Print this article Font size 16

It should be immediately noted that replacing the clutch on a VAZ 2110 is a drastic measure to repair the unit. In some situations, it is quite possible to get by with repairs that will extend the life of the existing clutch. Today we will look at these issues in more detail in our material.

Disk

How it works and what it consists of

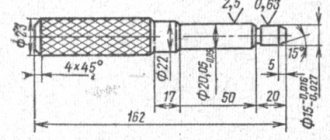

The VAZ 2110 has a single-plate clutch with a central pressure spring. The drive operates via a cable. The casing is attached simultaneously to the pressure plate and flywheel. The design also provides for a driven disk.

Device diagram

The factory clutch system for the VAZ 2110 is called VIS. Many people complain about it because it doesn’t work very effectively, although others are sure that there is no more worthy alternative for the “ten”. So opinions differ on this matter.

The main components of the system include:

- casing;

- Crankcase with a cover and supporting planes with which the unit is attached to the frame;

- Driven and pressure plate;

- Release bearing. It disengages the clutch;

- Flywheel;

- Shutdown plug;

- The cable wire that goes to the pedal (far left in the car interior).

Replacing the VAZ 2110 clutch: adjustment

Adjusting the length of the clutch cable. To work, you need to take a ruler or tape measure.

The adjustment consists of changing the length of the cable:

- You need to place a ruler or tape measure next to the clutch pedal area. It is better to take a ruler, since now you need to rest it on the car floor mat. Next, we need to measure the distance from the surface of the rubber pedal pad to the mat. If the ruler shows that the distance is more than 130 millimeters, then adjustment is needed. If the distance is less than 130 mm, then setting the cable length is also required.

- The next step is to loosen the locknut that secures the cable. By rotating the nut, we change the length of the cable. We need to ensure that it is in the range of 125-130 millimeters.

- We measure again. If the result is successful, you can slide the restrictor sleeve into the fork. Ready.

Choice

If you plan to simply replace the disk, purchasing a completely new node does not make sense from a financial point of view. But when the old clutch leaves much to be desired due to the quality of its work, it’s worth thinking about completely replacing the unit.

Set

Today the market is represented by an extensive list of alternatives made in Europe and China. We strongly do not recommend using Chinese spare parts, but European analogues should be considered as a replacement for VIS.

According to a study conducted among VAZ 2110 owners, the five best kits for the domestic “ten” were determined:

- Kraft Tech.

- LUK.

- Valeo.

- Sachs.

- VIS.

As we have already noted, VIS is installed as standard and works quite well. An important advantage compared to European counterparts is financial accessibility. But if your wallet allows it, replace the old clutch with a better and more expensive one.

In defense of the VIS system, we note that repairs often require simply adjusting the pedal and tightening the cable . And if you are going to completely change VIS to VIS, it will not cost you a pretty penny.

Results

If there is an overpass or lift, the operation is carried out quickly and efficiently, and when there is a reliable assistant, it is also fun. However, not everyone has such capabilities, and this is where engineering ingenuity comes into play.

Some car enthusiasts practice repairing the clutch without removing the gearbox; for this purpose, instead of the upper standard mounting bolts, they screw in longer bolts. For this, for example, two bolts from the upper arm of the front suspension of the “VAZ classic” are suitable. By screwing them into the upper holes, the box can be moved back by 14-15 cm with a pry bar. In this case, the transverse rod should not be unscrewed, because the rear part of the gearbox will lie on it. These conditions are quite enough to replace faulty parts.

If repairs are necessary, experts recommend doing a complete replacement of the entire assembly along with the release bearing, especially since the choice of clutch kits is quite wide. This position is explained simply - an old part left behind threatens to fail at any moment. The procedure, as you yourself saw in the video, is quite labor-intensive, and repeating it over and over again is not a pleasant pleasure, except for real “homemade people.”

Source: autobann.su

Popular problems and their solutions

There are several characteristic faults that occur on the VAZ 2110. Let's try to understand the reasons for their occurrence, and also consider ways to solve the problem.

- The clutch drives. The reasons may be: The pedal has insufficient travel, the tension is too tight. To eliminate this, you need to adjust the drive;

- The driven disk is deformed. Only replacement will help here;

- The driven disc hub sometimes gets stuck. If so, try washing it and lubricating the input shaft splines. If the element or the shaft itself is worn out, then replace them;

- The friction linings are broken and the rivets are loose. The best solution is a complete replacement of the casing, which includes a spring and a disk;

- The pressure plate is warped or warped. Replace the linings, but first make sure that there are no deviations in the end runout of the disk;

- There were problems with the cable. Pull it up. If there is no result, replace with a new one.

- The friction linings on the driven disk often burn or wear out. There is only one solution - replacement;

- Oil has reached the surface. We have already described how to solve the problem above;

How to change the clutch yourself: sequence of work performed

So, replacing the clutch on a VAZ 2110 can be done by specialists or with your own hands in a regular garage. Note that the procedure for replacing the clutch on a VAZ 2110 is not complicated. If you have the knowledge and the necessary tools, repairs and replacements can be done independently.

Preparatory work for replacing the clutch:

- new clutch kit for VAZ 2110;

- a set of socket and wrenches;

- screwdriver, crowbar, jack, bricks (“goats”).

Self-replacement of the VAZ 2110 clutch:

- Having loosened the bolts securing the left wheel, lift the front part of the car with a jack, substitute the “goats”;

- Having removed the left wheel, unscrew the two fastening bolts of the lower ball joint;

- Having removed the negative terminal from the battery and removed the connector from the mass air flow sensor, loosen the clamp securing the corrugation to the mass air flow sensor, remove the car air filter element housing;

- Having removed the clutch cable from the clutch fork, loosen the two fastening nuts of the cable to the bracket on the gearbox;

- unscrew the M3 mounting bolt to the gearbox housing and the first mounting bolt of the gearbox itself;

- Using a wrench with a “19” head or a pipe-wrench, unscrew another fastening bolt of the gearbox, loosen the fastening nut;

- unscrew the upper mounting bolt of the starter and remove the connector from the speed sensor, unscrew the speedometer cable;

- remove the longitudinal brace with the lever;

Unscrew the lower mounting bolt of the starter and the third mounting bolt of the gearbox (the gearbox mounting nut is located in the area of the internal constant velocity joint of the CV joint). - unscrew the two reaction rod mounting bolts;

- loosen the nut on the gearbox control rod clamp and remove it from the gearbox;

- After freeing the gearbox from the main fastenings, use a wrench to disconnect several mounting bolts and one nut and disconnect the unit from the vehicle’s internal combustion engine.

- unscrew the two nuts of the rear cushion, which secures the gearbox to the vehicle’s internal combustion engine, and remove it;

We also recommend reading the article about why your car may have a tight clutch and what are the reasons why the clutch is tight. From this article you will learn about possible malfunctions and repair methods, as well as solutions to the problem when the clutch pedal is tight. - when dismantling the rear cushion, it is necessary to place a support under the vehicle’s internal combustion engine to avoid lowering the engine too low, as this may lead to the separation of the interior heater hoses;

- just like the internal combustion engine, raise the car’s gearbox, moving it away from the engine in advance;

- Having gained access to the unit for replacement or repair, perform the necessary operations to replace the clutch or repair it;

- after work has been carried out to replace the clutch or repair its individual components (release bearing, clutch disc, VAZ clutch basket, linings, etc.), the parts are installed in the reverse order

- during the assembly process, it is important not to forget to tighten the fastening screws of the gearbox to the internal combustion engine;

Let us also add that after replacing the clutch, it is necessary to center the disc. After dismantling the clutch housing, it must be inspected for various damages (cracks, thread wear, weakening of the “grip” of the paws holding the housing).

The total scope of repair work depends on the condition of the units. We also note that to install the clutch disc and basket, you must use a simulator of the gearbox input shaft.

What you need to know

The release bearing is not the weakest link in the clutch system, but for some reason it is the one that causes problems and troubles.

coupling

Some car owners have gotten used to the whistle and simply ignore it. But this cannot continue for long, since untimely solution to the problem can lead to even more complex and expensive repairs. If the situation gets worse, then a simple replacement will not be enough for you.

The clutch serves to act on the leaf spring of the clutch basket. It is also called diaphragm, so don't be confused if you hear this designation. Due to this impact, the driven disk is disconnected from the flywheel and the pressure plate of the basket. This disengages the clutch.

If the squeezer is faulty, this can lead to various consequences:

- The clutch fork will be damaged;

- The integrity of the clutch spring petals will be compromised;

- The guide bushings are deformed.

In order not to pay twice, or even three times, promptly react to the appearance of a whistle in the clutch and try to quickly take action.

What to do next?

If the fork lever or legs are severely worn at the point of contact with the clutch, the fork must be replaced. In this case, the worn part is dismantled, and then a new one is pressed into its place, until it stops. Before installing the part, treat the plastic and metal bushing with grease. Next, installation of the device is carried out in the reverse order similar to removal

Please note that the protrusion on the plastic sleeve must fit exactly into the groove on the clutch housing, and the petals must securely fix the installed part, preventing it from falling out

So, we found out how to replace the clutch on a VAZ-2110 car with your own hands. Knowing these rules, you will no longer need expensive services from service centers.

What is it like to be a virgin at 30? I wonder what it’s like for women who didn’t have sex until almost middle age.

Never do this in church! If you are not sure whether you are behaving correctly in church or not, then you are probably not acting as you should. Here's a list of terrible ones.

15 Cancer Symptoms Women Most Often Ignore Many signs of cancer are similar to symptoms of other diseases or conditions, which is why they are often ignored.

Pay attention to your body. If you notice

20 photos of cats taken at the right moment Cats are amazing creatures, and perhaps everyone knows this. They are also incredibly photogenic and always know how to be in the right place at the right time.

Top 10 Broke Stars It turns out that sometimes even the biggest fame ends in failure, as is the case with these celebrities.

7 Body Parts You Shouldn't Touch with Your Hands Think of your body as a temple: you can use it, but there are some sacred places that you shouldn't touch with your hands. Research showing.