The gas tank of any car always contains vapors formed due to a decrease in atmospheric pressure or heating of the fuel. In order to prevent the leakage of fuel vapors into the vehicle, a special gasoline vapor recovery system (VPSU) is installed. Thanks to it, the vapors retained by the adsorber (essentially activated carbon) enter the intake manifold and burn in the engine cylinders. To regulate the amount of gasoline vapor coming from the adsorber to the manifold, a special solenoid valve is used.

How to diagnose an adsorber malfunction yourself

As a rule, no serious malfunctions occur with the automobile adsorber, which is due to its simple design and the absence of serious loads. However, over time, the filter layer becomes clogged, which can be judged by a number of indirect signs. The first and fairly obvious signal indicating a malfunction of the adsorber is increased pressure in the gas tank. When it is opened, a strong hiss will be heard, and in some cases the tank cap may simply be knocked off, which can result in injury to the car owner.

Many drivers who do not know why an adsorber is needed in a car and what it is, in the situation described above, do simply - open the tank several times a day, releasing air from it. More “knowledgeable” people can completely exclude the adsorber from the fuel system, not considering it an important element. Both of these actions are fundamentally incorrect, since the absence of an adsorber, as well as its malfunction, significantly reduces engine power, “floating” idle speed appears, and fuel consumption increases noticeably.

It is worth understanding that the presence of an adsorber in a car not only increases its environmental friendliness, but also leads to fuel savings, which without this element would simply evaporate while the car is not in use. This is due to the fact that when the fuel is heated, its vapors “leave” the fuel tank and initially enter the separator, which retains the bulk of them. Condensation occurs in it, and the fuel in liquid form is returned to the tank. The same part of the evaporation that did not have time to condense ends up in the coal filler, where it safely remains, subsequently participating in the process of enriching the mixture.

Malfunctions, symptoms and solutions

Due to the extreme simplicity of the design, the adsorber in the VAZ-2114 has two malfunctions: it is clogged or the solenoid valve does not work. If this part breaks, the following problems may appear in the operation of the car:

- Unstable engine operation at idle (speeds fluctuate). To check, you need to disconnect the hose between the throttle assembly and the purge valve and plug it. A candle, for example. If the engine speed does not become normal, then the adsorber is clogged.

- When you unscrew the gas tank cap, you hear a hissing sound or gasoline vapors squeeze it out of the filler neck.

- Poor acceleration due to decreased pressure in the fuel line. If the purge valve is faulty, atmospheric air does not enter the tank. This leads to the fact that when the engine is running, a vacuum is created in the gas tank, interfering with the operation of the fuel rail. Also, a strong vacuum can lead to the tank being severely deformed by the force of atmospheric pressure.

- No repetitive clicking noises during overclocking.

Features of adsorber removal

What is ABS in a car and why is ABS needed? How does the anti-lock braking system work

? If you decide to completely remove the adsorber, you will need:

- replace the gas tank cap with a leaky one;

- replace the firmware of the electrical control unit;

- plug the outlet and supply pipes.

As mentioned earlier, before removing the adsorber, you should think about the advisability of such an action, since there are no unnecessary parts in the car.

But even if you decide to delete it, this process should be taken seriously. First of all, you need to take care of the ventilation of the gas tank, which is simply necessary in the absence of an adsorber. Those car owners who convert a carburetor engine to an injection engine have an undeniable advantage. If they do not touch the tank pipes, then they will not be able to disrupt the carburetor ventilation system. In this situation, there is no need for an adsorber in such cars. In the case of the VAZ-2114 car, which has an injection engine, everything is much more complicated. However, there is no need to remove the adsorber either. It should be noted that the only positive aspect of having an adsorber is the reduction in the amount of harmful emissions into the atmosphere of our planet. The undeniable “disadvantages” of this part include the rather high cost, as well as too much space occupied by the adsorber under the hood. It is the last two facts that, as a rule, become the reason for making a decision to remove it.

But most often, car enthusiasts remove the adsorber after it has failed. Its cost is so high that car owners come to the conclusion that they are not really concerned about the state of the Earth's atmosphere. Moreover, removing this part is quite simple. To do this, you need to put a fine filter on the separator hose. Now all gasoline vapors will go directly into the atmosphere. In this case, there is no need to close the hose from the valve. But if the Check Engine bothers you, then you should adjust the ECU control program so that this light stops glowing on the dashboard.

Any car is a fairly serious source of environmental pollution. To minimize this effect, automakers use many technologies that reduce the amount of harmful emissions into the atmosphere. Among the simplest methods for increasing the environmental friendliness of a car are a catalytic converter and a fuel vapor adsorber, which should not be released into the atmosphere. This is required by the Euro-3 standard. In addition to the fuel vapor adsorber, many modern cars are equipped with catalytic converters that reduce exhaust toxicity.

The principle of operation of the fuel vapor adsorber is quite simple - it collects fuel vapor, sending it back for afterburning. This eliminates the possibility of “emission” of gasoline vapors into the atmosphere, and also ensures more stable and sustainable engine operation. Many car owners do not know why an adsorber is needed and do not consider it an important element of the fuel system

In fact, in addition to a purely “ecological” function, it has another important practical significance - it maintains normal pressure in the fuel tank

Excessive pressure in the tank is formed due to active evaporation of fuel, which is observed in two cases:

- when atmospheric pressure decreases;

- when heating the fuel itself, which is observed in the summer under the influence of sunlight, or when returning fuel heated in the engine, but not used during combustion.

In the absence of an adsorber, many motorists are faced with the problem of difficulty opening the gas tank cap, which occurs when the pressure in it is increased.

How to check the adsorber

Static ignition systems. How the system works

Now let’s move directly to the algorithm for checking the adsorber (its other name is the fuel vapor accumulator). The main task in this case is to determine how sealed its body is and whether it allows fuel vapors to escape into the atmosphere. So, the check must be performed according to the following algorithm:

Adsorber housing

- Disconnect the negative terminal from the vehicle battery.

- First, disconnect all hoses and contacts going to it from the adsorber, and then remove the fuel vapor accumulator directly. This procedure will look different for different machines, depending on the location of the assembly, as well as the mounting means with which it was secured.

- It is necessary to plug (seal) the two fittings tightly. The first one goes directly to atmospheric air, the second one goes to the solenoid purge valve.

- After this, use a compressor or pump to apply a slight air pressure to the fitting going to the fuel tank. Don't overdo it with pressure! A working adsorber should not leak from the housing, that is, be sealed. If such leaks are detected, then most likely the unit needs to be replaced, since it is not always possible to repair it. In particular, this is especially true if the adsorber is made of plastic.

It is also necessary to perform a visual inspection of the adsorber. This is especially true for its body, in particular, for rust spots on it. If they occur, then it is advisable to dismantle the adsorber, get rid of the mentioned spots and paint the body. It is imperative to check whether coal from the fuel evaporation accumulator is leaking into the EVAP system pipelines. This can be done by inspecting the condition of the adsorber valve. If it contains the mentioned carbon, then you need to change the foam separator in the adsorber. However, as practice shows, it is still better to replace the adsorber completely than to engage in amateur repairs that do not lead to success in the long term.

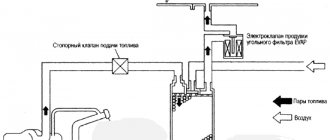

Gasoline vapor recovery system operating principle.

The engine is switched off.

Car gas tank device and principle of operation

When the car engine is turned off, pressure is created in the fuel tank due to the evaporation of fuel. Fuel vapor enters the separator. Fuel can also get there under pressure when the tank is fully filled. If gasoline enters the two-way valve pipeline due to excessive pressure, the blocking and safety valves will operate. In this case, an emergency release of pressure to the outside occurs.

The separator is used to separate vapors from gasoline. Under the influence of pressure, a two-way valve opens and vapors enter the adsorber through the pipeline, where they are absorbed by activated carbon.

Work after starting the engine.

After starting and idling the engine, due to fuel consumption and a decrease in its volume, the pressure in the gas tank decreases and the two-way valve closes. This leads to disconnection of the adsorber and the gas tank. Subsequently, when the engine is idling for a long time, an even greater vacuum is created in the tank and, under the influence of vapor pressure from the adsorber, the two-way valve opens and the adsorber is partially purged, that is, part of the vapor is returned to the tank. When the car speed is above 20 km/h, the engine temperature is not lower than 80 degrees. C, the calculation of the fuel supply to the cylinders will be carried out in a closed cycle, that is, with the participation of the oxygen sensor readings and the engine will not operate at idle speed (the throttle valve is open more than 2%), the process of purging the adsorber will begin. In this case, the controller will briefly begin to supply power to the adsorber purge valve.

The pulse frequency depends on the engine operating mode and is within 16 Hz. When the purge valve is activated, the adsorber filter element communicates with the atmosphere, from where outside air comes, and with the intake manifold, where gasoline vapors evaporated from the filter element enter. When the vehicle speed decreases below 2 km/h or the throttle valve is opened more than 98%, the controller stops supplying power to the canister purge valve.

admin02/10/2011

A comment

Name *

Website

This site uses Akismet to reduce spam. Find out how your comment data is processed.

“Oxygen sensor design, purpose, operation.

Ignition distribution »

Tags

VAZ, VAZ malfunctions Sensors Ignition Injector Devices Starter Circuits Electric cars Power supply VAZ 2110 gazelle gazelle business recorders car repair

Recent Entries

- Laser headlights.

- Advantages and disadvantages of halogen lamps

- Design and principle of operation of parking sensors

- Multifunctional device Roadgid X7 Hybrid GT

- Malfunction of the GAS ignition system

Archives

Archives Select month September 2022 August 2022 July 2019 December 2022 August 2022 July 2022 June 2022 May 2022 April 2017 March 2022 December 2016 November 2016 October 2016 September 2016 August 2016 July 201 6 June 2016 May 2016 April 2016 March 2016 February 2016 November 2015 October 2015 August 2015 July 2015 June 2015 May 2015 April 2015 March 2015 February 2015 January 2015 December 2014 November 2014 October 2014 September 2014 August 2014 July 2014 June 2014 May 2014 April 201 4 February 2014 January 2014 December 2013 November 2013 October 2013 August 2013 June 2013 May 2013 March 2013 February 2013 January 2013 November 2012 October 2012 September 2012 August 2012 July 2012 June 2012 May 2012 April 2012 March 2012 February 2012 January 2012 December 2011 November 2011 October November 2011 September 2011 August 2011 July 2011 June 2011 May 2011 April 2011

Categories

- Accumulator battery

- Video

- Generator

- Sensors

- Diagnostics

- Ignition

- News

- Equipment

- Devices

- Repair

- Spark plug

- Starter

- Scheme

- Devices

- Electric cars

- Electricity supply

We are in social networks

Autoelectrics@ All rights reserved. When copying site materials, you must provide a link to the site.

From which Euro standards is it installed?

According to international requirements, the installation of an adsorber is mandatory on cars with Euro-2 standards and higher. As for the standard known in Russia (Russia-83), there is no installation of an adsorber here.

So, in VAZ-2108 cars there is no adsorber. Here the separator and the fuel tank are connected to each other using a drain tube.

During operation, condensation occurs and returns to the fuel tank.

In addition, the separator interacts with the atmosphere using a 2-way valve, which does not allow the pressure in the tank to increase or decrease.

The connection between the tank and the neck occurs using a gasoline-resistant tube, fixed with clamps. It turns out that when the pressure in the tank decreases (increases), fuel vapors escape into the atmosphere.

The system is organized differently in VAZ Priora cars. Here, the fuel vapors that entered the separator from the fuel container condense. The condensate then accumulates and returns to the tank.

A gravity valve is mounted in the upper part of the separator, which prevents the fuel mixture from leaking out of the tank if the machine overturns.

If the engine is started, the vapors of the fuel mixture are mixed with air masses and discharged through the throttle assembly into the intake pipe - to the cylinders of the power unit.

It turns out that fuel vapors in a stationary position of the car accumulate in the adsorber, and if the car is moving, they are purged by the valve and sent to the receiver and to the engine for afterburning.

According to Euro-2 requirements, the fuel tank ventilation must not come into contact with ambient air, and vapors must be collected and directed to the engine (or adsorbed by the device in question).

As for the Russia-83 standards, contact between the atmosphere and ventilation of the fuel bank is not prohibited.

How the system works - operating principle

Why am I focusing on the solenoid valve, because it is practically the key one in this system.

For a better understanding, I am posting a diagram of an injection car, and in this case it is a VAZ of the 10th family.

So, fuel vapor rises to the top of the tank and stops at the separator, which is combined with a gravity sensor (as I wrote above, it prevents fuel from leaking out in the event of an accident - capsizing from the tank). In it they partially condense and return back (in the form of liquid fuel).

However, the other part of the evaporation bypasses the gravity valve and passes into the adsorber, where they actually accumulate. Accumulation occurs when the engine is not running! IT IS IMPORTANT.

After starting the engine, the solenoid valve opens - thereby connecting the adsorber cavity (where the gases are trapped, as it were) with the intake manifold or throttle assembly (in different cars in different ways). THE PROCESS OF THE SO-CALLED PURGE BEGIN! The vapors are mixed with air (from the street), which is supplied through the throttle assembly, then enter the intake manifold and then into the engine cylinders, where they are burned with the air-fuel mixture.

The system is very simple if you understand how it works.

Operating principle of the adsorber

Many people mistakenly believe that when the engine starts, voltage is immediately applied to the canister valve and it opens, purging the canister. I even saw “manuals” and “training videos” about this. In fact, the purge valve is controlled by the ECU using special algorithms based on readings from temperature, air flow, etc. sensors.

The greater the engine air consumption, the longer the duration of the ECU control pulses and the more intense the purging.

It is impulses, and not just the supply of voltage! Therefore, there is such a thing as “adsorber purge duty cycle,” which ranges from 0% to 100%. Here is the duty cycle of the canister purge in the Chevrolet Explorer diagnostic program

During the entire trip, this is only the first signal from the ECU to purge, equal to only 6%. So this is a complex and important process in engine operation.

Here is the duty cycle of the canister purge in the Chevrolet Explorer diagnostic program. During the entire trip, this is only the first signal from the ECU to purge, equal to only 6%

So this is a complex and important process in the operation of the engine.

Operating principle

So, what does the process of purging the adsorber in a VAZ 2114 look like? When the car is parked, gasoline from the tank evaporates and first enters the separator. There, some of the vapor turns into liquid and flows back. The remaining gaseous fuel, moving along the line, enters a sealed adsorber. Activated carbon absorbs vapors and holds them until the engine starts.

Signs of a malfunctioning canister valve

As it becomes clear, problems arise with the power system:

- The revolutions are floating. But not immediately, but after about 5 - 10 minutes on a warm engine

- At idle, if the engine is running, you press the gas pedal - it almost stalls. Feels like we're running out of fuel

- While driving, the car does not develop the required power, it feels like 10–15% of the engine power has been removed

- The fuel tank sensor may go crazy. It shows either “full” or “empty”, etc.

- If you open the tank to refuel. A strong whistle is heard, as if a vacuum has been created inside.

- Fuel consumption increases

- When cold, the absorber sensor can knock loudly and is often confused with engine valves

Now a useful video.

If you experience these malfunctions, then you definitely need to look - check the valve and, if necessary, change it, fortunately it costs a penny. And also the cavity itself with activated carbon.

What is the threat?

Of course, you can continue to travel on roads with such a fault. The car will start to drive, but it will still have floating idle. In addition, if the malfunction of the adsorber is not corrected in time, then at the nearest gas station, when trying to fill the tank with gasoline, the cap can literally “shoot” from the gases that are formed, which are not removed in time. So it would be best to replace the defective part with a new one.

In addition, if the gas tank is poorly ventilated, this can lead to a vacuum. And as a result - deformation and damage to such an important spare part as the fuel pump. And an unventilated adsorber can also cause fuel accumulation in the intake manifold. And this can already affect the stability of the entire engine.

Canister valve. How to check it

The principle of checking on most cars is the same, but we will look at the example of the Chevrolet Lacetti.

Problems with the canister purge valve can be divided into several main points:

- impulses do not arrive to the valve

- Valve coil failure

- valve stuck open

- valve jamming in closed position

It is very easy to check the pulses, wiring and valve winding with the Chevrolet Explorer program, in the “mechanism control - canister purge valve test” tab. When you click on the “ON” button in the program diagram, we will see the following signals

This means that the ECU is giving a command to the valve. At the same time, the sound of clicks will emanate from the valve in time with these signals, which, in turn, means that the pulses reach the valve and the winding is intact, since the valve is activated.

By the way, if you don’t have a diagnostic adapter yet, then I advise you to definitely read the diagnostics section and purchase an adapter.

The electrical part is OK. We checked this. But to be sure that the valve is not physically jammed, it can be removed and checked. It is very easy to dismantle and it takes me no more than 30 seconds.

Two tubes and a block with two wires are connected to the valve. The valve itself is not even screwed on, but simply inserted into its working place.

In the photo one tube has already been removed.

To remove the valve, just pull off the two tubes marked with a green and a red arrow (the red one has already been removed, and the green one is hard to see from this angle). The tubes are removed simply and easily without any clamps.

Then press the metal lock and unfasten the wire block (shown by the yellow arrow)

After this, press on the fitting shown by the red arrow and the valve will come out of its seat.

The valve is normally closed, that is, without voltage applied it does not allow air to pass through. You need to check this in any available way - with a rubber bulb, an inflatable ball, etc.

I had on hand a syringe and a piece of vacuum tube left over after replacing the absolute pressure sensor tubes.

When moving the syringe piston, resistance should be felt, and the piston itself tends to return to its original position, which means sealing the valve. When removing the tube from the syringe, a characteristic puff should be heard. This means that the adsorber valve is closed hermetically.

All that remains is to check the opening of the valve. To do this, we take two wires with such mini-mothers

And connect it to the adsorber valve connector. You can carefully and simply use a wire without a tip.

Move the syringe plunger and connect the wires to the battery. When connected, you should hear that same zilch sound, which means that the valve has opened and released pressure.

It happens that the valve does not open. Then just replace it with a good one.

That's all the simple methods on how to check the adsorber valve.

Peace and smooth roads to everyone!!!

I like 41+

Members who liked this post:

Removal and inspection

2. Having released the latch, disconnect the wiring harness block from the canister purge valve.

3. Connect the negative voltage probe (to the car body).

4. Turning on the ignition, use a voltmeter to measure the supply voltage at terminal A of the wiring harness block (the pins are marked on the block).

Comment. The voltage at the terminal must be at least 12 V. If the voltage does not flow to the block or it is less than 12 V, it means that the battery is discharged, the power circuit is faulty, or the ECU is faulty.

5. Use a Phillips screwdriver to loosen the clamp securing the hose to the canister purge valve.

6. Remove the hose from the valve nozzle.

Advice. If the hose on the nozzle is seated tightly and cannot be disconnected, then you can remove the valve from the adsorber and, by rotating the valve, remove the hose from it.

7. Using a screwdriver, remove the valve from the adsorber.

8. We apply 12 V voltage from the battery to the valve terminals (“+” to terminal A, “-” to terminal B).

Comment. When voltage is applied to the terminals, the valve should open with a characteristic click. The faulty valve must be replaced.

The principle of operation of the adsorber on the VAZ-2114

First, you need to understand what adsorption is. So, this is a certain process due to which the absorption of liquid and solid gaseous substances is carried out. A striking example of this can be the world’s first gas masks, where Activated Carbon acted as an adsorber. In the VAZ-2114 car, the adsorber is approximately the same device, only its design has become much more complex. A car adsorber today is a plastic case, inside of which there is a special filler that can trap gasoline vapors, thereby protecting the atmosphere from pollution. But this detail on the VAZ-2114 is not limited to this. The fact is that the adsorber also includes various valves and pipes.

The adsorber has no effect on fuel consumption at all, since its main purpose is to improve the environmental friendliness of the car. As the gas tank empties, fuel vapor rises up the neck and then enters the separator. At this point it again acquires a liquid state, as a result of which it returns to the tank. Some of the vapor that failed to condense ends up in the above-mentioned adsorber. The latter, by the way, is filled with the same Activated Carbon, designed to absorb harmful gases. It is quite remarkable that this process occurs with the engine turned off.

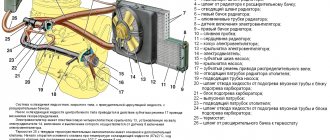

Components

In fact, this is a large plastic jar with activated carbon inside, because it is this composition that perfectly fights gasoline vapors. The main parts can be described as follows:

- Separator + gravity valve

- Pressure meter

- Filter part (usually carbon)

- Connecting tubes

- Solenoid valve

As you can see, there is absolutely nothing complicated. Separator - serves to catch part of the gasoline, then sends it back to the tank. Gravity valve - almost never used, but it is needed in emergency situations, for example during accidents, it prevents fuel from overflowing from the tank (for example, when a car overturns).

The pressure sensor is a very necessary thing - it monitors the pressure of gasoline vapors inside the tank, if necessary, it opens and resets it, preventing the structure from being damaged.

The filter part is, as I wrote above, a large jar into which coal powder is poured, in fairly large granules. This is done so that vapors can pass and condense freely.

Connecting tubes are needed to connect all the main parts, filters, sensors and valves, I think this is clear.

Solenoid valve - used to switch modes for capturing gasoline vapors, we will talk about it in more detail below.

How to check the adsorber valve

If after checking it turns out that the adsorber is in more or less working condition, then it makes sense to check its purge solenoid valve. It’s worth mentioning right away that for some machines, due to their design, some actions will differ, some of them will be present or absent, but in general the verification logic will always remain the same. So, to check the adsorber valve, you must perform the following steps:

Canister valve

Visually check the integrity of the rubber hoses included in the fuel vapor recovery system, in particular those directly approaching the valve. They must be intact and ensure the tightness of the system. Disconnect the negative terminal from the battery. This is done to prevent false alarms of the system diagnostics and to enter information about the corresponding errors into the electronic control unit. Remove the absorber (usually it is located on the right side of the engine, in the area where the air system elements are installed, in particular the air filter). Turn off the electrical power to the valve itself. This is done by removing the electrical connector (the so-called “chip”) from it. Disconnect the inlet and outlet air hoses from the valve. Using a pump or medical bulb, you must try to blow air into the system through the valve (into the holes for the hoses)

It is important to ensure the tightness of the air supply. To do this, you can use clamps or a thick rubber tube. If everything is in order with the valve, it will be closed and air will not be blown through

Otherwise, its mechanical part will fail. You can try to restore it, but this is not always possible. It is necessary to supply electric current from the power supply or battery using wires to the valve contacts. At the moment the circuit closes, you should hear a characteristic click, which signals that the valve has actuated and opened. If this does not happen, then perhaps instead of a mechanical failure there is an electrical failure, in particular, its electromagnetic coil has burned out. With the valve connected to an electric current source, you must try to blow air into it in the manner described above. If it is working properly, and therefore open, then this should work without problems. If it is not possible to pump through air, then the valve has failed. Next, you need to reset the power from the valve, and there will be a click again, indicating that the valve has closed. If this happens, it means the valve is working.

You can also check the adsorber valve using a multifunctional multimeter, switched to ohmmeter mode - a device for measuring the insulation resistance value of the electromagnetic winding of the valve. The probes of the device must be placed at the coil terminals (the places where the wires coming from the electronic control unit are connected to it; there are various design solutions), and the insulation resistance between them must be checked. For a normal, serviceable valve, this value should be within approximately 10...30 Ohms or differ slightly from this range. If the resistance value is small, it means that there is a breakdown of the electromagnetic coil (short interturn circuit). If the resistance value is very large (calculated in kilo- and even mega-ohms), then the electromagnetic coil breaks. In both cases, the coil, and therefore the valve, will be unsuitable for use. If it is sealed into the housing, then the only way out of the situation will be to completely replace the valve with a new one.

Please note that some vehicles allow a high insulation resistance value on the valve coil (in particular, up to 10 kOhm). Check this information in the manual for your car. Thus, in order to know how to check whether the adsorber valve is working properly, you need to dismantle it and check it in a garage.

The main thing is to know where its electrical contacts are located, and also to perform a mechanical inspection of the device

Thus, in order to know how to check whether the adsorber valve is working properly, you need to dismantle it and check it in a garage. The main thing is to know where its electrical contacts are located, and also to perform a mechanical inspection of the device.

Useful video

You can get additional information about the design of the adsorber and options for replacing it from the video below:

1200 rub. for the photo report

We pay for photo reports on car repairs. Earnings from 10,000 rubles/month.

Write:

Many car owners may be interested in the question of how to check the adsorber and its purge valve when the diagnostics showed it to be faulty (an absorber error popped up). It is quite possible to make such a diagnosis in a garage, however, for this it will be necessary to dismantle either the entire adsorber or just its valve. And to carry out such a test, you will need metalworking tools, a multifunctional multimeter (to measure the insulation value and the “continuity” of the wires), a pump, and a 12 V power source (or a similar battery).

Changing the device yourself

To change the adsorber, it is enough to perform a number of simple manipulations. In this case, there are two solutions - do the work yourself or go to a service station, entrusting the problem to specialists.

The advantages of the first option are cost savings and high speed of work. The sequence of actions is as follows:

The work time is 15-20 minutes.

As soon as the faulty unit is dismantled, proceed with the installation of a new device.

Here the sequence is as follows:

- Connect a long piece of rubber tube to the hose through which fuel vapors flow into the purge channel.

- Connect the short part of the tube to the intake tube from the separator.

- Put the adsorber in place.

- Connect the vapor supply pipe to the purge channel, which is installed on the motor cover.

- Connect the block with wires.

- Install a tube between the purge channel and the adsorber. Make sure that the material from which the pipe is made is resistant to oil and gasoline.

Possible malfunctions in the operation of the device

The VAZ 2114 absorber, due to its intended purpose, is susceptible to clogging and at some point may become faulty. Problems are not easily determined and often only by secondary symptoms, for example, increased pressure in the fuel tank. It’s just that gasoline vapors, due to wear of the separator, remain locked in the space of the tank and begin to put pressure on its walls. An increase in pressure can be detected when the tank cap is unscrewed and a characteristic hissing sound is heard.

Sometimes the gas tank cap simply shoots out of the neck, which means that the pressure has reached a critical level and the adsorber must be urgently changed. If there is a problem with the adsorber, the engine speed begins to jump up and down. Many car owners write on forums that you can remove the VAZ absorber and not suffer. But everything is not so simple, and there are never unnecessary parts in cars.

Removing the absorber alone is not enough; you need to think about what to do with gasoline vapors that have nowhere to be discharged, and that the ECU may also have to be reconfigured. After all, some types of on-board engine processors find a malfunction in the purging of the fuel system and put the engine into emergency mode, in which it will not be possible to drive normally.

As for malfunctions, the problem area of this adsorbent system is the purge valve. You can repair it yourself

All you need is a flathead screwdriver, but be careful when removing it. The point is in the valve fastening, it is often not metal, but plastic, it is not difficult to break it

The mount is located on the engine cover. There are also clamps on the valve itself, which also require a careful approach. We remove them and take out the problematic part.

https://youtube.com/watch?v=RfKNQGlqaEQ

https://youtube.com/watch?v=RfKNQGlqaEQ

Rare malfunction.

If you blow into the valve and air comes out of it, this means a 100% malfunction. A normal part will not allow air to pass through. If there is a problem with the valve, the car experiences problems when starting the engine hot, and gasoline consumption increases. If the problem is not corrected, there will be a Check Engine and loss of normal driving dynamics. Failure of the adsorber seal and failure of the purge valve can cause unstable engine operation at idle until it stops.

So, let's move on to valve repair. In its upper part there is an adjusting screw fixed with epoxy resin. Screw the screw in until it stops, counting the turns so that if something happens, you can return the canister valve to its original position. You can drop a little carburetor flushing fluid into the valve fittings. Then we blow it in the open position with compressed air. The repairs are done.

The valve can also wear out due to heat near the radiator, and there is nothing you can do to help it. The quality of the material from which the adsorber valve is made is not the best. The only solution can be to replace or change the location to a cooler one, for example, closer to the adsorber itself.

Determining possible damage

We have figured out why the adsorber is needed, now let’s determine the signs indicating its failure. Considering the quality of fuel at gas stations in our homeland, this part often becomes dirty and fails.

Any malfunction of this mechanism can be easily determined by obvious signs:

Damage to the absorber - the fact that this mechanism of your car has problems can be determined by hearing a hissing sound when opening the tank, it indicates the accumulation of an excess amount of gasoline vapor.

Excessive pressure appears in the tank when you open the lid, there is a moment when the contact area with the external environment is small, and the pressure is quickly “relieved” through it, and the tank “hisses”, similar to a bottle of soda.

In the event of a breakdown, the adsorber is often removed completely, we will discuss how to do this below, but there are no unnecessary parts in the car, it is worth remembering. If you don’t want to remove and gut the ECU, you can try to fix everything yourself. The weakest point in the absorption kit is the VAZ 2114 valve.

Before repairing, you need to make sure that the problem is here:

- Use a flat-head screwdriver to unscrew the fastener on the motor cover (be careful, the fastener is plastic, you shouldn’t break it), and then very carefully remove the clamps.

- We remove the part and blow out the valve. If air does not pass through, then the valve is operational, and the breakdown is elsewhere; if air passes through the valve, then you have found the problem.

A valve failure, in addition to unstable idle speed, will soon give you CheckEngine and significantly increased consumption.

Removal Features

The VAZ absorber is sometimes removed completely. To do this, you need:

- replace the gas tank cap with a leaky one;

- plug the supply and discharge pipes;

- often change the ECU firmware.

As mentioned above, you should not approach the adsorber as an unnecessary thing, and if you decide to remove it, remove it correctly so that the gas tank remains ventilated and not tightly sealed, as if there is an adsorber. Those who convert a carburetor engine to an injection engine have an advantage. If they do not touch the tank pipes, they do not disturb the carburetor ventilation system of the tank, so they do not need an adsorber.

Causes of adsorber malfunctions on a VAZ

But in the case of the VAZ 2114, which has an injection engine, everything is more complicated. However, there is no point in removing the absorber. The advantages that the VAZ absorber has are in reducing harmful emissions into the atmosphere, but that’s where they end. And the high cost and the fact that it can interfere with more important parts in the engine compartment become the main reason for removing the device. Why do some drivers make this difficult decision?

Basically, they just don’t like the device, but that’s not an argument. Experienced car enthusiasts remove it when malfunctions occur, so as not to spend money on a new one. It cleans up easily. A fine filter (usually from a VAZ 2108 carburetor) is put on the hose from the separator; in this case, gasoline vapors escape into the atmosphere. The hose from the valve is closed. The engine control program is adjusted so that the ECU does not turn on the Check Engine.

It is better to drill a 2 mm hole in the tank lid to make ventilation, like on a carburetor engine. Otherwise, the tank may not withstand either external or internal pressure. Most often, a vacuum develops in the tank and it crushes like an empty tin can. Many car enthusiasts talk about this for the edification of beginners. What is needed to remove the adsorbent device for replacement?

First you need to free it from its fastenings. We disconnect the block along with the wires, as well as the hose for supplying gasoline to the throttle assembly. We remove the purge valve and remove the fuel vapor outlet hose from the separator. The adsorber bracket is installed on 3 bolts, which must be unscrewed and the bracket carefully removed. The new device is installed on the same special mount, and the fuel vapor supply hose is connected to the purge valve. Remember: when changing the adsorber, you need to change all the pipes from it.

Take care of nature and do not throw away the adsorber. As a last resort, it is better to install a new one, since this is an ordinary filter that works for a very long time and does not require constant monitoring. Environmental standards were not invented to harm, but so that our children and grandchildren could live after us.

Don’t forget that the traffic police inspector and the inspection station personnel may catch you interfering with the design of the car, then you will not be able to pass the technical control. Listen to the advice of experienced car enthusiasts, take care of your car, be polite on the road, then any trip will only bring you a good mood.

Bottom line

An adsorber is one of those devices that does not in any way affect the dynamics of the car and is intended primarily to reduce the level of harm to the atmosphere.

As for , it is too insignificant to concentrate attention on it. At the same time, you shouldn’t throw the product out of the system either - just monitor its serviceability and change it on time

At the same time, it is also not worth throwing the product out of the system - it is enough to monitor its serviceability and change it on time.

If there is a video in the article and it does not play, select any word with the mouse, press Ctrl+Enter, enter any word in the window that appears and click “SEND”. Thank you.

Do you need an adsorber? This question worries many Togliatti car owners. The VAZ 2114 adsorber appeared after the introduction of Euro-3 environmental standards, which required the installation of devices on cars that allow them to retain evaporating fuel so that it does not enter the atmosphere. The black cylinder installed on the VAZ on the right in the corner of the engine compartment near the radiator is the VAZ 2114 absorber, the design of which we will consider.