Despite the fact that the ZMZ-402 has been out of production for a long time, it enjoys great love among Russian car enthusiasts. Not too voracious, it has amazing maintainability even compared to any VAZ engines, and its torque and power are quite enough not only for the Volga, but also for the rather heavy Gazelle. In this article we will talk about the order in which the valves of this engine are adjusted and reveal some secrets that will allow you to improve its performance.

Position mark of the first cylinder

The first label is of interest. It must be combined with the ebb on the front engine cover. But this is not enough. During a full engine operating cycle, the piston approaches TDC twice. The first time in the compression stroke of interest to us. And the second time the piston reaches TDC during the exhaust gas emission stroke. In the first and second cases, if the piston is aligned strictly to the mark, the camshaft will not exert pressure on the valves. During the compression stroke, the cams will be turned away from the rocker pushers. During the exhaust stroke at TDC, the exhaust valve will close but the intake valve will not open yet. Therefore, it is necessary to accurately install the piston of the first cylinder precisely in the compression stroke.

GAZ 2002, 92 l. With. - with your own hands

Novoaltaysk

GAZ 3110 Volga, 2004

50 000 ₽

Khabarovsk

GAZ 31029 Volga, 1994

30 000 ₽

Ulan-Ude

GAZ 3102 Volga, 2000

90 000 ₽

Chelyabinsk

GAZ 31029 Volga, 1996

60 000 ₽

See more cars on Drome

Participate in the discussion can only registered users.

Login Register

Installing TDC 402 engine

Setting the TDC 402 engine can be done in several ways:

- The easiest way. Remove the distributor cover. The contact of the slider when the piston of the first cylinder is at TDC is approximately under the contact of the high-voltage wire going to the first cylinder. We combine more accurately the first mark of the pulley and the ebb on the front cover. In this position, adjustment of the valves of the first cylinder and beyond begins.

- You can verify that the piston is on the compression stroke without removing the cover. Just turn on the ignition. Install a spark plug into the cap of the first cylinder. Place the candle against the mass. Crank the engine until a spark appears at the spark plug contacts. The spark must jump before the piston reaches TDC. As soon as the spark has slipped through, bring the mark to alignment with the low tide on the front roof.

- The most reliable way to determine TDC in the compression stroke is as follows. It is necessary to remove the spark plug of the first cylinder. Insert a paper gag into the candle hole. compact it. When cranking the crankshaft, the plug will shoot out. After this, all that remains is to combine the marks.

In this position, the valves of the first cylinder of the Gazelle engine 402 are adjusted.

Cylinder arrangement on engine 402

The first cylinder is counted from the cooling radiator

For further adjustment, you need to know the operating order of the engine cylinders.

Operating order of the 402 engine

That is, after adjusting the valves of the first cylinder, the crankshaft rotates 180 degrees. Half a turn. The valves of the second cylinder are adjusted. The valves of the fourth cylinder are adjusted by another 180 degrees. And finally turning the crankshaft half a turn, the valves of the third cylinder are adjusted.

Each time the crankshaft is turned, it is necessary to correctly align the piston of the next cylinder to TDC. The easiest way is to turn the crankshaft half a turn after adjusting the first cylinder and make sure that the piston of the second cylinder is at TDC. To do this, just insert a thin metal probe with a diameter of 3 mm into the spark plug hole. Or a screwdriver.

So that it rests against the piston. As the piston rises, the dipstick will move out. When it reaches its maximum distance it will be TDC. It's easier with the fourth cylinder. TDC of the cylinder piston can be set according to the mark. He will again approach the low tide on the front cover. The third cylinder after turning from the fourth can again be determined using a dipstick.

Adjusting the valves of the ZMZ 402 engine

The valve adjustment of the ZMZ 402 engine is carried out equally on all valves. The lock nut of the adjusting screw is unscrewed. A feeler gauge is inserted between the rocker arm and the upper valve neck. The dipstick is pressed with an adjusting screw. So that it moves between them with little effort.

The clearance for the intake valves is 0.3 mm and 0.4 mm for . You can easily distinguish which valve is inlet and which is exhaust. The intake valves are located opposite the intake manifold passages. The exhaust valves are located opposite the exhaust manifold passages. After the probe of the required size is pressed with the adjusting screw, it should be secured with a nut. The screw itself must be held from turning with a screwdriver.

The ZMZ 402 engines were previously installed on the Volga car, starting with the GAZ 24 model. Before the appearance of the ZMZ 406 engine. Of course, the ZMZ 406 is in many ways superior to the old engines. Both in power and durability. In addition, fuel consumption on ZMZ 406 is lower. No valve adjustment required. Because hydraulic compensators are used. ZMZ 402 are gradually leaving our lives. But there are still a lot of cars with these engines.

Attention:

The tip of the screwdriver should fit tightly into the screw slot, so you need to select the appropriate screwdriver. Otherwise, you will simply damage the spline, and it will be inconvenient to adjust the valves in the future.

. We insert the probe appropriate for your engine model into the gap between the rocker arm and the valve stem and, by tightening or releasing the adjusting screw, ensure that the probe passes through the gap with little effort. After this, tighten the locknut while holding the adjusting screw. The GAZ 21 engine, in addition to a slot for a screwdriver, has 11 wrench edges on the adjusting screw; when adjusting, I advise you to use the wrench. It's much more convenient. We check the gap again. After adjusting the second valve of the first cylinder, set the TDC of the second cylinder and repeat the procedure with it. We repeat the operation until the cylinders run out. The gas ignition order, as we remember, is: 1-2-4-3 After all the valves are adjusted, we put the valve cover in place with a new gasket. If you have straightened it and the bead now lies entirely in one plane, no sealant will be required. When tightened evenly with the required force, oil will no longer leak out. We return the air filter, ventilation hose and vacuum corrector tube to their place. That's all the work. If you prepared everything in advance and used a good tool, you are unlikely to spend more than 40 minutes on everything. Start the engine and enjoy its smooth operation.

When is valve adjustment needed?

The parts of the gas distribution mechanism open one by one and at the right time. The camshaft controls them by pressing its cams on the rocker arms as they rotate. Thermal clearances of the valves are provided between the shaft protrusions and the elements. They are designed to compensate for the physical expansion of metal components from heating - the engine gets very hot during operation. In fact, adjusting the valves on a 402 engine means changing this very thermal gap up or down.

If the element does not close tightly due to thermal expansion, it will actually cease to hermetically seal the combustion chamber, without isolating it from the ducts. If the valve opens late, this already occurs due to an increase in the thermal gap and not only negatively affects the condition of the entire mechanism, but also worsens the supply of the fuel mixture.

The frequency of adjustment is specified in the engine manual: this needs to be done every 10-15 thousand kilometers. Such a short phase between settings is explained by the design failure of the ZMZ-402 motor. The camshaft here is too low and occasionally rattles, and the pushrods are too long. In addition, the quality of the parts used is low, which once again increases the vibration load on the timing belt. For example, the camshaft gear quickly falls off, as it is made of nylon. True, it is protected by a metal sleeve, but the ebonite gear, like on other engines, looks much more reliable.

Required Tools

To correctly adjust the valves of a Gazelle with a 402 engine, you need to prepare the following tools:

- set of screwdrivers;

- probes of different sizes or a universal probe;

- ratchet with extension and 10 mm socket;

- a set of keys, sizes from 8 to 14 mm;

- spark plug key;

- hammer;

- rags.

How to adjust the thermal clearance of valves on Gazelle cars

In case of incorrect adjustment, rapid wear of the gas distribution components and mechanisms occurs.

The engine is noisy and consumes more fuel. If, when the engine is running, a characteristic ringing appears, cold starting has worsened and the spark plugs are flooded, then it’s time for adjustment. The process of adjusting valves on a Gazelle with a 402 engine is not so complicated.

You can do it yourself. To do this, you will need a crankshaft ratchet wrench, a set of feeler gauges, and a new cylinder head gasket.

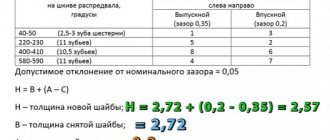

Adjustment is made only on a cold engine. The cylinder order is 1-2-4-3. The exhaust valve clearance on the first and fourth cylinders should be 0.35-0.4 mm, for all other cylinders 0.4-0.45 mm.

Recommended gap size ZMZ-402

The caliber of the thermal gap, in accordance with the engine passport data, should be 0.4 mm. This indicator differs between the intake and exhaust valves, since the latter elements heat up more. Measurements should be taken with probes equipped with a pitch of 0.05 mm or less.

Parameters may also differ due to different operating conditions and driving styles:

- constant transportation of heavy loads, periodic driving in the mountains, use of non-standard gasoline - 0.4 mm;

- engine gas supply - 0.35 mm and 0.45 mm (exhaust);

- constant sharp starts, sporty driving style - 0.3-0.35 mm.

In addition, by reducing the thermal gap, it is possible to increase engine thrust and reduce fuel consumption. But this will only work in quiet driving modes, without load.

Step-by-step instruction

Once you have reached the valves and the 402 engine has completely cooled down, you can begin the adjustment process itself. Here's what will come in handy when working:

- spanners;

- probes.

The work sequence is as follows:

- The first thing to do is get the crankshaft in the correct position for the job. We take a 36mm wrench, hook the ratchet and start rotating it clockwise. We're not in a hurry. As soon as the last mark on the pulley is opposite the mark on the cover, stop the rotation.

- We begin checking the valves of the first cylinder. First make sure they are all closed.

- Adjustment begins with the exhaust valves. We take out the probes and start checking. Normal readings are 0.4 mm, but 0.05 mm less is acceptable. Loosen the locknut before tightening the screw. If the value is greater, tighten the screw, insert the probe and double-check. Twist until a satisfactory result.

- After adjustment, tighten the locknut. After manipulation, the large probe should not pass into the gap between the parts.

- Next is the inlet element. We check the gap again, but this time the limit is 0.4 mm + 0.05 mm. If necessary, loosen the locknut, tighten the screw, tighten the locknut. Let's check.

- Next, the cylinders are adjusted in the following sequence: 2, 4, and the last 3.

- When moving from one cylinder to the next, you need to turn the crankshaft half a turn (180°).

- Adjusting the valves will take a few hours the first time, but the next time everything will go much faster.

- After adjustment, clean the cover and valves.

- We put the gasket on and screw on the compartment lid.

- We put the air filter back and install everything that was previously dismantled, only in the reverse order.

After cleaning and adjusting the valve on the Gazelle 402, the car’s engine should run much quieter. In addition, the vehicle’s normal speed performance will be restored. Fuel consumption will also be reduced. For the next 100 thousand km, you can forget about re-adjustment. After 3-4 adjustments, do not forget to inspect the integrity of the assembly parts; some of them may need to be replaced during operation.

The procedure for adjusting the valves of the ZMZ-402 engine

Below is the detailed procedure:

- remove the terminals from the battery;

- put the gear in neutral;

- disconnect all attachments that extend from the valve cover, including the UOZ hose;

- remove the throttle cables attached to the carburetor;

- remove the air filter;

- unscrew the bolts and remove the upper part of the mechanism;

- remove the spark plugs;

- set the piston of cylinder 1 to TDC, aligning the crankshaft mark with the tide on the front cover of the engine - it is recommended to rotate the crankshaft only with the starter;

- remove the cover of the electrical distributor, check the slider - this element of the distributor should look strictly at cylinder 1;

- start adjusting the valves.

It is advisable to adjust the valves only when the engine is cold! On the other hand, the ZMZ-402 motor is equipped with an aluminum head. The rods tend to expand as the internal combustion engine heats up, and the gaps decrease. For this reason, experienced craftsmen recommend adjusting the 402 system on a warm engine, setting gaps of 0.3 mm on all elements. The exception is Gazelle cars.

As for the marks: they may coincide at TDC with the first or fourth cylinder. How can I check this besides the direction of the slider? If valves 1, 2, 4 and 6 are clamped, and the rest are free, the mark coincides with the 4th cylinder. And vice versa, if 8, 7, 5 and 3 are clamped, the mark coincides with the 1st cylinder.

Adjustment of engine valves 402 in two stages is carried out according to the following scheme:

- first the first intake and exhaust valves;

- then the second intake and exhaust;

- third inlet;

- rotate the crankshaft 360 degrees, align the marks and install the slider on the 4th cylinder;

- adjustment of the remaining valves.

How often does it need to be tuned?

When operating a vehicle under high load - transporting heavy loads, driving in the mountains and at low speeds - the adjustment period is reduced to 8-10 thousand km. And if gasoline that does not match the cylinder head is poured into the tank, the valves need to be adjusted every 5-6 thousand kilometers. Otherwise they will burn out and the engine will lose compression.

To avoid stripping the threads while adjusting the valves, the nut must be rotated very smoothly with a wrench at the beginning of unscrewing and at the last turn of tightening. The tips of the valve mechanism rods of the ZMZ-402 engine are made of duralumin, and not steel, as on the ZIL-130, for example. Therefore, it is extremely difficult to adjust the valves by ear. Rattling and knocking noises can be made by:

- worn camshaft cams;

- unevenly operated rocker arms;

- worn out axis;

- loose springs.

Valves with a defective camshaft cannot be adjusted properly. Therefore, it would be more advisable to replace the camshaft. The same applies to worn-out spring retainers, since the rocker arms in this case will rest not against the valves, but against the spring cups.

Source

Frequency of the procedure

Despite its amazing maintainability, the ZMZ-402 was not very successful in its technical characteristics. The lower location of the camshaft, the presence of long pushrods, and the not very high quality of the parts, all this increases the vibration load on the gas distribution mechanism, and therefore reduces the time interval between adjustments. If the motor is used carefully, without operating under maximum load and without sudden starts, then adjustments must be made every 15 thousand kilometers. If the driver likes quick starts, driving at low speeds and high gears, and is also forced to carry heavy loads or drive through the mountains, then the mileage is reduced to 10 thousand kilometers. If you use gasoline that does not match the cylinder head (cylinder head), then regardless of the ignition settings, the valves must be adjusted after 5–6 thousand kilometers . This will reduce the likelihood of valve burnout and loss of compression.

This is interesting: Do-it-yourself adjustment of ZIL 130 valves

The procedure for adjusting the valves of the ZMZ 402 engine

If the engine doesn’t start well when cold, the spark plugs flood, and you hear a kind of ringing noise while the power unit is running, you need to adjust the valve clearances. Today we will help you understand how valve adjustment is performed on the 402 engine, which is equipped with many Gazelle cars. To perform the procedure, you need to prepare a set of feeler gauges, a key for the crankshaft ratchet, as well as a cylinder head cover gasket (we have already written separately about replacing the cylinder head gasket). Adjustment of engine valves 402 should be carried out exclusively on a cold engine. The adjustment sequence for the cylinders looks like this: 1-2-4-3. On the 1st and 4th cylinders, the optimal exhaust valve clearance is 0.35-0.4 millimeters, and for other cylinders it should be 0.4-0.45 millimeters.

Preparation process

Tools and consumables necessary for the procedure are included in the following list:

- universal probes for measurements;

- set of socket and socket wrenches;

- set of wrenches;

- valve cover gasket;

- spark plug key;

- powerful flat and Phillips screwdrivers;

- hammer;

- clean rag.

Before you begin work on adjusting the valve clearances of the ZMZ-402 valves, you need to familiarize yourself with some of the nuances of the operation. It is important to remember that valve adjustment can only be done when the engine is cold. The state of a cold engine implies equality of the internal temperature of the motor and the external temperature.

The preparation stage includes the following activities:

Checking the engine clearance with a feeler gauge

- unscrewing the license plate in order to install the starter (unit of the starting system of the mechanism);

- removing spark plugs;

- removing the distributor cover (ignition distributor);

- Isolating the negative charge of a car battery.

The type of fuel also affects the dimensions of thermal gaps. The cylinder head, which is designed for No. 92 gasoline, but is used with No. 80 fuel, needs to increase the clearances to 0.4 mm. The use of gas and gasoline No. 76 for the cylinder head is not recommended, since such a case can cause burnout of the valves.

Adjusting valves GAZ 402

The ZMZ-402 engine has been produced since 1985; it first appeared on the transitional GAZ 24M models. It is also widely used

on Gazelles. The eight-valve engine has a lower camshaft and an overhead valve arrangement; its gas distribution mechanism contains the following parts:

- camshaft, it rotates in five supports of the cylinder block;

- camshaft, transmits movement from the crankshaft to the camshaft;

- 8 pushers, driven by camshaft cams;

- 8 aluminum rods;

- the rocker axis, on which the rocker arms themselves are located (8 pcs.) with adjusting screws;

- exhaust and intake valves located in the cylinder head.