise, there is a high probability that the ignition module will burn out. 2) PPPPP The next method is the method of moving the module.

To do this, we move the block of wires, knock and move the module itself. If, at the moment of our influence on the module, the operation of the engine changes noticeably, then the matter is most likely in poor contact. This malfunction is not catastrophic, so you can try to repair the module yourself. If the module cannot be repaired, it must be replaced ( ).

3) PPPPP To check we need a tester. Using a tester in ohmmeter mode, we measure the resistance at the paired high-voltage terminals of the ignition module 1 and 4 of the cylinder; and between cylinders 2 and 3. The resistance should be the same but vary around 5.4 kOhm. P Article from. https://vaz-2114-lada.ru.

We have already learned what the ignition module is and what are the signs of its malfunction (unstable idling, failures during acceleration,

We have already learned what the ignition module is and what are the signs of its malfunction (unstable idling, failures during acceleration,

We have already learned what the ignition module is and what are the signs of its malfunction (unstable idling, failures during acceleration,

The ignition module is a complex electrical device designed to generate high voltage current (up to 30,000 V) and transmit

The module will not fail due to a broken wire, 100%, if the module has not yet been replaced, then change it or carefully look at the wiring to it in particular

How to check the ignition coil of a VAZ with a multimeter?

To make checking easier, the coil needs to be removed, but you can do this all on the engine. You need to switch the multimeter to resistance measurement mode and take measurements on the coil contacts. We measure the resistance at terminals 1-4 and 2-3; note that there are numbers on the ignition coil; they correspond to the cylinder numbers.

How to check the ignition coil of a VAZ with a multimeter?

The resistance should be around 5.5 kOhm. In my case, the resistance is 5.9 kOhm, which in principle fits into the standards; we take further measurements.

How to check the ignition coil of a VAZ with a multimeter? How to check the ignition coil of a VAZ with a multimeter?

The second test also showed 5.9 kOhm, which is again normal. In addition, those who were especially attentive noticed that both windings have the same resistance, which also indicates the good condition of the ignition coil.

At the end of the test, we will take measurements for grounding; to do this, we place one multimeter probe on pin 3 and the second on the ignition coil housing. We switch the multimeter itself to dialing mode and listen to see if there is sound.

How to check the ignition coil of a VAZ with a multimeter?

If the sound appears, the contact is normal. If during testing it turns out that the ignition coil is faulty, then simply replace it with a new one and the problem will be solved. We put the new ignition coil in place.

How to check the ignition coil of a VAZ with a multimeter?

After installing the new ignition coil, you need to connect the high-voltage wires from the spark plugs. As I said earlier, the terminals on the coil are numbered, so we connect the wires into cylinders of the same name.

How to check the ignition coil of a VAZ with a multimeter? How to check the ignition coil of a VAZ with a multimeter?

In conclusion, I will add that if your car is equipped with a gas installation and your ignition coils periodically burn out, then you should check how your gas equipment is connected. Often “gas equipment installers” connect it to the signal wire of the coil on a plug in order to determine the operation of the cylinders; because of this, the coil often burns out. It is better to attach such a wire not to the input of the coil, but to the output.

How to check the ignition module of a VAZ 2115

The correct operation of the VAZ 2115 ignition module determines not only the normal start of the engine, but also the stability of its operation in all modes. To fully check the serviceability of this element of the ignition system, you will need simple laboratory equipment. How to check the ignition module of a VAZ 2115 - preliminary results can be achieved in “field” conditions.

How to check the ignition module of a VAZ 2115

This electrical device creates high (up to 30,000 V) voltage, which is then transmitted to the spark plugs.

Some car owners call this device a coil, although this is not entirely correct, since two coils are included in the module. The 1st coil is responsible for the operation of cylinders 1 and 4, the 2nd for the operation of cylinders 2 and 3. In addition, the module contains 2 switches. These elements are located inside one plastic case. It is not difficult to find this module under the hood of the car; high-voltage wires go to it.

Among the main signs of a malfunctioning ignition module are loss of power, dips during a sharp increase in speed, unstable idle speed, and inoperative cylinders (1 and 4 or 2 and 3). These problems can be caused by a malfunction of the ignition module if the DS, MAF and IAC sensors are working properly.

Checking the VAZ 2115 module

Before you start testing the device, you must make sure that the wire blocks connected to it are in good condition. For these purposes you will need a tester. You should disconnect the block, then touch the “A” contact with one of the probes of the device, and the second to ground. After this, turn on the ignition and look at the tester readings.

The voltage should be 12 V. If it is missing, it can be argued that the fuse is faulty. At the next stage of checking the block, you will need a test light, which should be connected between the “A” and “B” contacts. Ask your assistant to turn the starter, and the light should blink. Otherwise, the wire going to the “A” contact may have broken. The same should be done with the “B” contact.

The easiest way to check the functionality of the module is to replace it with a working one. However, there are also nuances here. Ignition modules were installed on the very first Samaras. On later modifications, an ignition coil was installed, but the switch was part of the ECU, and therefore there was no separate module. This must be taken into account if you are going to use a donor car.

Another option for checking the ignition module of a VAZ 2115 is to measure the resistance. To do this, you need to touch the tester probes to the module output where the high-voltage wires are connected. Between the contacts going to cylinders 1 and 4 or 2 and 3, the resistance value will be 5.4 kOhm.

If the resistance indicator is normal, but the malfunction remains the same, use the method of “shaking” the module: lightly knocking on the device with the engine running. With changes in its operation, one can judge that there is poor contact between the elements located inside the ignition module.

We told you how to check the ignition module of a VAZ 2115, but it’s better not to fool your head and drop by the nearest car service center!

Did you like the article? Share with friends on social networks:

This blog is already read by 4756 people. Read it too!

Examination

It is a mistake to assume that damage to high-voltage wires does not in any way affect the condition of the module itself. Many people think of simply replacing high-voltage elements, but in reality they will still have to change the module.

In general, the best option for checking the ignition module on a VAZ 2114 is to use an oscilloscope . But, firstly, not every driver has it, and secondly, few people can use them. Therefore, we will carry out the check using improvised means:

- 12-volt light bulb;

- Tester (available for little money at any auto parts store).

Let's start with preliminary manipulations with the accompanying elements of the ignition module.

- Check the wiring harness. It is disconnected and the voltage indicator is checked.

- To do this, fix the tester on contact A, and connect the other terminal to engine ground.

- In normal condition, the voltage reading will be 12V.

- If there is no voltage, most likely the fuse has blown.

- If everything is fine, transfer the terminals of your tester to contacts A and B, start the car. In this case, the starter should turn and the 12-volt light should blink.

- In the absence of these phenomena, we can talk about the presence of a break in circuit A of the contacts.

Next we go to the ignition module itself.

There are several ways to check the condition of your unit. Therefore, let's look at each of them.

- Set the tester to ohmmeter mode. Use it to measure the resistance on the high-voltage lines going to cylinders 1 and 4, and then, by analogy, to the wiring of cylinders 2 and 3. In normal condition, the device will give you readings from 5.2 to 5.5 ohms.

- Give the device a gentle tug. Thus, you will shake the wiring block and the module. Moreover, this must be done in the operating mode of the power unit. If the device works without obstruction when loosened, everything is fine, you are lucky. If not, you will again have to study the condition of the wiring.

Ignition module VAZ 2115, VAZ 2114 description and its malfunctions

Welcome, friends, to the DIY car repair website. If you try to explain in simple words, the ignition module of the VAZ 2115, VAZ 2114, and other VAZ 2109 and 2110 models is an improved device for microprocessor systems that generate high voltage current and subsequently transmit it to the spark plugs.

Ignition module VAZ 2115

Its power comes from the vehicle's electrical system with a nominal voltage of 12 volts, the negative pole of which is attached directly to the body.

Description and purpose

Ignition coil VAZ 2114 8 valves, VAZ 2113, VAZ 2115 are two two-output ignition reels mounted in a single casing. It is designed to convert low on-board voltage (12 volts) into high sparking voltage. Sparking occurs in two pots at once (1-4 and 2-3). The ignition solenoid is connected to the spark plugs by high-voltage wires with permanent tips.

| 1 — ignition coil VAZ 2114 |

| 2 - package of high-voltage wires |

Below, in the figure, the design of the ignition coil of the VAZ 2114 8 valves is presented

Important ! Crankshaft sensor VAZ 2114

VAZ 2115 ignition module, description and malfunctions

The module's task is to generate high-voltage pulses on the engine spark plugs. As a result of compression of the air-fuel mixture, one spark plug is supplied with a working spark, and the second spark is supplied with an idle spark (exhaust stroke).

The “working” spark plug is connected to the first and fourth cylinders of the engine, and the “idle” spark plug is connected to the second and third. Thanks to this connection, the resulting spark synchronously jumps through the cylinders of the car.

What the module consists of, or so to speak, the composition of the device - two electronic control units, two high-voltage transformers, four outputs for high-voltage wires and a small plastic case. The weight of the device is no more than 1.32 kg, dimensions 110x117x70 mm.

The module is connected to the spark plugs using high-voltage wires that supply sparks to the spark plugs.

To ensure high accuracy of ignition control, the controller uses information about the crankshaft rotation speed; about the load on the engine /air consumption/; about the temperature of the liquid that is used to cool the engine of your iron horse; about the position of the crankshaft and the presence of detonation.

If there is a malfunction, the device cannot be disassembled or repaired. Such a module must be replaced, which is easy to do on your own without involving specialists.

Possible malfunctions of the ignition module:

If such malfunctions are detected, you must first check the reliability of the connection of the high-voltage wires and the serviceability of the spark plugs.

With the engine running, the check must be carried out, observing safety precautions: either work with rubber gloves, or the handles of the pliers must be insulated.

If everything works fine, then the ignition module should be replaced. It is located under the hood of the car and its location is easy to find by thickened high-voltage wires.

You will need tools: socket wrench “10” /head/, wrenches “13” and “17”, hexagon.

The procedure for removing a faulty ignition module:

In order to install a new ignition module, you must first insert the high voltage wires, following the prompts on the module body.

On the terminals of the wires themselves there are also designations of the engine cylinder numbers. Then you should carry out the described steps strictly in reverse order. After starting the engine, you need to check that the ignition module is installed correctly.

Owners of VAZ 2109 - 2115 cars who cannot independently monitor the technical condition of their cars can, of course, be serviced at a service station, where they will be offered diagnostics and high-quality repairs of the car’s engine. Here, as they say, to each his own.

Source

The principle of operation of the ignition coil VAZ 2114 8 valves, model 2111-3705010-02

The current in the primary windings of the ignition coils is controlled by a controller that uses information about the engine operating mode received from the engine control system sensors. To switch the primary windings of the ignition coils, the controller uses two powerful transistor valves.

From the ignition coil of the VAZ 2114 8 valves, a high voltage pulse is supplied to two cylinders at once: 1 - 4, 2 - 3. In one cylinder the compression stroke ends (working spark), and in the second the exhaust stroke (idle spark) occurs.

Due to the constant direction of current in the primary and secondary windings, the sparking current of one spark plug always flows from the central electrode to the side electrode, and the second - from the side to the central one.

The ignition coil of the VAZ 2114 injector 8 valves works according to the following principle. The vehicle's electrical system voltage is supplied from the ignition switch to contact “15” of the ignition coil. Next, the controller switches the pulse to terminal “1b”, the circuit of the primary winding of the ignition coil, as a result of which the secondary winding outputs high voltage to the spark plugs of cylinders 1 and 4. And the controller switches the pulse to terminal “1a”, the circuit of the primary winding of the ignition coil, as a result which causes the secondary winding to output high voltage to the spark plugs of cylinders 2 and 3.

| Deciphering the engine ignition system with an ignition coil VAZ 2114 | |

| Position number on the VAZ 2114 diagram | Explanation of position |

| 1 | accumulator battery; |

| 2 | main relay; |

| 3 | ignition switch; |

| 4 | spark plug; |

| 5 | ignition coil VAZ 2114 8 valves model 54.37005; |

| 6 | controller; |

| 7 | crankshaft position sensor; |

| 8 | master disk. |

Ignition module VAZ 2115 - check, malfunctions and replacement

To begin with, I would like to note that the ignition module on the VAZ 2115 is a fundamentally new device that is more reliable than what was installed on earlier models of VAZ cars. The essence of the operation of this device is that it produces a high voltage electric current, which is subsequently transmitted to the spark plugs of the vehicle’s ignition system.

Operating principle of the ignition module

As mentioned earlier, the main task of the ignition module is that it generates a high level of voltage, which is subsequently transmitted to the spark plugs. The generated current undergoes a compression procedure, as a result of which a working spark is supplied to one of the spark plugs of the ignition system, and an “idle” spark is supplied to the second. To be more correct in statements, the working spark is supplied to the first and fourth spark plugs of the vehicle’s ignition system, and the “idle” spark is supplied to the second and third. Thanks to this high-voltage electric current supply system, the spark appears at the right stroke and on the right cylinder, which ensures stable operation of the system.

Video. Checking the ignition module of the VAZ 2115

Power to the VAZ 2115 ignition module is supplied directly from the vehicle’s on-board electrical network. The voltage supplied to the ignition module is twelve volts. At the same time, you should know that the negative wire of the ignition module is attached directly to the vehicle body. Design of the VAZ 2115 ignition module

The vehicle ignition module consists of a housing made of plastic, a pair of electronic control units, a pair of high-voltage current transformers, and four outputs for BB-type wires. Dimensions of the VAZ 2115 ignition module: one hundred ten by one hundred seventeen by seventy. The weight of the ignition module is one kilogram, three hundred and twenty grams.

Operating principle of the ignition module

The supply of electric current is carried out using wires of the BB type; the supply of electric current is controlled using a special controller, which makes decisions based on information that comes to it from various sensors of the vehicle. Also, the controller’s tasks include setting the sequence in which the ignition coil operates.

The ignition module can carry out its uninterrupted operation at temperatures from minus forty degrees to plus one hundred and thirty degrees Celsius.

What are the signs that indicate a faulty ignition module?

There are several typical signs that directly indicate problems with the ignition module:

1. The engine idle is floating. 2. Engine thrust periodically disappears for no reason. 3. The car picks up engine speed very slowly when accelerating. 4. The cylinders stop working in pairs.

Note that the same signs indicate a malfunction of the BB wires and spark plugs of the vehicle’s ignition system, so in the beginning, you should check them, and if everything is fine with them, then replace the ignition module.

Tools you will need:

To replace the ignition module on a VAZ 2115 car, you will need very few tools:

1. Open-end wrenches for seventeen and thirteen. 2. Ten socket wrench. 3. Hexagon.

Replacing the ignition module on a VAZ 2115 with your own hands

To independently replace the ignition module on a VAZ 2115, you should strictly adhere to a certain sequence of actions, which you can find below:

1. First, you must find the ignition module itself in the engine compartment. This can be done by following the high-voltage wires that come from the spark plugs of the ignition system.

2. Next, you must disconnect the negative cable from the battery.

3. Now, you need to remove the block to which the wires are connected from the ignition module.

4. Next, you should disconnect the high-voltage wires.

5. Now, you can unscrew the mounting bolts that secure the ignition module to the engine and remove it.

6. Then all you have to do is mount the new ignition module and assemble the entire structure in reverse order.

Source

Signs of a malfunctioning ignition module

Checking the ignition module with a removed spark plug

A malfunction of the ignition module is determined by the following symptoms:

- Difficulty starting a cold engine due to lack of spark on one or more spark plugs.

- Floating engine speed at idle is a situation in which the speed changes without any action on the part of the driver.

- Dips in power, which manifests itself during acceleration and driving up a long climb.

- Decrease in engine power.

- Cylinders 1-4 or 2-3 do not work (engine “troits”).

- Indication of the “Check Engine” indicator.

Ignition coil breakdown

The term breakdown of an ignition coil or spark plug tip means a breakdown in the weakest point of the housing or wire insulation due to a decrease in resistance, occurring in short periods of time. This is mechanical damage that leads to the appearance of cracks or melting. On the surface of the case, the breakdown site appears as black, burnt-out dots, longitudinal tracks or white cracks. Such spark piercing areas are especially dangerous in humid weather. This malfunction leads not only to failure of the mixture to ignite, but also to complete failure of the ignition module.

Often such places are not difficult to notice visually, but sometimes it is necessary to check the ignition coil, not with a multimeter or oscilloscope, but with a simple device made of two wires. When a damaged area is identified, the part is usually completely replaced, although sometimes it is possible to delay the replacement using electrical tape, sealant or epoxy glue.

What is ignition coil breakdown and its causes?

Let's take a brief look at what coil breakdown is, what it affects, and what it looks like visually. First of all, it should be recalled that the coil itself is a transformer that has two windings (primary and secondary), isolated from each other. The definition of breakdown is a physical phenomenon when, due to damage to the primary and/or secondary windings of the coil, part of the electrical energy falls not on the spark plug, but on the housing. This leads to the fact that the spark plug does not work at full power, and accordingly, the engine begins to “trouble” and its dynamics are lost.

Ignition coil device

There can be many reasons for the breakdown of the ignition coil - damage to the insulation of one or both windings, damage to the tip body, damage to its rubber seal (due to which water gets inside, through which electricity “sews”), the presence of dirt on the body (similar to water, current passes through it), damage (oxidation) of the electrode in the tip. However, most often the problem lies in the “wired” insulator, and therefore, to eliminate the problem, this place must be localized and insulated.

An interesting reason for the failure of ignition coil tips is the fact that when replacing a spark plug, in some cases, car owners, through carelessness or inexperience, can tear their waterproofing. This can lead to moisture getting under them and problems with engine operation. The opposite case is that when the car owner tightens the top nuts of the spark plug cups too tightly, there is a risk that engine oil from the engine will begin to penetrate into the plug housing. And this oil is harmful to the rubber from which the reel tips are made.

Also, the reason that spark breakdown occurs outside the cylinder is incorrectly set gaps on the spark plugs. This is especially true if the gap is increased. Naturally, the spark in this case has a detrimental effect on both the spark plug body and the rubber tip of the ignition coil.

Ignition coil device

The coil is a pulse step-up transformer. It is she who ensures the conversion of low voltage, which is supplied to it from the battery or generator, into high voltage pulses.

Thanks to these impulses, a spark jumps between the electrodes of the spark plug, which ignites the working mixture in the cylinders. Like any transformer, the coil consists of two windings (primary and secondary), a magnetic circuit and a housing.

The module is structurally somewhat more complex and includes two coils and a switch, but its operating principle is identical to the coil.

Symptoms of a faulty ignition coil

Signs of a malfunction of the ignition coil are that the engine periodically “trips” (triggering is especially important in rainy weather, and when starting the engine “in cold weather”), “failures” occur when accelerating the car, when visually inspecting the coil, “paths” of electrical breakdown are observed, burning of contacts, signs of thermal overheating, the presence of a large amount of dirt and debris in the coil body and other, smaller faults. The most common cause of coil malfunction is a break in its primary or secondary windings. In some cases, their insulation is simply damaged. At the initial stage, the coil will work more or less normally, but over time the problems will worsen and the symptoms described above will appear to a greater extent.

There are several typical signs of an ignition coil breakdown. It’s worth mentioning right away that the malfunctions listed below can be caused by other reasons, so diagnostics should still be carried out comprehensively, including checking the condition of the ignition coils. Thus, symptoms of breakdown can be divided into two types - behavioral and visual. Behavioral ones include:

When dismantling the ignition coil if it malfunctions, you can observe visual signs that it has completely or partially failed. So, these include:

The main sign of a coil malfunction is the lack of ignition of the fuel mixture. However, this situation does not always arise, since in certain cases part of the electrical energy still goes to the candle, and not just to the body. In this case, it is necessary to conduct additional diagnostics.

Well, on modern cars, in the event of a breakdown of the ignition coil, the electronic engine control unit (ECU) will notify the driver about this by activating the Check Engine lamp on the dashboard (and a misfire diagnostic code). However, it can also light up due to other faults, so this requires additional diagnostics using software and hardware.

The symptoms of malfunction described above are relevant if the engine has individual ignition coils. If the design provides for the installation of one coil, common to all cylinders, then the engine will stall completely (this, in fact, is one of the reasons why several individual modules are installed on modern cars).

How to check a coil for breakdown

You can check for breakdown of the ignition coil in one of 5 ways, but as a rule, the average car owner has the opportunity to use only three of them. The first is a visual inspection, because often the breakdown site is visible to the eye; the second is a check with a multimeter, and the third, and the most reliable quick method, if nothing is visually noticeable, is to use a simple ignition system tester (it’s easy to do it yourself).

Ignition system diagnostics

Recommendations for diagnosing the ignition system (spark plugs, wires, coils, module). Instructions on how to check the ignition units of a car with your own hands Read more

To check the operation of the ignition system, first of all, it makes sense to use a program to read errors from the ECU. Usually in such cases it shows errors from the groups P0300 and P0363, indicating misfire in one of the cylinders. However, please note that in this case, errors can be caused not only by faulty coils or spark plug tips. Therefore, in order to make sure that the fault is with one of them, it makes sense to move the problem unit to another cylinder, erase errors from the ECU memory and carry out diagnostics again.

If the problem is in the coil (we are talking about an individual coil), then the situation with errors will repeat, but indicating a different cylinder. True, when this is precisely a breakdown of the coil, and such that gaps appear, then you can already understand by the vibration of the engine, see with your eye a broken insulator track, or even hear a characteristic crackling sound with your ear. Sometimes at night, in addition to a crackling sound, you can also see a spark appearing.

Visual inspection

The next way to determine a breakdown of the ignition coil is to dismantle it and visually inspect it. As practice shows, on the coil body it is usually not difficult to find the very “path” of breakdown along which the spark “sews”. Or you should pay attention to chips, potholes, and geometry violations in the reel body that were not there before.

Measuring parameters

There are two mandatory methods for checking the condition of the ignition coil - checking for spark and checking the insulation resistance of both windings (low and high voltage). To measure the parameters, you will need a working spark plug and a multimeter with the ability to measure insulation resistance. But the most reliable way is to use a spark generation tester, only with a slight modification, so that you can move the conductor along the coil body and look for the weak point of the insulation that breaks through.

Homemade spark tester

The most interesting and reliable method for checking the breakdown of the ignition coil is to use a special homemade probe. It helps when the defect is not visible visually, checking the resistance of the windings did not reveal the problem, but there is no way to use an oscilloscope. To make a spark tester you will need:

The manufacturing process sequence consists of the following steps:

How to determine ignition coil breakdown with a spark tester

After a homemade tester has been made to find the location of the penetration, the procedure itself must be performed according to the following algorithm:

Finding a breakdown using a homemade tester

The verification method is simple and universal. With its help, you can not only find the place where the spark “sews” across the body, but also determine the general operating condition of the ignition coil itself.

This is done by adjusting the gap between the spark plug electrode and the wire on the syringe plunger. At the initial stage, a minimum gap is set with a value of about 1.2 mm and gradually increases. The value of the gap at which the spark disappears depends on the engine size, the type and condition of the ignition system and other factors. On average, for engines with a volume of about 2 liters or less, the distance at which the spark should disappear is about 12 mm, but this is conditional. In general, when checking all individual ignition coils, you can simply compare their operation with each other and identify the faulty element, if present.