Have you started to notice a strange knocking noise coming from the engine compartment? When driving on an uneven road with potholes and bumps, the sound appears, but when accelerating or on a flat road it disappears?

Most likely, the engine fasteners are broken, which means it’s time to look under the hood. And if the knocking is accompanied by strong vibration of the body, there is a problem with the engine mounts. What are they and what are they for?

The VAZ 2114 car is equipped with three rubber cushions, two of which support the gearbox, and one serves as a support for the engine.

The direct purpose of rubber supports is to reduce vibrations. When the car moves, strong vibrations occur, transmitted from the engine to the body. To make the ride as comfortable as possible, and the driver not to be distracted by extraneous noise and jolts, airbags are installed.

Without rubber softeners, driving a car would be like riding a cart, just as noisy and shaking.

Purpose of VAZ 2114 engine mounts and requirements for them

This applies to both the design features of the support and the materials used in its manufacture. Additionally, product manufacturers apply special marks to them as confirmation of the brand and quality of the product to protect against counterfeiting. Such unit supports are constantly under the influence of various forces, even when the vehicle is not in use. When a vehicle starts moving in forward gears, a certain moment of force is used, and when moving at reverse speed, the opposite is applied.

Rubber engine mounts of the VAZ 2114 act as a damper. They compensate for the loads from one-time rapid acceleration or the action of brakes in extreme situations, driving on uneven road surfaces and in other cases when forces of different signs and values act when driving and parking.

Therefore, the purchase of a set of supports made of rubber products must be carried out only of the factory type, using proven technology and with the appropriate certificate. Such VAZ 2114 engine mounts are capable of operating in a temperature range from -45 to 70 degrees Celsius.

How to replace the flywheel of a VAZ 2114

To prevent a short circuit, before starting work you need to remove the negative terminal from the battery. The VAZ 2114 flywheel is dismantled in the following sequence:

- install the machine on a viewing hole or lift;

- open the hood;

- unscrew the bolts securing the crankcase protection and remove it;

- Unscrew the bolt securing the ground to the crankcase and disconnect the wire;

- loosen the clutch cable tension nuts;

- remove the clutch cable from the lever;

- disconnect the wire terminal of the starter traction relay;

- unscrew the nut securing the starter power wire;

- remove the starter power wire;

- unscrew the three nuts holding the starter and remove it from the car;

- loosen the clamp securing the gear shift joint;

- remove the gear shift rod from the tip;

- disconnect the wires from the speed sensor (located in the upper part of the gearbox);

- remove the reverse switch wire terminal from the sensor located on the gearbox;

- Unscrew the bolt of the lower right mounting of the gearbox to the body;

- Unscrew the bolts and remove the clutch housing cover;

- unscrew the lower left gearbox mount;

- hang or support the engine so that it does not fall over;

- unscrew the nuts holding the engine mounts;

- remove the supports;

- remove the gearbox from the bushings using a powerful screwdriver;

- move the gearbox back so that the input shaft disengages;

- lower the front end of the gearbox and remove it from the car;

- unscrew the 6 bolts securing the clutch basket to the flywheel;

- remove the basket, holding the driven disk;

- unscrew the flywheel mounting bolts and remove them together with the locking plate;

- remove the VAZ 2114 flywheel from the crankshaft flange.

After dismantling the flywheel, you should inspect its condition and make sure there are no burrs or deformations. Minor risks and scuffs can be eliminated by grinding the surface of the flywheel on a machine. The layer of removed metal should not exceed 1 millimeter. If deep scoring or deformation is detected, the flywheel should be replaced with a new one. The flywheel runout should be no more than 0.1 millimeters. The flywheel ring teeth cannot be restored. If they have severe wear or are missing at least one tooth, the flywheel must also be replaced.

Checking and replacing the engine mount

Timely replacement of the VAZ 2114 engine mount is of great practical importance. This is one of the most important components of a car engine suspension.

After all, it is with the help of these elements that reliable fastening of the engine to a non-rigid body and its depreciation are achieved. Such a replacement of the VAZ 2114 engine mount must be carried out on time, preventing the appearance of disturbing noises and knocks when crossing uneven road surfaces. Otherwise, the following malfunctions may occur:

1. The power plant, due to faulty supports, acquires excessive mobility. This may lead to deformation of the air purification filter housing upon contact with the hood. 2. A cooling system fan with faulty supports can touch the radiator grille, and, as a result, the blades become deformed and the fasteners become loose.

Car enthusiasts often ask the question, how much does a VAZ 2114 engine mount cost? This product is in the price range from 1500 to 1800 rubles.

What is required to replace the engine mount:

- new support;

- 2 jacks;

- car repair stands;

- locksmith kit;

- polyethylene bags;

- colored marker;

- adhesive composition for threaded connections;

- scrap.

Pillows always require close attention from the car enthusiast, since if they are defective or aging, they require replacement, otherwise the increased vibration impact can lead to vehicle breakdown, resulting in failure of the vehicle’s transmission system.

In this case, it is important to remove the weight load from the VAZ 2114 engine mounts by lifting the car. To do this you need:

- Raise the vehicle on a jack and place it on supports, then place a lifting device under the bottom of the engine crankcase.

- Install a wooden beam between the pallet and the vehicle lifting device to evenly redistribute the load force. Carefully lift the engine a little to remove the weight load from the power plant mountings. It is forbidden to work on a car that is hung on jacks!

- Visually check the engine mountings for various defects (cracks, delamination or hardening). There are cases when the rubber coating has a defect in the central part of the support.

- Determine the wear of the pillow plates at the point of contact with the chassis (frame) using a “mounter” or a large-size screwdriver. If there is play, remove the engine from the jack and tighten the engine mounts, followed by assembly.

- To prevent early obsolescence of rubber products of engine mounts, it is necessary to apply a protective component to their surface.

To replace the VAZ 2114 engine mount, the following measures must be taken:

1. Remove the negative cable from the battery terminal. 2. Raise it on a jack and place it on supports. 3. Raise the power unit on a lifting device, being careful not to touch the radiator or fan guard. 4. Loosen the bolt and remove the mounting of the cushion to the chassis. 5. Remove the through-type fasteners and the cushion.

Installation of a new VAZ 2114 engine mount is carried out in the reverse order; in this case, it is necessary to apply adhesive sealant to the threaded segment and tighten the fasteners tightly.

How to check engine mounts yourself Simple tips

Signs of a malfunction in the VAZ 2114 ignition module

- First, you should drive the car into a garage or other area with a flat floor;

- Secondly, we lift the car using a jack at the same time from the front wheels and in the middle of the car, more precisely under the engine, we install a wooden log or other support and remove the jack;

- Third, lie under the car and inspect the engine mounts. A visual inspection can reveal: hardening of the rubber, the presence of cracks and tears, as well as delamination of the support, or more precisely, separation of its metal part from the rubber.

- 1. Disconnect the wire from the battery that goes to ground, lift the car and install supports if necessary;

- 2. Using a jack, lift the engine to provide access to the faulty part;

- 3. Unscrew the bolts from the mounting points to the engine and body and remove the faulty part;

- 4. Install the new one in place of the old one and tighten it, while in order to avoid vibration and extraneous noise, tighten the nuts with the engine running. And assemble all the components that were previously dismantled.

AutoFlit.ru

Replacing engine mounts on VAZ-2113, 2114, 2115

Most likely, the engine fasteners are broken, which means it’s time to look under the hood. And if the knocking is accompanied by strong vibration of the body, there is a problem with the engine mounts. What are they and what are they for?

The VAZ 2114 car is equipped with three rubber cushions, two of which support the gearbox, and one serves as a support for the engine.

The direct purpose of rubber supports is to reduce vibrations. When the car moves, strong vibrations occur, transmitted from the engine to the body. To make the ride as comfortable as possible, and the driver not to be distracted by extraneous noise and jolts, airbags are installed.

Without rubber softeners, driving a car would be like riding a cart, just as noisy and shaking.

Signs of a malfunction of the VAZ 2114 knock sensor. List and comments from the service station

Causes and Symptoms of faulty spark plugs and ignition coils. Signs of faulty ignition coils

- The engine begins to throttle. This is to say that the DD does not send signals to the control system, and it does not adjust the ignition timing;

- The dynamics noticeably deteriorate, the car begins to stall when accelerating;

- Acceleration becomes slow, the engine roars, and the car picks up speed slowly;

- The "Check Engine" comes on when you take off, when you roll downhill, and when you accelerate. Moreover, if the “Check” lights up only when the ignition is turned on, and goes out after 6 seconds, this is normal: the “brains” test all the components of the car.

- Code 0325 indicates that there is a break in the power wire. The most common version of what happened is oxidation of the contacts; the wiring itself breaks extremely rarely. Cleaning the terminals will eliminate the problem in most cases. However, if after processing the error does not disappear, you need to check the timing belt: it means it has jumped several teeth. After marking it, the problem disappears;

- 0328 in most cases signals a malfunction of high-voltage wires, but in some cases it can again indicate a belt jump;

- 0326 and 0327 indicate a low signal coming from the knock sensor. There are 2 options here: either the DD tightening has become loose, or the contacts have again oxidized.

- Turn off the ignition and climb under the hood;

- If there is a 2-pin knock sensor, the nut is twisted with a 13 wrench; if it is a 1-pin, use a 22 wrench;

- The multimeter (or voltmeter) is set to operate with a maximum of 200 MV;

- The electrodes of the device are connected to the DD terminals. It is officially believed that the voltmeter reading (they say there is voltage) is sufficient. However, experienced drivers do not think so: the sensor must respond to shocks caused by detonation. Therefore, additional research is carried out: the sensor is lightly tapped with the handle of a screwdriver; During impacts, the meter readings should change. If they remain constant, the DD requires replacement.

AutoFlit.ru

Engine mount malfunctions

The main damage to a pillow is loss of elasticity. The support is made of rubber, which loses its properties with prolonged use.

This is due to constant loads accompanied by changing weather conditions (cold, heat). In the future, the pillow will begin to deteriorate: it will crack and delaminate.

To prevent destruction of the rubber support, it is necessary to inspect it regularly. If damage is detected, the part should be replaced, otherwise strong vibration and extraneous knocking will be felt in the cabin, which will soon affect the operation of the engine.

This is interesting: Replacing front shock absorbers for Ford Focus 2

It is better to replace the airbags in a timely manner than to later spend money on expensive repairs or purchasing a new engine.

The cost of engine mounts depends on the manufacturer, the minimum price for the front support is from 600 rubles, the rear and left ones are 500 rubles each. Average prices start at 1,200 rubles for the front, and 900 rubles for the rear and left.

It is possible to buy a set of three pillows from 3,500 rubles.

To replace engine mounts at a car service center, you will be asked for 1,500 rubles, but you can replace them yourself.

What is this

If we talk about the VAZ 2114 model, then there are three supports, two of which are intended directly for the gearbox, and another one for the engine itself.

The main purpose of pillows is to reduce vibrations.

When the car drives, serious vibrations occur, which are transmitted to the body from the power unit. To ensure the necessary level of comfort while driving and not to be distracted by extraneous noise or shaking, special supports are mounted on the car. If you remove them, driving a VAZ 2114 can be compared to riding an old wooden cart.

Causes of malfunctions

The most important problem that pillows face is the loss of elasticity of the material. This is due to the fact that the supports are made of rubber. Over time and with use, these elements lose their original characteristics. Various factors accelerate the wear process of bearings:

- Regular exercise;

- Long service life;

- Cold;

- Heat;

- Temperature changes, etc.

If elasticity decreases, this entails the formation of cracks and delamination of the material.

Replacement is purely a matter of time. But the procedure for changing the front and all other pillows should be carried out on time. If you drive for a long time with worn out bearings, this will result in a negative impact on engine performance. Then the repair will cost much more than the cost of new supports.

Price issue

If you do everything correctly and in a timely manner, then your costs will be insignificant. You will have to purchase new supports and contact a car service. Of course, it is quite possible to do it on your own. This is a matter of desire and availability of appropriate skills.

How much will it cost to replace engine mounts? We suggest that you familiarize yourself with the current prices for the VAZ 2114.

Set of three supports

There is no need to pay someone, since the replacement can be done by yourself.

Replacement

As already mentioned, there are three rubber supports on the “fourteenth”:

Front cushion

- It is necessary to drive the car onto the overpass and make sure that it does not move. To do this, put the handbrake on and engage first gear.

- We remove the crankcase and engine protection, freeing access to the support.

- If the car is not new, to make work easier, all fasteners should be treated with anti-rust solution, and before assembly, all bolts should be cleaned with the same solution.

- Raise the engine slightly using a jack. It is recommended to place a wooden beam or board between them to prevent damage to the part. We carry out the lifting very carefully, avoiding damage to the fan housing and radiator.

- On the body cross member we find a long bolt connecting the bracket to the support and unscrew it.

- We unscrew the mounting bolts connecting the support to the engine block.

- We remove the damaged pillow.

- We install a new one and assemble everything in reverse order.

Left pillow

To replace the left airbag, you need to equip yourself with a cable.

- Using a cable, we hook up the gearbox and place a jack under it.

- If the starter is an old type (large size), remove it.

- Find the bolt that holds the support to the bracket and unscrew it.

- We remove the pillow.

- Install the new pillow by performing the steps in reverse order. Before firmly tightening the bolts, check that everything is in place.

Back cushion

To replace the right airbag you will also need a cable.

- Similar to replacing the left airbag, you need to hook up the gearbox with a cable and place a jack under it for safety.

- We loosen the bolts connecting the gearbox and the cushion.

- We also loosen the 2 nuts on the body that hold the cushion.

- Raise the gearbox with a jack and unscrew these 2 nuts.

- We unscrew the bolts from the box that secure the mountings of the pillow.

- Remove the rubber support.

- We install a new pillow, to do this we do what is written above in reverse order. Don't forget to clean off any rust before screwing in the bolts.

Features of the procedure for replacing motor mounts

It is necessary to ensure easy access to the cushions, so in addition to wrenches, you will also need a good jack. Let's look at the list of measures to replace a defective cushion using the example of a rubber-metal product:

- Loosen the nut securing the airbag to the body.

- Jack up the engine and remove the bolt.

- Unscrew and remove the faulty support.

- We install a new one and tighten it.

- Jack up the engine and insert the mounting bolt.

- Tighten the bolt and lower the motor.

Self-replacement

If a visual inspection reveals problems in the pillow, it should be replaced as quickly as possible. Start by purchasing a new part. It should be noted that it is better not to buy this spare part for disassembly, even if it is in good condition. In this case, saving money may cause more harm than good. Ideally, it would be to buy an original part.

- Remove the terminals from the battery. Raise the car to a height that will allow access to the engine from below. In this case, you can use a jack and wooden blocks as support.

- Raise the engine with a jack to release the load on the required part.

- Remove the bolts that secure the cushion to the engine and body.

- Place the new part in place, guiding it properly into place. Tighten the mounting bolts well. It's best to tighten them while the engine is running to avoid excessive vibration in the future.

- Once you have finished installing the cushion, put all the dismantled parts back in place.

In each individual case, it may be that there is no convenient access to replace the part. In this case, try to remove those components that prevent you from making a replacement.

Sometimes this operation may require another person to help guide the motor while you push the part into place. If we are talking about the top cushion, then, as a rule, it will not be difficult to inspect it and, if necessary, replace it. It will be possible to do without a hole.

Periodically check the condition of the engine mounts on your car. As you can see, this is not at all difficult, but it can help avoid many problems in the future and provide you with a comfortable ride in any conditions. Remember that a car feels when it is being looked at and then thanks its owner for a long and good service.

Replacement result

After assembling all the parts, you should check whether the replacement was carried out correctly. To do this, you need to start the car and drive the car on a rough road.

If no more knocks bother you, and the car doesn’t shake like a tractor, then the job was done correctly. Otherwise, you should check whether you have placed the pillows evenly.

In order to extend the service life of the engine mounts, you should check that the bolts are well tightened and periodically remove dirt from them. Only regular monitoring will help delay the occurrence of engine mount malfunctions.

Assembly of the unit

After purchasing all the new components, you only have to do a few simple steps:

- Compress the spring using a puller. It must be installed in such a way as to engage at least three turns.

- Install rubber pads on the spring; they can be secured with tape or tape.

- Place the bump stop on the rod and the boot on top.

- Install the rod into the hole in the body and tighten the nut.

- Secure the lower part of the shock absorber to the rear beam by aligning the holes and inserting the bolt. Tighten the nut.

Check the tightness of all threaded connections. After a run of 50-100 km, it is recommended to re-tighten all the nuts. When replacing the rear struts of a VAZ-2115, use nuts with plastic bushings - they are much more reliable.

Replacing the front and rear engine mounts of a VAZ 2114

The engine mount on any domestic car is a rubber-metal silent block on a bracket. It connects the cylinder block body to the stationary parts of the car. On the VAZ 2114, the factory provides three such supports:

- the front one, also known as the bottom one, connects the crankcase to the beam;

- the right one, also known as the side one – between the engine and the spar;

- rear - attached to the gearbox housing and body.

Also, sometimes an additional mount is installed on the VAZ 2114, which is attached to the cross member on one side and to the clutch housing on the other.

Replacing the left support

- The beginning of the replacement actions coincides with the previous example, but in this case we place the jack under the gearbox.

- When the support is freed from the load, unscrew the bolt securing it to the body.

- Then unscrew the two bolts that attach the cushion to the gearbox housing.

- We also clean the contact area and install a new part.

Inspect the condition of the bolts before installing the support; they may need to be replaced.

Signs of wear

Since the function of the engine mount is to dampen vibrations, if they are noticeable even at idle, this indicates a problem. Among other signs of wear on the airbags on the VAZ 2114:

- Vibration of the gearshift lever. This indicates that all motor vibrations are transmitted to the box.

- If you open the hood, strong vibrations of the engine are visible.

- Uneven car operation. The fact is that when the silent blocks are heavily worn, the crankcase begins to move slightly relative to the clutch. Because of this, the crankshaft position sensor (CPS) constantly produces different signals. The ECU is forced to mistakenly “catch” the revolutions to eliminate the imbalance.

avtoexperts.ru

The car engine is quite heavy and subject to vibration, so it must be secured against any displacement during operation. If the fastening points are rigidly connected to the body elements, they will fail very quickly, since when driving over uneven road surfaces, the fastening points will absorb significant alternating loads.

Plus, the entire body will constantly vibrate, which, in addition to discomfort for those inside the car, will also negatively affect the durability of all elements of the car.

VAZ engine cushion (support)

Purpose

Special supports, or cushions as they are also called, are used to dampen vibrations during engine operation and to securely fix it.

The name of the support as a pillow is not accidental, as it fully corresponds to its purpose. So, in Ozhegov’s explanatory dictionary, one of the meanings of the word “pillow” is something that supports something, takes on the pressure of a mechanism.

The main task of installing supports is to securely fasten and minimize sideways movement during operation.

In addition, thanks to the pillows, the power unit is isolated from all body parts, which makes the car comfortable to drive.

Depending on the car model, the engine can have from 3 to 5 airbags.

So the front and rear airbags monitor vibration at idle and when the engine reaches maximum load.

Design

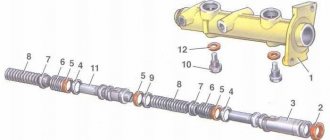

The simplest support is a rubber-metal element, where a layer of rubber is placed between two steel plates. The plates have a threaded part in the form of a pin at the ends for connection with body parts. Such products can be made either integral or collapsible.

Some supports, for example, the classic VAZ 2101-07 models, also had a spring and a rubber bumper inside the cushion, which increased rigidity and softened strong impacts.

Recently, increasingly, instead of rubber, manufacturers have begun to use polyurethane, as the most wear-resistant, and metal in most cases has given way to aluminum.

On more expensive car models, more modern designs, such as hydraulic supports, are used for greater driving comfort. They consist of two chambers and a membrane between them; the chambers are filled with liquid, which, when loaded, can move from one container to another.

Electric hydraulic engine mount

Such supports can be adjusted to the operation of the power unit in any mode of operation and are capable of maximally damping any vibrations that occur, significantly increasing the degree of comfort when operating the car.

The greatest loads on the engine mountings occur when starting the engine, starting and stopping the vehicle. A faulty mount increases the stress on the engine and transmission, making them more likely to fail.

Malfunctions:

• Cracks, breaks in the filler body or steel plates;

• Deformation of the pillow;

• Peeling of rubber from metal;

New and old pillow

Signs of malfunction:

• Engine vibration;

• The motor “bounces” when starting and braking the car;

• Vibration radiating to the steering wheel, gear knob and the entire body;

• Shocks when changing gears;

• Knocks out the speed;

• Impact when planing at reverse speed;

• When driving on an uneven road, knocking noises are heard, similar to a malfunction of the chassis.

Causes of malfunction

There can be several reasons for premature pillow failure. For example, when tuning a car, shock absorbers with a stiffer characteristic and low-profile tires are installed to improve handling and change the appearance of the car. However, in this situation, the shock absorbers in the pits do not completely dampen body vibrations, which have a negative effect on all suspension elements, including the engine mounts.

Driving style. These are sudden starts and braking that provoke huge loads on the engine mounts due to a rapid shift in the center of gravity. This also includes driving over bumps on the road without slowing down.

Natural wear and tear. These are mechanical loads, temperature changes, aging of the rubber filler, which loses its elasticity.

Tired pillow

Replacement timing

On average, the power plant supports are capable of operating for about 100 thousand kilometers or more (up to 200 thousand) with moderate driving and proper monitoring of their condition.

If any signs of malfunction of the engine and gearbox mounts are detected, it is recommended to replace them without delay. At the same time, you should not purchase products from an unknown manufacturer, giving preference to the original.

Finally. Serviceable supports mean comfort and safety of movement, as well as extending the life of your power unit.

Self-replacement

Before replacing the pillows, it is necessary to diagnose their condition. The condition of any silent blocks is checked with a mount: with its help you need to influence the support, simulating the movements of the engine during operation. If:

- rubber ruptures are visible,

- the bushing of the silent block touches the joints,

- the motor moves easily when pressed and hits the protection,

- the support bracket is broken,

the part needs to be replaced. Even if the signs of wear are not so noticeable (for example, the rubber is cracked but not torn), it is better to replace them as a set. Silent blocks lose their elasticity over time and begin to perform their functions poorly.

There are regular and reinforced supports for the VAZ 2114 on sale. The second type uses a harder rubber compound, but they are more durable only in quiet driving mode. Fans of sharp starts and braking will have to change any of them every 15-20 thousand; for other drivers they can last 50 thousand kilometers. This is the answer to the question of how long the supports last.

Front engine support VAZ 2114

On a VAZ 2114, the supports can be replaced independently, without contacting a car service center. It is more convenient to use a pit or overpass, but you can do without them. To do this, the car is jacked up and placed on supports (bricks or tree stumps). If crankcase protection is installed, it must be removed.

Replacing the front support. You need to jack up the oil pan. First, use a 17mm head to unscrew the 4 bolts securing the bracket to the crankcase, then the silent block bolt. To remove the bolt, you need to use a jack to get it into a position where the engine will not put all its weight on it. When installing a spare part, it is important to lubricate the silent block bolt well: not only the threaded part, but also the body. It is in contact with the metal sleeve, so it can stick.

This is interesting: Adjusting the carburetor of an Alpha moped

Side engine support VAZ 2114

Replacing the right support is similar, with the difference that it is better to jack the gearbox housing rather than the engine. Another option is to install a jack in the area of the oil filter housing. It is attached to the crankcase with three bolts. Another trick is that the right pillow needs to be changed by two people. Without a side stop, the motor moves up, not down. The jack will not help here, so an assistant must press on it so that the silent block bolt can be secured.

Replacement of the rear support is the most difficult task if done without a pit or lift, requiring some skill in performing auto mechanic work and perseverance. It is located at the connection between the engine and gearbox, so you will have to work in a confined space. In addition, when unscrewing the bolts from the body, the key may rest against the gearbox housing.

How to remove a generator on a VAZ 2114 and 2115 Available methods

- The terminal is removed from the battery; this should be done for all work on the car’s electronic systems;

- The car is jacked up, the right wheel is removed;

- The mudguard is unscrewed;

- Remove connector block D from the generator;

- After that, using a 10mm wrench, unscrew the wire from terminal B++. The wires are removed;

- The generator adjusting screw is loosened. The belt is removed. The screw should be completely unscrewed. Remove the tension bar;

- Using a 17 socket, unscrew the 3 screws securing the generator bracket to the cylinder block;

- The generator is removed;

- Remove the bracket, to do this the nut is unscrewed, this is done with a 13 key. The screw is removed.

- Unlock the cover fastening latches and remove it;

- Use a Phillips screwdriver to unscrew the 2 screws securing the voltage regulator;

- The block of wires from the regulator is disconnected, and it is finally removed from the generator;

- Using a 10mm wrench, tighten the nut securing the capacitor wire. Next, unscrew the screw securing the capacitor itself;

- We remove the diode bridge. To do this, unscrew the screw securing the block with a Phillips screwdriver. Next, unscrew several screws securing the winding terminals. There are insulating washers on the screws;

- We remove the winding leads and remove the diode block;

- While holding the head from turning with a gas wrench, use a hexagon to unscrew the pulley;

- Using a Phillips screwdriver, unscrew the 4 screws holding the covers together;

- We mark the position of the covers relative to each other. Separate both halves;

- We remove the stator;

- We clamp the cover with the rotor in a vice. We knock it out with a punch;

- All that remains is to remove the bearing using a puller.

AutoFlit.ru

Replacement of VAZ 2114 engine mounts.

A beautiful exterior, excellent technical characteristics and a multifunctional interior, of course, play an important role in choosing a car, but not as much as comfort. Agree, if the car is beautiful and powerful, but driving in it is uncomfortable for you, you are unlikely to decide to buy it.

Over time, nothing changes. All those conditions to which we get used from the very beginning should not worsen during operation. One of the main guarantees that these conditions remain unchanged is the proper operation of the engine mounts, which can only be guaranteed by regular diagnostics and timely replacement. Let's talk about the last one.

When replacement is necessary

Since the pillow has rubber inserts, it loses its elasticity over time. This becomes noticeable even in the cabin, as an unpleasant vibration appears. The replacement period for a part varies, depending on weather conditions and sudden temperature changes. It is these factors that affect the structure of rubber: it becomes harder.

If you do not replace the cushion at this stage, then in the future the part will begin to deteriorate, which can lead to more serious damage to the engine mount. If while driving you hear a knocking noise under the hood and notice increased vibration, you should conduct a visual inspection and, if defects are found, begin preparing for repairs.

Tip: We recommend buying only high-quality pillows from the manufacturer with a guarantee, since a bad part will not properly dampen vibration and will begin to quickly deteriorate.

Step-by-step instructions for replacing VAZ 2114 engine mounts/mounts.

Preparatory stage of work.

Having determined by knocking from the engine compartment, vibrations in the body or visual inspection the need to replace the engine, do not delay this procedure, otherwise you may end up with a much more expensive repair than simply replacing the supports. Moreover, even a beginner who has never encountered this type of work before can carry it out. You just need to prepare a certain set of tools, spare parts and simply follow the instructions given below.

This set consists of:

- jack;

- new engine mounts;

- spanners;

- ratchet;

- small board;

- set of socket heads and wrenches.

Depending on the condition of the car and its components, you may also need a rust remover.

When everything you need is at hand, you can begin the replacement process itself.

Replacing the front airbag.

- We drive the car onto an overpass or “pit”, in general, we do everything to make it convenient to work under it.

- We protect ourselves with stops.

- For our safety, we remove the terminals from the battery.

- Using a wooden plank, carefully (so as not to touch the radiator and fan) jack up the engine in the place where the support will be replaced.

- We loosen the protection fasteners, remove the old support and install a new one in its place. All threaded connections are pre-lubricated with sealant.

- If necessary, repeat all the above steps with another (other, photo below) pillows.

- We install the dismantled parts in the reverse order described above.

Replacing the rear cushion.

Replacing the left/side airbag.

Choosing a support

The cost of supports starts from 500 rubles per piece. It all depends on the manufacturer, manufacturing method and materials used.

The front airbag is the most expensive of the three.

As a rule, prices for the front “cushion” are slightly higher than for the left and rear ones, since this is due to the much greater load-bearing capacity of the part and the use of the largest amount of materials.

All supports are in one place, ready for replacement.

In order to replace the supports, it is not necessary to contact a service center, because such work can be easily done with your own hands.

You can suspect that something is wrong with the engine mounts of your car by the characteristic knocking noise under the hood and vibrations while driving.

Today we’ll talk about what engine mounts or mounts are, what they serve and how they are replaced.

Device type

How to change supports

To replace, you will need to purchase front, left and rear airbags. Experts advise replacing the entire set during repairs, since after replacing one part, another one may break after a while. The average cost of parts is 2000 rubles. If you have the necessary tools, you can do the repair yourself and save on car service.

List of tools

To replace the pillows we will need:

- 2 good jacks;

- metalworking tools;

- scrap;

- steel rope;

- glue.

Tip: At some stages you will need to lift a lot of weight, so it would be a good idea to invite a neighbor or a fellow car enthusiast here.

Replacing the front airbag

The repair of each support has its own characteristics. Replacing the front airbag is carried out as follows:

- Put the car in 1st gear or the handbrake so that it does not move.

- To gain access to the support, remove the upper engine protection.

- Raise the engine with a jack. To avoid damaging its lower part or other elements, place a wooden board underneath.

- When we have freed the support from the load, we can unscrew the bolt that connects it to the bracket.

- We unscrew the bolts connecting the pillow to the motor.

Removing the bolt that secures the cushion to the engine - We remove the old part and install the new one.

Replacing the rear cushion

Here we will need a steel cable to make it more convenient to work with fasteners.

- We hook up the gearbox with a cable and install a jack under it.

- Slightly press out the bolt connecting the gearbox to the support.

- Unscrew the nuts securing the support to the body.

Loosening the nuts that connect the cushion to the body - Raise the gearbox and unscrew the nuts and bolts.

Unscrew the bolt and nuts - We replace and reassemble in reverse order.

When replacing the side airbag, you will need to perform the same steps. If you have a large starter installed, it will need to be removed to get to the bolt. It is better to coat rubber products with a special protective substance - this will ensure a long service life of the parts. After completing the repair, do not forget to test the car. If during movement the knocking stops and the vibration becomes almost unnoticeable, then everything was done correctly.

Characteristic

What is this item? An engine mount is a gasket between body elements and the power unit. This is installed on all cars without exception. On Soviet Zhiguli cars, the cushion was a durable piece of rubber with fasteners on both sides. On more modern “nines” and “eights” (and subsequently all VAZs with a front-wheel drive layout) full-fledged rubber-metal supports were installed.

So, the power unit was mounted on four pillows. Two of them are on the gearbox, and the rest are on the engine. To avoid unnecessary loads, the box and motor are rigidly fixed. Any distortion leads to a change in the geometry of the input shaft. As a result, all the vibration is strongly transmitted to the gearbox lever and the transmission itself.

Where are the pillows? This element is installed on the engine from several sides:

- Front cushion. Attached to the front beam of the power unit.

- Back cushion. Installed to the front subframe. Located in the bottom area.

- Right support. It is located on top, near the front side member of the body.

Also note that not all vehicles have a rear support. This function is performed by the gearbox itself.

In this case, it is attached closely to the motor. The pillows themselves are made in different shapes. They are often an aluminum or steel cylinder with a silent block inside. To secure it to the body, a so-called “paw” is used. It also has a rubber spacer. This is exactly how modern engine mounts are designed. Symptoms, how to diagnose a part, what affects wear - we will consider in the course of this article.

Replacing the front support

- Place the car on a level surface. Be sure to raise the handbrake or engage first gear. For safety, you can support the rear wheels.

- Remove the engine protection to gain access to the mounts.

- To remove the load from the support, place a jack under the oil pan and raise the engine. It is imperative to place a spacer between these elements in the form of a board.

- When the engine is supported by the jack, we inspect the mounting location of the cushion. We unscrew the bolt that connects the bracket to the support.

- After this, you can disconnect the pillow from the motor unit.

- We clean the fixation points and install the new part in the reverse order.

It is possible that in order to replace the front cushion, you will need to further lift the engine, since the mounting location of the old one has been worn out.