VAZ 2110 fuel pump injector, VAZ 2112 fuel pump, etc. — electric fuel pumps, installed on many VAZ models with an injector. The operation of this type of fuel pump is partially controlled by an electronic control system (ECM), which takes into account the air-to-fuel ratio, throttle position and exhaust composition.

The VAZ fuel pump (2110, 2112) is designed to supply fuel from the gas tank to the vehicle’s internal combustion engine. In this case, fuel from the car’s gas tank must be supplied uninterruptedly to the internal combustion engine, and under a certain pressure. This is the key to stability and reliability of the car’s power unit.

If the fuel supply is disrupted or stopped altogether, there is a high probability of failure of one of the devices in the overall fuel supply circuit. One of these elements is the VAZ 2110 (21102) fuel pump. Next, we will look at why the pump can fail, what its malfunctions are and how to fix them.

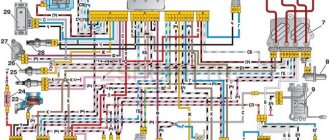

VAZ 2110 fuel pump diagram

The electric fuel pump 2110 is a fairly simple device - the unit is an electric motor, which is supplied with a voltage of 12 V. The fuel pump is installed in a housing, and a mesh is installed at its inlet - a coarse filter. The filter element prevents dirt particles from entering the pump housing, which prevents clogging of the device.

The VAZ BN connection diagram includes the following elements:

- The engine control unit.

- Ignition.

- Wiring.

- Relay.

- Fuse.

VAZ 2110, produced before 2000, were equipped with mechanical fuel pumps.

It consists of the following parts:

- Metal body.

- Return spring.

- Top cover.

- Two valves.

- Diaphragm pusher.

Fuel is pumped from the tank by oscillating the diaphragm and opening and closing valves. The diaphragm with a pusher is driven by the camshaft eccentric, and the manual pumping lever is located on the lower casing of the fuel pump.

VAZ 2110 does not pump the fuel pump, reasons

First, let's look at breakdowns of mechanical refueling. All parts of a car engine are subject to aging and wear, and the life of a mechanical fuel pump also ages over time.

The main malfunctions in the operation of a mechanical device include:

- Valve fault.

- Diaphragm rupture.

- Shell deformation.

If the diaphragm is leaking air, the fuel pump may stop delivering fuel to the carburetor, or gasoline may pass through the ruptured diaphragm into the crankcase, where it mixes with the engine oil. When fuel gets into the oil, fuel consumption increases sharply and the engine begins to have difficulty starting, especially when warm. Checking the presence of fuel in the crankcase is quite simple - if you light the oil dipstick with a lighter, a fire will start. In addition, the sump will smell like fuel.

A common malfunction of mechanical fuel pumps is deformation of the mounting surface of the oil cylinder to the auxiliary housing. If the surface is deformed, engine oil begins to flow out at the meeting point of the planes.

Now about the electric fuel pump.

If it stops working, there may be several reasons for the failure:

- The fuel pump motor burned out.

- The relay has stopped working.

- The fuse has blown.

- Faulty electrical wiring.

- Engine control unit malfunction.

Repair kit

A Bosch fuel pump repair kit consisting of rubber products will help you make repairs.

Everything described above shows that your desire alone is not enough for the fuel pump repair to be carried out efficiently. It also requires high professionalism of the craftsman and special equipment. This repair technique can only be implemented at equipped service stations. In addition, large stations have a large number of used parts that can be used. If these conditions are met, two-thirds of the total number of failed fuel pumps can be efficiently repaired.

Real life proves that after restoration, fuel pumps can work for quite a long time.

Where are the fuel pump relay and fuse located?

The relay in every electrical circuit is designed to open and close the circuit; its primary role is to protect the elements of the electrical circuit from high inrush current. When starting the engine, the current required to turn the starter is 80-300 amperes, and if the relay is not installed, any element of the electrical circuit may fail.

On “tens” the fuel pump relay is standard, the plastic case has an electromagnetic coil and core, after applying voltage as a result of exposure to an electromagnetic field, the contacts close. On the VAZ 2110 the relay is four-wire and rated for a current of 30 A.

The fuel pump relay on the VAZ 2110 (injector) is located inside the car, under the instrument panel, near the center console. After removing the plastic protective cover, the relay responsible for the operation of the fuel pump will be in the center of three elements located in this place (in the figure, numbered 5). To the left of the relay is the fuel pump fuse.

How to check and replace the fuel pump relay

If the electric fuel pump does not show signs of life after turning on the ignition, this does not mean that it has burned out. The cause of failure may also be the “relay”. The easiest way to test the pump relay through your ear is to hear a clicking sound when you turn on the ignition. If you don't hear a click, the relay is probably bad.

However, not everything is so simple - the breakdown can be “complex”, for example, the car does not start the first time. The cause of the malfunction may be burnt out relay contacts.

In this case, checking the operation of the pump is very simple:

- Remove the protective cover covering the fuse and relay box.

- Unscrew the fuse box and remove it, it will remain attached to the wires.

- Remove the relay from the block and place a jumper between the 2 opposite contacts, this will power the fuel pump directly.

- If, with this connection, the pump motor begins to make noise, then the pump itself is probably working and the problem is in the relay. In this case, the relay must be replaced.

Coarse and fine fuel filters: where they are, when and how to change them

Russian gasoline is not always of the same quality, so over time, sediment accumulates in the tank due to low-quality fuel. Dirt also clogs the sieve of the electric fuel pump; as a result of accumulated dirt, fuel does not completely enter the fuel line and the engine fails. To fix the problem, you need to replace or clean the coarse filter. However, to get to the filter, you need to disassemble the fuel pump.

The fuel system must be relieved of pressure before disassembling, otherwise fuel may leak into the vehicle when disassembling the fuel line fittings. To relieve pressure, remove the fuel pump fuse, start the engine and wait until it goes out. Replacing the fuel pump sieve with a “ten” (nozzle) is done as follows:

- Turn off the ignition.

- In the rear, locate the hinges and pull them to fold the lower seats forward (right and left).

- There are two bolts under the seat on the underside that hold the hatch in place.

- Unscrew the bolts and remove the hatch.

- Disconnect the wire connector that supplies power to the electric fuel pump by opening the latch and pulling part of the connector away from you.

- We unscrew the fuel line connectors - main supply and “return” (17mm wrench).

- Unscrew the nuts of the fuel pump pressure plate, there are 8 bolts (at 7mm).

- Since the nuts are small, it is better to put them in a jar, otherwise you can lose them. Remove the plate and remove the pump assembly from the fuel tank. The pump must be removed with the sealing ring; lift the pump carefully so as not to damage the fuel level sensor. When removing the housing, tilt the fuel pump so that it comes out of the tank.

- We remove the screen from the fuel pump and install a new part.

- Install the fuel pump.

No power to fuel pump 2110, how to check and fix

The wiring goes to the BN in the amount of three wires: fuel level sensor, minus and plus. The reason why the fuel pump does not pump may simply be a lack of power. To check the power supply to the fuel pump, you need to take a 12V light bulb and connect its wires to the negative and positive terminals on the external BN connector. After turning the key in the ignition switch, the warning lamp should light up. If this is not the case, the problem is in the external circuits. To do this, connect the negative and positive contacts removed from the HD connector alternately to the ground of the fuel pump, and then to the relay.

If the negative contact is on the ground, the ignition is on and the light is blinking, the contact does not work, the light does not blink, then the positive contact is not working. If the contact on the relay and the light is on, the wiring harness is damaged. in the section from the BN to the relay.

Product selection

AvtoVAZ offers an original fuel pump for 4,000 rubles. The original catalog number is 2112-1139009 . But many car enthusiasts buy and install cheaper analogues instead of the original.

Analogs

Bosch fuel pump.

A non-original part is often no different in quality from the original. So, if the vehicle owner wants to save money, then you can install a non-original part. Let's consider the main offers of analogue companies:

- Fenox EFM33006O7 - the cost of such a part will be about 3,000 rubles.

- Bosch 0 560 454 035 - as they say, I took BOSCH, and ... (go ahead).

- Ween 192-0262 – the price on the spare parts market will be approximately 3,000 rubles.

- Pekar 2112-1139009 - will cost a little more than the previous two, the average price is 3,500 rubles.

- ATS 53453 - they praise, but the price tag is good. We know they put one like this as a replacement for expensive originals on Peugeot.

ATS fuel pump.

Why does the fuel pump on the VAZ 2110 not work?

The fuel pump on the VAZ-2110 is submersible and is installed in the gas tank located under the body, near the rear seat. When the ignition is turned on, the driver should hear the sound of his work, because at this time the pressure in the fuel supply line, the engine power system, increases. Its operation involves an electronic unit, a fuel pump relay and a fuse that protects the circuit from overload.

If, after turning the ignition key to the “on” position, you do not hear a short sound of the fuel pump, the car engine will not start. Finding the cause of this malfunction should begin by checking the fuse. You should look for it not in the mounting block, but in the interior of the car. To do this, unscrew several screws on the right side of the front console on the passenger side and remove the plastic cover. You will then see three relays in front of you and three fuses.

In the center of this row there will be a fuel pump relay, and to the left of it there will be a fuse that protects the electrical circuits of the fuel pump and injectors. Remove it and check the integrity, at the same time check the contacts on which it is located. If they have oxidized, they should be cleaned. If the fuse is intact or intact, replace the fuel pump relay with a known good one or ask other drivers for a new one.

If even in this case the fuel pump does not work, it will have to be checked for functionality. To access it, remove the rear seat cushion. Underneath you can see a hatch with a metal cover, the screws securing the hatch are unscrewed and in the opening you can see the upper part of the tank on which the fuel pump is installed.

Disconnect the wiring harness and try to power the fuel pump directly from the battery. If it works, then the fault must be in the wiring from the fuel pump or electronic control unit (ECU).

If our car has an alarm system that has the function of turning off the fuel pump, the positive power wire of the fuel pump is cut, and in its place an additional relay is installed, which, if the car is broken into, should turn off the fuel pump, due to which the engine will stall and not restart. In this case, this relay should also be checked.

If actions to eliminate this malfunction do not bring results, you will need to go to a service station to see diagnosticians, since self-testing of the electronic control unit is unlikely.

Advantages of injection models

The main function of the pump is to supply fuel to the combustion chamber. It must meet certain requirements. The main criterion is pressure.

The pumps for injection and carburetor engines are different. Thanks to the engine with direct fuel injection, there is no need for preliminary preparation of the combustible mixture. As you know, the carburetor is the weak link. Difficult adjustments, clogged jets, difficult starting in cold weather create inconvenience for owners of classic VAZ brands.

Tens and VAZ-2112 internal combustion engines have significant advantages. Let us note the advantages of injection units:

- support for environmental standards;

- direct injection into the combustion chamber;

- fuel economy;

- system reliability;

- increased engine power;

- starting a cold unit without warming up;

- dispensing a portion of the mixture;

- The fuel module is controlled electronically.

Problems with the operation of the VAZ 2110 fuel pump

Every motorist wants to be confident in the reliability of the components of his car, one of which is the VAZ 2110 fuel pump. By delving into the possible causes and ways to eliminate its errors, you can avoid unplanned cash costs and a waste of time. Diagnosing a faulty fuel pump and repairing it is simple.

Purpose of the fuel pump, characteristics and possible breakdowns

The fuel pump is designed for uninterrupted supply of gasoline to the internal combustion engine (ICE) of a car. Since, depending on the gasoline supply system, cars are divided into carburetor and injection, respectively, the VAZ 2110 pump comes in two types: mechanical and electric. The mechanical fuel pump is unpretentious, repairable and does not cause problems in operation, but currently does not meet the parameters of environmental friendliness and performance.

The current requirements are met by an injection injector, which helps to implement the VAZ electric fuel pump. It supplies gasoline to the internal combustion engine through high-pressure injectors, which facilitates fuel metering, reduces wear and increases engine power. The main characteristic is the pressure of the fuel pump, which can range from 4 to 7 atm.

Due to pressure fluctuations or lack thereof, the car engine is unstable, does not start and causes problems at the most inopportune moment. At the same time, by showing self-control and using the recommendations presented here for repairing a VAZ fuel pump, you can correct the situation in a short time.

The main symptoms of a malfunction of the VAZ 2110 fuel pump are as follows.

- There is no roar of rotation of the fuel pump (it is located in the fuel tank under the rear seat) at the initial moment of starting the engine (the key is in the ignition position). The reason may be the failure of the VAZ fuel pump itself, loss of power on it.

- Unusual operating noise may be caused by an empty fuel tank or a severely clogged fuel filter.

- Low power of an internal combustion engine (operation only in 1st or 2nd gear) is typical for a fuel pump used by more than 90,000 people. km. Due to real operating conditions, the service life of the VAZ pump is reduced, which is manifested by a decrease in pressure.

- A jerking car means that the pressure in the fuel pump system is changing, usually due to a clogged filter.

After determining the type of fuel pump problem, it makes sense to find the cause to fix the problem.

How to ensure an uninterrupted supply of gasoline

A car with a carburetor always uses a mechanical fuel pump, while an engine with fuel injectors always uses an electric fuel pump. Pressure drop: the injector creates a lot of pressure in the fuel system, this is not necessary for the carburetor.

How does a mechanical fuel pump work?

The operating principle of a mechanical fuel pump is quite simple. The fuel pump pusher constantly moves back and forth, but the diaphragm moves to the lower plane only when it is necessary to fill the chamber with fuel. The return spring moves the diaphragm to the up position and fuel is supplied to the carburetor.

The mechanical pump consists of the following parts:

- fuel chamber;

- inlet and outlet valve;

- diaphragm;

- return spring;

- pusher and camshaft.

Since carburetor engines are becoming less and less common, the principle of an electric fuel pump is much more interesting. Moreover, it is installed on all engines with injectors.

Electric fuel pump operation

The principle of its operation is in many ways similar to mechanical. It is based on a solenoid valve that retracts a diaphragm until a pulse is sent to a group of contacts, causing the circuit to open and apply voltage. The valve opens the chamber; after the voltage is removed, the valve closes the access of fuel.

The electric fuel pump consists of the following components:

- chamberfuel;

- inlet and outlet solenoid valve;

- diaphragm with return spring;

- fine filter;

- contact Group.

In general, the mechanism of a conventional fuel pump is equipped with electrical devices. If the mechanical pump is located under the hood, look under the rear passenger seat for the electric fuel pump.

Selecting a fuel pump

The pump power in an engine with injectors must be at least 7 atmospheres. It is better to choose from a range of imported models. A high-quality product not only serves without complaints for many years, but also extends the life of the engine. At the outlet of the injectors, the quality of the fuel-air mixture increases.

Bosch products are a great example of such a device. They can be distinguished by their significantly longer length, and sometimes by a different arrangement of contacts. Therefore, in order to avoid reworking and adjusting the device in standard places, it is recommended to go to the store with the faulty pump removed.

The main thing is not to buy fakes. The original Bosch fuel pump is packaged in a sealed container filled with purified gasoline. There should be no smell of gasoline from the packaging. If so, the seal is already broken and corrosion may have begun.

Features and replacement rules

If you follow the instructions, the process won't take long. The procedure is as follows:

- disconnect the negative terminal from the battery and thereby disconnect the voltage from the on-board network;

- Tilt the rear seat back and locate the fuel pump cap;

- Open the cover by unscrewing the screws, then disconnect all connectors;

- loosen the fuel hose clamp (there is no need to remove it completely);

- unscrew the fuel hoses;

- remove the gaskets (replace if possible);

- unscrew the fuel pump mounting bolts and remove the ring;

- Remove the pump from the fuel tank and replace it with a new one.

Assembly is carried out in the reverse order of disassembly. A faulty pump is rarely repaired, since after eliminating one fault another may appear. Therefore, it is recommended to immediately replace the device; besides, prices in stores are not very high. With proper practice, replacing the fuel pump will take no more than half an hour. All activities must be carried out strictly according to the instructions and not engage in amateurism. Otherwise, you may lose the device due to a breakdown, or you will have to turn to car service specialists for help, and this also costs money.

Signs of damage

A malfunction of the fuel pump is indicated by an increase in noise during its operation. This indicates natural wear of the supercharger or severe scuffing of its rubbing parts. This nuisance often appears in winter due to the fact that moisture gets into gasoline, which then becomes ice. The resulting ice crystals fall into the millstones of the fuel pump, abrading and tearing the parts of the supercharger, forming deep cavities on their surface. Defects often appear in the guide grooves of the supercharger rotor.

Troubleshooting, simple tips for reliable operation of the fuel pump

- If the VAZ fuel pump does not spin, first of all you need to check the serviceability of the fuses and relays by replacing these parts. They are located behind the console panel on the lower front passenger side. If their condition is satisfactory, to check their operation, the supply voltage must be supplied directly to the fuel pump. To do this, remove the rear seat cushion and open the cover secured with screws. It should be remembered that if the alarm is installed, the power supply to the VAZ pump will have an additional shutdown relay during run-in. If the fuel pump does not respond to voltage or you need to check and replace the filter, follow these steps to remove the fuel pump from the fuel tank. To relieve pressure in the fuel lines, turn off the fuel pump with the fuse and start the car. After stopping the engine, open the gas tank at the filler neck to relieve gasoline vapor pressure, disconnect the negative clamp from the battery (to prevent fire), disconnect the electrical connector from the pump mounting flange on the gas tank, and disconnect the gasoline hose. connections (it is necessary to replace the gas-tight rubber ring on the trunk), unscrew the flange (8 7 mm hex nuts), remove the rubber gasket and remove the VAZ fuel pump complete with a float and a strainer (pre-covered with a cloth nearby so as not to contaminate the interior with gasoline). Pump filter main points of its effective operation:

- Driving a car with an empty fuel tank is an extreme challenge for the gas pump, and in the long run it costs much more than simply filling up;

- The gasoline pump “does not like” suspicious gasoline, which also leads to frequent replacement of the filter and pump;

- When replacing a VAZ 2110 fuel pump, preference can be given to imported analogues, which have higher pressure and whose operation is more stable.

- To feel like you own a car means to take care of it like a family member. In this case it will last a long time. And every trip will be counted as gratitude to the owner for his care.

- Domestic cars have a significant advantage: spare parts and consumables are cheap. In addition, everything is structurally very simple. That's why our cars are easy to repair yourself. However, if you are a beginner and have never serviced or repaired equipment before, you should not gain experience in the industry by replacing a gas pump. To start getting acquainted with an independent car service, it is better to choose simpler tasks. If you dare to replace the fuel pump with your own hands, then you need to remember that the mechanism is installed in the fuel tank strictly so that the indicator arrow points towards the rear of the car. After completion, it is recommended to measure the pressure in the fuel system and make sure there are no leaks.

Replacing the electric fuel pump

Such a replacement is carried out in the following cases:

- failure or incorrect readings of the fuel sensor;

- weak throughput effect or defect in the fuel intake grid;

- failure of the electric fuel pump.

The tools you will need are a screwdriver and a 10mm socket wrench with a wrench.

- Reduce pressure in the fuel supply system.

- Using the fuel supply hose tip clamp, disconnect 2 hoses in turn.

- Disconnection should be carried out slowly, without using unnecessary force, so that the fuel block fittings remain intact.

- Unscrew the 8 nuts around the circumference of the clamping ring and remove it.

- A wire with negative polarity is attached to one of the nuts; it must be removed carefully.

- We take the electric pump block out of the fuel tank, tilting it slightly, to keep the fuel level indicator sensor lever intact, otherwise it will produce incorrect parameters.

- Remove the sealing rubber ring of the fuel block. If its properties are lost, the product must be replaced.

- Install the product in reverse order.

Important: during installation, the installation arrow on the electric pump cover must point towards the rear of the car!

Important: when installing fuel hoses, follow the direction of fuel supply indicated by the arrows!

Many people ask where the VAZ 2110 fuel pump relay is located? Let us clarify that this electronic device is located in a special recess on the front passenger side of the floorplane. You need to unscrew the plastic cover, there will be 3 relays. Closer to the hood is the required part.