To identify the noise of the clutch release clutch on LADA Vesta, Granta, Kalina, Priora, XRAY AMT, Lada 4×4 cars, a special technique was compiled at AVTOVAZ. Specialists of LADA dealership centers refer to this instruction. The methodology was sent to the Lada.Online website by one of the site’s readers.

When assessing the malfunction of the clutch release bearing, it is necessary to take into account that at the moment all cars produced by JSC AVTOVAZ use a clutch without clearance, so the clutch release bearing is always preloaded and rotates with the engine running.

Defects that appeared after replacing the clutch

What does it mean to replace the clutch? This action means changing the driven or driven clutch disc; often both parts are changed at once. In this case, the release bearing must also be replaced. After such an operation, side defects are suddenly revealed that were not there before the repair.

If we think logically, then there are few reasons for the appearance of new malfunctions. Typically this is:

- Unqualified repairs;

- Defect of new spare parts;

- Erroneous diagnostics, as a result of which not all or the wrong parts were replaced, and previously hidden problems manifested themselves in full.

In general, the issue of the appearance of new unpleasant signs is very difficult and is individual in each specific case, but these signs have common characteristic features.

Will disassembling the manual transmission help eliminate the whining?

Most Lada car owners, having tried the methods listed above, calm down, manage to get used to the noise and continue driving their car. But some are ready to go all the way, so they decide to disassemble the box themselves or contact a service center for this service. Is it possible to achieve the desired result using this complex procedure?

Sometimes when opening the box, significant defects in individual gears are revealed. In this case, the transmission usually makes a loud noise when engaging a particular gear. There may also be problems with the clutch and release bearing. Sometimes replacing these parts solves the problem.

In most cases, installing new parts does not make the gearbox quiet, because all gears are made on the same equipment, which, as already mentioned, does not allow for an ideal configuration.

The procedure for removing and disassembling the gearbox is lengthy and expensive, but may not yield results, so it is hardly worth going through the gearbox if howling is the only problem.

If after replacing the clutch the car jerks

For example, before the repair, the car did not pick up speed well, it was slipping, and the clutch pedal was activated at the very top. All the signs of a worn driven disc were present. After replacing the disk, the car began to jerk. What could happen after the repairs were carried out?

- The issue may be a defective part. This is not so rare when it comes to non-original spare parts. In Russian-made cars (VAZ, GAZ, AZLK, IZH), defects also occur in factory parts. That is, the driven disk is simply curved. On the clutch basket (drive disc), the pressure petals may be at different levels, then the release occurs unevenly and the car jerks.

- The car may jerk due to clutch adjustment. More precisely, it was not performed after replacing the disk. The linings of the new part are much thicker; in this case, the clutch pedal “takes at the very end”. When starting off, the car moves jerkily, and the gear shifts into gear with a crunch.

- The car jerks due to the replacement of not all the parts that needed it. In particular, the cause of jerking is the worn surface of the flywheel under the driven disk. If the flywheel has not been replaced, there may be jerking when driving, and the car may also slip.

Which boxes howl?

The noise problem appeared after Auto VAZ introduced a manual transmission of its own production with a cable drive. These boxes pleased us with clearer gear shifting, but disappointed us with a rather loud howl, especially in 2nd and 3rd gears. The transmission that has this problem is manual transmission 2181.

Box 2181 is an improved previous model 2180. Instead of rigid rods, it is driven by a cable drive. Thanks to the reduction in the bevel of the synchronizer teeth, the gears began to engage more clearly. In 1-2 gears, conventional synchronizers were replaced with multi-cone synchronizers. It would seem that everything should be for the better, but as an unpleasant bonus to the easy gear shifting, buyers received an unpleasant soundtrack.

The plant received a large number of complaints from car owners, so in 2014 the manufacturer modernized the transmission. As AvtoVAZ assures, the updated version has become 25% quieter, but it is still far from ideal.

If there is a noise or whistle after replacing the clutch

Many car owners often complain that after replacement, a noise or whistle appears that was not there before. What could be the reasons for the extraneous sound and why does this happen? » alt=»»>

- The new release bearing turned out to be of poor quality or does not contain enough factory lubricant. A whistling or noise appears when you press the clutch pedal. Many people mistakenly believe that the bearing makes noise when the clutch is disengaged. But this is even illogical, in this state the part does not bear the load, and accordingly the noise (whistle) in this state is minimal.

- The clutch basket has unevenness and roughness at the tips of the pressure petals. Typically, spare parts from Russian manufacturers have such a defect. It should be noted that as the parts are ground in, the whistle that appeared initially disappears. You can temporarily eliminate the noise by lubricating the petals with lithol. But this can be done without disassembly on GAZ cars; on front-wheel drive cars, to perform a similar procedure it is necessary to dismantle the gearbox.

- It is possible that before replacing parts, the car owner did not pay attention to extraneous noises such as whistling, as he was expecting repairs. But after replacing the clutch, extraneous sounds remained, which the owner of the car did not expect. Noises are often caused by the gearbox. If, when the clutch is depressed, the unpleasant sound disappears or noticeably subsides, then most likely this indicates wear on the gearbox input shaft bearing.

- The driven disc linings have roughness. A rustling noise occurs when changing gears. There is no need to worry too much ahead of time - the new parts will get used to it, and the defect will disappear during the operation of the car quite quickly.

- The input shaft bearing in the crankshaft may also make noise. When disassembling the car, you should do an external inspection of the bearing. If it is very dry, it must be lubricated with lithol or other suitable lubricant. It is better to replace a clearly worn part immediately.

Troubleshooting methods

Data-lazy-type=”image” data-src=”https://vazremont.com/wp-content/uploads/2017/11/foto-7-1.jpg” alt=”Gearbox repair” width=” 496″ height=”280″ class=”lazy lazy-hidden size-full wp-image-4366″ srcset=”” data-srcset=”https://vazremont.com/wp-content/uploads/2017/11/ foto-7-1..jpg 300w" sizes="(max-width: 496px) 100vw, 496px">

- If all the gears in the VAZ 2114 gearbox are lost, this means that the problem lies in the bearings. If the breakdown is not repaired in time, repairs will cost even more.

- Noise after starting the engine. The cause of the malfunction also lies in the bearing (drive shaft) or lack of transmission oil.

- The noise disappears after changing gears. The trouble lies in the synchronizer clutch. It is possible that there are problems with the locking mechanism.

- It is not possible to disengage the clutch completely. The “culprit” is the same drive shaft bearing.

Good for those carefree drivers who belong to the category of “riders”. They don't care what happens in the car. It makes noise, crackles, howls, whines - the main thing for riders is that the car is moving. And they ride on their “victims” until death.

But a normal vehicle owner pays attention to every squeak in their favorite vehicle. Therefore, upon hearing the noise that the gearbox makes, the driver begins to get nervous and look for the cause.

If he himself is not a professional, he naturally turns to a car service center. There they console him: “It’s okay. Let’s change the release bearing and everything will be back to normal!” Well, you can understand the repairmen too. Drivers are dummies, and according to service technicians, they exist so that the profession of an auto repairman will be prestigious. (In the monetary sense.) But, if you look at it soberly...

Even if you are a person of a humanitarian mindset, you should have enough sense to try to determine for yourself whether it is worth going to the mercy of prestigious auto repair shops or whether it will be a waste of money.

To begin with, you can try to disconnect the cable that goes from the pedal to the clutch fork, and move the fork itself towards the generator. Start the engine. If the noise persists, then most likely it is produced by the support bearings located at the rear of the primary and secondary shafts. If you change regular engine oil to a thicker one - such as GL-4 or GL-4/GL-5 - the extraneous sound may well disappear. And if it hasn’t disappeared, but you are confident that the diagnosis was made correctly, you can spit on this noise. In the sense that it does not affect anything other than your hearing.

Another reason for the sound that irritates the driver may be the clutch disc itself - if there is play in the central clutch of the disc, with which it sits on the input shaft. The damper springs of the driven disk can also play.

The release bearing, by the way, can indeed also make noise due to play coupled with the clutch release guide sleeve.

If the rubbing teeth of the gears and the input shaft in your car have worn out - this could be due to natural old age, or from your manner of jumping off a la a Hollywood stuntman - here you go, another reason for the noise of the gearbox.

It often happens that this extraneous noise appears for a very simple reason - the inattention or negligence of the driver. It is necessary to regularly check the oil level in the box. If the oil is “driving” somewhere, then noises may arise – and very quickly – for all of the above reasons.

And if the driver stops paying attention to the noise of the gearbox, then such a ride can end very badly - the gearbox will simply jam. It’s good if this happens without consequences - such as a traffic accident - and in the city

Imagine that you put your entire blessed family in the car - right down to the cat and mother-in-law - and drove out of town for a picnic with barbecue and badmintons. And already at a considerable distance from civilization, the above-predicted blunder will occur with the gearbox. It will be a sad story...

Let's start with the fact that one of the most common transmission-related problems is. This problem is well known to many owners of cars with, and quite often a vehicle with a humming gearbox is quite suitable for further use.

In other words, if a manual transmission is humming, but the unit itself is working normally, the gearbox is often used for quite a long time without repair. As for, in this case the appearance of automatic transmission hum and noise is a more serious problem.

Read in this article

If there is a knocking noise after replacing the clutch

As a rule, the cause of knocking after replacing parts is defective parts. In particular, there are dangling damper springs in the driven disk. Therefore, before installing such a spare part on a car, you need to carefully inspect it. Parts of the disk may also be poorly riveted. » alt=»»> Knocks in the clutch area can occur due to a crack in the release bearing bushing (the bushings are often made of plastic). Even at the site where the bushing fits on the flange of the gearbox input shaft, play may form, which also leads to a knocking sound.

The knocking noise occurs due to a broken clutch basket petal, but such a defect occurs infrequently. Another reason for the knocking is a broken starter housing in the Bendix area; it rattles when the car moves. A tooth on the flywheel crown may break off, and it will also knock when touching the rotating parts.

Clutch slipping after replacing all its parts

After replacing all elements, adjustment is required, but many car owners ignore this point. The cause is slipping, the car accelerates slowly, the engine speed does not correspond to the speed of the car. The engine just roars, and the car is driving quite slowly, as they say, slipping.

In cars with a mechanical clutch cable, adjustment is made by the cable itself. In hydraulically driven machines, this process is carried out using a clutch rod. In modern cars, you often come across rods that do not have adjustments. But this does not mean at all that it cannot be produced. In such cases, adjustment of the clutch pedal itself is provided, but not everyone knows about this possibility. » alt=»»>

What makes the gearbox on the Kalina noisy, what to do if the gearbox lever on the Lada Kalina 1 and 2 rings

The noise of the Kalina gearbox usually starts from the factory. This problem is caused by insufficiently precise machining of the gears - with a tolerance of 0.2 mm. In this case, noise or howling is heard only in a certain gear. Therefore, it is impossible to completely make the box silent; you can only reduce sound vibrations.

Lada Kalina of the 1st and 2nd generations has both manual and automatic transmissions. The box model depends on the engine size and the number of its valves. A common problem is that the gearbox on the Kalina (as well as on many other VAZ cars) is noisy.

Vibration that occurs after replacing clutch elements

There are few reasons why vibration occurs after replacing a clutch. Vibration usually appears in two forms:

- The pressure plate (clutch basket) is not balanced;

- During assembly, the driveshaft was installed in a different position from the original installation (but this only applies to rear-wheel drive or all-wheel drive vehicles).

By and large, on cars with front-wheel drive, you can inaccurately secure the wheel drive (CV joint), and the movement of the car will be accompanied by vibration and knocking, but this does not happen often.

If the clutch basket creates vibration, you can try moving it to a different position. As a rule, the pressure plate mounts are symmetrical. On many models, the basket is attached to the flywheel with six bolts, and the basket can be placed in three positions. In one position the vibration may disappear completely or be minimal. But it is better to exchange the warranty part immediately for another one. This will be less hassle for the car owner.

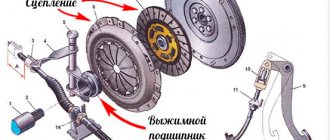

The clutch system is the main mechanism of the car, through which torque is transmitted from the power unit to the transmission. The smooth operation of the gearbox and, accordingly, the proper functioning of the gearbox depend on the correct, proper operation of the system. It consists of: a pressure plate, a clutch basket, a drive mechanism and a release bearing. When you press the clutch pedal, a mechanical (using rods) or hydraulic (using liquid) drive acts on the release bearing, which presses with the help of a damper spring, in common parlance: the clutch basket, the friction disc to the flywheel.

A bearing made of high-alloy steel is a fairly reliable part, but frequent connection of the clutch (driving a car in a big city), improper operation of the mechanism: holding the car for a long time with the clutch pedal depressed (a mistake by inexperienced drivers) leads to overheating and destruction of the bearing race. Replacing the clutch release bearing is described in the step-by-step instructions below.

How to extend the resource?

To increase the service life of the device, you must drive on smooth roads. In our country, it is problematic to comply with this condition. Keep in mind that uneven roads destroy not only the vehicle’s chassis, but also the clutch system. Therefore, regular off-road driving is also dangerous for bearings. Don't make mistakes when operating your car. When the car is stopped at a traffic light, there is no need to depress the clutch pedal and engage first gear if you do not plan to move. This should only be done at the beginning of movement, since the part operates under high load conditions. Regular lubrication will increase the service life of the device.

Signs of a faulty mechanism

The only sign of a faulty release bearing is an unusual sound (noise, whistling, knocking) when the clutch pedal is depressed, which disappears when the pedal is returned to its place. In winter, in severe frosts, noise is often heard when the clutch is engaged, but you should not pay much attention to this, since the materials from which the mechanism parts are made react differently to temperature changes, and the sounds disappear during the warming up process. There are no external, visible malfunctions of the unit, since the bearing is located in the clutch housing. The regular appearance of noise with each press of the clutch pedal indicates an imminent replacement of the release bearing. Unusual sounds occurring when the clutch is depressed indicate a malfunction in the gearbox.

Should I change the box?

Replacing a box with a Lada Granta, Kalina and Vesta is a lottery. The transmission has undergone several modifications, so manual transmissions produced at different times may sound differently. But it’s not a fact that you’ll be lucky: the new box may be even noisier. It’s good if they replaced it for free under warranty, but it definitely doesn’t make sense to buy a unit with your own money.

You need to understand that the howling of a VAZ cable-driven gearbox is not a problem with a specific instance, but a design feature.

Bearing replacement

Spare parts and tools

We recommend watching this video:

Without a pit, a lift and the help of a friend, it will be very difficult to complete the task. So if you decide to replace the release bearing yourself, you should provide as much space as possible under the bottom of the car for removing and installing the gearbox. The tool set is very simple: wrenches of various sizes, a container for draining oil, molybdenum high-consistency lubricant.

Algorithm for performing repair work on a unified unit

The work of dismantling the unit is labor-intensive, but does not require special mechanical skills; the main thing is to follow the sequence of actions:

- disconnect the battery;

- disconnect the cable or hydraulic clutch. On some cars, for example: Nissan, this requires removing the air filter and the battery mounting plate;

- disconnect the gear selector;

- dismantle the engine compartment protection;

- on cars with front-wheel drive or all-wheel drive, it is necessary to drain the oil from the gearbox, after which we disconnect and remove the front drives;

- on cars with rear-wheel drive and all-wheel drive, remove the driveshaft;

- disconnect all sensors and wires leading to the gearbox;

- Having installed the stops under the gearbox, unscrew the bolts connecting the gearbox to the power unit and mounting it to the car body, and carefully, without damaging the input shaft, remove the assembled mechanism;

- release the spring fastenings of the clutch release clutch and disconnect it from the drive;

- remove the clutch from the gear selection shaft;

- remove the bearing from the coupling;

- apply a thin layer of high-consistency lubricant to the surface of the gearbox input shaft (excess lubricant in the clutch mechanism leads to slipping of the clutches);

- install a new release bearing;

- install the transmission in the reverse order;

- connect all sensors, actuators and connectors;

- fill in the transmission fluid recommended by the manufacturer;

- pump the hydraulic clutch drive;

- adjust the mechanical drive of the system;

- install and connect the battery.

For proper use of fasteners, it is worth putting them, when dismantling, into labeled containers.

Features of the clutch system of some cars

Car manufacturers have taken different approaches to the design of the clutch mechanism; in cars of the French concern PEUGEOT, the release bearing, when you press the pedal, does not press, but pushes out the damper.

On some cars, for example: Volkswagen, equipped with a 020 gearbox, the release bearing is replaced without removing the gearbox. This part is located in the rear part of the gearbox. To replace it, you need to remove the left front wheel, disconnect the clutch drive, remove the box housing plug, move the pusher aside and replace the bearing.

Oil: maybe this is the reason?

There are several reasons why a transmission starts to howl. The first, most common, is the oil level in the box. Many motorists do not attach importance to the need to monitor the oil level in the gearbox. This leads to oil starvation mainly in the fifth gear, which is higher than the rest. Due to the lack of oil, the bearings begin to overheat and fail. This is accompanied by a high-pitched howl that occurs when driving in fifth gear. This disease is treated by overfilling 100 - 200 grams of gear oil above the level with constant monitoring.

Some may say that overfilling the oil will cause it to leak through the seal joints. To prevent this from happening, you must first clean the breather, and secondly, pour oil in parts, gradually. For example, at first 100 grams, and after a while, if there is no leakage, so much more. You can also add a second oil seal to the gearbox rocker.

The next, no less common reason for the sound of the gearbox is the poor quality of the gear oil poured into the gearbox or incorrectly selected. If we talk about domestic cars, then, for example, the use of oil of the APIGL-5 category in the gearbox of front-wheel drive VAZs leads to rapid wear of the synchronizers, which will cause gearbox noise when switching. Therefore, it is mandatory to use an APIGL-4 class transmission. Domestic oils of this classification are quite difficult to find, so you have to use lubricants from foreign manufacturers. But their use can significantly extend the life of the gearbox, avoiding various sounds when driving.

In addition, insufficient or excessive viscosity of the oil used also affects the wear of box parts and the presence of sound during its operation. For example, very thick oil with a viscosity of 85W-90 creates a strong film, protecting gears from wear, but at the same time it makes it difficult for lubricant to reach some gearbox parts, which may suffer from oil starvation, causing premature failure. It will also be difficult to change gears due to the need for synchronizers to squeeze out excess oil, which again will lead to rapid wear of parts. The first sign of very thick oil will be the presence of howling when cold and its disappearance when the unit is warm.

Change of oil

Too thin an oil will cause the opposite effect, in which the oil film will break off when hot, accelerating the wear of gearbox parts, which will again be accompanied by howling and humming.

You should be extremely careful when choosing gear oil according to the recommendations of the manufacturer and experienced servicemen.

Main problems after replacing the clutch

What does the concept of replacing a clutch include? Clutch replacement means complete replacement of the clutch disc. Quite often, after such manipulations, previously non-existent side effects appear.

If you think about this problem, then there are not very many special prerequisites for the emergence of such negative aspects. As practice shows this:

- illiterate work of non-professional craftsmen;

- factory defect of a new spare part;

- incorrect diagnosis of the problem, due to which the wrong elements or not all components requiring repair were replaced. As a rule, after this, hidden defects reveal themselves fully.

In general, the problem of the emergence of new problems and defects in the operation of a car is very complex and individual in each specific case. But there are still common characteristics.

What to do?

Unfortunately, there is no clear solution to the problem today. We can only wait for AvtoVAZ to find an opportunity to update equipment and improve technology. If you are planning to purchase a domestic car and silence in the cabin is important to you, abandon the mechanics in favor of, for example, a robotic transmission, which some models are equipped with.

In fact, the howl of a manual transmission is not so critical as to cause serious discomfort for the driver and passengers. It’s just that many, having heard a third-party sound, begin to doubt the serviceability of the unit, and when they learn that this is just a feature of a particular model, they calm down.

If you are planning to buy a Granta, Kalina or Vesta with a manual transmission, you should know that a howling gearbox is not a myth, but a reality that many owners of these cars face. It's up to you to make a purchase or look at a car of another brand.

Manual transmission 2181 with cable drive

Clutch cable location on manual transmission 2181

Checking the oil level in the gearbox