VAZ 1111 | Adjusting the clearances in the valve drive

1. Close the carburetor with a plug or a clean rag.

2. Remove the washers from both head cover mounting studs.

3. Unscrew the two nuts securing the cylinder head cover.

4. After loosening the clamps, remove the hose of the small branch of the crankcase ventilation from the fitting of the cylinder head cover.

5. . ventilation hose from the cylinder head cover pipe and.

6. . hose of the large ventilation branch from the fitting of the cylinder head cover.

7. Remove the washers from both head cover mounting studs.

8. Move the carburetor choke drive rod aside.

9. Remove the rubber bushings from both studs securing the cylinder head cover (replace bushings that have lost elasticity, deformed and torn ones).

10. Remove the cylinder head cover.

11. Use a wheel wrench to turn the crankshaft by the bolt securing the generator drive pulley through the hole in the right wheel niche (to make it easier to turn the shaft, you can unscrew the spark plugs) so that.

12. . The marks on the generator drive pulley and on the front camshaft drive cover coincide. In this case, you can adjust the clearances in the drive of either the 1st and 2nd, or the 3rd and 4th valves. The order in which the valves are adjusted does not matter. Note that.

13. . There are two marks on the cover. In this case, you need to focus on long mark 1. Mark 2 is marked on the inside of the pulley. For convenience, duplicate it, for example with a felt-tip pen, on its outer part.

14. Measure the gaps in the valve drive of one of the cylinders with a flat feeler gauge. Replace the adjusting washers of those valves whose clearances differ from the nominal ones. Record the measured clearances.

15. To make it easier to remove the adjusting washer, two grooves are made in the pusher. Using a screwdriver, turn the pusher by the groove so that it is convenient to pry off the washer. For ease of operation, remove oil from the top of the cylinder head around the valve tappets.

16. Install a special device on the head cover mounting studs.

17. Place the washers on the studs, turning them over so as not to crush the flange on them.

18. Secure the device with the nuts securing the cylinder head cover.

19. By pressing down the lever of the device, press down the pusher on which the adjusting washer is being replaced. Then.

20. . insert the clamp under the camshaft so that.

21. . the protrusion on the latch 1 fixed the pusher 2 in the recessed position.

22. Using a screwdriver, pry up the adjusting washer and.

23. . using, for example, tweezers, remove the washer from the pusher.

24. Write down the thickness of the shim, the value of which is marked on one of its sides.

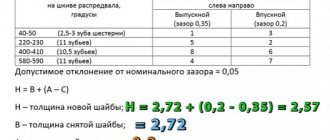

26. Calculate the thickness of the new shim using the formula:

(all values in mm)

where H is the thickness of the new washer B is the thickness of the old washer A is the value of the measured gap C is the nominal gap

For example (for intake valve): A = 0.26 mm, B = 3.75 mm, C = 0.2 mm, then H = 3.75 + 0.26 – 0.2 = 3.81 mm. Within the tolerance of the gap (±0.05 mm), we select the closest washer in thickness - 3.8 mm.

27. Install a new washer into the pusher with the thickness calculated according to the formula with the inscription facing down (toward the pusher). Press the pusher with the tool and remove the lock. Check the clearance again and repeat the adjustment if necessary.

28. Turn the crankshaft one revolution (360°) and adjust the valve clearances of the other cylinder in the same order. Then fill the top of the cylinder head with oil if it has been removed.

How to adjust the valve on the oka

Until recently, 15-20 years ago, the design of the valve drive on the Zhiguli seemed to many of us to be very advanced, especially in comparison with the Volgov one.

But the compact “Zhiguli” design with short intermediate arms (rockers) is long outdated. On modern engines, the valves are driven directly by the camshaft cams - through cylindrical tappets. The advantages are quite obvious: the mass of the drive is reduced, the number of friction pairs is reduced. Hence, there is less power consumption for the operation of the drive itself, and in addition, as already mentioned, less frequent maintenance. If on a Zhiguli the valve adjustment needs to be checked after 10 thousand kilometers, or even earlier, then on a VAZ-2108 with direct drive the clearance is checked half as often.

The clearances on the engines of front-wheel drive VAZs are adjusted in a cold state (plus 15-20 o C), which is not very convenient, especially in the summer - you have to wait a long time for the engine to cool down after a trip. But it is absolutely necessary to comply with this condition, because the engine cools unevenly. For example, after turning it off, the valves reduce their temperature by hundreds of degrees for a few minutes, while the cylinder block and its head reduce by only five to ten. Trying to adjust the gaps at this moment is at least risky. Only after a few hours the temperature of the engine parts will level out and you can confidently get down to business, and the best results will be obtained on an engine at room temperature, for which the clearances are determined: 0.15-0.25 mm for the intake valve and 0.3-0. 4 mm for graduation.

Usually, before adjusting the valves, it is recommended to check (and, if necessary, adjust) the tension of the camshaft drive toothed belt, although this in itself does not affect the size of the gaps, if, of course, the studs and nuts securing the camshaft housing are in good condition. A loose tightening, a broken thread, or an elongated pin may be the reason why the housing is not firmly attached to the cylinder head. In this case, the gaps may vary depending on the belt tension.

The gaps are adjusted by selecting the thickness of the replaceable washers (disks) 2, shown in Fig. 1. Spare parts are supplied with washers with a thickness of 3 to 4.5 mm with an interval of 0.02 mm. When going to the store, you don’t have to take a micrometer with you: the thickness of the washer is marked on its surface.

The washer is marked with the markings on the pusher, with the numbers located above the recess in the pusher so that they are not erased during engine operation. Unfortunately, this is not always observed even in the factory; the actual gap between the washer and the back (cylindrical) side of the cam must be checked using flat feeler gauges. Let's say you got 0.43mm for the intake valve. Since the acceptable value is 0.3-0.4 mm, it is clear: it’s time to reduce it by about 0.05-0.10 mm. How? The thickness of the worn washer is, say, 3.55 mm (even if it has the required markings on it, the use of a micrometer is mandatory!). In this case, you can buy and install a new washer with a thickness of 3.60 to 3.65 mm, then the gap will be in the range from 0.33 to 0.38 mm, that is, it will be within the norm.

Remember that the washers installed on your engine can be anything in the range mentioned above, and therefore you have to buy one for each valve.

How to disassemble the mechanism, keeping in mind that you need to compress the valve springs and fix the pusher in this position so that you can remove the washer? In Fig. 1 shows a device that greatly facilitates this operation. Rod 3 has holes with which it is attached to the same studs as the cylinder head cover. An additional, middle hole in the rod allows it to be used when servicing the Oka engine (it is done in exactly the same way).

Lever 4 and stop 5 in the shape of a curved wedge are connected by an axis, the ends of which are riveted after assembly. The lever does not have to be made from a whole piece of metal. It is possible, for example, to have a composite structure (a fragment of it is shown in the figure), riveted from individual sheet parts (5 mm thick).

When you press the lever, the stop enters between the camshaft cam and washer 2 of pusher 1 (see Fig. 1), lowering the latter and compressing the springs. Now the pusher needs to be securely fixed so that an attempt to remove the washer does not result in injury. Clamp 3 serves this purpose (Fig. 2). Install it as shown: with the emphasis on the edge of the pusher so that it does not interfere with the removal of the washer.

How to remove the washer? There are various techniques here. For example, they use a small flat magnet mounted on a metal or plastic strip that is bent approximately the same way as the retainer holder. The easiest way to attach a magnet to a strip is with any elastic glue (for example, “Moment”). You can use tongs with narrow jaws. Finally, the washers can be removed quite quickly and easily using a screwdriver sharpened as shown in Fig. 3, and ordinary tweezers.

VAZ 1111 | Adjusting the clearances in the valve drive

1. Close the carburetor with a plug or a clean rag.

2. Remove the washers from both head cover mounting studs.

3. Unscrew the two nuts securing the cylinder head cover.

4. After loosening the clamps, remove the hose of the small branch of the crankcase ventilation from the fitting of the cylinder head cover.

5. . ventilation hose from the cylinder head cover pipe and.

6. . hose of the large ventilation branch from the fitting of the cylinder head cover.

7. Remove the washers from both head cover mounting studs.

8. Move the carburetor choke drive rod aside.

9. Remove the rubber bushings from both studs securing the cylinder head cover (replace bushings that have lost elasticity, deformed and torn ones).

10. Remove the cylinder head cover.

12. . The marks on the generator drive pulley and on the front camshaft drive cover coincide. In this case, you can adjust the clearances in the drive of either the 1st and 2nd, or the 3rd and 4th valves. The order in which the valves are adjusted does not matter. Note that.

13. . There are two marks on the cover. In this case, you need to focus on long mark 1. Mark 2 is marked on the inside of the pulley. For convenience, duplicate it, for example with a felt-tip pen, on its outer part.

14. Measure the gaps in the valve drive of one of the cylinders with a flat feeler gauge. Replace the adjusting washers of those valves whose clearances differ from the nominal ones. Record the measured clearances.

15. To make it easier to remove the adjusting washer, two grooves are made in the pusher. Using a screwdriver, turn the pusher by the groove so that it is convenient to pry off the washer. For ease of operation, remove oil from the top of the cylinder head around the valve tappets.

16. Install a special device on the head cover mounting studs.

17. Place the washers on the studs, turning them over so as not to crush the flange on them.

18. Secure the device with the nuts securing the cylinder head cover.

19. By pressing down the lever of the device, press down the pusher on which the adjusting washer is being replaced. Then.

20. . insert the clamp under the camshaft so that.

21. . the protrusion on the latch 1 fixed the pusher 2 in the recessed position.

22. Using a screwdriver, pry up the adjusting washer and.

23. . using, for example, tweezers, remove the washer from the pusher.

24. Write down the thickness of the shim, the value of which is marked on one of its sides.

26. Calculate the thickness of the new shim using the formula:

(all values in mm)

where H is the thickness of the new washer B is the thickness of the old washer A is the value of the measured gap C is the nominal gap

For example (for intake valve): A = 0.26 mm, B = 3.75 mm, C = 0.2 mm, then H = 3.75 + 0.26 – 0.2 = 3.81 mm. Within the tolerance of the gap (±0.05 mm), we select the closest washer in thickness - 3.8 mm.

27. Install a new washer into the pusher with the thickness calculated according to the formula with the inscription facing down (toward the pusher). Press the pusher with the tool and remove the lock. Check the clearance again and repeat the adjustment if necessary.

28. Turn the crankshaft one revolution (360°) and adjust the valve clearances of the other cylinder in the same order. Then fill the top of the cylinder head with oil if it has been removed.

VAZ 1111 | Checking and adjusting valve clearance

Checking and adjusting valve clearance

Since the 16-valve engine is equipped with hydraulic compensators, it does not require valve clearance adjustment. In this case, the Renault service plan does not include work on checking and adjusting the clearance in the valve mechanism.

If you do not have a special wrench, when adjusting the clearance in the valve mechanism, you will need an SW 10 wrench (open-end or socket) to loosen the locknut and pliers, or better yet, a suitable small wrench for adjusting the valves. In addition, you need, as shown in the figure for the intake valve of the 1st cylinder, a feeler gauge with a thickness of 0.15 mm (to adjust the gap in the intake valves) or 0.20 mm (to adjust the gap in the exhaust valves).

Features of the timing device

The same applies to the gas distribution mechanism. The essence of the work is identical, as well as the design, but the VAZ Oka has 11113 distributors. the shaft has only 4 cams. Therefore, the maintenance of the power plant of a small car is no different from the VAZ-2108.

The Oka uses a gas distribution mechanism with an overhead camshaft, which is installed in the engine cylinder head. This made it possible to abandon a number of components (bars, rocker arms). In this design, the camshafts. shafts act on the valves through pushers. In this case, it is necessary to have a thermal gap between the component elements (cam-pushrod-valve heel), which compensates for the change in geometric parameters occurring due to expansion of the metal as a result of heating.

When should adjustment be made?

The valve clearance on the Oka, according to the manufacturer’s recommendations, should be adjusted every 30 thousand km. But this is far from an accurate indicator, since much depends on operating conditions. Thus, lubricants, fuel, climatic conditions, features and intensity of use of the car can significantly affect the operation of the timing belt, and work on adjusting the thermal gap will have to be carried out earlier.

There are a number of signs indicating a change in the thermal gap:

- Increased engine noise (the sound of the unit is similar to a diesel unit);

- Power drop;

- Poor launch;

Some note that fuel consumption also increases. This is true, but the Oka uses a carburetor power system (except for the latest models equipped with a Chinese 3-cylinder unit), so it is simply unrealistic to determine the amount of fuel consumed, and such a sign of a change in the thermal gap can be ignored.

This type of maintenance can be done with your own hands, since the whole process is not complicated, but you need to know how to properly adjust the valves on the Oka.

The main thing you need to know is what valve clearance on the Oka is considered normal. Here it all depends on what kind of valve it is: for the intake valve it is 0.2 mm (an error of 0.05 mm is allowed), and for the exhaust valve it is 0.35 mm (the same error).

The procedure for adjusting the valves oka 1113

The same applies to the gas distribution mechanism. The essence of the work is identical, as well as the design, but the VAZ Oka has 11113 distributors. the shaft has only 4 cams. Therefore, the maintenance of the power plant of a small car is no different from the VAZ-2108.

The Oka uses a gas distribution mechanism with an overhead camshaft, which is installed in the engine cylinder head. This made it possible to abandon a number of components (bars, rocker arms). In this design, the camshafts. shafts act on the valves through pushers. In this case, it is necessary to have a thermal gap between the component elements (cam-pushrod-valve heel), which compensates for the change in geometric parameters occurring due to expansion of the metal as a result of heating.

But during engine operation, wear occurs on the surfaces of the cams, pushers and heels as a result of friction, which causes the thermal gap to change. Moreover, it is not necessary that it will increase; it also happens that the gap decreases. This often happens due to low-quality oil, which leads to the appearance of deposits on the working surfaces of the timing belt.

As a result of a change in the thermal gap, a violation of the valve timing occurs, which is why the power plant loses power (which the Oka already has “sparsely”), fuel consumption increases, and dynamics decrease. And all because the valves either open insufficiently (increased clearance) or do not fit tightly to the seats (reduced clearance).

To compensate for changes in the thermal gap, the VAZ-1111 uses special adjusting washers, which are placed in a special seat in the pusher. That is, the contact of the camshaft cam occurs not with the pusher, but with the installed washer.

In order for the thermal gap to meet the standard, periodic adjustment of the valves on the Oka is required. Due to the design features of the timing belt, the entire process boils down to installing washers of the required thickness.

Lada Oka 2005, petrol engine 0.7 l., 33 l. p., front drive, manual transmission — scheduled maintenance

Participate in the discussion can only registered users.

Lada Oka almost like 08 › Logbook › Valve adjustment))

Today I finally adjusted the valves. I was already sick of this noise, I couldn’t hear the engine behind it) I started it in the morning when I woke up. I warmed up the car in a clever way - I stuck a thermocouple under the valve cover, and when the cylinder head warmed up to 20 degrees, I turned off the engine and began to measure the gaps.

1 exhaust valve - 0.45 clearance 2 intake valve - 0.2 clearance 3 intake valve - 0.2 clearance 4 exhaust valve - 0.4 clearance

As you can see, only one valve required adjustment. But if I climbed, then turn everything back) I decided to tighten the valves to the lower tolerance limit. That is, make the intake 0.15, exhaust 0.3

I pulled out the adjusting washers without any tools, using only a 19 mm wrench, a knife and a thin screwdriver) I turned the crankshaft with a wrench (it’s better to unscrew the spark plugs, it will be easier to rotate several times), the camshaft clamped the valve I needed, and with the blade of a knife turned on its edge I fixed the pusher. Everything turned out very easily and quickly, and most importantly, minimal costs)

Here are the results of what I measured, what was in the engine and what I considered buying:

Then I went shopping to look for washers. It turned out that this is a shortage (Although the chisels seem to be used a lot on the road. I found them only on the market, the washers seemed to be factory ones, with increments of 0.05. I bought 4 pieces with adjustments for each valve. The washers darkened a little over time, polished them at home with 1200-grit sandpaper and measured them with a micrometer - everything the dimensions corresponded to the inscriptions, which was pleasing. By the way, the washer costs 50 rubles, it’s kind of expensive, but there wasn’t much to choose from(

The last step was to put everything back together in reverse order and turn the engine over several times to make sure nothing was sticking. I started it, let it warm up, the idle values disappeared completely after adjustment)) About an hour after that, when the engine cooled down, I went to check the gaps again. All valves corresponded to my calculations) Intake 0.15, exhaust 0.3, everything was as I wanted.

At the end, I adjusted the carb and tightened the timing belt, otherwise it was too loose.

The result is that there is no rattling at all.

, the engine runs very quietly. Only now the timing belt pulley is straining and you can hear its howling. Although I changed it not so long ago (I noticed a good increase in power after 3 thousand, but the filling of the cylinders has improved. In general, one positive so far)

Adjusting valves oka 1111

Your request on the topic of adjusting the valves of the VAZ 11113 Oka with your own hands video has been processed. The best repair video and instructions on how to repair can only be found on our website. The presented videos are published with photos. Enjoy watching.

Owner reviews: after-sales service - competitors will die from shock

Category: Video instructions

Published by admin: at the request of Moses

VAZ 1111 | Checking/adjusting valve clearance

Checking/adjusting valve clearance

Engines E1, EZ, E5, VZ, V5, V6 until 9/89, PN

To compensate for various thermal expansions, the distribution mechanism must have a certain valve clearance.

If the gap is too small, the valve timing changes, compression becomes unsatisfactory, engine power decreases, and the engine runs unstable. In extreme cases, valves or valve seats may become distorted.

If the gap is too large, very strong mechanical noise appears, the valve timing changes, due to the valve opening time being too short, the engine does not develop maximum power, and the engine runs unstable. Valve adjustment achieves the desired result only if the valves seal perfectly, do not have unacceptable play in the guides and are not knocked down at the ends of the stems.

Valve clearance is checked and adjusted as part of maintenance, see Section Maintenance technology, tools and workplace equipment, and after repair, or if noise appears in the distribution mechanism. The valve clearance is checked and adjusted on a warm engine. The operating condition of the engine is achieved by driving 10-15 km under normal conditions, when the temperature gauge is in the middle region.

| Adjustment | high school graduation | |

| E1, EZ, E5 | 0.25 mm | 0.30 mm |

| VZ, V6 | 0.30 mm | 0.30 mm |

| PN (diesel) | 0.20 mm | 0.30 mm |

When should adjustment be made?

The valve clearance on the Oka, according to the manufacturer’s recommendations, should be adjusted every 30 thousand km. But this is far from an accurate indicator, since much depends on operating conditions. Thus, lubricants, fuel, climatic conditions, features and intensity of use of the car can significantly affect the operation of the timing belt, and work on adjusting the thermal gap will have to be carried out earlier.

There are a number of signs indicating a change in the thermal gap:

- Increased engine noise (the sound of the unit is similar to a diesel unit);

- Power drop;

- Poor launch;

Some note that fuel consumption also increases. This is true, but the Oka uses a carburetor power system (except for the latest models equipped with a Chinese 3-cylinder unit), so it is simply unrealistic to determine the amount of fuel consumed, and such a sign of a change in the thermal gap can be ignored.

This type of maintenance can be done with your own hands, since the whole process is not complicated, but you need to know how to properly adjust the valves on the Oka.

The main thing you need to know is what valve clearance on the Oka is considered normal. Here it all depends on what kind of valve it is: for the intake valve it is 0.2 mm (an error of 0.05 mm is allowed), and for the exhaust valve it is 0.35 mm (the same error).

Adjusting Oka valves

The domestic car of the especially small class VAZ with the index 1111 (11113) is the only AvtoVAZ model from the entire family that was equipped with a two-cylinder engine. At the same time, during the creation of this motor, the designers tried to unify this motor as much as possible with other types, in particular from VAZ-2108-21099 cars. The result of this work was that the principle of operation of the units and many elements of these installations are the same and interchangeable (for example, CPG), the only difference is in quantity.

What will you need?

The only problem with timing belt adjustment is the shims. The fact is that a professional set of them is quite expensive, since it includes washers with a thickness of 3.0 to 4.5 mm (in increments of only 0.05 mm).

But many auto stores sell these washers separately, so the price of one washer is low. Only in the process of carrying out the work will you have to make all the necessary calculations, go to the auto store, purchase the required sized elements and download the assembly.

In addition, you will also need special devices - a tool for squeezing the valve and retainer. Since this specialized tool is practically not found on Oka, you can buy a regular one - for the VAZ-2108, and modify it a little.

The squeeze tool consists of a tube with holes for attaching to the valve cover studs, and a handle with a curved lever (pointed at the end) connected through an axle, allowing the lever to move freely.

The tool works simply: a handle with a lever is put on the tube. It is then secured to the valve cover studs. The handle moves freely along the tube, allowing it to be positioned exactly opposite the cam. The lever is installed between the cam and the pusher; when you press the handle, it compresses the valve spring, and all that remains is to install a clamp to hold the pusher in the depressed position. You can see how everything happens in the photo below.

As for modifying the tool from the VAZ-2108 to work with the VAZ-11113, you just need to drill two through holes in the tube, the distance between which corresponds to the position of the valve cover studs of the Oka engine (it is 17.8 cm).

In general, to make the adjustment you will need:

- Set of keys (open-end, socket);

- Screwdrivers;

- Punch and tweezers;

- Tool for squeezing pushers;

- Retainer;

- Set of probes;

- A tool for accurately measuring thickness (at least a caliper);

- Washers;

- Rags;

- New valve cover gasket;

Adjusting Oka valves

The domestic car of the especially small class VAZ with the index 1111 (11113) is the only AvtoVAZ model from the entire family that was equipped with a two-cylinder engine. At the same time, during the creation of this motor, the designers tried to unify this motor as much as possible with other types, in particular from VAZ-2108-21099 cars. The result of this work was that the principle of operation of the units and many elements of these installations are the same and interchangeable (for example, CPG), the only difference is in quantity.

Features of the timing device

The same applies to the gas distribution mechanism. The essence of the work is identical, as well as the design, but the VAZ Oka has 11113 distributors. the shaft has only 4 cams. Therefore, the maintenance of the power plant of a small car is no different from the VAZ-2108.

The Oka uses a gas distribution mechanism with an overhead camshaft, which is installed in the engine cylinder head. This made it possible to abandon a number of components (bars, rocker arms). In this design, the camshafts. shafts act on the valves through pushers. In this case, it is necessary to have a thermal gap between the component elements (cam-pushrod-valve heel), which compensates for the change in geometric parameters occurring due to expansion of the metal as a result of heating.

But during engine operation, wear occurs on the surfaces of the cams, pushers and heels as a result of friction, which causes the thermal gap to change. Moreover, it is not necessary that it will increase; it also happens that the gap decreases. This often happens due to low-quality oil, which leads to the appearance of deposits on the working surfaces of the timing belt.

As a result of a change in the thermal gap, a violation of the valve timing occurs, which is why the power plant loses power (which the Oka already has “sparsely”), fuel consumption increases, and dynamics decrease. And all because the valves either open insufficiently (increased clearance) or do not fit tightly to the seats (reduced clearance).

To compensate for changes in the thermal gap, the VAZ-1111 uses special adjusting washers, which are placed in a special seat in the pusher. That is, the contact of the camshaft cam occurs not with the pusher, but with the installed washer.

In order for the thermal gap to meet the standard, periodic adjustment of the valves on the Oka is required. Due to the design features of the timing belt, the entire process boils down to installing washers of the required thickness.

When should adjustment be made?

The valve clearance on the Oka, according to the manufacturer’s recommendations, should be adjusted every 30 thousand km. But this is far from an accurate indicator, since much depends on operating conditions. Thus, lubricants, fuel, climatic conditions, features and intensity of use of the car can significantly affect the operation of the timing belt, and work on adjusting the thermal gap will have to be carried out earlier.

There are a number of signs indicating a change in the thermal gap:

- Increased engine noise (the sound of the unit is similar to a diesel unit);

- Power drop;

- Poor launch;

Some note that fuel consumption also increases. This is true, but the Oka uses a carburetor power system (except for the latest models equipped with a Chinese 3-cylinder unit), so it is simply unrealistic to determine the amount of fuel consumed, and such a sign of a change in the thermal gap can be ignored.

This type of maintenance can be done with your own hands, since the whole process is not complicated, but you need to know how to properly adjust the valves on the Oka.

The main thing you need to know is what valve clearance on the Oka is considered normal. Here it all depends on what kind of valve it is: for the intake valve it is 0.2 mm (an error of 0.05 mm is allowed), and for the exhaust valve it is 0.35 mm (the same error).

What will you need?

The only problem with timing belt adjustment is the shims. The fact is that a professional set of them is quite expensive, since it includes washers with a thickness of 3.0 to 4.5 mm (in increments of only 0.05 mm).

But many auto stores sell these washers separately, so the price of one washer is low. Only in the process of carrying out the work will you have to make all the necessary calculations, go to the auto store, purchase the required sized elements and download the assembly.

In addition, you will also need special devices - a tool for squeezing the valve and retainer. Since this specialized tool is practically not found on Oka, you can buy a regular one - for the VAZ-2108, and modify it a little.

The squeeze tool consists of a tube with holes for attaching to the valve cover studs, and a handle with a curved lever (pointed at the end) connected through an axle, allowing the lever to move freely.

The tool works simply: a handle with a lever is put on the tube. It is then secured to the valve cover studs. The handle moves freely along the tube, allowing it to be positioned exactly opposite the cam. The lever is installed between the cam and the pusher; when you press the handle, it compresses the valve spring, and all that remains is to install a clamp to hold the pusher in the depressed position. You can see how everything happens in the photo below.

As for modifying the tool from the VAZ-2108 to work with the VAZ-11113, you just need to drill two through holes in the tube, the distance between which corresponds to the position of the valve cover studs of the Oka engine (it is 17.8 cm).

In general, to make the adjustment you will need:

- Set of keys (open-end, socket);

- Screwdrivers;

- Punch and tweezers;

- Tool for squeezing pushers;

- Retainer;

- Set of probes;

- A tool for accurately measuring thickness (at least a caliper);

- Washers;

- Rags;

- New valve cover gasket;

Sequencing

All work is performed on a cold engine. The whole process is done like this:

- Remove the air filter housing from the car. Cover the carburetor with a rag;

- We disconnect the pipes from the valve cover and move them to the side;

- Unscrew the nuts securing the valve cover and remove it;

- We set the TDC. To do this, rotate the crankshaft until the marks on the generator drive pulley and the timing belt cover align (since there are two marks on the cover, you need to install it on the long one);

- The order of adjustment of the cylinders on the Oka is not important, since in the engine of this car they run synchronously. That is, start adjusting on any cylinder. It is only important to remember that the outer valves are exhaust, and the inner ones are inlet (exhaust-inlet-inlet-exhaust). This is necessary in order not to confuse the thermal gaps. For example, we will consider a cylinder located closer to the camshaft gear;

- We measure the gaps on the valves of the selected cylinder using feeler gauges and write them down;

- The pushers have special slots for removing the washer. Use a screwdriver to turn the pusher to turn one of the slots towards you;

- We install a squeezing tool on the valve cover studs and secure it with nuts;

- We place the handle opposite the first valve, place the lever between the camshaft. shaft and pusher, press the handle, overcoming the force of the spring;

- Install the retainer between the distributors. using the pusher shaft, remove the lever and move it to the side;

- Use a punch to pry up the washer, and then remove it with tweezers;

- The size is marked on the washer (if it is worn out, change its thickness with a caliper);

- We calculate the required thickness of the new washer. To do this, take the thickness of the removed washer, add the measured thermal gap to the value and subtract the nominal value. Let's take the intake valve as an example. The measured gap was 0.28 mm. We removed the washer, measured it and got a value of 3.80 mm. We combine these indicators - 4.08 mm. We subtract the nominal gap (0.2 mm) from it and it turns out that you need to install a washer 3.88 mm thick. Since there is no element with this value in the set, we select the closest one to it (for this we need an error of 0.05 mm). As a result, to restore the thermal gap, a washer with a thickness of 3.90 mm is needed.

- We install the selected washer and move on to the next cylinder valve. We calculate the thickness in the same way, but taking into account the fact that the exhaust valve has a nominal gap of 0.35 mm;

- After making adjustments on one cylinder, move on to the other. But to do this, it is tedious to rotate the crankshaft 360 degrees. And then all work is performed in the same way as indicated above;

- After adjustment, we install the removed elements from the engine, and the valve cover gasket must be replaced;

Finally, we note that this operation is also carried out in the case of work related to the removal of the camshaft, for example, when replacing valve seals.

“>

Do-it-yourself adjustment of Oka 11113 valves

In 1989, car enthusiasts saw the first copies of the VAZ 1111, which became the basis for the family. Three factories mastered the production of small cars: VAZ in Togliatti, KamAZ in Naberezhnye Chelny, Serpukhov, whose car plant specialized in the production of motorized wheelchairs for the disabled. This distribution of forces and resources made it possible to quickly begin production of this model without the construction of new production facilities.

Buyers were offered two versions of the car, which differed only in the power unit. The car has front-wheel drive, and replacing the Oka timing belt is carried out by analogy with VAZ 2108 and VAZ 21083 engines.

Repair and adjustment of the carburetor on an OKA car

A clogged carburetor becomes a source of headache for any car owner. The driver of an OKA car is no exception in this sense. If the carburetor is not repaired in time, you can forget about a comfortable ride. Can I repair this device myself? Of course.

Models of carburetors for OKA cars

There are several modifications of OKA cars. The very first car of this brand was model 1111. It was produced at the VAZ and KamAZ factories. This model had an engine capacity of 0.65 liters and was equipped with a DMZ brand carburetor, which was produced at the auto parts plant in Dimitrovgrad.

Main elements of the DAAZ 1111 carburetor for the OKA car

Then a new OKA car model appeared - 11113. The engine capacity of this car was slightly larger and amounted to 0.75 liters. Accordingly, the carburetor has also changed slightly. Model 11113 is equipped with DAAZ 1111 carburetors. This device is produced at the same plant in Dimitrovgrad. This carburetor differs from its predecessor only in the increased size of the mixing chamber. In all other respects, the device has not undergone any changes.

Common carburetor malfunctions and their causes

- the carburetor fires.

This is the most common malfunction associated with the carburetors of OKA vehicles. Usually the problem occurs due to low-quality gasoline. Because of it, a too lean fuel mixture begins to flow into the carburetor, after which the driver hears a loud bang under the hood, reminiscent of a pistol shot. To fix the problem, you should drain the low-quality fuel, change the gas station and clean the carburetor jets; - excess gasoline in the carburetor. If too much gasoline enters the device, it is very difficult to start the car: the engine starts, but immediately stalls. To eliminate this problem, you need to fine-tune the carburetor, and if the problem persists, install a new set of spark plugs;

- there is no gasoline in the carburetor.

If gasoline does not enter the carburetor, the car simply will not start. Typically, fuel stops flowing due to a blockage in one of the chambers of the device or due to poor adjustment. There is only one solution: remove the carburetor, completely disassemble it and wash it; - Condensation has formed in the carburetor.

This problem is rare, but it cannot be ignored. Most often, condensation appears in the carburetor in winter, during severe frosts. After this the car starts very hard. If you still manage to start, you need to warm up the engine properly for 10–15 minutes. Usually this is enough to completely eliminate condensation.

Dismantling the carburetor OKA 11113

Before proceeding with dismantling the carburetor, you should decide on the necessary tools.

Tools and materials

- set of open-end wrenches;

- flat screwdriver, medium size;

- set of spanners.