The GAZ-53 truck is the legendary Soviet “toiler”. The car was produced serially from 1961 to 1993. However, despite the cessation of production in the early 90s, this car is still found in the fleets of most enterprises. Private owners also have this car. Thanks to the fact that the truck was assembled with high quality, and the same high-quality and durable spare parts were used for assembly, the GAZ-53 was able to survive to this day. The only thing that sometimes raises questions about the 53rd LAWN is the gearbox. Let's look at how this unit works, typical faults and repair methods.

Story

The trucks, which were among the first to be assembled and designated “F”, were equipped with six-cylinder power units, as well as a rear axle from the GAZ-51 model. The transmission was also taken from this car, but they were previously modernized. It must be said that, if necessary, you can change the GAZ-53 gearbox to a GAZ-51. But such a replacement does not always make sense. The transmission that was installed on the GAZ-51 had different gear ratios and was created to work with lower-power engines.

The assembly of the GAZ-53F models was completed, and the GAZ-53A began to be produced instead. This model was equipped with a V8 engine, so to work with this unit, engineers had to modify the transmission and develop a new design for the rear drive axles. Old units showed poor results during testing and were unable to cope with the loads.

In early batches of the GAZ-53, the gearbox was equipped with synchronizers, which were supposed to make shifting smoother. In later versions, it was decided to abandon this - engineers began to consider them archaic.

How much oil is in the box Gas 53

Transfer to GAZ-53

The GAZ-53 truck is perhaps the only vehicle that has not been produced for 20 years, but still works with most people and companies. This is all down to the quality of the build and parts used to create the individual components of the truck.

It looks like a unique GAZ 53

The graph field is constructed like this. The front end of the input shaft is fixed in the bearing of the engine crankshaft, the rear end of the shaft is connected to the output shaft by a needle bearing.

The intermediate shaft transmits all movements to the output shaft depending on the speed involved, the gear ratio and, accordingly, the speed at which the car is moving. The fourth gear is direct; in this gear, the clutch connects the primary and secondary shafts.

example Gearboxes for GAZ-53

From the output shaft, through the drive shaft, the movement moves to the rear axle, which turns the rear wheels.

Content

Creation of the GAZ 53 checkpoint

The first numbers of GAZ 53 (with the index “F”) have a six-cylinder engine and a rear axle. The gearbox was also taken from the 51, but modernized. It should be noted that replacing the GAZ 53 gearbox with a GAZ 51, but this does not always make sense. The fifty-first box has different gear ratios. In addition, it is designed for a less powerful engine and a smaller payload.

Due to the fact that the production of the GAZ 53F was discontinued in 1967, the old modification was replaced by the improved GAZ 53A.

This car was already equipped with a powerful V-8 engine, so we had to build a new model rear axle and improve the checkpoint.

Example of a GAZ 53F truck

Previous editions of the transmission featured third and fourth synchronizer gears that were intended to equalize gear timing, but later versions removed the synchronizer units as redundant. All that remains is the replacement coupling. A gearbox without synchronizers began to be used on the GAZ 3307.

READ Complete automatic transmission oil change using a machine

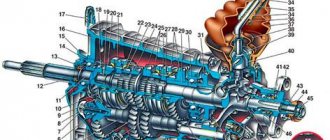

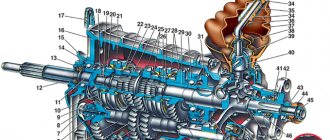

GAZ-53 gearbox diagram

Here we will talk about the gearbox of the famous GAZ 53 truck.

Design and diagram of a gearbox from a GAZ 53 truck.

The transmission of this truck has four forward speeds and one reverse. It is mechanical and consists of three shafts: main, drive, and intermediate. GAZ 53 has a three-speed gearbox.

Thanks to the gearbox, you can shift the engine torque to the drive wheels , the traction force changes. If necessary, you can use the gearbox to stop the transmission of these revolutions to the drive wheels. This corresponds to the neutral position of the gear lever.

Position of the gearbox GAZ-53A car.

GAS 53 Technical data

Trucks GAS 53A and GAS 53 12 have the following technical characteristics:

- Box type. mechanical;

- Type based on gearshift lever position. trilateral;

- Number of forward gears. 4;

- Number of reverse gears. 1;

- Weight. 56 kg;

- Fuel capacity. 3 l.

Check (replace) the oil of the main gearbox GAZ-53, GAZ-3307.

Checking the oil

or replacing the rear axle, final drive of

GAZ 53

, GAZ-3307 and their families.

+ Change oil for GAZ-66

Main channel here.

Schematic diagram of the drive shaft

In order for the car to develop at high speeds at low engine speeds, gears with different numbers of teeth are installed on the driven shaft.

In fourth gear No matter how much the engine rotates, at such speeds they also move the drive wheels . But these are all general concepts common to almost all manual transmissions.

GAZ 53 transmission malfunction

symptoms

You can judge whether the gearbox is faulty by the following signs:

- noise in the gearbox;

- speeds are not turned on at all or with great difficulty;

- one of the speeds does not turn on;

- failure due to one or more speeds;

- There is a rattle in one or more gears while driving;

- the speed is not turned off and the car moves in only one gear. The gear shift lever does not shift to neutral.

READ How much oil is in the ZIL 130 engine

Causes of malfunction

- insufficient or no oil in the gearbox;

- violation of transmission operating rules;

- natural wear and tear of parts;

- manufacturing defect of a part or assembly;

- The gearbox continued to operate in difficult conditions.

Noises and rattles during transmission

Transmission noise may vary in different operating modes.

Gear shift mechanism GAZ 53 A.

For example, if the clutch is noisy in neutral, it is more likely that the transmission input shaft bearing is worn. A noise or rattling noise while driving at one of the speeds indicates that the gears in that transmission are broken or worn. Speed noise may be caused by the countershaft.

Noise in fourth speed may indicate wear on the input shaft or the bearings on the input and output shafts.

Transmission noise in all modes may be due to a lack of oil in it.

The exact cause of the noise can only be determined by opening a test point. It should be noted that the malfunction is not always easy to determine visually, so the parts must be checked very carefully. Particular attention should be paid to parts that are directly related to noisy transmission.

It looks like a GAZ 53 gearbox

Poor gear shifting

Very often the cause of poor transmission is a failure of the GAS 53 clutch, not the transmission. First of all, you need to check the clutch parts and make sure that the pedal is released correctly. The box cannot be engaged or engaged in third and fourth gears through 3-4 clutches or synchronizers. Lack of oil in the gearbox will also make shifting difficult.

The speed will not work properly if the gear shift mechanism located in the gear lever cover is faulty. The cause may be wear on the rod. The springs in the mechanism may also be broken.

Transfer failures

A gear (or several gears) most often comes off for one of the following reasons. The first one is quite familiar. When the shift lever wears out (1-2, 3-4 or reverse), the gear is cut out and the transmission fails.

READ If you pour oil into an automatic transmission, what will happen?

Another cause is wear on the seat on the output shaft where the pinion or pinion itself is worn in the seat. The input shaft may cause the fourth gear to slip out. Due to poor clutch, 3-4 gears fly at one of these speeds or both at the same time.

Where is the drive shaft of the box?

The GAZ-53 has a gearbox drive shaft with the front part at the end of the crankshaft. The rear end is fixed to the crankcase, which is made of cast iron.

The roller bearing is mounted on the end of the drive shaft, on which the front end of the driven shaft is mounted, and the rear is supported by a ball bearing. Gear drives for 1st, 2nd and 3rd gears are mounted on the driven shaft, as well as a synchronizer, which is used to silently and smoothly connect pairs of gears.

GAZ 53 car transmission

Gearbox repair

Gearbox repairs should be entrusted to specialists; experienced craftsmen are well aware of the intricacies of their work. But box is not very difficult to repair, and you can fix it yourself if you want. Now buying spare parts for the Lawn box is not a problem. They can be found in almost any specialized car dealership, and their prices are reasonable.

You can save money by purchasing a used transmission yourself. All you need to do is agree with the seller about the possibility of returning the box in case of malfunction. At one time, many cars were produced with GAZ 53 and GAZ 3307 cars; used gearboxes were often sold and could be easily purchased. Moreover, their prices are sometimes simply ridiculous. By the way, the checkpoint on the GAZ 66 is exactly identical to the “53” box, and they are completely interchangeable. Therefore, the ad can be viewed on the 66th model.

Principle of operation

The GAZ-53 gearbox operates according to the following scheme. The front part of the input shaft is fixed in the crankshaft bearing. The primary shaft is connected to the secondary shaft at the rear via a needle bearing.

The torque is transmitted through the intermediate shaft. Each gear has a different ratio. Thanks to this, speed and thrust change. Direct transmission on the GAZ-53 gearbox is fourth, as on most cars.

How does the checkpoint work?

When the lever is moved to the left from neutral, its lower part moves the shift fork and rod, which forces the first gear gear to move backward and engages it with the gear responsible for first gear. The latter is installed on the intermediate shaft. When the clutch is engaged, the torque is transported through the gears, which are constantly in mesh, towards the intermediate shaft to the secondary shaft.

To engage the third speed, the selector is moved from neutral to the right, and then forward. Under the influence of the fork, the synchronizer clutch will begin to move backward, after which this mechanism will begin to act on the synchronizer. In this case, the torque comes from the gearbox input shaft through gears that are constantly engaged. The moment is transported through the intermediate shaft to the secondary shaft of the box.

To engage fourth speed, the selector must be moved from neutral to the right. Then the lever is moved back. The clutch will move forward and the synchronizer ring will engage the input shaft. Then, after balancing the speeds, the gear will engage.

To engage reverse gear, it is necessary to overcome the force of the safety system. The lever must be moved to the right.

Information for individuals

How can I pay for the ordered auto parts?

- Cashless payments.

- If it is not possible to transfer funds from the current account, our organization issues an invoice to the individual, which he can pay at any bank.

When can I make payment?

- Full payment upon purchase. NOTE! In this case, the order is sent by any transport company.

- Partial prepayment. Part of the cost of the goods is paid, the rest of the amount is paid after the unit arrives at the terminal of the transport company in your city. NOTE! In this case, the order is sent exclusively by Business Lines.

IMPORTANT! In case of full or partial payment, we will send you by mail a copy of the issued delivery note, certified by a seal, indicating the name of the product and its cost. The original invoice will come with the goods.

Synchronizer device and operating principle

As noted above, the first samples were equipped with a basic GAZ-53 gearbox. Its device includes synchronizers. Let's look at how they work and how they are designed.

Using a synchronizer, third and fourth gears are engaged. This mechanism is a hub, which is mounted on the secondary shaft of the gearbox. On its outer surface there are splines along which the coupling moves. The latter is controlled by a fork. In the grooves of the hub there are blocking “crackers” and locking springs. There are bronze blocking rings on the sides. The rings have an internal cone and a gear ring on the outside. Special conical surfaces are made on the third gear gear and on the input shaft gear. When switching, the locking rings come into contact with these surfaces, and then friction occurs between them. Due to this, the rotation speeds of the shafts and gears are equalized. Gears shift more smoothly.

How to set the piston of the first cylinder to TDC

To set the drive correctly. The piston of the first cylinder must be at top dead center precisely at the moment of fuel compression. It must be done extremely accurately. To do this, there is a mark on the drive belt pulley, a small slot. Which must be placed in the direction of the arrow on the bracket. The mark on the pulley is a drill with a diameter of about three mm from the end of the flywheel. This mark should be located in the middle of the inspection window on the clutch housing.

Now you need to make sure. That the first cylinder is at TDC at the moment of compression. There are two ways you can do this.

First way. Unscrew the spark plug of the first cylinder. Insert a paper gag into the hole. And compact it. When turning the crankshaft. Both valves of the first cylinder will close. Compression will be created and the paper plug will shoot out of the hole. You can simply pinch this hole with your finger. When compression occurs, your finger will feel the pressure of compressed air. All that remains is to combine the marks. So that the piston reaches top dead center.

Second way. You can determine it by the position of the valves. If the valves close when aligning the marks. And they behave motionless. This indicates that the piston is in the position we need. On the contrary, if when the marks are aligned, the exhaust valve closes. And after the piston passes TDC, the intake valve begins to open. Then this is not the correct position of the piston and camshaft. Moreover, you can make a mistake because in this situation. When the piston reaches TDC both valves will be closed.

But they close for a moment. When graduation closes. The intake will immediately begin to open. In the case when the valves are closed under compression when the piston approaches TDC and during its further movement, the valves remain motionless for some time.

After the position of the piston of the first cylinder is precisely determined. And the marks are strictly in their places. You can install a distributor drive.

Technical specifications

We looked at how the GAZ-53 gearbox works. Her characteristics were quite good. Let's consider the transmission capabilities.

The unit is equipped with a three-way lever, and the transmission has forward speeds and one reverse gear. The weight of the unit is 56 kilograms. The oil in the GAZ-53 gearbox is poured into a special 3-liter container.

Let's look at the gear ratios of this transmission. For first gear – 6.55. For the second – 3.09. Third gear has a gear ratio of 1.71. The fourth speed is direct, and the gear ratio is 1. The reverse speed has a parameter of 7.77.

Signs of transmission failure

On a GAZ-53, the gearbox rarely fails. Malfunctions can be identified by certain signs. Breakdowns are accompanied by noise and extraneous sounds when the unit is operating.

Malfunctions will be indicated by noise near the place where the unit is installed. Sometimes the transmission cannot be switched on. And if it turns out that serious effort is required, this is also a sign of breakdown. If any gear does not work and does not engage, the speed drops, it is worth inspecting the transmission in more detail. Also, noise during movement indicates a breakdown. Often on the GAZ-53 the gearbox did not allow the lever to be moved to neutral. Because of this, it was impossible to turn off the transmission.

Engine assembly ZMZ-51100A from storage.

Catalog number: 511-1000402 or 511.1000402 or 511-1000398

Used on cars GAZ-53, 3307, 33071, 33075, 33076.5 3-12, SAZ-3502, 3507-01, 3508, KAVZ-3270, 32703, 3976, 39761 with a gasoline engine produced by OJSC ZMZ with 4 step transmission.

The engine is from military storage with a high oil filter , a new type spider , assembled with a clutch housing and clutch (clutch pressure plate + driven clutch disk) and attachments , without ignition coil. Before sale, the conversion lubricant is removed, all gaskets are changed (manifold gasket, head gasket, crankcase gasket, water pump gasket, fuel pump gasket, valve stem seals, generator belt, water pump belt), since gaskets change their properties during storage and fall into disrepair. The generator and ignition distributor are also replaced with a new one (the old one is from 1988, it may fail during storage), the fuel filter, and ignition wires.

The engine is run in on the stand ,

Compression indicators in the engine cylinders are at least 8 kg to 10 kg,

Oil pressure indicators on a warm engine are 1 kg, at speed 3-4 kg.

Then we paint (we give the new engine a fresh look)

Our team is confident in the quality of the ZMZ-511 engine , so we can offer a 1-year warranty.

Also, in the event of a warranty claim, we provide express replacement of low-quality goods to our customers. It is enough to send by e-mail a photo of the motor, the delivery note number, the date of purchase and describe the reason for the defect, after which we will send you a replacement without waiting for you to return the defective product at our expense. This solution will allow you to quickly replace low-quality goods to your customers.

We would like to warn you against purchasing converted engines from armored personnel carriers. When purchasing an engine, what you need to pay attention to:

1. The ZMZ-511 engine has a single-section oil pump (oil is supplied through an oil filter on one side of the crankshaft), converted engines have a two-section oil pump

2. The generator on the ZMZ-511 engines is 14V 65A (small), on the armored personnel carrier the generator is 100A (large) with a high generator bar, the generator belt is not aligned with the drive to the water pump and the hood may not close.

About the causes of malfunctions

Often the main cause of all breakdowns in this box is from an insufficient amount of gear oil or its absence at all in the gearbox mechanism. Also, the incorrect use of the mechanism is often the cause of the malfunction. Often, breakdowns are associated with natural wear of gears. Less often - with a manufacturing defect (since in the USSR they were made “for centuries”). If the truck is operated in extreme conditions for a long time, this also leads to failure of the unit.

Extraneous sounds when the unit is operating

The transmission may make different sounds depending on what mode it is in. If an extraneous sound is heard only when the clutch is fully depressed, then the reason is the bearing. It is located on the transmission input shaft. If you put the car in gear and drive, the grinding noise indicates broken or worn teeth on the gears.

Extraneous sounds when fourth gear is engaged indicate wear on the input shaft, as well as the bearings on this shaft and on the secondary one. If there is no oil in the unit, the transmission will make noise regardless of the operating modes.

Disassembling the GAZ-53 gearbox with subsequent troubleshooting and replacement of parts will help to identify the exact cause of the sounds. However, sometimes it is difficult to determine the breakdown upon inspection. Maximum attention is paid to the element located next to the noisy transmission. The box often howls. This is especially pronounced when driving at low speeds. For the 53rd LAWN, this sound is quite normal.

Gears are difficult to engage

Often, if the gears are poorly engaged, it is not the gearbox mechanism that is to blame, but the clutch. The first step is to diagnose the clutch parts, and also make sure that the pedal is depressed normally.

If third and fourth gears do not engage, the cause is often a malfunction of the synchronizers or clutch in these gears. The speeds will be difficult to engage if there is no oil.

Failure or wear of the gear selector mechanism will prevent the transmission from operating normally. Often the cause is wear of the rods. It's also worth checking the springs. Repair involves disassembling and replacing worn or damaged spare parts - GAZ-53 spare parts, despite its age, can still be purchased.

Possible breakdowns of ZMZ-53

Among the most common malfunctions of the ZMZ-53 engine, the following should be noted:

- Increased fuel consumption. The cause may be an oil leak through the seals or other connections.

- Burnout of engine oil seals occurs due to overheating of the unit.

- The knocking of the connecting rod bearing occurs due to a decrease in the oil level, pressure in the system and wear of spare parts.

- Tapping of the upper bushing and the stroke of the piston means a crack in the skirt and partition of the piston ring, burnout of the bottom.

- The exhaust valve is burnt out - this is due to low-quality fuel, as well as oil getting on the valve and narrowing the gap in the valve.

Gearbox repair

In fact, it is not difficult to repair the box, but a professional will do it faster. Self-repair is also possible if spare parts are available. GAZ-53 is a very repairable car. Finding spare parts for it is now not a problem, and you can buy them in the markets at an affordable price.

Often, repairing a unit can be expensive. In this case, you can save money by replacing the box with a used one. The modern automotive market offers a lot of options. It is only recommended to agree in advance on the possibility of return in case of malfunction.

The plant produced many transmissions for these cars. Therefore, finding a used unit will not be difficult. Prices for units are affordable. You can also install a transmission from a GAZ-63 truck. It is completely identical and interchangeable.

Require topping up

Let us recall a joke from the 90s. A huge SUV has been sitting at the gas station for an hour. Fuel is poured into it, but the tank is not filled. The gas station attendant turns to the driver: “Perhaps you could turn off the engine?” In general, the gluttony of transport at today's gasoline prices has become a headache even for wealthy car owners.

On average, the price of AI-92 has increased by more than 6 percent since the beginning of May, and now this fuel costs almost 42 rubles per liter. And in some places the price reaches 45 rubles per liter of not the most environmentally friendly fuel. That is why interest in gas has almost doubled.

Let us recall that back in May 2013, the Russian government issued a decree “On regulating relations in the field of using gas motor fuel, including natural gas as a motor fuel.” According to it, at least half of Russian public transport will be switched to gas fuel. The planned amount of funding for the program until 2022 will be 110 billion rubles from the federal budget. However, before the May rise in gasoline prices, the issue of switching to natural gas motor fuel was not so relevant for private Russian car owners.

Along with rising prices for traditional fuel, a new problem has arisen. There are scams at many gas stations. That is, pour into the tank as much as will not fit there by definition. If the volume of fuel poured actually exceeds the technical capabilities of the car, this is not difficult to prove. Not a single gas station will enter into conflict. But if the driver simply knows that he can’t fit in so much, then this is not proof.

With gas, such fraud is practically impossible.