Checking and adjusting clearances in the valve mechanism of Lada Samara

Unadjusted valve clearances on a VAZ 2108 can cause a lot of trouble. A small gap leads to:

- inevitable burnout of valves;

- loss of pressure in the combustion chamber;

- drop in power indicators.

With an increased gap, the rustling of the valves can be clearly heard and the service life of the camshaft is sharply reduced. The operating instructions provide for adjustments every 20-30 thousand km. Experienced owners recommend adjusting the unit after 15-20 thousand km, especially if the engine runs primarily on gas.

Initial stage: opening access to the camshaft

The proper conditions under which the valve assembly is adjusted are formed after dismantling the cylinder head cover. You can easily remove the upper cylinder head housing with gasket after performing the following procedures:

- loosen the cable by rotating the two nuts to “13” near the bracket and remove it, after first removing the return spring on the plastic sector of the damper drive;

- Using a 10mm wrench, unscrew the two nuts securing the throttle cable bracket and remove it;

- Loosen the fastening clamps with a screwdriver and remove the inlet (located on the front side near the oil filler neck) and two outlet pipes for the crankcase ventilation (attached to the back of the valve cover);

- Unscrew the two nuts securing the housing to the cylinder head (use a “10” wrench);

- remove two rubber plugs located under the nuts already removed in the previous transition.

At the end of the preparation stage for adjusting the valve clearances of the VAZ 2108 engine, an operation is carried out to remove the gas distribution mechanism cover, which is secured with three “10” bolts. A set of necessary accessories is also formed:

- device for recessing the pusher;

- a special clamp that secures the pusher in the lower position;

- tweezers;

- valve tappet retainer;

- set of measuring probes;

- set of adjusting washers.

It is also worth preparing a new cylinder head gasket and sealant.

Preparing for regulation

Allow the engine to cool before starting repair work.

The temperature for adjusting the valves should be no more than 20 degrees. To work you will need the following tools:

- set of wrenches;

- screwdriver;

- tweezers;

- puller;

- measuring probe;

- adjusting washers;

- gaskets for 8 valves.

Set the car to the handbrake, lift one of the front wheels with a jack - this will allow you to turn the crankshaft, and then engage 5th gear.

After this, follow the sequence of actions:

- Disconnect the pipes from the valve covers and remove the air cleaner. Then disconnect the throttle drive cables from the carburetor.

- Unscrew the two nuts, remove the cover and remove any remaining oil. Remove the timing belt cover.

- Place the piston of cylinder No. 1 at TDC on the compression stroke.

Adjusting valve clearances on a VAZ 2108 engine: procedure

Checking and adjusting the valve mechanism is carried out in pairs in 4 approaches. Each approach is performed at a different camshaft position. Before the first approach, align the marks on the camshaft pulley and the timing belt housing by turning the pulley clockwise with a spanner.

The procedure for checking the actual gap using the first approach as an example is as follows:

- rotate the camshaft 40-50 degrees clockwise (2-3 teeth);

- remove the actual values of the gaps at 1 (exhaust) and 3 (intake) valves using feeler gauges (counted from the timing belt).

The steps for checking the gaps in the remaining pairs of VAZ 2108 valves are carried out by turning the camshaft at intervals of 180 degrees:

- 220-230: 5 (inlet), 2 (exhaust);

- 400-410: 8 (inlet), 6 (exhaust);

- 580-590: 4 (inlet), 7 (exhaust).

The valve adjustment process is carried out in the presence of unacceptable deviations from the norm. The sequence of actions is as follows:

- install the adjustment device on the studs of the bearing housings located at the ends;

- insert a curved lever between one of the valve tappets under study and the cam (the handle of the device should be facing the front bumper of the car);

- by pressing the handle, recess the pusher and install a lock between the edge of the end of the pusher and the camshaft to prevent the part from returning to its original position;

- remove the lever of the device and move it to the side;

- remove the washer using tweezers;

- install a new washer of the calculated thickness with the marking down;

- remove the lock;

- measure the resulting gap.

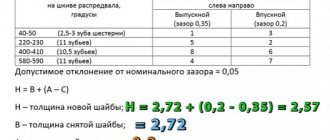

The selection of a new washer is made based on the following considerations:

- the thickness of the removed washer is determined (if the inscription is erased, the operation is carried out using a micrometer);

- the required thickness is calculated based on the previously made measurement in the format: size of the new washer = thickness of the old part + (measured - nominal clearances).

How to adjust: technology and setting procedure + table

For many VAZ models, the adjustment technology is not much different. Those who have already had experience of working with previous versions will find it easy to understand. The gaps are set according to the order in which the cylinders operate. The exhaust valves are 1, 4, 5 and 8 when counted from the camshaft drive belt. We use the following table in our work:

We use the table to correctly determine the cylinder number based on the crankshaft position

Tip: Before starting the adjustment, it is worth placing additional marks on the pulley every 90 degrees.

- Before adjustment, it is necessary to align the piston of the first cylinder. To do this, turn the crankshaft so that the marks on the pulley and the rear belt cover coincide.

The marks on the timing belt pulley and rear cover must be at the same level

- Using a 17 key, turn the camshaft 3 teeth clockwise. This is necessary so that the camshaft cams move away from the pushers.

We install the camshaft so that the fists move away from the pushers

- We test the gaps with an adjustment feeler; the tool should move under the influence of slight forces.

Using a feeler gauge, determine the amount of clearance on the first cylinder

If the gaps are increased or decreased, the following actions must be taken:

- We install the adjustment device on the bearing housing.

Installing the adjustment device

- Turn the pusher towards you.

- Using the lever, we fix the pusher in the desired position.

We press the pusher using the lever and fix it in this position

- Use long tweezers to remove the old washer.

Using tweezers, remove the old adjusting washer

The next task is to select a new washer of optimal thickness. Calculating this parameter is simple; we use the formula below:

H = A + (B – C), where

H – thickness of the new washer,

A – thickness of the removed washer,

B – gap size,

C is the required gap.

Install a new washer and remove the retainer. We check the gap with a feeler gauge and, if necessary, select another washer of the required thickness. The finished set of washers contains products with a pitch of 0.05 mm. This procedure is carried out for each engine cylinder.

Video: How to adjust valves on a VAZ 2109 with your own hands

If there is no valve adjuster

The functions of special equipment can be assigned to two powerful flat-head screwdrivers with a flat working surface width of at least 10 mm. In this case, setting the clearances of certain valves on the VAZ 2108 is carried out as follows:

- press the pusher down, leaning on the cam;

- install the edge of a screwdriver between the camshaft and the pusher;

- remove the first screwdriver;

- remove the washer with tweezers;

- install a new part;

- remove the second screwdriver, which acts as a lock.

The process of adjusting the valve mechanism is carried out every 20-30 thousand km and is carried out with the cylinder head cover removed. At a certain angle of rotation of the camshaft, the gap between two pairs of valve tappets and cams is checked with a feeler gauge.

Adjustment of the gaps should be resorted to in case of significant deviations from the norm: 0.15...0.25 mm for intake and 0.30...0.40 mm for exhaust. Using a special device or two screwdrivers, the pusher is bent and fixed, the old washer is removed, a washer of a new thickness is installed, the lock is removed and the resulting gap is checked.

Source

Adjustment table according to factory instructions

| car brand | Inlet | Release |

| Priora 21116 | 0,25 | 0,4 |

| Kalina 2 21116 | ||

| Lada Granta 21116 | ||

| grant 2190 | 0,2 | 0,35 |

| Priora 2170 | ||

| 21114 | ||

| 21102 | ||

| 21099 | ||

| 21093 | ||

| 21083 | ||

| 11186 | ||

| 11183 | ||

| 2190 | ||

| 2115 | ||

| 2114 | ||

| 2113 | ||

| 2112 | ||

| 2111 | ||

| 2110 | ||

| 2109 | ||

| 2108 | ||

| VAZ 99 | ||

| VAZ 083 | ||

| 1118 | ||

| 11113 oka | ||

| 1111 oka |

Do-it-yourself adjustment of VAZ 2108 valves

According to the established regulations, the valves are adjusted at intervals of 20 to 30 thousand kilometers; valve adjustment on VAZ 2108 vehicles is also necessary after each replacement or dismantling of the cylinder block. Typically, the cost of this kind of work at a service station is not particularly expensive for eight-valve engines on domestic iron horses. Moreover, the procedure requires the presence of a mandatory and specific tool. However, independent skills in repairing your own car have always been invaluable, so this manual will undoubtedly find its reader.

When adjustment is necessary

Valve adjustment is required when problems occur with the engine or after passing a technical inspection. Experienced car owners can quite accurately determine the cause of a power unit malfunction; the main signs are the following:

- the appearance of a characteristic knocking sound when the engine is running;

- a sharp increase in fuel consumption;

- Unstable operation at idle.

Valve adjustment is also required after every 25-30 thousand kilometers . During this time, some parts wear out and structural gaps increase. Diagnostics can be done at a service center; this service is inexpensive.

Necessary tools and spare parts

First, we need to purchase or borrow from friends a special device with which you can easily remove and install the washers. This device is necessary in order to push the glass down, thereby making it possible to pry the washer through a special gap in it. The most sophisticated valve replacement specialists can do without this device, simply using a screwdriver as a lever; the other procedure remains the same: it is not so convenient, but the savings are obvious.

Another interesting tool allows you to easily and easily measure valve clearances using a gauge micrometer. The meter is installed on a special bar and allows you to determine with millimeter accuracy the amount of clearance by which the washer is recessed into the seat. However, the ability to measure gaps with a special set of feeler gauges has also not been canceled. Of course, the accuracy there is not as high as in the previous version, but it is also much cheaper and quite effective for the task assigned to you.

In addition, you will need a set of simpler and more affordable tools. The most common tweezers to grip the valve washer and the screwdriver used as a lever. A micrometer will also not be amiss: sometimes it is necessary to clarify the thickness of the washer, since its markings are erased. This list of the necessary tools can be considered exhaustive.

You also cannot do without a set of mounting washers for the VAZ 2108 of various sizes. The gap has to be calibrated to the nearest millimeter, so we will need a full store of spare parts if we want to accurately adjust the distances, as required by correct adjustment. If you have stocked up on all of the above tools and a store of spare washers, you can consider that half the job is done. The devil is not as scary as he may seem to us; adjusting the valves on the VAZ 2108 itself is, in fact, not so scary; it is much more dangerous not to do it.

Puller drawings. Repair equipment. Tool

Device for tensioning the timing belt (for a new type of roller).

The device is a metal, slightly curved strip, 2 - 3 mm thick, 120 mm long. and width - 25 mm. On one side at a distance of 10 mm. two pins with a diameter of 4 mm are installed from the end. The height of the pins is 10 mm, the distance between the pins is 17 mm. The diameter of the semicircle is 16 mm. Everything should be clear from the photograph of the device.

Instead of this device, to tension the timing belt, you can use two drills (4 mm in diameter) inserted into the holes of the tension roller. We insert a screwdriver between the drills and use it as a lever to tighten the timing belt.

Device for adjusting valves.

Due to the relative complexity of this device and its low cost (less than 200 rubles), I recommend just buying it.

As a last resort, you can use a pair of regular flathead screwdrivers. Using one powerful screwdriver, we recess the pusher, and with the second (you can bend it a little and sharpen it in place) we fix the pusher by the side. But this method is extremely inconvenient and the fixing screwdriver can fly out; in general, it’s only suitable as a last resort.

Device for desiccation of valves.

Like the previous device, it is easier to buy it than to make it yourself. Costs less than 200 rubles.

Homemade device for pressing valve stem seals.

It consists of old pliers slightly modified on a sharpener. The central part of the pliers must be ground off so that when the seal engages, it does not touch the valve stem.

When replacing the oil seal, carefully grasp the cap body with pliers and slowly press it together. The main thing here is not to rush, not to use excessive force (so as not to damage the valve itself and the guide sleeve) and good lighting.

Devices for replacing oil seals (valve seals).

To replace the valve stem seals we will need: 1. A device for loosening the valves. 2. Remover of old caps (modified pliers). 3. Mandrel for pressing in new oil seals. 4. A rod of soft metal, 8-10 mm thick, is inserted into the spark plug hole between the piston and the valve so that the latter does not fall into the cylinder when desiccated. 5. Device for adjusting valves (if adjustment is planned).

Device for adjusting Solex carburetor floats

Drawing of a device for adjusting the fuel level in the float chamber of a Solex carburetor

Photo of a device for adjusting floats

Device for measuring fuel pressure in the fuel rail on injection engines

It is a pressure gauge (used in tire pumps), the markings should be large and at least up to 6 (foreign cars seem to require more). A piece of hose. In this case, a hose for the vacuum brake booster is used. Two normal clamps.

How to measure pressure is described in the following topic: Measuring fuel pressure

Handbrake adjustment key

I highly recommend purchasing a wrench like this for 13, with a ratchet and a hinge. It is a pleasure for them to adjust the tension of the handbrake. It will also be useful for other repair work.

Wrench for bleeding the brake system and unscrewing brake pipes

8 x 10 wrench with the ability to fit onto the brake pipe and securely fasten. The edges of the brake pipe nuts and bleeder fittings remain intact. Indispensable when working with brakes.

Clutch adjustment key

Key for adjusting the clutch drive. It's a 17mm key cut off. It's very convenient to adjust the clutch cable; with a large key you can't really turn it around. On carburetor Samaras, you don’t need to remove anything additional; you can use a short wrench to get to it. On injection engines, unscrew the adsorber, stick your hand in and adjust the clutch.

Source

Why do you need valve adjustment on a figure eight?

We have gradually arrived at a very interesting question, what if. What if you didn’t or for some reason forgot about the need for periodic adjustments. It is worth understanding that the design of the VAZ 2108 engine leads to the fact that the gaps decrease over time, which, at best, negatively affects the dynamic characteristics of your iron horse, and fuel consumption, on the contrary, increases. The most advanced cases provoke increased wear of the main parts of the power unit, including:

- camshaft;

- the valve seat and even the adjusting washers themselves burn out;

- The problem may also occur with the pushrod (rocker) and valve system.

In order not to provoke premature aging of your stallion, turning him into a sluggish, tortured horse, you should not forget about the need for periodic maintenance of the valve head on the VAZ 2108, and we also advise you to carefully listen to the sounds from the power unit when the car is running. A sure signal for action is the characteristic clattering sound emitted from the top of the internal combustion engine (actually, from its “head”), the first thing that suffers in this case is the saddle. Well, in order to become a sophisticated specialist in the matter of adjusting VAZ 2108 valves, all you have to do is familiarize yourself with the practical part of this article and get a little experience.

Bottom line

As practice shows, there is no need to carry out repairs yourself. In this case, this can lead to the fact that even with savings, there is no likelihood that installing washers will lead to a positive result. A significant amount of effort and time will be spent.

Service center specialists will perform all work promptly. This will save you time and resources, and provide you with ideal conditions for operating the vehicle.

IMPORTANT! Be sure to keep in mind that the equipment is first diagnosed, after which the need to adjust the gaps is determined. Take advantage of this offer, which will guarantee you the best working conditions.

From theory to practice. We adjust the VAZ 2108 valves with our own hands

To correctly calibrate the gaps you only need to know a few basic points. The most important is the recommended range of normal values, measured in millimeters:

- for the exhaust valve it ranges from a minimum of 25 mm, and the maximum distance from the washer to the camshaft cam is limited to 35 mm;

- for the intake valve the range is similar, but the gap sizes themselves are somewhat different. The minimum is 15 mm, and the maximum is 25.

We also do not forget that this distance on VAZ 2108 injection engines tends to decrease over time. Therefore, we recommend adjusting the valves taking this nuance into account, approaching the maximum distance to the cam. On the classics, the effect is exactly the opposite, for this reason, with increasing gaps the problem is much easier to localize. However, drivers who at one time switched from classics to more modern domestic cars like the V8 run the risk of being hostage to an erroneous idea about setting the valves of the power unit, as a result of which the seat burns out and further wear of the “head” parts occurs.

Source

Inlet and exhaust valves

The valves are arranged in a V-shape in two rows. The design is similar to the valves of the VAZ 2110 engine, but with a smaller diameter of the plates and rods. The diameter of the intake valve plate is 29 mm, and that of the exhaust valve is 25.5 mm. The diameter of the intake and exhaust valve stems is 7 mm. One spring is installed on each valve.

Car enthusiasts, regardless of how long they have owned a car, are constantly looking for ways to increase engine power. There are several options for improving your car, one of which is modifying the cylinder head (cylinder head).

Adjusting valves on VAZ 2108, VAZ 2109, VAZ 21099

Welcome! There must be a valve clearance, but it must be minimal, otherwise, if there is no clearance, the valves will not be able to close reliably. In this case, depressurization will occur in the cylinders and the power will noticeably drop, and the exhaust valves will begin to burn out. On the other hand, the gap is increased - the valves will not be able to open completely while the engine is running, thereby the power will again drop, because the engine will not be able to supply the fuel-air mixture, because the valves do not open completely. Moreover, the valves can rattle when there is a large gap, and after adjusting them, when you start the engine, you will immediately feel how it will run quieter and in the future you will understand when it is time to adjust the valves on the car.

Note! You will need the following tools: tweezers, a screwdriver, a set of all kinds of wrenches (spanners, sockets, etc.), a set of probes (purchased at a car dealership or car market) and a micrometer.

Summary:

Valves location

You won’t be able to see them that easily, you’ll have to remove the cylinder head from the car, after removal the camshaft and its cams will appear in front of you, under the camshaft cams there are eight valves (or rather their shims, and under them there are pushers, and under the pushers the valves themselves ), which you need to adjust. The shaft cams and valve washers, through which the clearance is adjusted, are indicated by arrows. Under each arrow there is a number indicating the valve number; you will use these numbers to adjust them, so do not forget about this photo as you read the article.

When to adjust valves?

Their gap increases as you drive the car, for example, a hard driving style will require adjustment after 30 thousand, a quiet ride - after 40 thousand you will need to think about adjustment. It is imperative to make adjustments if you buy a used car (few people adjust the valves before selling), especially if you hear the loud sound of the engine running (the valves are knocking). In general, the easiest way to understand whether valves need to be adjusted is to check their clearance: just remove the cylinder head cover from the car engine and use a set of feeler gauges to check the clearance of all valves on the car.