In modern cars, the microclimate in the cabin is provided by three systems - ventilation, heating and air conditioning. And the most structurally complex of them is the air conditioner, whose task is to cool the air in the cabin in the summer. Despite this, the air conditioning system is quite common and is installed on many cars, even in the budget segment.

The operating principle of a car air conditioner is based on the property of certain substances to absorb and release heat when their state of aggregation changes. The same principle is used in household refrigerators and stationary air conditioners. Therefore, all of the listed devices are structurally very similar and consist of the same components. But a car air conditioner is distinguished by its more compact size and the type of drive of one of the main components - the compressor.

Purpose and functions

A car air conditioner is designed to cool the air during the hot season. The main task of the device is to create a comfortable microclimate in the vehicle interior and make the trip comfortable for the driver. The air conditioner also cleans and dehumidifies the air entering the car and ensures its circulation.

Air conditioning in your car will ensure a comfortable ride even on the hottest days

Using an air conditioner allows you to clean the air from dust and harmful substances. The device provides an antibacterial effect and protection against unpleasant odors.

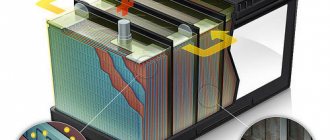

Device and main elements

The design of the device is considered the most complex of all elements of the HVAC system. The air conditioner in a modern car consists of:

- compressor;

- condenser (capacitor);

- high and low pressure lines;

- receiver with dryer;

- evaporator;

- expansion valve (throttle);

- elements of electrical equipment (sensors).

The system is completely sealed and looped with lines. The operation of the air conditioner is ensured by a special gas - a refrigerant that absorbs moisture and releases heat.

Diagram of the device and main elements of the air conditioning system

Compressor

The pressure created by the compressor ensures that the refrigerant moves further through the air conditioning system. Dividing the entire system into high and low pressure circuits, it is driven from the crankshaft via a belt drive. Additionally, the design is equipped with a shutdown mechanism, which is most often used as an electromagnetic clutch.

Condenser

The main task of the element is to cool the refrigerant. The condenser, installed in front of the radiator of the cooling system, consists of curved tubes. They are connected to each other by partitions, increasing the cooling area and providing higher heat transfer. The gas in the condenser is cooled by air currents while the car is moving. Cooling can also occur forcibly - using a fan.

Highways

They are divided into two types: high and low pressure. The former are designed for increased temperature exposure: when heated, the temperature of the refrigerant can reach 110 degrees. The lines are also resistant to increased loads and can withstand pressures of up to 1500 kPa created when refrigerant is pumped.

The gas enters the low pressure lines after passing through the evaporator. At this point, the refrigerant pressure is already close to atmospheric, so ordinary tubes are used as low-pressure lines.

Dehumidifier

A container with a special filler that can retain moisture is used to eliminate moisture that has entered the system. Without a desiccant, water droplets formed as a result of temperature changes would begin to crystallize. Small pieces of ice can damage the system, primarily the compressor.

Expansion valve

The element provides pressure control. Also in this unit the process of evaporation of the refrigerant begins.

Evaporator

The evaporator is the second radiator of the air conditioning system, located under the dashboard in the vehicle interior (in the HVAC module). This element evaporates the refrigerant, taking heat from the environment. A temperature sensor is also installed on it, which regulates the operation of the compressor and prevents icing of the evaporator.

Condensation appears on the surface of the radiator. To prevent moisture from getting onto other elements, the evaporator is equipped with a drainage system that removes condensate outside. The forced supply of cooled air into the car interior is provided by an electric fan installed on the evaporator.

Electrical equipment

The electrical equipment of the air conditioning system performs several functions:

- maintaining the set temperature;

- forced air supply;

- management of the entire system.

The electronic control unit is responsible for maintaining the operation of the air conditioner, which receives and analyzes signals from the following sensors:

- high and low pressure sensors;

- evaporator temperature sensor;

- sea temperature sensor;

- throttle position sensor;

- coolant temperature sensor.

The received data enters the control unit, which, in turn, controls the operation of the compressor clutch.

Exploitation

For trouble-free operation of the equipment, you must comply with several simple requirements:

- change the interior filter in a timely manner, using carbon-containing anti-allergenic inserts to prevent the growth of bacteria in the installation;

- clean the drainage holes to keep the evaporator dry;

- Do not allow the air conditioner to operate with the windows open in the cabin, as this will overload it;

- turn on the air conditioner regularly even in winter, this is required by the condition of lubricating its parts with oil distributed along with freon;

- Do not turn on the compressor if there is not enough refrigerant in the system; use only a fully charged air conditioner with freon and oil.

Despite some danger of colds due to temperature changes, it is difficult to imagine a modern car without a climate system. She is quite reliable. The operating principle of a car air conditioner, with the exception of the compressor, does not imply heavily loaded, quickly wearing parts. On average, maintenance will be required at intervals of about two years, and unscheduled failures can only be associated with aging and wear in sufficiently used machines.

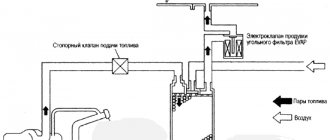

Principle of operation

The air conditioning system operates in a vicious circle. Let's look at the work step by step.

- Compression . The refrigerant gas is forced into the high pressure circuit by the compressor. At the same time, it is in a gaseous state. The refrigerant temperature is about 65°C and the pressure reaches 1.4 MPa. The substance then passes through the high-pressure line and enters the condenser.

- Condensation . Here the refrigerant turns into a liquid, which is still under pressure of about 1.4 MPa and at a temperature of about 55°C. Next on the path of the refrigerant is a desiccant, which removes water and small impurities.

- Extension . Next, the refrigerant enters the expansion valve, which is a throttle (bottleneck). Spraying of the substance occurs, accompanied by a decrease in pressure from 1.4 MPa to 0.12 MPa, which leads to the beginning of the transition to the gaseous state. The process is accompanied by a decrease in temperature to approximately -2°C.

- Evaporation . The refrigerant enters the evaporator and begins to evaporate, taking heat from the environment. At the same time, the water formed during evaporation is discharged through the throttle channel outside the vehicle. Cooled air enters the cabin. The gaseous refrigerant then passes through the low pressure line and returns to the compressor. The pressure is approximately 0.12 MPa, and the temperature is 5°C. From this moment on, the entire described cycle is repeated again.

Air conditioner operating diagram

Cleaning scheme

Cleaning products are available in foam or aerosol form. They have disinfecting properties and contain biologically active components, alkaline additives and acids. They should be used according to the instructions on the packaging.

Chlorhexidine will help you save on special cleaning products. It effectively copes with dirt, fungi and bacteria, and its price is much lower. Used in medicine as an antiseptic solution. You can buy it at any pharmacy.

Self-cleaning the heat exchanger includes several stages.

Disconnect the device from the power supply. For greater safety, turn off the power supply in the apartment during the operation.

Open the front panel and remove the air filters. Rinse the coarse filter under warm running water and put it to dry. Hot water and forced drying with hot air should not be used, as the filter mesh may become deformed.

Depending on the air conditioner model, the evaporator is located under the filters or under the cover. You need to clean it carefully to avoid damaging the device. It is recommended to use a vacuum cleaner with a narrow hose attachment.

Carefully remove any accumulated dust from the heat exchanger. Then use detergent. The best choice for cleaning the evaporator is a spray due to its ease of use. Spray the spray onto the heat exchanger until the product begins to drip from it. Stop, wait 5 minutes and spray again.

Carefully wipe off any remaining detergent from the housing and tubes. The heat exchanger cannot be wiped - there is a high probability of accidentally deforming the lamellas. The product will gradually drain naturally.

Reinstall all removed parts. The filter can be inserted when it is completely dry. Restore power and turn on the air conditioner.

If the device is too dirty due to lack of maintenance for a long time, you should contact the service. In a critical condition, conventional cleaning products may not cope with the task. Professionals most often use a steam generator to combat stubborn dirt.

What is refrigerant?

A refrigerant is a substance that can easily change from one state of aggregation to another. Circulating along the system circuit, it ensures proper operation of the air conditioner.

Some time ago, chlorine-containing freon R12 was used in air conditioners. However, this substance had a negative effect on the ozone layer of the atmosphere. Therefore, all cars produced after 1993 began to use fluorine-containing R134a. These two types of substances are incompatible.

There is also a new generation - R1234yf. This is the most environmentally friendly refrigerant, which, however, is flammable. Until 2022, car air conditioners were extremely rarely adapted to the new refrigerant. However, today many countries have begun to gradually switch to R1234yf.

R134a is the most common refrigerant in modern cars

When is refueling needed?

The refrigerant tends to gradually evaporate, so the air conditioner must be recharged periodically. New cars require refueling on average once every 2-3 years. Vehicles older than 5-6 years are refueled annually (or once every two years).

If the air conditioning system fails, you must first ensure its serviceability and tightness and only then refill the gas.

It is recommended to entrust charging the air conditioner with refrigerant to car service specialists who have the necessary equipment to successfully complete the work.

Equipment cleaning

Indoor unit of a split system

Cleaning of the air conditioner is carried out at least 2 times a year - in spring and autumn. Animal hair and too dirty or humid air, which promotes the appearance of fungi and mold, quickly bring the device into critical condition. If these factors are present, cleaning is carried out at least once every 3 months.

Signals of severe blockage:

- cooling properties have deteriorated;

- The air conditioner power has decreased and energy consumption has increased;

- When you turn on the device, an unpleasant odor appears.

For the cleaning procedure, you can call a professional or do it yourself - the process is not too complicated.

Conditioner oil

In addition to refilling the refrigerant, the air conditioning system must be periodically filled with oil, which is necessary for proper operation of the compressor. The choice of substance directly depends on the refrigerant used. With R12, used in cars manufactured before 1994, Suniso 5G mineral oil is used.

Cars running on R-134a can only be filled with synthetic oils PAG 46, PAG 100, PAG 150.

In 1994, cars were also produced with compressors that allowed the use of both R-12 and R-134a. But even if the car left the assembly line during this transition period, it is unacceptable to mix synthetic and mineral oils. Such a mixture can quickly damage the entire system.

Malfunctions

A common evaporator malfunction is that the air does not cool. As a rule, this happens due to accumulated dust and dirt, a layer of which covers the heat exchanger. The main function, evaporation, is not performed, since the contaminated surface prevents air from reaching the heat exchange surface. If the air conditioner operates in this state for a long time, not only the evaporator, but also other elements of the cooling system may fail (for example, the compressor will burn out).

Fixing this problem is simple - just clean the heat exchanger, and then monitor it more carefully, carry out timely maintenance, independently or with the help of specialists.

In addition, due to depressurization of the circuit or freon leakage, the evaporator may become covered with a layer of ice. The ice will gradually melt, increasing the volume of liquid in the drainage container. Water from an overfilled tank will overflow into the room, causing many unpleasant problems.

Experts will help eliminate the cause by identifying the source of the refrigerant leak. They will carry out repair work on site. When replacing parts, you may have to take the indoor unit to a service center.

Area of application of siphon for air conditioner >>>>