The abbreviation CV joint is an abbreviation for the phrase “constant velocity joint.” In driveshafts of rear-wheel drive cars, similar functions are performed by hinges consisting of a cross and cups with needle bearings. The only difference between them is that the cross provides a much smaller degree of freedom than the CV joint. But the cheapest CV joint is much more expensive than the most expensive spider. This circumstance increases the desire to extend its service life. For which, of course, you can use good lubricant and monitor the condition of the boot. Therefore, the question of what is the best lubricant for CV joints is natural. Timely replacement of a torn boot will also extend the life of the grenade if the lubricant is changed at the same time.

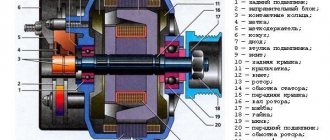

CV joint design

At the beginning of the last century, many CV joint designs were developed, which are used to this day. For example, cracker or cam, cam-disk, ball with dividing grooves or with dividing levers, with spherical rollers and a fork, paired cardan shafts. All CV joints have both advantages and disadvantages. The performance of each design is better for some conditions and not so good for others. Therefore, there is no question which design is more successful.

For external drive joints of modern fast passenger cars, the characteristics of a ball joint with 6 balls turned out to be better. The CV joint body and the inner ring under the separator, which keeps the balls from falling out of the CV joint, have the same number of grooves for them. The connection of the inner ring with the drive and the CV joint housing with the hub is splined. At large angles of rotation of the drive wheels, the maximum permissible torque transmitted by the hinge is much less than at small angles. Therefore, for long-term trouble-free operation of the CV joint, it is necessary to prevent it from working with a heavy load in the extreme positions of the steering wheel. Each CV joint is necessarily protected by a boot.

Tripoids are often used as internal grenades. They are less mobile, but more wear-resistant, since needle bearings are used in their design.

Types of CV joints and required characteristics for lubrication

“Grenades” (as motorists call ball and studded CV joints, due to their resemblance to this military device) come in three main types: balls with axial movement, simple balls and tripoids.

Ball CV joints

A whole family of ball CV joints, originating from the “progenitor” “Rtsep” with a dividing lever inside the hub. The maximum angle of rotation of such a hinge did not exceed 37⁰ , while the comfort of control largely depends on the maximum angle of possible rotation of the drive wheels. And the more degrees you can turn the wheels, the more comfortable the control - at least in terms of the smaller turning radius (which largely determines the convenience of parking).

Ball CV joints are used as external in contact with the wheel hub. Rotation from the shaft to the joint body is transmitted by balls sitting in a cage. The transmission of rotation is not hampered by either the vertical movements of the wheel hub during suspension operation or its rotation.

Such external hinges are balls sitting in a cage without the possibility of axial displacement along the shaft. They are located in a circle. Sometimes there is a support ball in the center of the structure.

Ball with axial displacement

They are installed as internal hinges, that is, in contact with that part of the transmission that is connected directly to the engine. They serve to compensate for inevitable axial displacements while the vehicle is moving on roads with varying degrees of unevenness. They are the same ball assembly, but with the possibility of axial movement of the ball cage inside the “glass” with a channel cut for each of the balls.

Classification – “universal CV joint type GKN”. The grooves for moving the balls in such a hinge are parallel to each other. But there are also hinges that are also used as internal ones, where such grooves converge in the form of a truncated cone (Lebro pita CV joint) or go around a metal sphere. Here the balls do not sit rigidly in the cage, with no possibility of moving them. On the contrary, they actively move in it and in the outer glass.

Spike tripods, or “tripods”

A compromise version of the drive from ball and ball with offset along the axes. In many ways, free from the shortcomings of their predecessors - although, strictly speaking, they are not real constant velocity joints. Fixed tripods, which do not involve the principle of axial displacement, can be either external (external) or internal. And even in cardan drives. An example is the transmission from the gearbox to the differential.

As varieties of this type of hinge, universal ones with the possibility of axial movement, tripods with rollers with angular adjustment, cam-disk CV joints and their variety “Tracta” . They have the maximum possible deflection angles when transmitting rotation (up to 50⁰). The axles can move due to the fact that the cages use needle bearings that move in conjunction with the body and the three-beam fork.

Lubricant composition for CV joints

For modern ball CV joints, lithium grease is used, most often based on mineral oils containing molybdenum disulfide as an antifriction additive (from 3 to 5%). Due to its black color, it can be confused with graphite grease, which should never be used in CV joints. Due to its weak anti-friction qualities, regular lithol cannot be used to lubricate CV joints either.

For tripoids, you cannot use the lubricant described above. For them, you can only use a special barium-based lubricant. One of its differences is the wide temperature range in which it can operate. After all, in winter the drive cools down to -30, and in summer it heats up to +160 ○ C.

Greases are made by thickening the base oil with various thickeners, which can be salts of higher carboxylic acids: lithium, calcium, aluminum, sodium and others. Inorganic thickeners, such as bentonite clay, and synthetic thickeners, for example, polytetrafluoroethylene, can also be used. As a rule, the lubricant contains up to 90% base oil, the remaining 10% consists of a thickener and various additives that determine the main characteristics of the substance.

In what cases does the CV joint lubricant change?

- When replacing a torn boot. In this case, it is necessary to change the lubricant

- After 100 thousand kilometers or after 5 years of operation of the CV joint.

If the drive is crunchy, it is too late to change the lubricant in it. The drive itself needs to be replaced. This is explained by the fact that if the hinge crunches, it means that it already has significant wear and no matter how much you change the lubricant in it, it will not get any better. To determine which of the joints has crackled, you need to select a flat asphalt area and drive along it, turning the steering wheel all the way to the left, and then all the way to the right. At this time, the assistant, being outside the car, must evaluate in which case the crunch is louder. If the sound is louder when the steering wheel is turned to the left, then the left outer drive needs to be replaced. When the crunch is louder with the wheels turned to the right, you need to change the right outer drive.

What lubricants should not be used

There are also a number of compounds whose use is not recommended. Among other things, it is worth highlighting the following types of compositions:

- graphite. Such substances are suitable as a lubricant for bearings and a number of other elements in electric motors. The use of graphite lubricant on CV joints is inappropriate, as this will lead to failure of the unit after 20-25 thousand kilometers. In addition, low-quality substances are often added to such compositions, which only further accelerate the wear of moving parts;

- hydrocarbon (including technical petroleum jelly). Yes, such compositions prevent the penetration of moisture and also inhibit the development of corrosion. At the same time, when the temperature reaches 45 degrees Celsius, the substance will begin to break down. Since the temperature in the CV joint is an order of magnitude higher, the use of hydrocarbon compounds will lead to deformation of the unit over time;

- consistency compositions made from calcium or sodium. They are suitable for bearings and a number of other moving joints, but in the case of CV joints they show complete incapacity and also contribute to the development of corrosion. After only 15-30 thousand kilometers, metal elements can completely fail;

- zinc. Such compositions, like iron-based substances, are completely contraindicated as transmission lubricants, since they lead to a deterioration in its functional characteristics, as well as complete failure.

How to properly change the lubricant in CV joints

Correct lubricant replacement. Replacing the lubricant in CV joints is done due to its contamination after the boot ruptures or its service life expires when it contains a lot of wear products. It is necessary to completely remove the old grease from the joint to eliminate the possibility of increased wear of the CV joint. To do this, it should be disassembled and thoroughly wiped with a clean rag. It will not be possible to wash it without disassembling it, because the grease is extremely difficult to wash off.

There are usually no difficulties with disassembling the internal hinge, so we will describe disassembling the external one. If you do not have a special tool for removing the outer hinge, then remove the drive assembly and clamp it in a vice. Remove the clamps from the boot. When removing, try not to damage them; the factory ones are usually better than those that come with the new boot. If the cover is torn, cut it off with a knife; if not, slide it onto the drive rod. Use a hammer to knock the joint off the drive using a drift on the inner ring. Turn the inner ring with the separator so that the holes in the separator are visible, and the symmetry axes of the separator and the housing will be perpendicular. Using a flathead screwdriver, remove all the balls from the separator. In the separator, two of the six holes are longer than the others. Turn the separator so that they are pressed against the walls of the housing and remove the separator with the inner ring from the housing. After adjusting the position of the inner ring, remove it from the separator. Remove any remaining grease from the parts as best you can, and the hinge can be assembled.

Insert the inner ring into the cage. Orient the cage so that the long holes in it are pressed against the hinge body, and insert the cage and ring into the body. Insert the balls into the holes of the separator and rotate the inner ring so that the hole for the drive is located along the axis of the housing. The unit requires from 120 to 150 g of lubricant. How much will fit in your case depends on the size of the hinge.

To properly fill the joint with lubricant, clamp it in a vice with the drive hole facing up. If you bought the lubricant for it in tubes, then press it into the hole under the drive, pressing the tube more tightly to the ring, until it appears between the separator and the housing. If you have it in a different package, then put it on with a spoon and press it into the hole for the drive with a cylindrical object of suitable diameter; The filling criterion is the same.

When installing the boot, do not put a lot of grease into it, otherwise it will tear it apart while the boot is working. Before tightening the boot clamps, lubricate the grooves for them with lithol.

How to change the lubricant

When the question of how to replace the lubricant has been decided, you should think about how to carry out this process. It is worth noting that the procedure is distinguished by its simplicity, so that even the most inexperienced drivers can easily cope with all this.

It is only important to follow the following points:

- disassemble the body. Quite often, two locking rings are used to secure it together. To remove them, you will have to use a flathead screwdriver;

- dismantle the boot and seals. It is very important to check the integrity of these elements. In case of visible damage, it is necessary to purchase a new element;

- we take out the internal parts, after which we completely disassemble them;

- We wash all elements with gasoline or solvent. This will help remove old grease.

It is also important to clean the internal walls of the case from the substance:

- put a little lubricant in a glass;

- place the tripod on the axis in its place;

- We report more substances. It is important to do this evenly to fill the case as much as possible;

- We assemble the unit.

Lubricant testing

The tests included the following checks:

- Rinse with water and protect the unit from penetration of this liquid into it.

- Fluidity when temperature rises to 180 ○ C.

- Lubricating properties.

- Resistance of the lubricating film to pressure.

- Wear of metals protected by lubricant.

Places during the testing process were not allocated to the competitors, they were simply graded, so you will have to determine which lubricant is better. Below are the results of testing of ball joint greases by one of the independent researchers.

- CV joint-4 manufactured by AZMOL JSC, Berdyansk. Rated "Good".

- CV joint-4M manufactured by Sibneft OJSC Omsk Oil Refinery. Rated "Good".

- LM 47 Langzeitfett manufactured by Liqui Moly GmbH (Germany). "Excellent" rating.

- Chevron Moly Grease EP 2 manufactured by Chevron Products Company, San Francisco (USA). "Excellent" rating.

- Castrol MS/3 Spezialfett manufactured by Castrol (Germany, Hamburg). "Excellent" rating.

- BP Energrease L21M manufacturer British Petroleum British oil and gas company.

Molybdenum grease and its application

Molybdenum grease is one of the most common lubricants for industrial units and machine systems. And this is not surprising. Molybdenum disulfide (MoS2) exhibits excellent extreme pressure and anti-wear properties, helps prevent premature aging of the metal and protect friction units during severe mechanical loads. The compound of molybdenum and sulfur is mined in the form of ore, then purified and takes the form of black fibrous crystals that, when rubbed, leave a gray-green mark. Lubricants with molybdenum disulfide are characterized by high adhesion to metal surfaces. This means that a protective microfilm is formed on the surface of the friction unit part, which levels the working surface, preventing the formation of scuffing and reducing the temperature in the friction area.

Distinctive properties of lubricants with the addition of molybdenum disulfide:

- High specific strength;

- Chemical stability;

- Temperature resistance;

- Low coefficient of friction;

- Good alloying properties;

- Anti-seize qualities.

NPP MAPSOL LLC has molybdenum lubricants in its product line, which are perfect for use in machine tool building and the automotive industry for lubrication of ball and roller bearings, worm gears and hard-to-reach components.

Greases with molybdenum disulfide under the MAPSOL trademark are the optimal choice for servicing units and mechanisms operating under heavy loads and high temperatures.

Properly lubricate the tripod joint

Despite the fact that the design of the tripoid hinge is based on the use of needle bearings, lubricating them with 158 grease, which is usually used for needle bearings, is strictly prohibited. The fact is that a lithium thickener is used for its manufacture, and it can work at a temperature no higher than 120 ○ C, and the temperature of the internal grenade reaches 160 ○ C. Since the lubricant for the internal grenade is quite liquid, it is better to pour it inside the boot installed on drive, and then assemble the tripoid. You need to fill in from 100 to 130 g of lubricant. More precisely, to the question, “how much?” the manufacturer will answer.

Barium

Recently, such CV joint lubricant has been in increasing demand on the market. The progressive composition allows you to extend the service life of the hinge, as well as protect it from a number of negative influences. The main advantage here is that the substance is not at all afraid of moisture.

Thus, if the boot ruptures, there is no need to change the substance. In addition, the lubricant has excellent corrosion resistance and is also suitable for use even in fairly aggressive conditions. The composition is chemically neutral, so the anthers will not be damaged, regardless of the material of the seals.

The main disadvantage of such a substance is its relatively high price, which is caused by the complexity of the production process. We produce only ShRB-4 lubricant; everything else has to be purchased in other countries.

At the same time, the latter option is even more expensive. Another drawback of this composition is its inability to withstand low temperatures.

What functions does a lubricant perform?

Motorists know that lubricants used in car components and joints not only reduce friction and prevent premature wear of car parts. But they also reduce the load on the parts, as a result of which the parts rotate freely and the car continues to move without friction or load.

CV joint lubrication allows you to reduce fuel costs and losses in transmission operation. A very important property is to prevent the spread of corrosion. It is during corrosion that the operation of CV joints is accompanied by the appearance of an unpleasant knocking noise, which intensifies when the steering wheel is turned and torque is not transmitted effectively. To prevent CV joints from getting dirty, boots are used. It is important to prevent grease from getting on the boots; they are made of rubber or plastic, which is eaten away upon contact with grease.

How to choose a lubricant?

Today, the best option for lubrication of CV joints are compounds containing molybdenum disulfide - they provide reliable protection against corrosion and can also significantly reduce friction in a car transmission. It is also worth knowing that lubricants containing sodium and calcium, zinc, graphite, iron, and hydrocarbon compounds cannot be used to protect CV joints - they cause significant damage to them and contribute to accelerated wear. In any case, before purchasing a specific lubricant, you will need to study the vehicle's operating instructions to find the manufacturer's recommendations. If we talk about brands of lubricant manufacturers, it is better to give preference to companies such as BP, Texaco, ESSO, Liqui Moly, Mobil. However, domestic lubricants SHRUS-4, Litol, Fiol, ShRB-4 and their analogues are practically not inferior to the products of the above-mentioned manufacturers in terms of basic properties.

When does the CV joint lubricant change?

The lubricant is replaced in the following cases:

- torn boot and its replacement;

- replacing the angular velocity adjustment hinge;

- CV joint operation for more than 5 years;

- mileage over 100 thousand kilometers.

You should not apply a large amount of lubricant, this will not provide better protection, but will only increase the likelihood of damaging the anthers. There should be enough lubricant so that the part is completely lubricated and no grease drips from it.

How much grease should I fill into the CV joint? It all depends on whether it is indoor or outdoor. For an internal CV joint, 100-110 grams is enough, and for an external CV joint, 70-80 grams.

Indiscriminate replacement

You can replace the lubricant in the CV joint without removing its components. To do this you need:

- Remove the CV joint itself from the car.

- Insert the tip of the tube and press the oil into the assembly.

- Press the tube tightly and wait until the color of the substance changes to fresh.

- Wipe the part, removing excess substance.

- Put the part in place.

Attention! This method has one drawback - a thin layer of old substance remains on the walls of the parts inside.

There is no need to rush to use the lubricated unit when driving. It is worth turning the assembly in place while the car is suspended on jacks. This is necessary to evenly distribute the lubricant over the parts.

Attention! On a car with an automatic transmission, with the wheels hanging, the pressure in the system will quickly drop.

The replacement process is not that complicated and if you have a minimum set of tools and skills, you can easily do it yourself. This will save money and allow you to get a better feel for the car. And remember, high-quality replacement of lubricant in CV joints cannot be done without removing it. If it is not possible to remove the assembly, then it is better to go to a car service center and see specialists.

- How to change the front silent blocks on a Mercedes 211 4matic

- How to change silent blocks on a Daewoo Nexia

- How to change silent blocks on Mazda cars 3-6

- How to change silent blocks on a Chevrolet Aveo: video

Types of lubricants

Along with the question: which CV joint is better, motorists are faced with the problem of choosing a lubricant. There are many different lubricants for caring for CV joints and each has its own advantages and disadvantages. Here we will consider only those that have proven themselves and are considered most suitable.

Lithium based greases

The most common lubricants are lithium foam lubricants in organic acid. These lubricants are yellowish in color and a little thick. In the cold they thicken even more, as a result of which spreading them on the part becomes a little problematic. This problem makes itself felt at sub-zero temperatures at the beginning of driving - you can hear the tapping of the CV joints and suspension. When all the mechanisms warm up, the car's operation is improved. Such lubricants reduce friction well and reduce the load on components by up to 10 times.

The big advantage is the neutralization of trapped dust and the ability to prevent moisture from reaching the parts. Another feature of lithium greases is that they are fully compatible with polymers that are installed on CV joints, with the exception of some hard plastics that are present on modern cars.

The disadvantage of lithium greases is that most of them have poor corrosion resistance. This is what you need to pay attention to first when choosing this type of lubricant.

Lithium-based lubricants can be used such as Litol-24, Renolit, Xado. These lubricants have already proven themselves on the market and have the most suitable properties.

Molybdenum disulfide based lubricants

Barium based lubricants

Recently, scientists have created many different lubricants for CV joints, but only one type combines the advantages of lithium and molybdenum without their disadvantages - barium lubricants. The main advantage of such lubricants is their high resistance to moisture. For example, if the boot ruptures, the barium-based lubricant can not be changed until a lot of dirt has accumulated in it.

Equally important is that such barium grease protects CV joints from all types of corrosion and does not dissolve boots made of any polymers. The only thing that this type of lubricant cannot boast of is the price and low resistance to negative temperatures. Barium-based lubricants are much more expensive than lithium and molybdenum lubricants due to the complexity of their manufacture and are much less common.

On the market you can find only one domestically produced barium-based product - ShRB-4.

What is a CV joint, its functions and types

Before we move on to talking directly about lubricants, let’s take a closer look at CV joints. This will be useful in order to find out what properties a lubricant for a “grenade”, as the CV joint is popularly called, should have, and what composition to use in a given case. The purpose of the hinge is to transmit torque from one axis to another, provided that they are at an angle to each other. This value can be up to 70°.

In the process of their evolution, the following types of CV joints were invented:

- Ball . They are one of the most common, in particular their variant “Rtseppa-Lebro”.

- Tripod . They are often used in the domestic automotive industry as internal CV joints (that is, those installed on the power drive side).

A feature of any angular velocity joint is high shock loads. They occur when starting a car, climbing hills, driving on uneven roads, and so on. With the help of special CV joint lubricants, all negative consequences can be neutralized.

Properties of lubricants for constant velocity joints

Due to the difficult operating conditions of the mentioned joints, CV joint lubrication is designed to protect the mechanism from negative factors and provide:

- increasing the coefficient of friction of the internal parts of the hinge;

- minimizing wear of individual parts of the CV joint;

- reduction of mechanical load on the components of the assembly;

- protection of the surfaces of metal parts from corrosion;

- neutral reaction with rubber joint seals (boots, gaskets) so as not to damage them;

- water-repellent functions;

- durability of use.

Based on the requirements listed above, the lubricant for the outer or inner CV joint must have the following characteristics:

- a wide temperature range, allowing the composition to be used at critical temperatures (modern CV joint greases are capable of operating at temperatures from -40°C to +140°C and above, this range depends on the specific brand of lubricant);

- high degree of adhesion (the ability to adhere to the working surface of the mechanism, simply put, stickiness);

- mechanical and physico-chemical stability of the composition, ensuring constant performance characteristics of the lubricant under any operating conditions;

- high anti-scuff properties, ensuring the proper level of sliding of lubricated working surfaces.

Thus, the characteristics of the lubricant for CV joints must fully comply with the given list. Currently, the industry produces several types of such compositions.

Why do you need lubrication anyway?

Any competent motorist understands why lubrication is needed. With its help, premature wear of metal elements that are subject to friction is prevented. In addition, such a substance allows you to reduce the load on components and allow them to rotate freely.

Grease for CV joints also performs a number of other important functions. Thanks to it, you can greatly reduce fuel consumption, as well as reduce transmission losses of the machine. In addition, such a substance helps prevent the occurrence of corrosion (namely, rust is mainly the cause of failure of CV joints).

If you are thinking about what you can replace the lubricant with, then you should choose substances that are gentle on organic matter and synthetic polymers. Indeed, for additional protection of this unit from external influences, anthers made of plastic or rubber are used. It is important that the lubricant does not dissolve such materials.

Why does a CV joint need lubrication?

It's no secret that manufacturers decided to lubricate some car parts with special technical fluids for a reason. There were reasons for this - tasks/problems that this liquid could minimize or solve. In a constant velocity joint such bases are:

- preventing the appearance and spread of corrosion - in metal elements it leads to the appearance of cavities, called cavities in CV joints, which significantly reduce the efficiency of the transmission and create a clearly audible knock when turning the steering wheel;

- reducing the coefficient of friction, ensuring free rotation of elements and, as a result, minimizing the load on the front axle transmission;

- reduction of energy losses during power transmission (less energy losses - less fuel costs);

- safety in relation to synthetic and organic polymers, because plastic or rubber boots are always used to protect the hinge joint from dust and dirt, so the lubricant used in this joint should not corrode them.

TOP 5 lubricants for internal (tripod) CV joints

EFELE MG-251

1

place

EFELE MG-251

0

/100

RATING

0

100

EFELE MG-251 is the best domestic grease for servicing internal CV joints of cars. Made from mineral oil and polyurea. Operating temperature range from -20 to +180 °C.

In addition to internal CV joints and other automotive components, the lubricant is used in sliding and rolling bearings, sliding guides for equipment in the textile, cement, and steel industries, conveyor systems, cooling units, electric motors, blowers, furnaces, etc.

The material has high extreme pressure, anti-wear and anti-corrosion properties, and excellent heat resistance. It pumps well into the CSS, is resistant to washout and has a long service life.

EFELE MG-251 is the best grease for servicing internal CV joints. Due to its high performance characteristics and low cost, this material takes 1st place in our TOP.

Kluber Stabatherm GH-461

2

place

Kluber Stabatherm GH-461

0

/100

RATING

0

100

Kluber Stabatherm GH-461 is a mineral oil and polyurea based grease designed for servicing internal CV joints. Operating temperature range from -20 to +180 °C.

The lubricant can be used in drying and firing furnaces, sliding bearings of lifting devices in foundries, conveyor systems, cooling baths, bitumen pouring machines, equipment in the automotive, glass, ceramic industries, etc. It is also suitable for use in centralized lubrication systems.

The material protects against corrosion, wear, and is resistant to washout and high temperatures. It pumps well and has a long service life.

Kluber Stabatherm GH-461 lubricant is similar in characteristics to EFELE MG-251, but the price of foreign material is much higher.

Mobil SHC Polyrex 222

3

place

Mobil SHC Polyrex 222

0

/100

RATING

0

100

Mobil SHC Polyrex 222 is a synthetic polyurea grease. Used for servicing internal CV joints. Operating temperature range from -30 to +160 °C.

In addition to internal CV joints, the lubricant is used in industrial equipment whose components operate at high temperatures, in particular it is intended for rolling and sliding bearings. It can be mixed with other polyurea or lithium complex greases.

Mobil SHC Polyrex 221 is resistant to stress, corrosion, high temperatures and water wash-off. In addition, the material does not oxidize under high temperatures.

Imported lubricant loses first place not only in terms of heat resistance, but also in cost, which is several times higher than that of the leader in the ranking.

Total Altis MV 2

4

place

Total Altis MV 2

0

/100

RATING

0

100

Total ALTIS MV 2 is a universal grease for internal CV joints. Made from mineral oil thickened with polyurea. Operating temperature range from -25 to +160 °C.

Lubricant is used as a primary material added to components at the factory. Can be used in high-speed fans and electric motors. Suitable for anti-friction bearings, steering systems, and components of general industrial equipment.

The material is thermally stable, protects against corrosion, and has good adhesion to metals. It does not contain lead or heavy metals and does not lose its properties during storage.

Total ALTIS MV 2 loses to the first three places in terms of performance. As for the cost, it is slightly more expensive than EFELE MG-251, but much cheaper than Mobil and Kluber lubricants.

MS CV joint tripod

5

place

MS CV joint tripod

0

/100

RATING

0

100

MS CV joint tripod grease is a mineral grease based on a lithium complex. Operating temperature range from -40 to +160 °C.

The material is intended for internal CV joints of any vehicles. In addition, it can be used in rolling and sliding bearings, where a lubricant with NLGI-1 consistency is required.

MS CV joint tripod lubricant does not contain solid additives (graphite, PTFE, molybdenum disulfide), penetrates into friction zones due to its consistency, and protects against wear and scuffing.

In terms of characteristics, this lubricant is inferior to other representatives of the rating, and there are complaints about the quality of the product.

How to choose a lubricant

Grease lubricating CV joints has a different appearance. Considering all the features and internal set of characteristics of lubricants, the most suitable option today is lubricants based on molybdenum disulfide. A good option, suitable for all cars, minimizing friction in the components and resistant to corrosion, with minimal impact on the boot. By lubricating each CV joint unit, you will extend its life. But still, when choosing a lubricant, you should follow the recommendations in the instructions for your car.

Lubricant for CV joints exists for good performance of the equal-velocity joint, reduces the level of rubbing, increases the efficiency of the system and prevents rust from forming on some parts of the joint. Many car owners are wondering what lubricant to use for CV joints? We have selected for you the material and their functions for comparison, which are in the range of lubricants. Also in the text we provide information for their use in practice, and what people say based on personal experience of using the six most common lubricants by many drivers.

We will look at these aspects:

- types of CV joints and the necessary qualities for lubrication

- types of lubricants used for angle speed joints

- type of lubricant used in severe conditions

- how to change the lubricant in a CV joint

- lubricant models for internal and external CV joints

- the best lubricant

characteristics of CV joints, its properties and varieties

Before moving on to describing the properties of lubricants, let's talk about CV joints. This is necessary in order to know what qualities lubricants for “grenade” lubricants should have, as CV joints are popularly called, and what composition to use in certain cases. The hinge exists in order to transmit torque from one axis to the second if it is located at an opposite angle. The value can reach up to seventy degrees.

Over the course of the existence of CV joints, the following were made:

Ball . These are the most popular, specifically their analogue “Rtseppa-Lebro”.

Tripod . They are often used in the Russian automotive industry as internal CV joints (those that are installed on the side of the power drive).

Crackers (also called cam ones). They often get hot, so they are installed in trucks where the rotation angle is low.

Cam-disk . These are also installed on trucks and construction vehicles.

Twin cardan shafts . Typically used on construction equipment and trucks.

At significant angles in the middle of the axes, the effect of the hinges decreases. In other words, the value that transmits the torque of the joint is smaller. Therefore, avoid heavy loads with the wheels deployed.

A special feature of each angle velocity joint is the large impact loads. They appear when the car starts driving, climbs, rides over potholes, etc. With special CV joint lubricants, all bad consequences are neutralized.

The current hinges work at the same angle speeds a lot (if you maintain the tightness of the boot), and even as long as the car will drive. The lubricant must be changed when replacing the boot or the entire CV joint. Although according to the manual, changing the CV joint lubricant should be done after 100,000 km of driving or once every five years (whichever is required earlier).

Characteristics of lubricants for joints of equal angular speeds

Since there are difficult operating conditions for the hinges, CV joint lubricant will protect the system from the negative and provide:

- Increased coefficient of rubbing of parts inside the hinge;

- Minimizes wear of some parts of the CV joint.

- Will reduce the mechanical load on the component parts.

- Protects the surface of metal parts from corrosion.

- Neutral reaction with rubber joint seals (boots, gaskets) in order not to spoil them.

- Repels water.

- Long lasting use.

About lubrication

Each vehicle component has its own operating and maintenance features. Before purchasing anything, you should read the instructions and find out the recommended lubricant.

Lubricant selection

If the manufacturer does not indicate which lubricant to use for CV joints, then you can use a universal product. You should choose carefully, since the device is operated under serious loads.

In auto stores you can purchase a special mixture, which differs:

This is required to keep the substance on the surface of moving parts even at high temperatures. The oil features:

- stability of characteristics under changing conditions;

- anti-corrosion properties;

- the ability to retain its original characteristics for a long time.

When to change the lubricant

The viscous substance in CV joints is replaced in the following cases:

- with a unit mileage of over 100 thousand km;

- when replacing the assembly boot;

- when replacing the CV joint itself.

The amount of lubricant required when replacing is indicated:

- in the car’s operating manual – not always;

- always on the packaging.

Molybdenum

A more progressive option, which is made from the same lithium soap, only now the additive is molybdenum disulfide. Lubricating properties are the same as the previous version. At the same time, molybdenum compounds have one important advantage - they have high anti-corrosion properties.

This was achieved by using metal salts in the composition, which replaced some acids. In addition, the substance is completely safe for rubber and plastic elements, so it will not lead to premature wear of the boot.

One of the disadvantages of such a substance is its low resistance to moisture. As a result, if even a little water gets under the boot, due to certain chemical reactions the composition turns into an abrasive. This only promotes friction, which leads to a number of CV joint failures. To prevent such a situation, it is necessary to regularly check the node.

There is also an opinion that the use of molybdenum lubricants leads to the restoration of damaged transmission components. This statement is incorrect, so if you hear a crunching noise in the CV joint, it is better to contact the service center technicians.

Among the most popular options available in our country are CV joints-4 and LM47 lubricants.