Dear readers! Our article is for informational purposes only, which does not imply the provision of services described in the article!

A modern car consists of thousands of parts that determine its functionality in different ways. Some of them directly affect the very possibility of driving a vehicle, others - on its safety and quality, and others - on the comfort of the driver and passengers. For example, broken optics do not allow driving at night, especially on a busy highway, so they need to be replaced with high-quality factory headlights. What to do when shock absorbers leak? The car retains the ability to move. Does this part need to be repaired or can it be done without replacing it?

What does it mean - shock absorbers are leaking?

Since the material is intended for a wide range of readers, it contains a lot of obvious information. But it’s not obvious to everyone. Therefore, those who are more experienced should be understanding. After all, you didn’t start understanding cars out of nowhere either. Beginning car enthusiasts also need to get basic knowledge from somewhere. And finding them today among all the garbage that fills the modern Internet is not so easy.

So, the shock absorber is leaking - what does this mean? To understand the essence, you need to at least get acquainted in general terms with the typical structure of this car part. Shock absorbers (also known as shock absorber struts or just struts) come in three main types. The most common ones have been oil based for many years. There are also gas and gas-oil ones. Actually, the breakdown considered here can happen to racks of any type. But the same fault manifests itself in different ways.

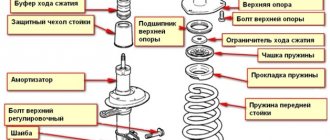

Since oil shock absorbers are found on production cars more often than others, let’s get acquainted with their design. In its simplest form, the rack is, roughly speaking, a sealed tube within which a piston with a rod moves. Physically, this pipe is divided into two compartments connected to each other by bypass holes. Also in the oil shock absorber, as the name should indicate, there is oil.

And that's how this whole thing works. The stand is attached to the machine at two points. The first point is the so-called “glass”. In fact, we can consider that this side of the shock absorber is “tightly” attached to the car body. Although, if we consider the front struts, they can rotate in “cups” on support bearings. In any case, this attachment point cannot move any more.

The second attachment point is the vehicle's movable suspension. Whether in front or behind, the suspension along with the wheels has the ability to move up and down. When this happens, the piston inside the shock absorber moves, squeezing oil into an adjacent compartment. Since the compartments are connected to each other through small holes, liquid cannot quickly flow from one compartment to another. Thanks to this, the effect is obtained, which is popularly called - the stand “holds”.

We will return to the work of shock absorbers later. At this stage it should be clear what it means if the stand is leaking. This means that the working fluid has partially or completely leaked out of it. The more oil a shock absorber has lost, the worse it does its job. Why this happens is also discussed further. But first, it’s worth understanding how the loss of working fluid affects the functionality of the rack.

Suspension knocks and creaks. How to fix

Extraneous sounds often occur in the suspension and shock absorbers. These are knocks and creaks. Most often this is present in the front part of the suspension. Moreover, the reason does not necessarily lie in the rack itself. Sounds can be made by:

- Tie Rod;

- support bearing;

- spherical bearing.

Problems in these units arise more often than in shock absorber struts. Therefore, if extraneous sounds occur, you must first check them. Usually the problem lies in the bearing. Replacing it is not a problem even if you have no experience. A minimal set of tools is enough. The situation is similar with the ball joint.

But sometimes the problem lies precisely in the shock absorber strut. One of the common problems is that the bump stop makes strange sounds. It just falls down the stem. Which leads to squeaking.

The problem may lie in the strut washer: when it does not press the bushing of the support itself well against the bearing. It is necessary to immediately change the washers and supports at the same time. Creaking often occurs in certain situations. For example, on bumps. In this case, the reason in almost 1000% of cases lies in the shock absorber struts. There is only one way to fix this - complete replacement.

How does a dry shock absorber work?

Again, to understand the essence of the issue, it is useful to go from afar. Namely from where the shock absorber strut has not yet leaked. That is, it is in good condition. By itself, it works very simply. When the corresponding wheel moves up or down, the load is partially mitigated by the suspension spring. And the shock absorber strut only does what it “holds” the forward movement of the suspension. As if, it does not allow the wheel to move too quickly under the influence of a sudden load and spring. In addition, the shock absorber dampens the vibrations that the spring seeks to transmit to the wheel.

The stand does this job extremely simply. Moving in one direction or another, the wheel on the suspension pushes or pulls the shock absorber rod. That, in turn, is made inside in the form of a piston moving in an oil environment. Since the piston cannot quickly transfer fluid to the adjacent compartment, the movement of the rod is inhibited.

Now let’s look at how a working shock absorber and one that has leaked work in different situations:

- When hitting a hole . The wheel tends down to the bottom of the pit. The expanding spring contributes to this. However, a working shock absorber “holds” the wheel, preventing it from going down too sharply. Under certain conditions (a small hole and sufficient vehicle speed), the wheel may not even “feel” the hole, simply flying over it. If the shock absorber is leaking, it cannot hold the suspension in such situations. Accordingly, it turns out to be a rough blow.

- When hitting a tubercle . In this case, a working shock absorber at the first stage is even harmful. When hitting an uneven surface, the impact is softened by a spring, but the strut, on the contrary, does not allow you to “take” the entire shock load upon yourself. But when the wheel reaches the highest point of the obstacle, by inertia it tends to go up and further. But the stand doesn’t allow him to do this. As a result, the wheel does not hit the body, and contact with the road surface is restored faster. When the stand is dry, it does not hold anything back. On serious bumps, the wheel hits the body, contact with the road is not restored for a long time, and the car also sways under the influence of the inertia of the spring.

- When accelerating . The vehicle's mass shifts rearward. When the shock absorbers are in good working order during sharp acceleration, they prevent the nose of the car from lifting up and the stern from “squatting.” This is especially important if the car is front-wheel drive, since the grip of the wheels with the road does not deteriorate. When the shock absorber is leaking, the car, during any confident acceleration, looks like that high-speed boat planing through the water.

- When maneuvering . The vehicle's mass shifts in the direction opposite to the direction of rotation. If the struts are in good condition, they partially restrain the strong roll, which has a positive effect on the safety and comfort of the car. Additionally, the anti-roll bar is also responsible for this. If the drains have started to flow, then the car will tilt unpleasantly and dangerously at every sharp turn, and after the maneuver is completed it will also sway.

- When braking . The vehicle's mass shifts forward. Serviceable shock absorbers prevent the body from leaning forward sharply and strongly. If the struts are leaking, the car will nod off when braking. Moreover, due to an even greater mass shift, the traction of the rear wheels with the road deteriorates. In the event of emergency braking, this increases the braking distance and can lead to an uncontrolled skid.

- On a bad road . The suspension works constantly, trying to dampen vibrations and return the wheels to the road surface as quickly as possible. If the shock absorbers leak, the shocks are not fully softened, the vibrations are not damped, and the car’s handling is reduced (sometimes completely lost).

From all this it follows that dry racks are simply useless. That is, they don't work.

Basics of diagnosis

In the era of intensive automobile production, we have been taught that only a service station can give a complete verdict on the condition of the suspension. In fact, there are a number of tests, based on the results of which you can judge the condition of the chassis components without leaving the garage. Thus, a common cause of failure of a shock-absorbing strut is leakage of working fluid/gas escape. This breakdown, first of all, can be visually inspected: traces of oil are clearly visible on the shock absorber body (it is commonly said that it is “snotty”), while a serviceable part always remains dry. It is clear that this only applies to oil and gas-oil struts. Gas analogues do not contain liquid.

The essence of the second test is to evaluate how a single shock absorber dampens body vibrations (read: reacts to swaying). To do this, near each rack you need to push the body down. A serviceable shock absorber element has the following reaction:

- The body returns to its original position the first time without swaying.

- The body returns to its original state smoothly and evenly.

- During operation of the suspension, a characteristic sound (“zilch”) is clearly audible.

A defective rack does not perform its main function - absorbing swing energy. Because of this, instead of one “down-up” oscillation, the body makes two or three. Also during the reverse stroke (upward) no resistance is felt, i.e. the body of the car quickly returns upward, and by definition there is no characteristic sound.

( 2 ratings, average 4.5 out of 5 )

Why do shock absorbers leak?

There can be several reasons for a leak. Contrary to popular belief, the least likely of these is the advanced age of the shock absorbers. According to the regulations, they are supposed to be changed every 60-80 thousand kilometers. However, this only applies to those cases when the car is operated on normal roads. If we take into account the state of our roads, then “old age” or even death of the racks can occur at any moment. Even on the day of purchase and installation of new ones. So, if the shock absorbers on your car have served for more than 80 thousand kilometers, this does not mean at all that they have leaked from old age.

A more likely reason why struts leak is due to excessive loads on the suspension. Sometimes just one hole is enough for the shock absorber to “cry”. This happens because the working fluid has nowhere to go during a sudden movement of the piston. Accordingly, it looks for weak spots in sealing gaskets and oil seals, and flows out through them.

It is worth noting that not every oil leak from a shock absorber is fatal to it. If the working fluid has leaked out a little as a result of the impact, but the stand itself is not worn out, then it is quite capable of continuing to work somehow. To determine whether it can do this, read how to check shock absorbers.

The next reason why car struts leak is mechanical wear as a result of the destruction of the anthers. They protect the mirror surface of the rod from abrasives in the form of dust, dirt and sand. If the anthers are cracked, destroyed, slipped out of place or are completely absent, then the stand wears out very quickly, losing its tightness. It is clear that as a result of this, the shock absorber may begin to leak even under minimal loads. That is, as they say, out of the blue.

Another possible reason why shock absorbers leak is a large load on the cold suspension. This happens in winter. Under the influence of negative ambient temperatures, the working fluid thickens and its fluidity decreases. As a result, during movement, such oil cannot be normally distilled by the piston from compartment to compartment. That is, again, it has nowhere to go, and it looks for weak points to leak out.

In addition to the fact that the viscosity of the working fluid increases in winter, the sealing elements of the shock absorbers also “tanner” in the cold. Cheap counterfeits, originally made from low-quality raw materials, especially suffer from this problem. In order to partially preserve the car's suspension, it is recommended that in the cold season you always start driving so that the shock absorbers are not exposed to shock loads.

There is even a rumor among car enthusiasts that the racks need to be “swinged” manually in winter. This is done very simply. Before starting the trip, you need to press the car body several times so that each shock absorber compresses and unclenches. It is believed that due to this the oil will warm up slightly, and the consequences described above will be avoided.

As for the effectiveness and expediency of such a “buildup”, then who says what. Some are for the fact that this should be done. Others consider such an activity useless, and even stupid. In any case, it won't get any worse. As for warming up, such small loads are most likely not enough for it. So, if you wish and have extra time, you can “download”. But it’s much better to just start driving without forcing the cold suspension until it gradually warms up.

Trivial and obvious reasons for shock absorber leaks include careless driving, inattention, and lack of experience. For example, not all motorists know how to properly drive over potholes and other irregularities on the road. That’s why for some, the suspension lasts for years even on bad roads, while for others it requires repairs almost every spring. Much depends on the quality of the racks. Very often, car enthusiasts, trying to reduce the cost of maintaining a car, buy non-original spare parts, which a priori are not required to last long. Even on ideal roads.

Is it possible to drive if the shock absorber strut has leaked?

There are no restrictions on operating a car with a faulty suspension. Then what is the reason for the widespread recommendations to immediately change the defective shock absorber? Yes, if only because the steering wheel pulls to one side, which in itself is dangerous. However, there is also an economically rational grain in this recommendation.

Normally, the load is distributed between four shock absorbers. When one of them fails, its functions are distributed among three workers. Loading in excess of the nominal value and deviation from coaxial motion leads to rapid breakdown of the rest of the trinity. Moreover, the diagonally located rack will be the first to suffer.

For reasons of economy, it is better to replace one rack at the dawn of its failure than all four, but two months later. The oil does not flow out immediately, but over a long period of time. Therefore, if leaks are detected, it is necessary to immediately replace it. The reference option is to replace two racks located on the same axis at once. The identical characteristics of the shock absorbers lead to the fact that factory controllability is restored, there is no distortion of the sides of the body and their service life increases.

If the failure of one shock absorber does not make significant adjustments to the vehicle's directional stability, then three empty struts pose an extraordinary danger. And here it is better to refuse daily use, and if you drive, then do it very carefully, with minimal speeds both in turns and on uneven roads.

Indirect signs of malfunction

To see that the shock absorber strut is leaking, just look at the suspension from below. However, it is not always possible to do this. And on some cars, due to the design of the shock absorbers, they are simply not completely visible. Accordingly, it will be useful to know about indirect signs that the rack is leaking.

This includes the following signals:

- long rocking of the car even on a flat road;

- knocking when driving over uneven surfaces;

- beating in the steering wheel;

- severe body roll when accelerating, braking or maneuvering.

This is more difficult to notice, but when shock absorbers leak, fuel consumption and braking distance increase, the car handles worse, and does not hold the road during aggressive driving.

Video on the topic

Support a car without a service station:

Privat Bank — 4149 4996 5042 0423

YuMoney — 410 012 458 013 739

WebMoney - Z321475546931

QIWI - 80959400661

- Car without service station

- Chassis