For experienced drivers, systematically adjusting valves becomes a habit - this procedure has such a strong impact on the efficiency of the engine. It is the motor valves that play the leading role:

- in precise regulation of the supply of air-fuel mixture;

- in timely and complete evacuation of exhaust gases from the cylinders.

The slightest dissonance in these processes will inevitably lead to failures in the operation of hub transport systems and their costly repairs. In addition to the obvious loss of power, increased fuel consumption and exhaust toxicity, a car enthusiast may face a complete loss of engine functionality!

That’s why timely and competent checking of the valves’ performance status is the main way to avoid their radical destruction, leading to irreparable wear of the engine and its systems.

Operating principles

To understand why adjustment of engine valves is needed, you will have to delve deeply into the operation of the valves of an internal combustion engine (ICE). The first thing you need to know is that there are always two types of valves in an engine:

- inlet;

- high school graduation.

Second: the standard, full engine operating cycle consists of 4 sequential movements:

- Inlet of the air-fuel mixture into the cylinder;

- Compression of the mixture and its ignition;

- A working stroke performed by pressure force;

- Discharge of the spent mixture from the cylinders.

Moreover, in each individual phase (stroke) the valves occupy a strictly defined position:

- at the inlet (1st movement) the inlet valve opens;

- during compression (2nd movement), the intake and exhaust valves are closed;

- the working stroke (3rd movement) is similarly performed with the valves closed;

- at the exit (4th movement) the exhaust valve opens.

Third: the operation of the valves is possible due to the rotation of the camshaft: its modification (mainly the design of the “cams”) structurally determines the duration and completeness of the phases (their sequence is always the same!) of gas distribution in the cylinders.

Why is it necessary to regulate?

There are only two reasons. This is their “squeezing”, when the thermal gap disappears between the camshaft cam and the pusher. And vice versa, increasing the gap. Both cases do not bring anything good. I will try to tell everything in more detail on my fingers

Why does the valve clamp?

This happens very often among those who drive on gas (natural gas engine fuel). The widest part of the valve is called the plate (it has a chamfer along the edges), it is this that is located in the combustion chamber on one side, and on the other it is pressed against the “seat” in the head of the block (this is the part where the valve goes, thus sealing the combustion chamber).

From high mileage, the “saddle” begins to wear out, as well as the chamfer on the “plate”. Thus, the “rod” moves upward, pressing the “pusher” to the “cam” almost tightly. This is why “clamping” can occur.

THIS IS VERY BAD! Why? Yes, everything is simple - thermal expansion has not gone anywhere. This means that in the “clamped” case, when the rod heats up (elongation occurs), the plate will slightly come out of the seat:

- Compression drops and power drops accordingly.

- The contact with the block head (with the seat) is broken - there is no normal heat removal from the valve - to the head

- When ignited, part of the burning mixture can pass past the valve directly into the exhaust manifold, melting or destroying the “plate” and its chamfer

- Well, a secondary reason is that this mixture can negatively affect the catalyst .

It must be remembered that the “inlet elements” are cooled by the newly incoming fuel mixture!

But the heat removal of the “exhaust” depends on how tightly it is pressed against the “saddle”!

Increasing the gap

There is another situation. It is typical for gasoline engines. On the contrary, the “thermal gap” increases. Why does this happen and why is it bad?

Over time, the plane of the pusher, as well as the surface of the camshaft cams, wear out - which leads to an increase in the gap. If it is not adjusted in time, it increases even more from shock loads. The engine starts to run noisily, even when “hot”.

Engine power decreases due to irregular valve timing. To put it in simple terms, the intake valves open a little later, which does not allow the combustion chamber to be filled normally, and the exhaust valves also open later, which does not allow the exhaust gases to escape normally.

In any case, “clamping” or, conversely, “increasing the gap” negatively affects the operation of the entire power unit. DO NOT NEGLECT ADJUSTMENT! It is worth performing it within the time limits specified by the manufacturer. If you don’t do it, then sooner or later you may end up with a cylinder head overhaul

Now let's watch the video version of the article.

And here I end, I think my materials were useful to you. YOURSINCERELY AUTOBLOGGER

Similar news

- Engine oil pressure. Which should it be? Let's take it apart and move...

- How many filters are there in a car? What are they? I am listing for...

- Timing chain resource. We will also touch on Volkswagen products. Everything is ambiguous...

How does a camshaft work?

If we compare the operation of the camshaft with the speed of a Kalashnikov assault rifle, then the speed of the latter’s shots will be 10 times less. The crankshaft produces 6,000 or more revolutions per minute, with one working cycle consisting of two revolutions, ensuring the intake and release of the air-fuel mixture.

Thus, the frequency of opening and closing of each valve (intake and exhaust) in one minute is at least 3000 times. Moreover, the frequency of the so-called “dead spots” of the valves (i.e., when they occupy their extreme positions in the cylinders) is even greater - 6,000.

Whenever manipulating the crankshaft, valves and cylinders, it is necessary to take into account even hundredths of a second of engine operation, which significantly affects its operational capabilities and durability.

Scooter rider

Scooters are used by both fans of two-wheeled transport and those who save on fuel.

The scooter still remains an indispensable assistant for both. But like any other vehicle, it also sometimes requires attention. For example, periodic tuning. Incorrectly adjusted valve clearances can cause a lot of trouble for the owner. Below we will look at valve clearances on a 4-stroke scooter, or rather their settings. Although four-stroke scooters are reliable, they also require maintenance. If they do not receive service on time, then over time you can end up with serious sums of money. If you feel a hum or knock in the engine that was not there before and is not typical for standard engine operation, then something is wrong. It's probably time to start regulating. It’s a pity not everyone understands this, some just drive with it and then wonder why repairing such a small vehicle is so expensive.

It is recommended to check valve clearances on a scooter regularly (especially clearances on a Chinese scooter). After about 3-4 thousand kilometers. It happens that a scooter can travel 10,000 and not have any extraneous sounds, but it happens that after 1000 km it needs to be adjusted. Regulation is recommended even if there is no extraneous noise after a mileage of 4000 km.

Negative consequences of advanced tuning

Increasing the power of a car by installing a new camshaft with expanded characteristics not only transforms the valve timing, but in proportion to the increased power reduces fuel efficiency and even increases the rate of engine wear!

That is why a radical change of the camshaft is the lot of those vehicles for which, for the sake of speed, it is possible to sacrifice environmental friendliness, efficiency and service life.

or call back 7 (921) 932-25-54

Difficulties in diagnosis

There is an opinion that if a valve burns out, symptoms and problems will be hidden in the ignition system. Very often, car mechanics, who still have little work experience, first of all begin diagnosing and repairing the ignition.

In the process of such repairs, the distributor cover is replaced, high-voltage wires and spark plugs are replaced. The ignition angle is also set - of course, there is no result and there will not be one. The engine has worked and will continue to work. The car mechanic will continue to look for the problem, not knowing the true cause of the problem. Even those mechanics who guessed that the problem lies in the engine see signs of burnt valves only after removing the cylinder head.

How valves work

To understand the procedure for adjusting valves, you need to have a general understanding of the features of their operation. Here we can conditionally highlight three fundamental points.

First: the camshaft can act on the valve stem in 2 ways:

- directly;

- by means of a rocker arm.

In the second case, the indirect effect minimizes the profile difference while maximizing the possible movement of the valve being opened.

Second. The direct impact on the rod due to the lateral loads occurring on it leads to accelerated wear of the rod. To avoid destruction of the rod, its end is protected by the so-called. glass moving in its own guide seat. By absorbing almost 100% of the lateral force, the glass prolongs the service life of the valve.

Third. To improve performance characteristics, adjustments are often used in the design:

- washers (installed between the camshaft cam and the cup);

- screws (installed on the rocker arms, secured with locknuts).

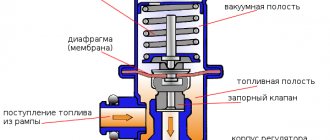

Advantages and disadvantages of using hydraulic compensators

The use of compensators in the valve mechanism made it possible to significantly soften its operation, minimize shock loads and eliminate excess noise. The wear of timing parts has decreased and they have become more accurate, which increases the engine life, its power and torque. The disadvantages of introducing hydraulic compensators include the emergence of special requirements for the operation of internal combustion engines, as well as certain nuances at the time of cold start.

Structurally, the working fluid for compensators is engine oil. In the first seconds after starting the engine, there is practically no pressure, and the operation of the compensators at this moment is accompanied by a characteristic knocking sound. The hydraulic compensators knock especially loudly when they are cold, but as they warm up the noise disappears.

What are gaps and why are they needed?

Modern modifications of engines provide for the presence of more than 2 valves in their cylinders, equipped with gaps with hydraulic compensators; this design does not require intervention. If there are no hydraulic valve compensators, their systematic adjustment is necessary (every maintenance!).

The fact is that completely closing the valve during gas expansion logically leads to the fact that the steel cylinder will not withstand the pressure and will rupture! The reason for the fatal destruction is not only in the mega Pascals acting on the cylinder wall, but also in its critical heating, reaching up to 900 degrees Celsius.

To prevent the valve from closing the cylinder silently, the pusher and the camshaft cam profile are separated by a small gap - a gap. Its size necessarily correlates with the increase in the length of the valve stem when heated and some other indicators.

Join the conversation

You can post now and register later. If you have an account, sign in now to post with your account.

Related content

Hello comrades. We have a problem. mot irbis ttr250 motor 166fmm piston said hello to the valves. The intake was bent. There's a lot of production at graduation. The edge is sharp as a blade. I have already purchased 4 sets of valves, none of them fit. The legs are the same in length, but the plates are different. I'll attach photos. So the question is, how to live? valve took CB250. I ordered it and looked at it in the store. We didn't pick anything up. The new valves have larger poppets than the old ones. at graduation somewhere around 1mm around the circumference. At the intake 0.5mm around the circumference. Plus, the plate itself is a little thicker on the new ones. In the photo you can see the difference (it shines where there is more), it seems like such a small thing, but the motorcycle has been laid up for 2 months now (I took both expensive valves and cheap ones (it would have been easier to take the head with the valves assembled)

Consequences of incorrect thermal clearance

It happens that on a particularly cold day, when the engine is not warmed up, extraneous noise appears: a quiet clicking of metal. Normally, the sound gradually stops as the engine warms up.

If the clicking continues in this state, this is a signal that the thermal gap of one or all valves at once is too large. Such a defect is fraught with not only an unpleasant sound! The valves are forced to remain open for too short a time, which leads to:

- to interruptions in engine operation;

- to a decrease in efficiency;

- to problems starting the engine.

In the worst case, detonation combustion can destroy the engine.

A gap that is smaller than necessary is still a big “evil” for the engine! Heating the cylinder to operating temperature (600-900 degrees Celsius!) expands the metal, eliminating the too small gap.

As a result, efficiency decreases, fuel consumption increases, and the conical chamfers on the valves/seats begin to burn out.

What are "pushers"?

Let's start with something simple (many, I'm sure, don't know what it is). In order for the upper part of the valve and the camshaft cam to run longer, so-called pushers began to be put on them. This is a cylinder, on one side it has a bottom, there is one on the opposite side (to exaggerate, it looks like a metal “cup”).

The hollow part fits onto the valve system with a spring, but the bottom rests on the “cam” of the camshaft. Since the surface of the pusher is large, from 25 to 45 mm (different manufacturers have different values), it will wear out longer than, say, just the upper part of the “rod” (which has a diameter of only 5-7 mm).

Pushers are divided into two types:

- Solid - their adjustment occurs completely by replacing the housing

- Collapsible - when there is a groove on top of the lid into which a special adjusting washer is installed. You can replace it, thus choosing the size of the thermal gap

These elements do not last forever, and they (or the washers on top) also need to be replaced after a certain mileage.

Adjustment of valves

Proper adjustment of valve clearances is a process that requires skill, specific tools (feeler gauge, tweezers, etc.) and complete cooling of the engine. The clearance values of the intake and exhaust valves, the crankshaft rotation angle and other design features of the engine, as well as the sequence of its assembly/disassembly are determined in accordance with the manual for a specific car brand.

The adjusted gaps are checked twice, with permissible deviations not exceeding 0.05 mm.

Tools

- Small pliers or special wrench

- Open-end wrench 9

- 14mm socket wrench or socket

- Socket wrench 8

- A set of measuring probes, preferably with a pitch of 0.02 mm

We free access to the cylinder head: depending on the scooter model, we remove the hood or seat tank. We find the valve cover there, unscrew the four 8mm bolts and remove it from the engine.

The valve cover looks like this. In my case, to get to it I had to remove the hood, saddle and seat tank.

There is a generator casing on the right side of the engine - remove it. If you are too lazy to remove it, just take out the plug. The plug is located in the upper part of the case and can be removed using a regular screwdriver. Through the plug we will control the position of the marks on the rotor.

We insert a 14 mm socket wrench into the center of the generator casing and turn the engine (clockwise) until the “T” mark (from the English “Top” means top, in our case the piston position is at TDC) on the generator rotor is exactly opposite the ledge.

After the mark on the generator coincides with the ledge on the engine crankcase, we check what position the camshaft is in. The camshaft should be in a position where both valves are closed. And it gets into this position every second revolution of the crankshaft since it rotates twice as slow.

The correct position of the camshaft is determined by its sprocket. The sprocket should become the large hole facing up, and the small holes and the marks that are knocked out near them should become parallel to the plane of the valve cover connector.

Cost to fix the problem

You can replace a valve on a domestic car with your own hands at minimal cost, spending about 1,000 rubles on the valve itself, a new cylinder head gasket, lapping paste, and antifreeze for topping up. But usually it doesn’t end with just one burnout: it may be necessary to mill or replace a cylinder head deformed due to overheating, as well as grooving the valve seats. A pinched valve causes the camshaft cam to wear out.

Service stations are reluctant to change one valve, and full maintenance and repair of the cylinder head starts from 5-10 thousand rubles for a VAZ - up to tens of thousands for modern foreign cars.

What does valve clearance affect? With rattling ones or with too tight ones - is it worse? Engine ZMZ-402.

Volga-3110, ZMZ-402, carburetor.

For the second week I can’t understand WHAT it is. The valves rattled a little and they said, “Everything’s fine, let them rattle like that, nothing will happen when they’re too tight, that’s worse.” For about 10 days now I’ve been FEELING that SOMETHING IS NOT SOMETHING. WELL, I DON'T LIKE THE HOW the engine works, there seems to be some kind of extraneous sound (not a hum or an obvious knock, but something in between). WHEN STARTING THE ENGINE (ONLY AT START!) there is a smell of gasoline, which disappears after a minute of running the engine. It feels like the car seems to be driving worse, especially during acceleration. He got our mechanic to complain, looked at it, and said, “EVERYTHING IS NORMAL, he doesn’t hear or smell ANYTHING abnormal.” Another source said that the rattling valves will break the rocker arms and the shaft - as a result, fuel will rush there, the consumption will be through the roof, and it will not run at all, the result is a replacement of the shaft, rocker arms, valves (It happened on a VAZ-2107). Question - WHERE is the truth - how scary are rattling valves? And in general, WHAT does valve clearance affect? WHAT do the above symptoms look like? Or again, “I’m imagining all kinds of dregs - this is the norm for the Russian auto industry”? Gasoline is crap, can the whole reason be the quality of the gasoline? Thank you.

Register, share links on social networks, receive

20% from each money transfer from users who come to the project through your link. More details After registration, you will also be able to receive up to 100 rubles for every thousand unique search clicks to your question or answer More details

I wouldn’t trust this source on the VAZ 2107, since he brought the car to such a state, and there are no rocker arms in the VAZ timing belt, and neither In any way, fuel cannot rush there, because the pistons suck it into the cylinders, and not under the valve cover. Also, philosophical arguments about worse clamped valves or a large gap do not make sense, because both of them are very bad, both for the correct operation of the engine and for the service life of the valves themselves. In short, the conclusion is this: it is imperative to adjust the valves, at the same time it is advisable to inspect the gas distribution mechanism, check for increased clearances of the rocker arms, the integrity of the pusher rods (sometimes the steel tips bounce off them)…

qna.center