Adjusting the dimensions of the valve clearances of a VAZ 2109, 2108 car is mandatory. There is a need to perform this operation in order to ensure correct operation of the gas distribution mechanism.

There is a strictly defined procedure for performing valve adjustment work. But in some books you can find a mention that the corresponding order does not matter. Below we propose to review the process and give important recommendations regarding its implementation.

Diagram 1. Gas distribution mechanism of VAZ 2109, 2108

Diagram 2. Gas distribution mechanism of VAZ 2109, 2108

Why do you need to adjust valves?

With mileage, the metal valve stem tends to stretch and contract. The seats in the cylinder head sag, which is why the thermal gap changes. And it is physically needed of a certain value due to the design features of the engine. The consequences of untimely adjustment are not reversible. A clamped valve during operation of an eight-valve engine loses its seal, and the avalanche flow after ignition burns its edges and the cylinder head seat, which is recessed into the body of the head. This type of repair is expensive and does not come with a warranty. It is better to regulate in time, especially since the cost of tuning an 8-valve engine at 600 - 800 rubles per 30,000 km is not so significant.

With correctly adjusted clearances, the car will drive freely, without loss of traction, consuming less fuel. Under no circumstances should you adjust it to hot. Just cool the engine to 30-40 degrees. Otherwise, you can make a mistake and jam the valves.

There are times when the valves have been adjusted, but the knock remains. The reason may not be gaps. On a cold engine, piston skirts and cups and pushers in the body of the head can knock. There can be many reasons, so don’t rush to conclusions, but check everything carefully. There is a special device - a stethoscope, with which you can easily listen to engine noise.

Adjustment procedure

The procedure for adjusting the valves on all modifications of the 8-valve vase is the same. There are differences only in injection Grant cars, Kalina 2 with a Grant engine. They have a lightweight piston group and metal-ceramic seats. In this regard, the gaps differ upward by 0.05 mm. Knowing the order and adjustment scheme, you can adjust the valves yourself. The downside is the lack of a set of washers for adjustment. It’s expensive to go to the market to buy them every time, and it’s also expensive to buy the entire range.

Here is a detailed diagram of valve adjustment for VAZ 2108, 2109, 2114, 2115

- First you need to cool the engine. You can use an additional cooling fan from any VAZ car. Place it on top so that the airflow is towards the internal combustion engine and turn on the 12 V power supply;

- When adjusting 8 valve engines (11186, 11113 oka, 1118, 1111) with a mechanical throttle assembly, unscrew the throttle cable from the intake manifold receiver;

- Disassemble the valve cover, timing belt side casing. Disconnect the large and small breather hose going to the throttle body pipe;

- Pump out the oil near the valve cups using a syringe or bulb. It is most convenient to use a regular medical syringe with a white silicone hose at the end;

- Install a device for adjustment - a rack for pressing the valve, also called a ruler;

- Set the first adjustment position. Turn the camshaft clockwise to the mark and tighten 2-3 teeth. For cars with a lightweight piston group (Granta, Kalina 2, Priora), turn strictly by the crankshaft. If you turn the camshaft, the timing belt may slip, and if this is not noticed and the engine is driven, the valves may bend;

- Adjust in the following sequence: 1 outlet and 3 inlet valves;

- Rotate the camshaft 90 degrees. Adjust 5 outlet and 2 inlet valves;

- Rotate 90 degrees. Adjust 8 exhaust and 6 inlet ports;

- We make the last turn by 90 degrees and adjust the 4th exhaust and 7th inlet valves;

- Reassemble in reverse order. We install a new gasket under the valve cover to prevent oil from leaking out.

- On carburetor engines, everything is done in a similar order. First you need to unscrew the filter housing and the suction cable. The frequency is the same as on the injector 30,000 km.

On engines with 16 valves, adjustment is not required, since thermal clearances are selected automatically using hydraulic compensators.

Checking the gaps is also required after repairing the cylinder head. Especially after replacing the guides. When replacing bushings, the seats are countersunk with a special tool and deliberately recessed into the head. Accordingly, you need to follow the sequence, set the optimal gaps and repeat after 1000 km.

Adjusting the 8kL engine for gas increases the mileage between adjustments. If the engine is not intended to operate on gas equipment, the seats and valves will quickly burn out, and in order to somehow extend the service life, the clearances should be made a little larger than standard. Usually they do +0.05 mm. If the gap is not set, that is, does not expand, then the saddle is sunk a decent distance into the head. In this case, you need to measure how much the gap needs to be increased, disassemble the cylinder head and file the end of the valve. The second option would be to replace the seat or the cylinder head itself.

Interaction of gas distribution mechanism parts

It is very important to preview the engine performance requirements. The values of its clearances and other indicators of the interaction of parts of the gas distribution mechanism of VAZ 2109, 2108.

On a cold engine, specific clearance values are set between the pusher and the camshaft. The indicator is 0.20 millimeters (a deviation of 0.05 millimeters in different directions is allowed), which is relevant for intake valves . For exhaust valves, the gap value is set within 0.35 millimeters with the same tolerance. Here you need a specific set of feeler gauges that can measure gaps within 0.30-0.40 millimeters.

If the maximum probe fits into the hole, it means that you will need to select an appropriate washer that is slightly thicker in size, and then replace it.

In the same case, when the gap value is smaller, the valve can easily close on a preheated engine. In fact, this is very dangerous, because such a value can lead to the valve and seats burning out. Consequently, there is a sharp loss of pressure, the occurrence of compression and a drop in power level.

Ultimately, this necessarily leads to the need to perform a complete cylinder head repair, which will be too expensive. This can be diagnosed without problems. Indeed, in the case when the gap is increased, a corresponding knock in the engine is noted.

As numerous masters say, this indicates that there is a situation with increased wear on the camshaft. It is exposed to unnecessary shock loads. This in itself is not a pleasant moment. It is in this case that it is important to promptly complete the process of adjusting the gaps at a strictly defined time.

This solution will be especially relevant in the case when the vehicle runs on gas, thereby causing increased wear of the washers. Consequently, the size of the gap will constantly change.

Gap calculation

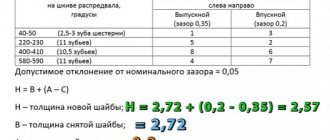

In order to find out the size of the washers, there is an adjustment formula:

H = B + (A - C)

H – thickness of the new washer;

B – thickness of the washer that was removed;

A – existing gap;

C – nominal clearance (0.2 or 0.35)

We check the gaps with a feeler gauge. It is advisable to have several of them in increments of 0.02 - 0.03 mm.

Correct valve adjustment guarantees a long engine life.

Checking and adjusting clearances in the valve mechanism of Lada Samara

Unadjusted valve clearances on a VAZ 2108 can cause a lot of trouble. A small gap leads to:

- inevitable burnout of valves;

- loss of pressure in the combustion chamber;

- drop in power indicators.

With an increased gap, the rustling of the valves can be clearly heard and the service life of the camshaft is sharply reduced. The operating instructions provide for adjustments every 20-30 thousand km. Experienced owners recommend adjusting the unit after 15-20 thousand km, especially if the engine runs primarily on gas.

How to understand valve adjustment

To better understand the process of adjusting the 2108 valves, it is necessary to briefly consider the design of the timing valve mechanism of this engine. So, to open the intake or exhaust valve, the camshaft cams are used, which, when the shaft is turned, press on the rod of one or another valve, according to the valve timing, and open it.

This is interesting: How to make a rear shelf on a Daewoo Matiz with your own hands?

The valve is closed by the valve return spring. The cam does not directly act on the valve stem and engines have additional elements in the valve drive. So these can be rocker arms (ZAZ, AZLK, BMW, etc.) of a rocker (classic VAZ) or pushers (glasses) with adjusting washers embedded in them, as in our case under consideration with the VAZ 2108 car and its modifications.

There are special recesses in the block head, round in shape, where a valve with a spring is mounted. A pusher is placed on top of the valve. The pusher has a flange to hold the shim. The washer for adjustment is inserted into this recess in the pusher. The camshaft cam presses on this washer, the washer transmits force to the pusher, and it, in turn, to the valve stem, forcing it to open at the right moment.

Between the camshaft cams and the adjustment washer, it is necessary to maintain a certain gap, designed for thermal expansion of the parts. It turns out that the higher the height of the adjusting washer (its thickness), the smaller the gap between it and the camshaft cam and vice versa.

Each washer has its nominal value in the form of numbers, say 3.15 or 3.80, etc., which is necessary when selecting an adjusting washer by setting the required gap. If for some reason the inscription is erased, then the thickness of the washer is measured with a micrometer. The factory provides a set of adjusting washers from 2.5 to 5.0 mm or more and in increments of 0.05 mm, say 2.5, 3.0, 3.05, 3.10, 3.15, etc. This makes it possible to very accurately select the size in any case - about 122 of the most popular sizes.

In addition, today there are intermediate sizes, such as 3.27; 3.52; 3.78 and others, which further increases the accuracy of adjustment. This is especially true after a major overhaul of the engine with the cylinder head, when the valves were ground in or replaced.

Initial stage: opening access to the camshaft

The proper conditions under which the valve assembly is adjusted are formed after dismantling the cylinder head cover. You can easily remove the upper cylinder head housing with gasket after performing the following procedures:

- loosen the cable by rotating the two nuts to “13” near the bracket and remove it, after first removing the return spring on the plastic sector of the damper drive;

- Using a 10mm wrench, unscrew the two nuts securing the throttle cable bracket and remove it;

- Loosen the fastening clamps with a screwdriver and remove the inlet (located on the front side near the oil filler neck) and two outlet pipes for the crankcase ventilation (attached to the back of the valve cover);

- Unscrew the two nuts securing the housing to the cylinder head (use a “10” wrench);

- remove two rubber plugs located under the nuts already removed in the previous transition.

At the end of the preparation stage for adjusting the valve clearances of the VAZ 2108 engine, an operation is carried out to remove the gas distribution mechanism cover, which is secured with three “10” bolts. A set of necessary accessories is also formed:

- device for recessing the pusher;

- a special clamp that secures the pusher in the lower position;

- tweezers;

- valve tappet retainer;

- set of measuring probes;

- set of adjusting washers.

It is also worth preparing a new cylinder head gasket and sealant.

What is needed for adjustment

As already noted above, you can adjust the thermal clearances of the valves on the vase with your own hands. To do this you need a set of washers, some fixtures and tools. You can make a homemade rail, but it is more cost-effective to buy a ready-made fork for setting gaps at the car market.

Heels for adjustment will be needed in the range from 3.40 to 4.05 mm if the guides in the cylinder head have not been changed. If, however, repairs were carried out, or the car runs on gas, you will have to purchase washers in the range of 2.50 mm for the exhaust valves. Intake valves, as a rule, remain at the same clearance; the seats on them do not flush.

Thus, in this article we briefly examined the procedure for adjusting valves on VAZ cars with front-wheel drive. The consequences of untimely tuning and driving on gas were also touched upon.

To adjust the valve clearances of VAZ 2109, 2108 you will need:

- Availability of a special set of probes, values 0.10-0.50 millimeters.

- A tool designed to perform work on replacing a set of washers.

- Directly the set of replacement washers itself, in accordance with the engine configuration, regulated by the passport data.

Initially, it should be noted that the engine of the car model has 8 valves . According to the vehicle operating regulations, the operation is performed every 20,000-30,000 kilometers.

Everything is done extremely simply, you just need to:

- Set a special TDC or make marks.

- Check the position of the first cylinder , which is done by turning the camshaft 90 degrees clockwise.

- In the future, it is necessary to similarly check the third cylinder , after the fourth and finally the second .

If there is no valve adjuster

The functions of special equipment can be assigned to two powerful flat-head screwdrivers with a flat working surface width of at least 10 mm. In this case, setting the clearances of certain valves on the VAZ 2108 is carried out as follows:

- press the pusher down, leaning on the cam;

- install the edge of a screwdriver between the camshaft and the pusher;

- remove the first screwdriver;

- remove the washer with tweezers;

- install a new part;

- remove the second screwdriver, which acts as a lock.

The process of adjusting the valve mechanism is carried out every 20-30 thousand km and is carried out with the cylinder head cover removed. At a certain angle of rotation of the camshaft, the gap between two pairs of valve tappets and cams is checked with a feeler gauge.

Adjustment of the gaps should be resorted to in case of significant deviations from the norm: 0.15...0.25 mm for intake and 0.30...0.40 mm for exhaust. Using a special device or two screwdrivers, the pusher is bent and fixed, the old washer is removed, a washer of a new thickness is installed, the lock is removed and the resulting gap is checked.

Source

Adjusting valve clearances on a VAZ 2108 engine: procedure

block The nominal value of the “thermal compensator” determined by the manufacturer on a cold engine for the intake valves is 0.2 mm, exhaust valves – 0.35 mm.

Permissible deviations from the nominal value are also specified - 0.05 mm in both directions. A good example: when adjusting the intake valve, the 0.15 probe enters without hindrance, the 0.2 probe enters with slight interference, and the 0.25 probe does not enter at all. This is interesting: Purpose, errors and checking the camshaft position sensor

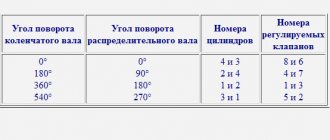

Checking and adjusting the valve mechanism is carried out in pairs in 4 approaches. Each approach is performed at a different camshaft position. Before the first approach, align the marks on the camshaft pulley and the timing belt housing by turning the pulley clockwise with a spanner.

The procedure for checking the actual gap using the first approach as an example is as follows:

- rotate the camshaft 40-50 degrees clockwise (2-3 teeth);

- remove the actual values of the gaps at 1 (exhaust) and 3 (intake) valves using feeler gauges (counted from the timing belt).

The steps for checking the gaps in the remaining pairs of VAZ 2108 valves are carried out by turning the camshaft at intervals of 180 degrees:

- 220-230: 5 (inlet), 2 (exhaust);

- 400-410: 8 (inlet), 6 (exhaust);

- 580-590: 4 (inlet), 7 (exhaust).

The valve adjustment process is carried out in the presence of unacceptable deviations from the norm. The sequence of actions is as follows:

- install the adjustment device on the studs of the bearing housings located at the ends;

- insert a curved lever between one of the valve tappets under study and the cam (the handle of the device should be facing the front bumper of the car);

- by pressing the handle, recess the pusher and install a lock between the edge of the end of the pusher and the camshaft to prevent the part from returning to its original position;

- remove the lever of the device and move it to the side;

- remove the washer using tweezers;

- install a new washer of the calculated thickness with the marking down;

- remove the lock;

- measure the resulting gap.

The selection of a new washer is made based on the following considerations:

- the thickness of the removed washer is determined (if the inscription is erased, the operation is carried out using a micrometer);

- the required thickness is calculated based on the previously made measurement in the format: size of the new washer = thickness of the old part + (measured - nominal clearances).

Here is a detailed diagram of valve adjustment for VAZ 2108, 2109, 2114, 2115

- First you need to cool the engine. You can use an additional cooling fan from any VAZ car. Place it on top so that the airflow is towards the internal combustion engine and turn on the 12 V power supply;

- When adjusting 8 valve engines (11186, 11113 oka, 1118, 1111) with a mechanical throttle assembly, unscrew the throttle cable from the intake manifold receiver;

- Disassemble the valve cover, timing belt side casing. Disconnect the large and small breather hose going to the throttle body pipe;

- Pump out the oil near the valve cups using a syringe or bulb. It is most convenient to use a regular medical syringe with a white silicone hose at the end;

- Install a device for adjustment - a rack for pressing the valve, also called a ruler;

- Set the first adjustment position. Turn the camshaft clockwise to the mark and tighten 2-3 teeth. For cars with a lightweight piston group (Granta, Kalina 2, Priora), turn strictly by the crankshaft. If you turn the camshaft, the timing belt may slip, and if this is not noticed and the engine is driven, the valves may bend;

- Adjust in the following sequence: 1 outlet and 3 inlet valves;

- Rotate the camshaft 90 degrees. Adjust 5 outlet and 2 inlet valves;

- Rotate 90 degrees. Adjust 8 exhaust and 6 inlet ports;

- We make the last turn by 90 degrees and adjust the 4th exhaust and 7th inlet valves;

- Reassemble in reverse order. We install a new gasket under the valve cover to prevent oil from leaking out.

- On carburetor engines, everything is done in a similar order. First you need to unscrew the filter housing and the suction cable. The frequency is the same as on the injector 30,000 km.

Initial stage: opening access to the camshaft

The proper conditions under which the valve assembly is adjusted are formed after dismantling the cylinder head cover. You can easily remove the upper cylinder head housing with gasket after performing the following procedures:

- loosen the cable by rotating the two nuts to “13” near the bracket and remove it, after first removing the return spring on the plastic sector of the damper drive;

- Using a 10mm wrench, unscrew the two nuts securing the throttle cable bracket and remove it;

- Loosen the fastening clamps with a screwdriver and remove the inlet (located on the front side near the oil filler neck) and two outlet pipes for the crankcase ventilation (attached to the back of the valve cover);

- Unscrew the two nuts securing the housing to the cylinder head (use a “10” wrench);

- remove two rubber plugs located under the nuts already removed in the previous transition.

This is interesting: How much oil should be poured into the VAZ 2107 engine?

At the end of the preparation stage for adjusting the valve clearances of the VAZ 2108 engine, an operation is carried out to remove the gas distribution mechanism cover, which is secured with three “10” bolts. A set of necessary accessories is also formed:

- device for recessing the pusher;

- a special clamp that secures the pusher in the lower position;

- tweezers;

- valve tappet retainer;

- set of measuring probes;

- set of adjusting washers.

It is also worth preparing a new cylinder head gasket and sealant.

If there is no valve adjuster

The functions of special equipment can be assigned to two powerful flat-head screwdrivers with a flat working surface width of at least 10 mm. In this case, setting the clearances of certain valves on the VAZ 2108 is carried out as follows:

- press the pusher down, leaning on the cam;

- install the edge of a screwdriver between the camshaft and the pusher;

- remove the first screwdriver;

- remove the washer with tweezers;

- install a new part;

- remove the second screwdriver, which acts as a lock.

The process of adjusting the valve mechanism is carried out every 20-30 thousand km and is carried out with the cylinder head cover removed. At a certain angle of rotation of the camshaft, the gap between two pairs of valve tappets and cams is checked with a feeler gauge.

Adjustment of the gaps should be resorted to in case of significant deviations from the norm: 0.15...0.25 mm for intake and 0.30...0.40 mm for exhaust. Using a special device or two screwdrivers, the pusher is bent and fixed, the old washer is removed, a washer of a new thickness is installed, the lock is removed and the resulting gap is checked.

How to adjust valves on a VAZ 2109? Constant problem

Fans of the domestic automobile industry are interested in how to adjust valves on a VAZ 2109. Problems with thermal clearance can arise on almost all engines that were created at the end of the 20th century. Therefore, the engine requires tuning quite often. Some car enthusiasts visit car repair shops to carry out this work, but adjusting the valves is within the capabilities of everyone. The main thing is that this must be done strictly according to a specific plan. It is advisable to ask for help from someone who has already done this work. He will be able to check the engine tuning and draw your attention to any shortcomings made.

Why do you need setup?

How to adjust valves on a VAZ 2109? To answer this question, you need to decide why this work is needed and when the need for it arises. The engine constantly heats up and cools down during operation. Over time, the location of some elements of its design may shift. Most often, this happens with elements of the gas distribution mechanism. The first thing that suffers is the valve clearance.

On modern cars, a hydraulic compensation mechanism is provided to eliminate this problem. But, on machines like 2109, the adjustment system is mechanical, and therefore requires regular intervention by the owner. If this work is not done, then the valves may either not close at all or not open. In any case, this will negatively affect the performance of the engine.

Settings

- Set of probes;

- A set of keys;

- Adjusting washers;

- Remove the cover covering the timing drive, and at the same time unscrew the spark plugs;

- Set the piston of the first cylinder to the top dead center of the compression stroke. For greater confidence, plug the spark plug hole with a plastic bag; when it “shoots”, the desired position is close. Be sure to check the position of the marks on the pulley and motor. They must match;

- Remove the valve cover. Using a syringe, we pump out the oil present in the head, otherwise we will not be able to see the washers;

- The camshaft gear rotates by 2-3 teeth, on the crankshaft it will be 40°-50°;

- In this position, check the gap on valves 2 and 3. If the indicator differs from the recommended one, then you need to make adjustments. To do this, use a special device to recess the pusher, and use tweezers or an awl to pull out the washer. We look at its value and calculate the thickness for a new one. We put the washer in place;

- Having turned the motor 90° from the mark, bring it 2-3 teeth forward. In this position, valves 5 and 2 are checked;

- Crank the engine again and again turn it forward a little. Check 8 and 6;

- Having turned the ratchet another 90° and tightened it, adjust valves 4 and 7;

- Next, they check again. If everything is in order, then you can assemble the engine. It is recommended to install a new gasket under the valve cover.

- To calculate the thickness of the washer, it is necessary to subtract the excess clearance from its size. For example, the washer is 3.5 mm, and the gap is 0.07 mm less; in this case, the washer is taken 3.43. You probably won’t find one like this, so you can take one with a tolerance of 3.45 mm. If the gap is larger, then the difference is added.

Conclusion

. Owners of old domestic cars are often faced with the need to tune the engine. This is due to the features of their design. To reduce maintenance costs, it is advisable to figure out how to adjust the valves on a VAZ 2109. And in the future, do this work yourself. Fortunately, no special skills are required for this.

vote

Article rating

Actions with the crankshaft when adjusting the valves of VAZ 2109, 2108

Work on the crankshaft to adjust the valves of VAZ 2109, 2108 is carried out without problems. To make it convenient to work, you need to unscrew the spark plugs. This will make it easier to manipulate the shafts and other mechanisms involved in the process. Use the figure below to understand the essence of the process.

And the sequence is:

- The crankshaft must be rotated so that the mark on the camshaft pulley coincides with the mark on the gear shaft cover. Other marks must be placed strictly in their places. You need to focus on the fact that the piston of cylinder No. 1 should be in the top dead center position.

- After this, the crankshaft is rotated 40-50 degrees to move the cams away from the pushers. The technician measures the gaps in 1, 2, 3, 5 valves. The gaps on valve 2 and 3 should be 0.2+-0.05 mm. And on valves 1 and 5 is 0.35+-0.05 mm, respectively If the gaps do not meet the required values, they must be adjusted.

- After this, the crankshaft is rotated 360 degrees, and similar clearance values are checked, only in relation to 4, 6, 7, 8 valves. In the event that there are deviations in the gaps, they also need to be adjusted using a replaceable set of washers.

Valve adjustment diagram for VAZ 2109, 2108

Adjustment table according to factory instructions

| car brand | Inlet | Release |

| Priora 21116 | 0,25 | 0,4 |

| Kalina 2 21116 | ||

| Lada Granta 21116 | ||

| grant 2190 | 0,2 | 0,35 |

| Priora 2170 | ||

| 21114 | ||

| 21102 | ||

| 21099 | ||

| 21093 | ||

| 21083 | ||

| 11186 | ||

| 11183 | ||

| 2190 | ||

| 2115 | ||

| 2114 | ||

| 2113 | ||

| 2112 | ||

| 2111 | ||

| 2110 | ||

| 2109 | ||

| 2108 | ||

| VAZ 99 | ||

| VAZ 083 | ||

| 1118 | ||

| 11113 oka | ||

| 1111 oka |

Bottom line

As practice shows, there is no need to carry out repairs yourself. In this case, this can lead to the fact that even with savings, there is no likelihood that installing washers will lead to a positive result. A significant amount of effort and time will be spent.

Service center specialists will perform all work promptly. This will save you time and resources, and provide you with ideal conditions for operating the vehicle.

IMPORTANT! Be sure to keep in mind that the equipment is first diagnosed, after which the need to adjust the gaps is determined. Take advantage of this offer, which will guarantee you the best working conditions.

Necessary tools and spare parts

First, we need to purchase or borrow from friends a special device with which you can easily remove and install the washers. This device is necessary in order to push the glass down, thereby making it possible to pry the washer through a special gap in it. The most sophisticated valve replacement specialists can do without this device, simply using a screwdriver as a lever; the other procedure remains the same: it is not so convenient, but the savings are obvious.

Another interesting tool allows you to easily and easily measure valve clearances using a gauge micrometer. The meter is installed on a special bar and allows you to determine with millimeter accuracy the amount of clearance by which the washer is recessed into the seat. However, the ability to measure gaps with a special set of feeler gauges has also not been canceled. Of course, the accuracy there is not as high as in the previous version, but it is also much cheaper and quite effective for the task assigned to you.

In addition, you will need a set of simpler and more affordable tools. The most common tweezers to grip the valve washer and the screwdriver used as a lever. A micrometer will also not be amiss: sometimes it is necessary to clarify the thickness of the washer, since its markings are erased. This list of the necessary tools can be considered exhaustive.

You also cannot do without a set of mounting washers for the VAZ 2108 of various sizes. The gap has to be calibrated to the nearest millimeter, so we will need a full store of spare parts if we want to accurately adjust the distances, as required by correct adjustment. If you have stocked up on all of the above tools and a store of spare washers, you can consider that half the job is done. The devil is not as scary as he may seem to us; adjusting the valves on the VAZ 2108 itself is, in fact, not so scary; it is much more dangerous not to do it.

From theory to practice. We adjust the VAZ 2108 valves with our own hands

To correctly calibrate the gaps you only need to know a few basic points. The most important is the recommended range of normal values, measured in millimeters:

- for the exhaust valve it ranges from a minimum of 25 mm, and the maximum distance from the washer to the camshaft cam is limited to 35 mm;

- for the intake valve the range is similar, but the gap sizes themselves are somewhat different. The minimum is 15 mm, and the maximum is 25.

We also do not forget that this distance on VAZ 2108 injection engines tends to decrease over time. Therefore, we recommend adjusting the valves taking this nuance into account, approaching the maximum distance to the cam. On the classics, the effect is exactly the opposite, for this reason, with increasing gaps the problem is much easier to localize. However, drivers who at one time switched from classics to more modern domestic cars like the V8 run the risk of being hostage to an erroneous idea about setting the valves of the power unit, as a result of which the seat burns out and further wear of the “head” parts occurs.

Adjusting valve thermal clearances

The design of the engine on VAZ 2109-2108 cars is such that it is sometimes, although not often, necessary to adjust the valve clearances. Of course, this procedure is slightly different from the VAZ “classic” models, since in this case it is necessary to select the thickness of the adjusting washers. It is because of this that this operation is a little more labor intensive. Also, to perform this type of maintenance, you will need a special device, the so-called rack. A more complete list of required tools is given below:

- adjustment device

- ratchet and socket 10

- long-nose pliers or tweezers

- Phillips screwdriver

- set of flat probes

- shims

Before you begin this procedure, you must complete the following preparations:

It is also worth keeping in mind that the described adjustment work must be carried out at an engine temperature of no more than 20-25 degrees, that is, completely cold (in the summer).

Why do you need valve adjustment on a figure eight?

We have gradually arrived at a very interesting question, what if. What if you didn’t or for some reason forgot about the need for periodic adjustments. It is worth understanding that the design of the VAZ 2108 engine leads to the fact that the gaps decrease over time, which, at best, negatively affects the dynamic characteristics of your iron horse, and fuel consumption, on the contrary, increases. The most advanced cases provoke increased wear of the main parts of the power unit, including:

- camshaft;

- the valve seat and even the adjusting washers themselves burn out;

- The problem may also occur with the pushrod (rocker) and valve system.

In order not to provoke premature aging of your stallion, turning him into a sluggish, tortured horse, you should not forget about the need for periodic maintenance of the valve head on the VAZ 2108, and we also advise you to carefully listen to the sounds from the power unit when the car is running. A sure signal for action is the characteristic clattering sound emitted from the top of the internal combustion engine (actually, from its “head”), the first thing that suffers in this case is the saddle. Well, in order to become a sophisticated specialist in the matter of adjusting VAZ 2108 valves, all you have to do is familiarize yourself with the practical part of this article and get a little experience.