The VAZ classic family cars: 2101, 2102, 2103, 2104, 2105, 2106, 2107, 2121, 2123, 2131, 21053, 21213, 21214 have a four-stroke engine.

The carburetor was installed on the engines of Zhiguli cars until 2000 and subsequently, after a simple modernization, an injector was used on cars 2105 and 2107. This is an in-line engine with vertically arranged cylinders in a block. The channels of the cooling system in the cylinder block are made along the entire height of the cylinders, effectively cooling the piston group, piston rings from “stagnation”, and also preventing deformation of the cylinder block from local heating.

The crankshaft is located at the bottom of the cylinder block on five main sliding bearings. Oil seals made of oil-resistant rubber are used as seals to prevent oil leakage.

An important engine component is the cylinder head. It is a complex cast aluminum alloy block with valve seats and guide bushings pressed into it. The cylinder head contains a cooling jacket and oil passages for supplying lubricant under pressure to the camshaft bearings and rockers that drive the valves.

Oil seals are installed on the valves to prevent oil from entering the combustion chamber. A total of 8 valves are used.

The camshaft is mounted on the cylinder head and is driven by a double-row chain from the crankshaft. Semi-automatic chain tensioning device, powered by a spring. It is possible to install a device for automatic chain tensioning, the rod of which adjusts its position based on the oil supply under pressure.

Unlike the UMZ engine installed on Gazelle, Volga, UAZ cars, the transmission of movement to the valves from the camshaft is carried out through levers (rockers), without the use of rods and rocker arms. The OHC rocker system ensures stable operation of the valves at idle and at high crankshaft speeds, reducing the ringing noise of their operation.

Adjusting valves of VAZ 2106, 2107, etc. According to the maintenance instructions, it is performed every 10,000 km and, due to the simple and compact layout of the engine, there are no difficulties in the procedure.

Getting started and disassembling

Before starting work related to adjusting the thermal clearances of the valves, it is necessary to prepare the engine, tools and related materials.

Secure the car with the handbrake and move the gearbox to neutral. For safety reasons and to prevent independent movement, additionally install shoes under the wheels. Open the hood and check the engine temperature, which should be approximately 20 degrees to carry out the valve adjustment process.

As an exception, there is a correction table for valve clearances depending on engine temperature, but given the unpredictable deformations of the metal structure, we recommend adjusting at the temperature specified in the manufacturer's instructions. It is at a temperature of 20 degrees that the metal structure is in a stable state, without noticeable thermal linear expansion or contraction (negative temperatures).

Before disassembling parts and assemblies to provide access to the valve regulation operation, turn off the power to the on-board electrical network of the machine by disconnecting the negative terminal of the battery.

Further operations for preparing the gas distribution mechanism of a carburetor engine differ from those of an injection engine.

On a carburetor engine:

- Unfasten the retaining spring latches of the air filter housing cover or unscrew the wing nut;

- Remove the cover and put the air filter element aside;

- Using an “8” socket or an open-end wrench, unscrew the four nuts holding the air filter housing on the top of the carburetor and move it to the side, separating it from the crankcase ventilation pipe;

- Remove the carburetor choke drive cable by partially unscrewing the half-clamp holding the cable sheath and the cable rod clamp;

- Using a slotted screwdriver, unfasten the plastic ends of the accelerator pedal drive on the carburetor and, by removing the locking ring from the drive axis mounted on the valve cover, remove the rod.

On an injection engine:

- Remove the limiter (in the form of a bracket) for spontaneous release of the cable from the throttle linkage groove.

- Turn the throttle linkage counterclockwise and pull the cable tip to the side;

- Unscrew the two bolts holding the accelerator cable assembly bracket with a 10mm head;

- If there is an adsorber, remove the connector on the purge valve;

- Loosen the clamps on the air duct and gas ventilation pipes, unscrew with a “10” head the bolt securing the plastic sleeve of the pipes on the valve cover and remove them;

Using a “10” socket, unscrew the eight bolts securing the valve cover and remove it from the block head. Inspect the parts of the gas distribution mechanism for damage and the condition of the springs.

Valve adjustment process

The procedure for adjusting valve thermal clearances is the same for carburetor and injection engines. The only difference is the thermal clearance of the valves. On a carburetor engine, the clearances on all valves are set to 0.15 mm when the engine is cold, and on an injection engine, 0.20 mm. Adjustment begins with setting marks on the crankshaft and camshaft.

By turning the nut securing the belt drive pulley (drive disc on an injection engine) with a special wrench to “38”, we align the mark in the form of a mark on the pulley with the protrusion on the front cover, while the mark on the camshaft sprocket should coincide.

In this position, the piston of the fourth cylinder is at TDC (00 kV) and the eighth and sixth valves are adjusted (numbering from 1st to 8th starts from the radiator).

For this:

- the dipstick is inserted between the camshaft cam and the working surface of the valve lever;

- use key 17 to loosen the locknut to allow free movement of the adjusting bolt;

- by rotating the adjusting bolt with wrench 13, achieve a gap value at which the feeler gauge will move with little effort;

- holding the wrench 13 against turning the adjusting bolt, tighten the locknut.

It must be borne in mind that when tightening the lock nut, the resulting gap may “move” to a larger or smaller direction, so it is important to re-check the thermal gap after fixing the adjusting bolt.

The next pair of valves is adjusted by turning the crankshaft by 1800, while the camshaft sprocket will rotate by 900. The mark on the sprocket will be located at the cut of the junction of the lower and upper camshaft beds.

In this position the fourth and seventh valves are adjusted.

By positioning the crankshaft 360 degrees, the first and third valves are adjusted. And in the position of the shaft set at 540 degrees, the fifth and second are subject to adjustment.

How to determine the need to adjust valves on a VAZ-2107

Returning to the car from the Russian automotive industry VAZ-2107, it should be noted that the production of a modification of the injection engine was launched in 2006. From 1982 to 2006, the Seven was equipped with a carburetor injection system.

Both types of engines, despite certain structural differences, will definitely need to debug the valves. Manufacturers recommend diagnostics of valve adjustment on all cars every 20-35 thousand. km mileage However, many car owners resort to this procedure only when extraneous noise occurs during engine operation.

On the VAZ-2107, adjustments should be made much earlier, since clearance violation is a disease of domestic cars. According to the manufacturer's recommendations, this value is 15-20 thousand. km mileage

This is interesting! Not all internal combustion engines require valve adjustment. If the machine is equipped with hydraulic compensators, there is no need to periodically adjust the valves.

A hydraulic compensator is a device that automatically regulates valve timing. Modern cars are equipped with such devices, so the VAZ-2107 was not equipped with such parts from the factory. You can install them yourself, but it is cumbersome and quite expensive.

You can determine the need to adjust the thermal valve gaps by detecting the following characteristic signs:

- Extraneous noise when the engine is running. These are audible clicking or “clunking” sounds that are usually noticeable when you press the gas pedal hard.

- The engine begins to bore, which is associated with a loss of compression or its complete disappearance.

- Fuel consumption increases without good reason.

- Reduced dynamics during acceleration.

Particular attention should be paid to metallic impact noise, which is the main symptom; everything else is an indirect symptom. The video shows what a metal click is.

If such symptoms appear, a diagnosis should be made and, if necessary, the valves should be adjusted. If the mileage of a VAZ-2107 car is more than 20 thousand km, but there are no signs of timing failure, follow the “do no harm” principle. If the engine is running normally and there are no signs of malfunction in the gap, there is no need to rush to remove the valve cover. There are cases that the carburetor and injection “seven” “traveled” more than 30 thousand. km and did not require any adjustments. Hence the conclusion is that the need for the procedure depends on the nature of the vehicle’s operation.

The adjustment procedure on the VAZ-2107 does not present any difficulties, so every car owner can cope with this task independently. When carrying out the procedure, it is important to know which fuel supply system is installed on the VAZ-2107 car; as for the injector and carburetor, the technician has slight differences.

This is interesting! If you are tired of adjusting the thermal valve gaps on the “Seven”, then an alternative option is to install a cylinder head with hydraulic compensators on a VAZ-2107. Despite the high cost, many car owners resort to installing hydraulic compensators on their own.

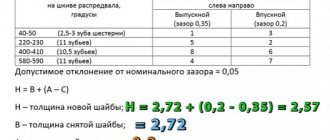

Adjustment order table:

On a carburetor engine, to more accurately determine the position of the camshaft, it is possible to use a distributor, the slider of which is directed to the socket of the high-voltage wire of the corresponding cylinder. If the distributor cover is removed, then four screws on the housing that coincide with the sockets of the high-voltage wires can serve as a guide.

You can also use the distributor with the cover removed: connect a control light to the low-voltage circuit and turn the crankshaft with the ignition on. The moment the light turns on indicates the exact position of the camshaft at which the corresponding pair of valves is adjusted.

Two-step technique

There is a simplified method for adjusting valves in two steps.

- Set the crankshaft to top dead center.

- We combine the marks on the camshaft and the shaft bed.

- We adjust the 4th, 6th, 7th, and 8th valves.

- Immediately after this, turn the crankshaft a full turn.

- We adjust the 1st, 2nd, 3rd and 5th valves.

The two-turn adjustment technique allows you to reduce the time for servicing the gas distribution mechanism, and is also convenient for beginners to carry out this procedure with their own hands.

On a Chevrolet Niva car and a number of Niva cars, the thermal valve clearances are adjusted automatically by hydraulic compensators.

All valve train parts

1 - valve; 2 - retaining ring; 3 - guide sleeve; 4 — oil deflector cap; 5 — support washer of the outer spring; 6 — support washer of the internal spring; 7 — internal spring; 8 — outer spring; 9 — spring plate; 10 - crackers; 11 — valve drive lever; 12 — lever spring; 13 — adjusting bolt; 14 — lock nut of the adjusting bolt; 15 — bushing of the adjusting bolt; 16 — locking plate of the lever spring.

Adjustment Tools

The adjustment procedure begins with disassembling the valve cover and parts that prevent access to it.

Necessary tools for preparing the gas distribution mechanism for adjustment:

- 1/2 inch ratchet wrench with extension and socket for “10” and “8”;

- universal screwdriver;

- pliers.

To adjust the thermal clearances of the valves, the following tool is required:

- Ratchet key to “38”;

- Open-end wrench 17;

- Open-end wrench 13;

- The probe is 0.15 mm thick (for an injection engine - 0.20 mm).

Adjustment with a micrometer

The most accurate method for regulating valve thermal clearances is to use a device with a dial indicator - a micrometer. A micrometer is a very sensitive device that responds to changes in the translational movement of its measuring rod every hundredth of a millimeter.

The procedure is similar to the order of adjustment using a feeler gauge. The peculiarity of this method is to install a rail on the studs of the camshaft bed, onto which a micrometer is attached. The rack contains information on the angles of the crankshaft position to the valves corresponding to adjustment.

Before starting work, the micrometer is mounted on a device that has a lever in the form of a rocker arm. One side of the lever rests on the micrometer rod with a light touch, and the other on the extreme part of the rocker. By lifting the rocker without force with a special “spade” until it touches the back side of the camshaft cam, note how many divisions the arrow has deviated from the zero position. For a carburetor engine, the needle should deviate by 52 divisions.

A micrometer for adjusting valves is supplied with a description and all necessary accessories.

A homemade rail can be made according to a factory design. With the help of such a rack, the actions when independently adjusting the valves are more confident and there is no need to remember the routine or sequence of operations.

What will happen if you do nothing?

Improper combustion causes increased wear on almost all engine parts.

If the valve clearance is greater than desired, the camshaft cam will hit the actuator arm and valve stem. And as a result, they all wear out quickly.

If the gap is small, the valve does not sit entirely on the seat. Hot gases from the combustion chamber penetrate into the resulting gap. As a result, the exhaust valve burns out, the seals wear out, oil starts to burn and other joys begin. Therefore, if symptoms appear, do not waste time. Adjusting the valves of the VAZ 2107 is a must.

Consequences of untimely adjustment

Untimely maintenance of the gas distribution mechanism negatively affects engine performance, causing unbalanced operation. The engine runs rough, there is no traction performance, and fuel consumption increases. It is known that the injection phase is directly dependent on the thermal clearance of the valves. Correct and correct adjustment allows the valves to open and close in a timely manner. If the gap is set less than the permissible value, then the valve begins its operation with some advance, and vice versa, if the gap is large, it opens late. Reduced clearance on exhaust (hot) valves increases the time they remain open, which can cause the edges to slowly burn out, leading to loss of compression in the cylinder.

When operating the engine on gas (propane or methane), the thermal clearances must be adjusted with the same gaps, the value of which is determined by the instructions for operating the engine on gasoline. Adjusting the valves for gas does not have scientific and technical validity and can lead to unstable engine operation.

Bottom line

As practice shows, there is no need to carry out repairs yourself. In this case, this can lead to the fact that even with savings, there is no likelihood that installing washers will lead to a positive result. A significant amount of effort and time will be spent.

Service center specialists will perform all work promptly. This will save you time and resources, and provide you with ideal conditions for operating the vehicle.

IMPORTANT! Be sure to keep in mind that the equipment is first diagnosed, after which the need to adjust the gaps is determined. Take advantage of this offer, which will guarantee you the best working conditions.