A pulley is a disc-like part that takes rotational energy from the crankshaft and sends it to other components through the belt system. It transmits torque as well as mechanical power to the generator.

Once you have decided to replace the timing belt or crankshaft seal, know that you will have to remove the pulley. In this article we will talk about the correct, convenient and simple way to do this. By the way, if you are far from the nearest auto parts store, we recommend that you carefully select a new pulley.

If the goal of your work is to replace it, and as you know, on one car model a pulley can be presented in two or more varieties, then it will be very unpleasant to disassemble the unit and find out that you need to return to the store and change the spare part.

Listen to the advice of experienced auto mechanics and, when reassembling the components, tighten a new bolt, replacing the old one.

How to unscrew a hard-to-reach nut?

The easiest option is to use a gas wrench to unscrew it. After all, a gas wrench clamps the nut and unscrewing it is much easier. If this option does not suit you, you can use a more complicated option. Using a grinder, grind the edges of the nut to the size of a wrench of a smaller diameter, and then everything is simple - unscrew the nut with a wrench.

Interesting materials:

What business can you do at sea? What was Gorbachev like? What sealant should I use to seal the seam between the bathtub and the wall? What kind of glue can be used to glue polyethylene foam? Which clubs did Messi score against? What oil should I use to treat a cast iron frying pan? Where to hit the ball in volleyball? How do premises differ with respect to electrical hazards to people? How are the bones of the brain part of the skull connected? What ocean is Egypt washed by?

Classic methods

Essentially, standard dismantling methods involve two main methods.

You will need:

- jack to remove the wheel

- tool kit

- hydraulic jack to lift the engine, or replacing it with a “stump”

First way

In the first case, we will have to make significant physical efforts, therefore, you need to clearly focus on your own strength. We are talking about the need to put stones or special stops under the wheels that would not allow them to move during operation. The gearbox should, if possible, be set to maximum gear. The higher it is, the easier it will be for you to cope with the task. In third and lower gears, it will be almost impossible to make a turn with your hands. But everything is unscrewed by hand. To make this task easier for yourself, it is appropriate to use a lever that will reduce the necessary effort. In some cases, the length of the lever can reach one and a half meters.

Getting to the bolt is not always easy

Second way

As for the second method, it involves placing the vehicle in neutral gear. Next, you need to install a suitable sized head on the bolt with a piece of pipe, which, in turn, rests on asphalt or concrete. Ordinary soil will not be able to hold it. But the bolt itself is already loosened by the starter.

This saves a lot of effort and makes it possible to complete the task the first time. The main thing is to take into account the reliable fixation of the pipe so that it does not jump out and damage anything around it.

Be careful not to lose the pulley key

But, in any case, the threads in this nut are correct, so you need to unscrew it counterclockwise, with some exceptions, which we will now look at.

Myths, guesses, misconceptions

On one of the guitar forums I read a thread where a person asked - to what degree should the truss rod be twisted? And they answered him - until the click.

You can't do that. A click means that you have at least stripped the threads, or even broken the neck and have a crack running through it.

The rod must be twisted carefully, constantly checking the correct deflection. This can be done simply by looking at the block on the plane - as shown in the photo. This will make it perfectly clear how much it was bent, and how long it will take to twist. Often it only takes a couple of turns to fix the whole situation, so remember - accuracy is paramount.

In addition, before making repairs, it is necessary to remove or loosen the strings - so a beginner should first learn how to change strings on a guitar in order to do this without problems.

Types of Guitar Anchors

First of all, it’s worth understanding what kind of guitar rods there are, and how they generally work. This is important because each type has its own adjustment mechanism.

Contracting

The most popular type of truss rods, which is installed on almost every acoustic guitar. Its principle of operation is to compress the neck as you scroll the rod with the key. Conventionally, it consists of two parts - the first, static, which is responsible for holding part of the tool in one position, and the second, which can be twisted, and which regulates the degree to which the tree is compressed.

bending

A more complex design, which is more typical for electric guitars, especially those manufactured by Gibson. It also represents itself as a mechanism of two elements - a rod, which is fixed inside the tree, as well as a washer, which precisely regulates the compression force. This type of anchor is called compressive precisely because the rod pulls the tree in the direction opposite to the strings, which is why forceful bending occurs.

Design features of car wheel mounting bolts

Product parameters must correspond to the characteristics of a car wheel. The main parameters of bolts include:

- dimensions and direction of thread;

- turnkey size;

- strength class.

Cars

Nuts of types “A”, “B” and “C” are available with six types of small format threads. For M12 the thread pitch can be 1.25 mm, for M12, 14, 18, 20, 22 the thread pitch is 1.5 mm.

Freight

Class “D” nuts are intended for truck wheels. These are M18, 20, 22 hardware with a thread pitch of 1.5 millimeters. The thread direction can be right or left. The size of the wrenches for the nuts is 17, 19, 24, 27, 30 or 32.

Patience

The secret to success is to take your time. | Photo: popularmechanics.com.

The first and most important thing you need to have in such a situation is endurance and patience. If a stuck bolt does not give in, you should not use extra force to immediately move it. This way you can break off the head and delay the repair, as they say, with your own hands. There are many effective means that will help unscrew problematic fasteners. Read more about them in the following paragraphs of our review.

Tool selection

Not every tool is suitable for dealing with problematic fasteners. | Photo: popularmechanics.com.

To unscrew a stuck bolt or nut, you need a spanner or socket, preferably with 6 edges. A regular open-end wrench is likely to slip, smear the edges, and can cause injury. It is undesirable to use 12- and 18-sided tools, as there is a high probability of slipping.

If the fasteners are already licked off, you should get a special head, which is called “for torn edges” or an extractor.

Socket set for removing damaged nuts and bolt heads. | Photo: yaplakal.com.

Main stages of work

As it may seem at first glance, the work ahead is not very difficult; the main thing is to understand what will have to be done.

- First of all, we find access to the pulley so that we can access it with a key or ratchet.

- If the bolt cannot be unscrewed with a wrench, you can try to remove it using the starter.

- Alternatively, you can always use special removable devices.

Now about all this in more detail.

Pulley search

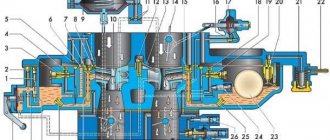

Obviously, your very first action is to find the location of the crankshaft pulley in the engine. As a rule, it is located on your right, less often on the driver's side. Sometimes it can be hidden in the lower front part of the engine.

You need to start looking for it by inspecting the place behind the generator. Most likely you will see something resembling a disk at the bottom of the engine compartment. This will be the part you are looking for.

Preparatory work for convenient access to the necessary components

You need to be prepared for the fact that, depending on the car model, you will have to remove the coolant reservoir, the air filter unit, possibly the radiator and almost always the wheel.

Quite often, such work has to be started by removing the right wheel. You also need to know the location of the ignition coil.

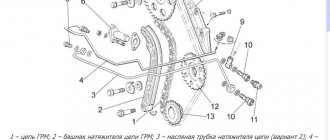

How to remove the crankshaft pulley bolt for starters

The main problem will be to fix the shaft, since its rotation coincides with the threads of the bolt.

On rear-wheel drive cars of the Lada family, the pulley is fixed with a nut (the element is known as a ratchet, due to the ledge for the crooked starter), on front-wheel drive cars with a bolt.

If you don’t have a special tool for removing a bolt in your arsenal, then this job will not be easy for you. The shaft will have to be locked using a fairly long wrench that rests on a hard floor. Head sizes, depending on the brand of vehicle, usually range from 14 to 38.

In some vehicle models, this function can be performed by screwing a bolt designed for this into a special socket. We disconnect the ignition wires or take out the fuse for the fuel pump so as not to accidentally start the engine. It is necessary to place special shoes, bars or any other objects under the wheels that will completely prevent the vehicle from moving.

We take all spectators, assistants and just friends to a safe zone. We ourselves send the gear knob to fourth speed and turn the ignition key with lightning speed. It didn't work the first time, let's try again. Until the bolt turns.

After a successful attempt, we go for the puller and get to work on the pulley itself. Unscrew it counterclockwise. If you are the happy owner of a Honda car, then there is a special ½-inch holder for you that will make your work much easier. It is available for purchase from many online stores.

What problems might you encounter?

There is a possibility that you may not immediately notice the characteristic disc part under the hood of your car. It may also be difficult to access. It will be difficult to fix the shaft. Over a long period of time, the joints of fasteners will “stick” and you will have to use special liquids.

To perform all the necessary steps step by step, you will need the following tools:

- impact wrench;

- puller set;

- jack;

- a set of wrenches or other tools for removing bolts;

- presence of an inspection hole.

Grinder or cut

Perhaps the very last thing, if all else fails, and even if the edges are torn off, then the only thing to do is “cut”! This is usually done with a grinder; you can use a hacksaw if you can’t get to it with a grinder (or it’s dangerous). There’s really nothing to comment on here, we cut it off, remove the remains, and install a new bolt (nut).

I’ll finish here, I would like to note that in 80% of cases WD-40 (or the analogue that I showed you) helps. In other cases (catalyst, manifold, catalytic converter), heating helps. Tested – 100%!

Installing the wheel and tightening the bolts

If the wheel is attached with 4 bolts, you should attach any bolt, and then the next one on the opposite side of the center hole.

- The wheel is installed on studs and secured with bolts.

- The security bolts are lightly tightened using a wheel wrench.

- The car is jacked up and the supports are removed.

- The car is lowered to the ground and all the wheel bolts are tightened in a circle. It is recommended that every effort be made to ensure that the wheel is securely secured. There is no need to be afraid of stripping the thread.

During installation, you need to make sure that the wheel lock parameters match and are suitable in length and diameter. When servicing the machine, the lock is always installed last. And this element should always be dismantled first.

Reverse motion can significantly complicate the dismantling process

But it also happens that the engine works, as they say, “in the other direction.”

We are talking about the fact that the motors are installed with belts to the right. So, they will spin in the opposite direction, that is, counterclockwise. This difference may seem insignificant, but it greatly complicates the search for an answer to the question of how to unscrew the crankshaft pulley.

Moreover, such a procedure may be required every hundred thousand kilometers. We are talking about the need to replace the timing belt. And this does not apply to emergency situations, such as replacing the oil seal or other repair work.

For example, a seventeen bolt can be tightened to a torque of up to one hundred and eighty-five Nm, which can be considered simply a huge indicator.

And to unscrew it you will need even more force. The second method described above will not work, since the starter will spin the motor in the other direction, only tightening the bolt more . Pressing the brake pedal will lead to a similar result, since the transmission will spring back, but the bolt itself will remain in place.

Last resort

A professional impact wrench will help where other methods are useless. | Photo: club.dns-shop.ru.

If even heating does not help, then the rusted fasteners most likely cannot be saved. Pneumatic or electric impact tools are very effective, but impact wrenches often break off the heads of "difficult" bolts.

Unscrewing problematic nuts also often ends with their mechanical removal. To do this, cut the nut into pieces with a saw or grinder; you can also drill with a drill in several places. Sometimes two notches on opposite edges are enough, and the nut begins to rotate. And the easiest way to quickly split an old nut is to use a special device known as a nut cutter or nut splitter.

Set of steel pullers for stuck nuts. | Photo: zubr68.ru.

Nut cutter (nut splitter) at work. | Photo: drive2.ru.

When removing a stuck nut using the methods listed above, the thread is sometimes damaged. To “align” it, it is enough to drive away the damaged studs with a die.

You must be logged in to post.

Due to the lack of the required number of guarded parking lots, car owners install not only alarms on their cars, but also secret bolts on the wheels. Fastening elements with non-standard head shapes are called “secret”. They cannot be unscrewed with a balloon tool; fastening can only be done with the special tool that comes with the kit.

What is a guitar truss rod used for?

Many beginning guitarists who do not understand how the instrument works generally misunderstand its structure. The neck of the guitar is not at all horizontally straight, as many people think. Moreover, it is not so much a perfectly even beam as an arc onto which the strings are stretched, like a string on a bow. If this part of the guitar were perfectly level, then the strings would lie on it and it would be impossible to clamp them. The anchor performs two tasks at once - it takes on the enormous load that a stretched string puts on the tree, and also keeps the neck in one position for more comfortable playing.

Accordingly, if changes occur to the guitar rod, this directly affects the ease of play, as well as the ability to perform songs in general. Two very common problems are directly related to a crooked neck

- This is one of the reasons why the strings rattle - that is, they ring against the saddles, and instead of giving an even, ringing sound, they get along, and sometimes don’t play at all.

- It becomes very difficult to clamp the strings - this is especially felt at the 5th fret and above. It becomes extremely difficult to play with the barre technique - the guitarist begins to spend much more effort than is required. This situation is also directly related to the fact that the guitar truss rod is overtightened and compresses the neck much more than required.

At the same time, the instrument may stop tuning and produce a note a little higher or lower than it should be.

How to fix this? This is exactly what this article is dedicated to.

Lubricate rusty threads

The famous product WD-40 and its analogues. | Photo: popularmechanics.com.

On nuts and bolts that do not come loose easily, you can use one of many lubricants. Penetrating oil like WD-40 is very popular among car enthusiasts. By the way, this is a very useful drug in solving other everyday problems.

Apply penetrating oil generously to the mating surfaces of the parts and leave for some time. If the bolt or nut is very rusty, you can leave the chemical to work overnight.

You can also moisten rusted parts with kerosene, solvent, plain water or Coca-Cola. These remedies also help a little.

Unscrewing the hub nut on a VAZ: “burn, hit and twist!”

Now let’s look at the methods that may be the only effective ones in your case, but that doesn’t make them any less radical, even barbaric.

Strong hammer blows

If you hit the hub, you hit the bearing! If you are going to make a replacement, then go ahead! If you value the bearing, avoid this method.

Warming up the hub nut with a burner. Not recommended!

Using the burner

The law of physics is guaranteed to work, and the body (read: hub nut) will expand. And this will make it much easier to remove the stubborn part. There is one “but”: not only this one part heats up, but also everything else in the area of the burner. For example, a bearing. And it’s better not to allow this. As a more gentle option, we can suggest using a soldering iron and... patience. You'll need it.

Jumping on a lever

A chisel will help you remove the hub nut.

The “method” is fraught with the danger of unexpectedly breaking off the edges of the nut, breaking the key, and so on. Just don't do it.

Video on removing a pulley on cars from various manufacturers

Now let's talk about specific brands and a method that can solve the problem of removing parts.

VAZ car

In this video, auto mechanics managed to unscrew the bolt without any problems, but the pulley itself could not be removed and had to drill holes. We recommend that everyone use this method.

Ford car

Here an expert talks about the difficulties with the damper option. Pays attention to working with the puller.

Renault car

A car mechanic shares the intricacies of fixing the crankshaft. Uses an 18 mm wrench and an old screwdriver.

Honda car

The recording talks about the shaft rotating in the opposite direction: not like most cars. The author also shows us a homemade device for work.

Reasons for self-unscrewing wheels

The dishonesty of tire service workers is a common cause of the problem of wheels unscrewing while driving. The driver rarely monitors its operation; you can hear that the wrench is working, and that’s fine. And this is no wonder; a large number of city car owners never change tires on their own. And it’s great if that tire shop has responsible employees who understand the importance of their work. What if not? You can understand what went wrong somewhere only if you yourself have an understanding of how the nuts are tightened correctly. The result of excessive gullibility is usually a situation where the wheel simply leaves your car at speed.

The main thing about secret bolts

The purpose of the secret bolt is to protect the wheels from theft. The fastening unit has a head for a special key. Only the owner of the car will have the key to the bolts. Locks are popular among car enthusiasts, and many auto repair shops have similar or similar keys in stock, so it is recommended to select less common models.

Advantage and difference from conventional fastening bolts

The advantages and differences from traditional bolts are as follows:

- The bolt head is positioned low.

- The elements are protected by special rings.

- The wheel security bolts are made from high quality raw materials.

Varieties

Certain design differences should be taken into account when choosing secrets:

- The products have an outer head in the shape of an asterisk or polyhedron. The models are very popular among consumers.

- A bolt with an internally shaped head in the form of stars or special shapes. The downside of such secrets is their tendency to accumulate dirt.

- An element with one or more protective rings.

- Bolts that have heads of non-standard sizes. The shape of the pattern can be internal or external.

- Secret wheel bolts with several holes in the head. The design features are that the holes are not located according to a strictly established system, but correspond to certain dimensions of the fastener head. It will be difficult to adapt and unscrew this type of hardware in case of loss of the secret key.

How to install anti-theft bolts

Features of installation of anti-theft bolts:

- When removing nuts or bolts, you need to remember which way to unscrew the bolt on the wheel - counterclockwise.

- Only one lock is installed per wheel. The work is carried out using a wheel wrench. It is recommended to lubricate the bolts with grease before installation.

- The lock is tightened without excessive effort; it is better to use a torque tool.

- They check whether there is a gap between the wheel rim and the nut or whether the bolt is of the required length.

- Install plastic plugs.

All the news, hurry up to visit us.

New on the site

How long can the suction line be ? How to test the pump on a bench. Secrets of dry running of household pumps Water supply with your own hands or the hands of specialists. Selecting a pump for a pumping station.

Latest reviews

Senovad : Hello, Lyubov Nikolaevna. I don’t really understand why Lyubov Nikolaevna : San Samych, hello. Thank you for your reply. I'll try more. Senovad : Hello, Lyubov Nikolaevna. I really wouldn't like to see you. Lyubov Nikolaevna : Hello, San Samych. A very unpleasant thing happened to me. Yuri : No matter how much you want to. You still have to get the pump. And then b.

About the site

I created this site to tell you about my mistakes, to share my experience, my knowledge, my past, present and future projects, my ideas - not only about plumbing. Do not judge strictly. Here I am also learning, and mistakes are inevitable. Ask, I will definitely answer. Share your experience, it will be interesting to everyone.

In branding

To protect against the use of counterfeit parts in the automotive industry, manufacturers resort for commercial purposes to the marketing ploy of using left-hand cutting, from which their products acquire uniqueness and individuality.

This idea ensures that customers will only buy spare parts for repair or replacement from the official manufacturer.

If you find an error, please select a piece of text and press Ctrl+Enter.

Direction of rotation

Typically the bolts are unscrewed counterclockwise. | Photo: popularmechanics.com.

Most people are accustomed to the fact that all screws are tightened clockwise and unscrewed counterclockwise. But in cars, fasteners with a reverse thread direction are often used, for example, left-hand wheel studs. Those who don’t know this will probably “play around” for a long time.