Bearing units of the front and rear wheels operate in difficult conditions, experiencing loads from friction, vehicle weight and impacts due to uneven road surfaces. In addition, they are heated on the brake side, since metal conducts heat well. Applying a high-quality composition to the working surfaces that reduces friction will help reduce the impact of these factors. In order to extend the service life of parts and not cause harm, you need to decide what kind of lubricant to lubricate the hub bearings and how to do it correctly.

Which wheel bearings are lubricated and when?

As mentioned above, closed double-row rear or front wheel wheel bearings are lubricated only during operation, on average after 50-60 thousand km. But it is recommended to check the hub assembly for lubricant leaks and for violations of the integrity of the seal, regardless of the ball or roller type of product installed.

Roller hubs are more resistant to load, but their service life is often shorter than that of ball hubs and they have a lower maximum rotation speed, and therefore the temperatures are lower there. They require more lubricant to ensure that the internal rolling parts do not overheat and become deformed.

If we talk about single-row tapered roller bearings (only this type of single-row is used in hub units), then they are more demanding of special lubrication, since they do not have seals and the lubricant often leaks out. For such units, you should be careful about the protective seals that are installed in units of this type.

Many cars use a prefabricated type of hub assembly design, when the bearing is combined with the hub. It is possible to lubricate a part in this design if there is a special hole, or if there is an open side with a soft seal - which is very rare. Such bearing units have an increased service life, so the amount of factory special lubricant is sufficient for the entire service life, but there are exceptions.

Additionally:

Read more about the types of hub units in the articles:

- Rear hubs and bearings and their replacement

- Front hubs and bearings and their replacement

When to lubricate a bearing

Replacing the grease for the hub bearings is required to increase the service life of the part and ensure its proper operation. Experts advise replacing lubricants after 20-30 kilometers in units with single-row standard sizes, and after 40-60 in closed double-row ones.

But in addition to natural wear, sometimes situations arise when it is necessary to add special lubricant, for example, in the summer it may decrease faster, or if there are small leaks of the oil seal or seal.

Maximum chassis reliability

To decide which lubricant will be the best option for protecting wheel bearings, be sure to pay attention to reading the vehicle's operating instructions. As a rule, the manufacturer indicates the type of composition that is approved for use or even the specific name of the product. If such instructions are not available, lithium grease can be used, which provides excellent protection against accelerated wear and corrosion. The domestic composition Litol-24 and foreign analogues have almost the same effectiveness of use, so you can ignore the brand name when purchasing. In addition, molybdenum disulfide-based lubricant is an alternative option, although it is not as resistant to moisture and has some other features.

What kind of lubricant is used in wheel bearings

The following types of lubricant are distinguished:

- Compositions containing lithium. One of the common ones. Available for sale, but there is a drawback - the virtual lack of surface protection from moisture. Representative – “Litol 24”.

- Temperature-resistant lubricators. It acquires heat-resistant characteristics due to copper and nickel powder. Other metals are also added. Typical products: Castrol LMX.

- With polyurea. A popular solution in the automotive industry. The lubricant contains: calcium sulfonate for stabilization. Resistant to temperatures up to 220 degrees Celsius. Example – AIMOL Greasetech Polyurea EP 2.

- With molybdenum. Has thermal resistance. Disadvantage: when connected to water, it releases condensation, which reduces the service life of parts.

- Perfluoropolyether. Used in racing models and premium cars. The high cost does not justify practical use.

Marking

The lubricant is indicated by the marking p/sh. According to GOST 3189-89, the manufacturer must provide in its products a lubricating component of a certain brand and in a certain quantity according to the standard.

| Lubricant brand | Sign |

| CIATIM-201 | — |

| OKB-122-7 | C1 |

| CIATIM-221 | C2 |

| VNIINP-210 | C3 |

| CIATIM-221S | C4 |

| CIATIM-202 | C5 |

| PFMS-4S | C6 |

| VNIINP-271 | C7 |

| VNIINP-235 | C8 |

| LZ-31 | C9 |

| N 158 | C10 |

| SIOL | C11 |

| VNIINP-260 | C12 |

| VNIINP-281 | C13 |

| FIOL-2U | C14 |

| VNIINP-207 | C15 |

| VNIINP-246 | C16 |

| LITOL-24 | C17 |

| VNIINP-233 | C18 |

| VNIINP-274 | S20 |

| ERA | S21 |

| SVEM | S22 |

| CV joint-4 | S23 |

| SEDA | S24 |

| INDA | S25 |

| LDS-3 | S26 |

| FINOL | S27 |

For example, 6-256907EK12С20. C20 is a type of lubricant.

Foreign manufacturers have their own internal standards. As a rule, lubricant designations are indicated in manufacturers' catalogs. For example, SKF and NSK have their own codes indicating the types of lubricants and the amount of volume put into a sealed bearing.

Recommended lubricants

What can be used to protect the bearing not only from high temperatures, but also from corrosion, and to ensure a minimum coefficient of friction? There are a number of well-proven formulations.

Disulfite-molybdenum agents

Considered one of the best. The lubricant contains molybdenum salt, which reduces the coefficient of friction. In addition, the material is capable of forming a dense protective film that “saves” the assembly from corrosion. There is one more important advantage: the service life of the lubricant coincides with the service life of the bearing itself, i.e. trouble-free operation of the hub over 100 thousand kilometers is guaranteed. There is also a minus - relatively rapid contamination. But if you don't allow the hub to depressurize, everything will be fine. There is one more point: it is worth checking the condition of the lubricant regularly if you constantly move at high speed. A signal for replacement will be a bluish tint to the product. Among the manufacturers of the composition, the most famous companies are Mobil, Castrol (British Petroleum), ESSO, Liqui Moly. Among the Russian brands, it is worth highlighting “Fiol” and the more expensive “ShRUS-4”.

Lithium greases

They are characterized by high resistance to friction, which guarantees an extended service life. Also, lithium products have a long service life: the product does not lose its qualities even after the car has driven 110 thousand km. Among the negative aspects, it is worth noting the average resistance to corrosion processes when compared with lubricants on a different basis. Another disadvantage is the substance’s ability to dissolve some polymers, this is due to the fact that the composition contains organic acid. Therefore, before using lithium grease, read the car manufacturer’s recommendations about the permissibility of using such a product.

Lithium grease is produced by several foreign companies, the most famous of which are Renolit, British Petroleum, Very Lube. But you can also use the Russian analogue, known on the market under the brand “Litol 24”. This is a composition that successfully copes with elevated temperatures, friction and actively fights corrosion. Another serious plus is the affordable price.

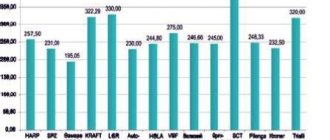

Lubricant rating for wheel bearings. Which is better

What kind of lubricant is better to use in hub assemblies if the choice of the best auto lubricant is influenced by several indicators:

- Characteristics of parts/assemblies

- Temperature

- Moisture level

- Climatic conditions

- Reviews

- Manufacturer

- Owner preferences and cost of goods

Based on the above indicators, a rating list of preferred brands was compiled.

| Name | Short description | Price for 2022, rub. |

| LIQUI MOLY LM 50 | The lubricator is characterized by resistance to different temperature conditions. The base is lithium substance. | 865 ₽ – 400 grams |

| SKF LGWA 2 | Consists of minerals and lithium. Used at high operating temperatures. Effective in wet conditions. | 889 ₽ — 200 grams |

| Step Up HIGH TEMPERATURE WHEEL BEARING LITHIUM GREASE | Suitable for all types of spare parts. Contains metals with anti-corrosion properties. | 730 ₽ – 450 grams |

| Castrol LMX Li-Complexfett 2 | Consists of a thickener. Includes minerals, lithium. No additional additives. | 790 ₽ – 400 grams |

| Motul Tech Grease 300 | Plastic. Used under high loads. Withstands temperatures up to 200 degrees. | 340 ₽ – 200 grams |

| Mobil XHP 222 | The main element is lithium. Designed specifically for high-load conditions. Provides good protection against corrosion and water. Temperature resistant. | 410 ₽ – 700 grams |

LIQUI MOLY LM 50

Special grease for wheel bearings, blue. It belongs to the lithium type, or more precisely to the second class NLGI greases.

- Shows resistance to severe operating conditions, does not lend itself to corrosion, oxidation, or exposure to water.

- Complies with the German industrial standard DIN 51502 KP 2 P-30.

- Temperature range of application: from -30°C - +160°C short-term +200°C

Video – LIQUI MOLY LM 50 friction test

SKF LGWA 2

A plastic composition that consists of lithium and minerals. Used in conditions of extreme temperatures and loads. In terms of moisture resistance, it is one of the best in its class. Developed by SKF: leading on the list of bearing manufacturers, but this is also a minus, since it is difficult to find on store shelves.

- operating temperature – up to 220 degrees,

- active lubrication under loads and low frequencies,

- anti-corrosion properties.

Recommended for use in trucks, trailers, and ordinary cars.

Step Up HIGH

The base substance is lithium. Contains metal inclusions with anti-corrosion properties. Retains useful characteristics when exposed to foreign solutions, dirt, and moisture. Other characteristics include:

- able to withstand temperatures up to 250 degrees;

- load – 1166 N;

- speed up to 10,000 rpm.

A characteristic feature is high temperatures. Used in severe frost or heat in the southern regions of the country. Installed on sports cars that are subject to high loads.

Castrol LMX Li-Complexfett 2

A lithium thickener is used for plasticity, the base is mineral oil and with a package of additives. Resistance to hardening, reduced oil release, as well as adhesion to metal surfaces. Suitable for high hub temperatures.

- green color;

- retains properties at -35° C;

- easily washed off with water;

- does not tolerate direct sunlight;

- temperature – up to 260 degrees.

It is important to know:

At temperatures above 70°C, oxidation of the lubricant occurs. With each increase in temperature above this threshold by 10 °C, the oxidation rate increases by 2 times. Therefore, compositions with a high temperature limit, by definition, always have better resistance to oxidation at high temperatures.

Motul Tech Grease 300

The lubricating complex is developed using mineral and synthetic solutions with the addition of a lithium element. Class - NLGI 2. Green in color. Additives included: extreme pressure, anti-wear, antioxidant and anti-corrosion.

- anti-scuff properties;

- temperature – from -30° C to +150° C during continuous operation, up to 200 – under load;

- corrosion resistance;

- retains properties at -30° C;

- does not wash off, stays on the surface;

- maintains resistance under high loads.

Mobil XHP 222

Belongs to the plastic type. Manufactured on a lithium base. Development using special technology to provide increased protection. Mobilgrease XHP greases are available in NLGI grades 00, 0, 1, 2 and 3 with ISO VG 220 base oil viscosity. Dark blue color.

- resistance to water;

- ensuring adhesion to a metal surface;

- protection against corrosion formation;

- resistance to destruction under high temperature conditions.

Lubrication Instructions

Product evaluation criteria

A quality product must have the following characteristics:

- Water resistance. The performance qualities of the lubricant should not deteriorate upon contact with moisture; it must reliably protect the metal elements of the wheel bearing from corrosion. It is desirable that the product be water-repellent and form a continuous film on the surface.

- High temperature protection. Thermal lubricant should not be destroyed when heated: wheel bearing units, working under conditions of strong and constant friction, can withstand up to +120 degrees Celsius , accordingly, the consumable material must retain its qualities under equally strong heating.

- Freeze resistance. It is necessary that the products do not freeze at temperatures down to -35... -40 degrees , otherwise in winter the bearings will begin to jam.

- Chemical composition safe for metal elements.

- Preservation of lubricating properties during sudden thermal fluctuations.

Different car manufacturers recommend lubricants with different compositions, so it is advisable to select products that meet the requirements of the concern that produces cars of a particular make and model. This is especially important for foreign cars, which are more sensitive to the quality of consumables.

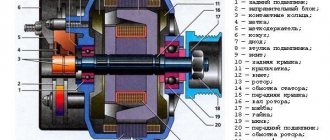

How to Lubricate an Open Tapered Wheel Bearing

As a rule, two open tapered wheel bearings are installed in the hub assembly. If you are installing new parts when replacing old ones, you must carefully lubricate the inner races along with the rollers, then the outer races on the inside, and only then install the roller bearings.

If you are lubricating already installed parts, then consider the procedure step by step:

- Place the transport on a flat surface.

- Loosen the wheel bolts and hub nut.

- Raise the wheel with a jack.

- Dismantle the wheel to remove the hub nut.

- Next, depending on the wheel (front or rear), we dismantle the steering knuckle (if front) or the brake drum (if rear).

- Remove the hub, remove the sealing protective washer (oil seal).

- Next, remove the inner races.

- Remove the old lubricant, wash the races in oil (it can be slightly heated). Wipe the parts dry.

- Apply new lubricant to clean races so that it gets inside (into the separator and onto the rollers).

- Wipe the inside of the hub, along with the outer races.

- Insert the inner clips and assemble the assembly.

- Install the parts in reverse order.

Photo report:

Watch the process on video:

Video of the process with removal and disassembly:

How to lubricate a sealed wheel bearing without disassembly

Enclosed front or rear wheel bearings usually have metal shields that cannot be removed without damaging them. Because of this feature, lubricating closed types of bearings is problematic, but there are several life hacks.

Advice:

Note that in any of the methods it is impossible to completely remove the old lubricant. It is recommended not to deliver the old lubricant, but simply add new one.

- Lubrication with heated lithol through a syringe with a needle.

- We heat the lubricant in the bath to a liquid state, but here it is not allowed to exceed the maximum temperature.

- We pour the liquid into a medical syringe and introduce the composition inside through a small gap between the ring and the protective washer or between the inner rings, as in the photo below.

Note:

If the inner races are moved apart a little, a gap is formed into which we pump new lubricant under strong pressure.

- Make “injections” evenly over the entire diameter.

- Please note that not all bearing sizes are suitable for this method.

- Pressing in the lubricant with a syringe from the tube. The process is clearly shown in the video. The difficulty is that it is difficult to find a large syringe of suitable diameter.

Video: “Lubricating a closed bearing”

Video: “How to Lubricate a Sealed Ball Bearing”

- We use an industrial vacuum cleaner and use suction to lubricate the ball bearing cavity. An interesting way, watch the video.

Video: “Lubricating a closed bearing through a vacuum cleaner”

- Removing the protective washer. This is done with a sharp small screwdriver or an awl.

- Carefully pry the edge of the washer along the entire diameter.

- Try to deform the seal as little as possible and avoid damaging the rubber lip.

- To install the element back, you need to straighten it, then put the washer exactly in its original place.

- Select a pipe or spacer with an outer diameter such that the edge is located exactly along the outer diameter of the washer, as shown in the photo.

- Next, you will need a press to push the washer into place, or use a vice.

- If necessary, carefully press the edge of the washer into the groove using a screwdriver.

Photo report:

Video: “How to lubricate a closed wheel bearing”

Note:

Of the above methods, it is recommended to use No. 4.

How to lubricate a non-removable structure

When the bearing and flange are connected, problems with the procedure arise. In this case, you will have to disassemble the part, removing the cage, balls, and separator. For some types of structures, such an operation is impossible, or vice versa, manufacturers designly provide a hole for lubrication. Let's give the most common example, when there is no hole and it is necessary to disassemble the hub.

- We start disassembling from the inside of the joint venture.

- Use a screwdriver to press between the two inner races and remove the inner race with the metal boot.

- Having removed the cage, we see the oil seal, as well as the rolling elements and a plastic separator.

- We pry up and remove the oil seal.

- Next, carefully remove the inner ring.

- Clean separators from old composition. Wipe all parts with a rag.

- Separators vary significantly in configuration and size.

- We apply a new lubricant to the track of the rolling elements.

- We install several rolling elements for lubrication.

- We insert the separator and the remaining rolling elements into it. Add a lubricant.

- We close the balls with the inner race, turn the hub over and continue the assembly process.

- Apply special lubricant to the working surface (path).

- We insert the separator with the rolling elements into the cavity of the joint venture. Add a lubricant.

- Install the oil seal with the metal side facing the inside of the hub.

- The part is ready for installation.

Photo report:

Video: Through-hole lubrication process

Stories of car owners

“I was wondering whether it is necessary to lubricate the wheel bearing before installation, since it should already be prepared for use. I decided that the manufacturer himself was puzzled by this problem, but, as practice has shown, no, the next day I had to disassemble and lubricate everything again.”

Owner of VAZ 2114:

“I started to notice that there was a certain squealing noise coming from the rear wheel. A similar sound appeared only when the speed was about 90 km; it did not happen either lower or higher. Having reached and removed the rear hub, it became obvious that the grease content was extremely low, I added it and everything was fine.”

“Once I lubricated the bearing and everything began to work like clockwork, but after a while the problem returned, and soon. Again I had to disassemble the wheel and when I got to the hub fixing ring, everything became obvious, it was poorly secured and because of this the lubricant was gone, and the bearings were filled with debris. I cleaned it, lubricated it, and the swallow began to fly again.”

Frequently asked questions about lubrication and its replacement

How much lubricant is required?

The volume of lubricant added is regulated by standards. But to put it simply, high-speed rolling elements are installed at 40-50% or less of the internal free volume. If the ball bearing is low-speed (less than 1000 rpm), then it can be filled with almost 100% of the volume.

Should I lubricate a new wheel bearing?

When a new part is purchased when directly replacing the front or rear wheel bearing, the new closed-type parts are not lubricated for 30-40 thousand kilometers, as they are supplied from the manufacturer with factory lubricant. When installing an open roller bearing, it is recommended to lubricate according to the instructions.

Should the grease be blue?

The blue color does not convey information about quality and composition. In the well-known “158” auto lubricant, the blue color was imparted by an antioxidant additive based on copper inclusions.

“158th” was durable, used in hinges and cardan joints. Now unscrupulous manufacturers add blue dye, thereby promoting it as “the best.”

Why don't they use Litol24?

This type is rarely used, but Litol-24 still has its advantages: it is a reliable thickener based on lithium soap, with excellent water resistance. The thickness of Litol helps to lubricate all surfaces well, and the low price is also a plus.

However, for such critical components as joint ventures, it is recommended to use only imported lubricants designated in accordance with the NLGI classification:

- NLGI LA and NLGI LB.

- NLGI GA, NLGI GB and NLGI GC.

Lubricant for wheel bearings and truck hubs

From the samples presented, I recommend buying SKF LGWA 2 or Motul Tech Grease.

How to lubricate the wheel bearing of a VAZ, Gazelle, Niva?

For passenger cars, lubrication requirements depend on the design feature (roller or ball). For VAZ, buy any auto lubricant from those presented in the review; for Niva and Gazelle, Motul Tech Grease is suitable.

Is it possible to mix wheel bearing greases?

It is not recommended to mix formulations. The decision is explained by the fact that different types of auto lubrication are used in different conditions. By mixing substances, you risk reducing their original qualities and properties.

Choose a product based on the operating conditions of the vehicle and following the tips presented in the article. An exception would be if it is not possible to remove all the grease when adding it to a sealed ball bearing.

How to lubricate a wheel bearing without removing it

Whether or not to remove a part depends on the design of the unit. In the case of a closed version, it is recommended to remove the ball bearing at least from the hub (without pressing out). For open units, it will be possible to apply the compound only to the outer roller bearing, since it will not be possible to reach the inner one - it is closed with an oil seal.

Additional Tips

The service life of the lubricant is usually from 35 to 45 thousand kilometers traveled. But it is very important to take into account the conditions and intensity of use of the vehicle. Before purchasing, it would be a good idea to read the recommendations of the car manufacturer.

When choosing a lubricant for wheel bearings, the following factors must be taken into account:

- Steel type. The iron from which the element is made is of great importance.

- Intensity of vehicle use. If the car is used constantly, the lubricant must withstand stable loads.

- Load level. When it comes to components and mechanisms that are subject to maximum load, it is necessary to select appropriate lubricants.

- Bearing type, speed and frequency of its rotation.

- Level of protection of the mechanism from dirt and moisture.

Experience suggests that the optimal solution for many will be to purchase high-temperature lubricant. Otherwise, the substance will quickly leak out and the bearing will run dry. Before using a new product, be sure to remove any remaining old substance from the assembly. You need to lubricate the bearing wisely - saving sooner or later will lead to a wedge, and if there is an excess of substance, it will begin to be squeezed out.