Adsorber or absorber, which is correct? Any internal combustion engine is a source of emissions of harmful substances into the environment. New methods are being invented and old ones are being improved to reduce harmful emissions. Today, environmental friendliness is the reputation of a car manufacturer. For example, in order to comply with the environmental friendliness of Euro 3 engines, a capture device must be installed in the vehicle design, which will ensure lower CO2 emissions.

Fuel absorber

An absorber is a device that absorbs gases and vapors that appear at the outlet of the fuel tank as a result of heating and evaporation. From the Latin sorbeo translates as absorb.

When a car's internal combustion engine is running, the trapped vapors are sent to the fuel injection system - to the intake manifold.

When the engine is not running, part of the fuel vapor is captured by the separator and sent back to the gas tank, and part is captured by the fuel vapor adsorber, where they are neutralized.

Why do you need an absorber in a car?

The automobile fuel absorber appeared when the Euro2 engine environmental class was established. Environmental standards do not allow gasoline vapors to escape into the atmosphere, as this greatly pollutes the environment. Fuel vapors should not enter the car interior.

Such a filtration system does not exist in cars with carburetors. Absorbers began to be installed on cars with injection internal combustion engines.

Is it possible to remove the adsorber? Pros and cons of turning off the system.

The adsorbent system is an integral component of a modern vehicle. A properly functioning filter does not affect the functioning of the engine. Moreover, it allows you to save a little on gasoline, because the trapped fuel vapors are not thrown out, but burn in the engine.

Is it possible to ignore environmental standards and remove the adsorber from the car? This can be done, and it will not affect the operation of the car in any way. From a technical (but not environmental) point of view, this is even better - vapors from the tank will escape directly into the environment, and without additional cans, valves and tubes, the reliability of the car will increase.

It is not difficult to carry out this manipulation - you need to connect a fine filter to the separator through a hose, shut off the adsorber itself and do chip tuning (engine firmware).

Disabling the adsorber has other positive aspects:

- the engine compartment space is significantly freed up, because the system (especially the filter bank) takes up a lot of space;

- the known problem of unstable engine idle operation disappears;

- There is a small cost savings due to the unnecessary purchase of a new adsorber and valve in the event of their breakdown.

At the same time, we should not forget what threatens the shutdown of the adsorbing system, namely:

- There will be a smell of gasoline inside the car, because some of the vapor will go into the cabin;

- light hydrocarbons will be released into the atmosphere and pollute the environment;

- the car itself (outside) may also begin to smell of fuel.

About why an adsorber is needed, how it works, and how to check it, see the following video:

The adsorbent system is a fairly simple but useful component of a car. Maintenance of this element is not difficult or expensive, but if desired, you can go against environmental standards and turn off the adsorber, slightly increasing the reliability of the machine.

That's all for me today. If you have any questions, or if you want to add to the article, write comments.

Best regards, administrator

Automotive absorber design

In simple words, the absorber design is a plastic jar with a filled filter catching element. The best substance for trapping and neutralizing fuel vapors is activated carbon.

The absorber consists of:

- Separator. The separator captures gasoline vapors and sends them back to the fuel tank.

- Gravity valve. It protects against fuel overflow if the car overturns. The valve blocks the movement of fuel.

- Pressure meter. The pressure sensor performs an important function - it monitors the vapor pressure in the fuel tank. When the maximum permissible pressure in the tank is reached, the sensor opens and releases the pressure.

- Filter element (activated carbon). The filter element in a car absorber is carbon in large granules. Large granules allow vapor to pass through the layer of carbon powder and condense.

- Connecting tubes. Connecting tubes serve to connect all structural elements.

- Solenoid valve. The solenoid valve changes the fuel vapor recovery modes.

Reviews have been published about the performance of the Full Free fuel saver.

What is the correct name for an adsorber or absorber?

Both concepts exist in the world. But despite the fact that “sorbeo” and “absorbeo” are translated from the Latin alphabet almost identically: adsorber - (from the Latin Ad - he, with and sorbeo - absorbing) and absorber - (from the Latin absorbeo - I absorb), the semantic load of both words are different.

- In our case, it is an adsorber, since it is a device that absorbs gaseous or soluble substances onto its solid surface without undergoing chemical reactions. There are devices of periodic and continuous action.

- And an absorber is a device that completely absorbs gases (vapors) inside, followed by a chemical reaction, as a result of which one of the substances is completely absorbed by a special liquid (absorber).

Therefore, for our situation, the first option will be correct.

Principle of operation

One of the most important elements in the design of the absorber is the solenoid valve, on which the operation of the entire cleaning system depends.

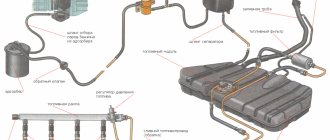

VAZ 2110 diagram

Operating principle and vapor movement in the system:

Gasoline vapor rises to the top of the fuel tank and is captured by a separator, which works in conjunction with a gravity sensor. The gravity sensor ensures safety and prevents fuel from leaking out of the tank in the event of an accident. The captured vapors in the separator condense (take on a liquid form) and return to the fuel tank.

The rest of the fuel vapor enters the absorber, where it accumulates and is neutralized. Accumulation in the absorber occurs when the engine is not running!

After the vehicle’s internal combustion engine is started, the solenoid valve opens and provides a connection between the absorber cavities and the intake manifold or throttle assembly (depending on the design). The purging process begins! Air from the street enters through the throttle valve and mixes with fuel vapor. Next, this mixture is sent to the intake manifold, from where it is supplied to the cylinders. This is how fuel vapors from the absorber are burned.

Checking the functionality of the adsorber

To make sure that the malfunction is related specifically to the valve of this element, you can send the car for a full diagnosis. But this is expensive, so let’s first try to identify possible problems ourselves.

First of all, you need to see if the controller is generating errors, for example, “open circuit control.” If everything is fine, then it will use a manual check. To do this, just prepare a multimeter, a screwdriver and several wires. After this you need to follow a few simple steps:

- Raise the hood of the car and find the valve you need.

- Disconnect the wiring harness from this element. To do this, you must first release the special lock that secures the pad.

- Check if there is voltage going to the valve. To do this, you need to turn on the multimeter and switch it to voltmeter mode. After this, the black probe of the device is connected to the ground of the car, and the red probe is connected to the connector marked “A”, which is located on the wiring harness. The next step is to start the engine and see what readings the device gives. The voltage should be the same as the battery. If it is not there at all or is too small, then you will probably have to look for a more serious problem. If everything is fine with the voltage, then you can move on to the next step.

- Remove the purge valve. To remove it you need to use a screwdriver to slightly loosen the clamps. After this, you can easily move the valve slightly up and smoothly pull it out along a small bracket. After this, the device must be connected directly to the battery terminals. One wire goes to the purge valve (to “+”), and the second is connected to “minus”. After this, both conductors are connected to the corresponding battery terminals. If there is no click, then the valve is completely out of order and it is best to replace it.

Absorber valve: what is it for and what does it affect?

The valves in the absorber are a technically simple device that operate differently depending on whether the engine is running or not. Like all valves, it must open and close.

When the absorber cavity is clogged or some other malfunction occurs, the valve malfunctions. With a faulty adsorber valve, serious vehicle damage can occur because pressure is not released from the fuel tank and the cavity is not purged.

Symptoms of Absorber Valve Problems

There are several signs and symptoms that can help identify the technical condition of the valve:

- The fuel gauge shows either a full tank or an empty one.

- After starting the engine, after 5-10 minutes the revolutions begin to fluctuate.

- At idle speed, when you press the pedal, the car begins to stall.

- The engine does not gain speed when driving. It takes a long time to accelerate.

- When opening the gas tank cap, a vacuum is felt and a whistle is heard.

- Increased fuel consumption.

- When it’s cold (when the engine is running but not yet warmed up), knocking noises from the absorber are heard, as if valves are knocking.

The cause of absorber failure is not always the valve. This may be severe contamination of the absorbent element, in this case coal. Gases should easily pass through the coal granules and condense there.

The valve is very cheap. Therefore, it is possible to change if signs of improper engine operation are detected. You can also replace the adsorber filter element with your own hands: disassemble it, pour out the old coal, pour in new coal in large granules.

Do-it-yourself cleaning of the adsorber, checking the adsorber valve and adjusting it

Please note that if the cause of internal combustion engine malfunctions is precisely problems with the adsorber, it is forbidden to remove this element or connect the hose from the engine and the hose from the tank directly, bypassing the system.

Otherwise, the vacuum created by the engine may damage the tank, fuel will enter the engine, etc. Also, if you remove the valve, the engine ECU will immediately show an error, the engine will go into emergency mode, etc.

The most correct and expensive option is to replace the adsorber. If the owner, for one reason or another, is unable to purchase this item, you can try to clean the old one.

- In some cases, if the adsorber is clogged, it can be cleaned. To do this, simply remove the flask and carefully disassemble it. There is carbon (adsorbent) inside.

Next, you can pour out the coal and heat it in the oven, gradually increasing the temperature. You should be prepared for the fact that when heated, a strong and unpleasant odor will be heard, and the coal will also begin to smoke.

The coal needs to be heated slowly, first to 100 degrees Celsius, then heated for about an hour. Next, the carbon from the adsorber is heated to 300, after which it is kept until the smell disappears. During the “roasting” process, the coal also needs to be stirred from time to time.

After heating is complete, you should leave the coal in the oven and wait until it cools down. The mesh and sponges previously removed from the body, as well as the rubber bands (previously cleaned), are put back in place, then the coal is poured back into the adsorber body. By the way, old sponges can be replaced with new ones by making them from available synthetic synthetic material.

- If we consider the adsorber valve, this element is responsible for ventilation and directs fuel condensate to the engine. In this case, the possibility of failure of the adsorber purge valve cannot be ruled out.

Normally, the valve makes characteristic clicks that can be heard at idle or when the air temperature outside is low. Clicks indicate that the vapor absorption system is working (the canister valve clicks). If you press the pedal sharply, the sound will remain the same, that is, regardless of engine speed.

We also recommend reading the article on how to check the fuel pump in a car. From this article you will learn about the signs of a fuel pump malfunction, as well as ways to check this element.

If the valve knocks loudly, this may indicate the need for adjustment. You need to adjust the adjustment screw, which should be turned 0.5 turns. If you overtighten, the ECU may give an error.

If the canister purge valve malfunctions, this can be identified by diagnosing errors or mechanically checking the operation of the valve. As a rule, electrical damage often occurs, and corresponding errors are recorded in the ECU memory.

What happens if you remove the fuel vapor absorber valve

Is it possible to remove the valve completely? Some people do this, thinking that because of the valve, fuel consumption increases and the car accelerates more slowly.

In fact, if the adsorber and valve are working properly, then the internal combustion engine, on the contrary, works like a clock and the consumption is at the optimal level. The savings are not as noticeable from burning off the remaining fuel vapor, but there is also less choice for the atmosphere.

To the question, is it possible to remove the absorber valve completely? Answer: yes, you can. The engine is not affected by its presence or absence. It only affects if it is installed and faulty.

Disadvantages of a car without a valve and absorber:

- the smell of gasoline in the cabin;

- environmental pollution;

Advantages of a machine without valve and absorber:

- there is more space under the hood (this may be important to some);

- no need to change the absorber and valve.

Owners of carburetor cars, I think, remember how the car’s interior often smelled of gasoline, which is why some people get headaches. For this alone, it is better not to remove the valve and absorber, but to replace them in a timely manner in case of breakdowns.

What is the adsorber used for?

During operation of the vehicle engine, gasoline heats up slightly, releasing very volatile vapors. Their formation is enhanced by the vibration of a moving vehicle. If the vehicle does not have a system for neutralizing harmful fumes, and primitive ventilation is installed, then the formations are simply discharged to the street through special openings.

This picture was observed with almost all old carburetor cars (which is why the car often smelled unpleasantly of gasoline) before the advent of the EURO-2 environmental standard, which controlled the level of harmful fumes into the atmosphere. Today, every car must be equipped with an appropriate filtration system to meet the standards. As a rule, the simplest of them is the adsorber.

Where is it installed?

As a rule, the adsorber is installed under the hood on the right in the direction of travel of the car, for example, in the VAZ 2110 it has the shape of a barrel.

In other cars, it may be square and installed to the left of the engine (in the direction of travel), under the air duct (Lada Granta), the vacuum brake booster (some Nissan models) or in the radiator area. In the VAZ 2114 it is located next to the battery and air filter.

On the Volkswagen Passat B3, the adsorber is located under the air filter on the right side in the direction of travel.

Other vehicles: Refer to model owner's manual.

How to disable or remove the adsorber on a car and do you need to reflash the ECU?

It should be understood that when removing the adsorber, the solenoid valve is turned off, which is connected directly to the controller and is controlled by the latter.

This will result in error p0443, which we already mentioned above. The pipes are also plugged, especially the one that goes to the intake manifold.

What is the disadvantage of such a shutdown?

The fact is that air is constantly drawn in through the pipe going into the intake manifold; even in idle mode, the so-called small purge of the adsorber occurs. At high speeds from 1500 to 2000 and above, a large leak occurs.

The ECU firmware takes into account constant air leaks and fuel vapor consumption during the formation of the air-fuel mixture, despite the fact that all this comes from the mass air flow sensor, the causes of the malfunction of which can be found by clicking on the link.

If you plug the hose, which many people do, a certain amount of air will not get into the intake manifold bypassing the ECU, but the ECU will still take this into account.

That is, the controller takes into account one volume of air, but actually another (smaller) one enters. As a result, the amount of fuel produced by the engine control unit is based on more air than is supplied. This leads to an enrichment of the air-fuel mixture.

As a result, the engine does not perform properly because the mixture is constantly richer in places where it is and is not needed, and fuel consumption increases.

It is also worth talking about the transient mode of engine operation, which can occur when approaching an intersection, a traffic light, a lying policeman, or the moment the gas comes out.

At this moment, a malfunction may occur - a decrease in speed below the minimum. The engine seems to be choking, there is not enough air, the reason is that the mixture is too rich. In a few seconds the situation will be resolved electronically.

Therefore, disabling the adsorber will be correct in the following ways:

- After removing the device, install a nozzle with a diameter of 1 mm in the pipe passing directly in front of the flow meter. This will at least partially solve the problem, since only air without gasoline vapors will be dosed.

- The ECU flashes (difficult). If the test error cannot be resolved, the motor chip may need to be reconfigured, which is expensive.

- Disassembling the entire system with the exception of the solenoid valve, which is at a minimum.

- By installing a resistor (valve emulation) in the electrical circuit of 200 - 250 Ohms and 2 W. To do this, bend the legs of the resistor and insert it into the valve chip. We secure everything with electrical tape. But this doesn't always help.

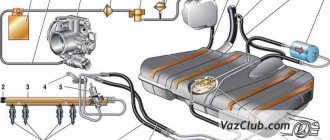

How to disable the adsorber on a VAZ 2110, 2112, 2114

Taking into account the above recommendations, we do the following:

- Disconnect the power connector from the valve.

- Disconnect all hoses from the adsorber and remove the adsorber along with the caliper.

- We fix the valve in a place where you can reach the plug with wires and pipes.

- Connect a hose with a fuel filter to the lower fitting (see Photo below).

- At the end of the upper fitting: connect the pipe going to the intake manifold.

- On the pipe going to the tank, we place another filter, similar to the first.

With this scheme, when the valve opens, clean air enters the system, albeit without gasoline vapors.

We exclude the valve

This method is even simpler. We disassemble everything, including the valve. We put a fuel filter on the pipe coming from the gas tank, and we dampen the pipe going to the intake manifold with a bolt and clamp.

The consequences of this method are described above, but this method also has a right to life.

As for Priora, Granta, Lada Largus, Gazelle and other cars, turning off the shock absorber is similar to that described above.

Toyota Chaser

It is worth considering one of the foreign cars, for example Toyota Chaser.

The shutdown principle is similar to the previous ones:

- Find the cylinder valve. It is located next to the mass air flow sensor on the air filter housing.

- Disconnect the microcircuit with wires and all hoses from it (the controls on the instrument panel may turn on).

- Find the adsorber, disconnect the pipes from it and connect.

- Disconnect the pipe going to the valve from the throttle assembly and connect it with a bolt to the clamp.

- We put the fuel filter from the VAZ carburetor onto the pipe leading to the tank.

What's the catch in flashing from Euro 4 to Euro 2?

Many people ask for ECUs from Euro-4 to Euro-2; as a rule, this is done when removing the catalyst and installing the mixture. At this point, the adsorption valve may be turned off (intentionally or accidentally), and the ECU does not control the latter and does not control it in any way.

As a result, if the valve fails, the engine will run rough and the error will not be displayed on the instrument cluster. To verify this, close the valve and watch the engine operate.

If the version is confirmed, plug the canister pipes and close the valve; the controller still does not control it.