Symptoms of malfunction

- Pump noise when the engine is running. Extraneous noise is caused by bearing wear. It is recommended to replace the cooling system pump after one or every time replacement. If maintenance intervals are not observed, the rolling elements, inner and outer rings will wear, causing noise and whistling. Quite often, the cause of accelerated wear is antifreeze, which gets into friction pairs due to leakage of oil or rubber seals.

- Antifreeze leak. Like the pump bearing, the oil seal and rubber bushing have a limited service life. Play due to bearing wear will result in much less sealant leakage.

- Misalignment with respect to gears, shafts (pump is misaligned). Uneven stress distribution causes accelerated wear not only of the bearing, but also of the seal. Incorrect assembly or manufacturing defects, when the pulley rotates misaligned, leads to accelerated wear of the loaded part of the belt. Such a malfunction, even with low mileage, can break the timing belt and break valves with pistons.

- Engine overheating. When the impeller vanes break, the pump's performance drops, resulting in less coolant flow through the small circulation circuit.

A decrease in performance is often noticeable after applying sealant to repair a radiator leak. The mixture clogs the cooling system passages and sticks to the pump impeller.

Unless grease has clogged the body coolant drain, leaking sealant will not cause water pump failure. However, it is necessary to disassemble the pump and flush the system.

Should I change antifreeze after replacing the pump?

A question for those who want to save money everywhere and on everything. If I answer this briefly, I can confidently say that yes, the coolant needs to be changed. Please also pay attention to the question regarding mixing antifreeze in the cooling system. It will be useful and important to know all the nuances.

If we talk about the necessity of replacement, then everything is extremely simple. To begin with, in the vast majority of cases it is impossible to replace and remove the pump without first draining the antifreeze from the system. But some people want to save money; they drain the coolant into a clean container, install a new pump, and then pour the old antifreeze back in.

A big mistake, since any water pumps for cooling systems are characterized by increased demands on the quality and purity of the liquid. Therefore, you should absolutely not use previously drained antifreeze, even if you just recently changed it, even before the pump failed. Do not attempt to filter or strain the coolant. Just buy a new can of quality antifreeze that is suitable for your car and fill it up. There simply cannot be any other options. Remember this. Otherwise, you will soon have to spend money on a new pump again.

To ensure that the water pump lasts as long and reliably as possible, make it a rule to use only high-quality compounds. As you remember, 90% of pump failures are related precisely to the quality of the coolant used. I think it will not be difficult to draw the appropriate conclusions.

Have you encountered a water pump failure and how early were you able to identify the presence of malfunctions?

Thanks to everyone who reads us! Don't forget to leave comments, ask questions and invite your friends to join us!

( 1 ratings, average: 5.00 out of 5)

Did you like the article?

Subscribe to updates and receive articles by email!

We guarantee: no spam, only new articles once a week!

How to check the cooling system pump?

By checking the pump without removing it from the engine, we can only indirectly assess its efficiency. With a reduced volume of pumped coolant, the heating element begins to warm up poorly. But before disassembling the water pump to check the impeller, we recommend checking the thermostat and making sure there is no air blockage in the cooling system.

After disassembly, you should pay attention not only to the integrity of the blades and the impeller seat on the drive shaft, but also to the shape of the blades. For example, on the VAZ 2121 over many years of production, rotors of different diameters, numbers and shapes of blades were installed. Installing a less efficient pump in an engine with a higher thermal load will result in the cooling fan running more frequently and an increased risk of overheating.

Be sure to check the engine block in the housing area and the pump itself. Fogging or a slight coolant leak from the drain hole does not mean the pump needs to be replaced. If you find a significant leak, try to find it. If the leak is only in the area of the housing adjacent to the engine block, most likely it can be fixed without replacing the pump. Simply apply sealant and install a new gasket.

Risk of timing belt breakage

The danger of a misaligned water pump sprocket is when there are no obvious signs of trouble. The first thing you should pay attention to is the timing belt. If uneven wear is observed in any case, check the pump and shafts. The cause of misalignment may be a manufacturing defect, worn bearings, or uneven contact between the housing and the cylinder block (dirty, rusty seating surfaces). Sometimes the malfunction begins to appear after an accident, when parts of the body or installed equipment get into the pump pulley.

If you find misalignment, replace the damaged pump as soon as possible. Do not hesitate to also eliminate noise and whistling from the water pump. In case of critical wear, the bearing may fail, blocking the gear. A stuck pump will definitely break the timing belt. If the pistons in your car encounter valves when they break, repairing the damage will cost quite a lot of money.

Bearing check

The easiest way to check the pump is to ensure that the pulley is in an accessible place and can be turned by the drive belt. Just take the pulley in your hand and move it in different directions (watch the video). If it breaks, you will feel a lot of weakness. To determine whether the whistling noise when the engine is running is coming from the coolant pump, remove the drive belt and unwind the pulley by hand. A worn bearing with washed out lubricant will rotate and turn over with noticeable noise.

Checking the pump, the pulley of which rotates the timing belt, is a little more difficult. Once you overcome the belt tension, you can try moving the sprocket in different directions. But in order to fully check and evaluate the smoothness of rotation, the timing belt will still have to be loosened.

The main cause of breakdowns

If the seal or rubber flange leaks, the coolant washes the lubricant out of the bearings. The problem will get worse if you use cheap toluene or water instead of high-quality antifreeze. The lack of anti-corrosion additives and minimal lubricity will very quickly “kill” the pump bearing.

However, it is much more important to use a good quality antifreeze to ensure the long life of the sealant. At the point of contact with the drive shaft, it is necessary to lubricate the rubber seals, which cannot be said when using aggressive toluene or water.

Where to begin?

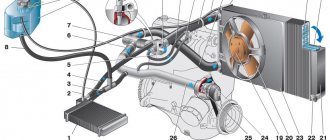

There are some signs of failure of the VAZ pump. In these models, the pump ensures the passage of antifreeze through the cooling jacket, hoses and pipes, as well as through the radiator. During the warm season, even a slight malfunction of the pump can lead to overheating.

It is worth noting that the symptoms of a pump malfunction on the VAZ-2112, 2107, 2109, 2114 and some other models should be determined as soon as possible. The fact is that in these models the pump is driven by a timing belt. If the pump jams for any reason, it will fail. This, in turn, leads to deformation of the valves in the engine. This situation occurs in most cases when such a failure occurs. Therefore, it is important to independently identify signs of pump failure in the cooling system.

Knowing the symptoms of failure of the VAZ-2114, 2112 or earlier models, you can avoid expensive engine repairs or constant overheating.

It is worth noting that the cooling system water pump has a certain service life. Once the expiration date has passed, this system component must be replaced. In cars with a pump driven by a timing belt, this element of the system should be replaced every 60 thousand. km mileage This distance is usually around 48 months (with regular driving).

What is a pump?

First, a few words about what a VAZ 2107 pump is and what you can expect if it suddenly leaks. In fact, this is an ordinary liquid pump, which consists of a housing, a rotor, an impeller, and a drive pulley. On classic series cars, it is driven from the crankshaft using an alternator belt. It is also worth mentioning that on older machines a fan was installed on the drive pulley. But this was at a time when electric radiator fans were not even dreamed of.

Why does the pump break down?

Before dealing with the signs of a malfunction of the pump 2110, 2107 or other models, you should pay attention to the reasons for the rapid wear of this system component. A high-quality pump can withstand about 100-110 thousand. km mileage For this reason, not all drivers change them after driving 60 km, as indicated by the manufacturer.

Most often, replacing the pump coincides with the second replacement of the drive belt, which is mounted in the timing belt. Therefore, replacing the pump usually neatly coincides with replacing the antifreeze.

High-quality pumps have a long service life. They can serve as long as you like, like two timing belts. However, it is not always possible to buy a high-quality pump. Such a device is not capable of operating without failures for a long time. Therefore, problems arising in the cooling system cannot be ruled out.

Low quality antifreeze or mixing different types of coolant can shorten the life of the pump. This causes the pump to fail much earlier. For this reason, the driver is recommended to regularly check the pump for faults.

Why does the car pump break?

What is a pump and why can it break? This question is asked by many novice car owners on thematic forums on the Internet. This is the name of the pump that circulates coolant in the engine cooling system.

In other words, the cooling of the engine during operation depends on the pump - if the pump suddenly fails, then the antifreeze will simply stop circulating through the system, as a result: overheating of the internal combustion engine.

Structurally, the pump consists of a housing with a low-pressure pump placed inside it

The part itself is a very simple device, and therefore breaks extremely rarely. If the owner properly monitors his car and undergoes all necessary procedures and maintenance in a timely manner, then the likelihood of a breakdown is reduced to zero. However, a caring car owner is rare. Therefore, without maintenance and monitoring of its condition, the pump may break down one day and stop moving antifreeze through the cooling system.

There are only three reasons for failure:

Depletion of service life (severe wear of components, including physical aging of the oil seal).

Initial defect (low quality of the product due to the fault of the manufacturer).

Replacement of a part or its repair, performed with neglect or poor quality.

Symptoms of a problem

The main thing in the operation of the engine cooling system is its tightness. If the system is depressurized, then even a functional pump will not be able to cope with the need for antifreeze circulation.

Fluid leaking from the drain hole or from under the seating surface

There may be various symptoms of pump failure for VAZ-2109, 2107, 2114 and other car models. So if the coolant was of poor quality, there may be a leak in the drain hole area. In this case, leakage occurs, the formation of drops after the car is broken in. This can be determined by looking at the surface of the drain hole. Please note that a small leak in a new pump is normal. This happens during the first 10 minutes of engine operation. This is because the mechanical seal moves to the correct position.

If a new pump has a break-in period. If the pump is not operating properly but fluid continues to flow from the drain port, the pump is damaged. It is necessary to thoroughly flush the cooling system and install a new pump. Then you need to fill in the required amount of new antifreeze of acceptable quality.

If there is leakage from under the seating surface, this also indicates a malfunction. In this case, a sign of failure of the VAZ-2107, 2110, 2109 or other models is humidity, the appearance of drops, drops on the body or around a certain area. The cause of such a breakdown is incorrect installation of the pump or incorrect use of sealants and gaskets.

If the pump is new, remove it and check that it is installed correctly. It is especially important to pay attention to the tightening torques. If the pump is already old, it needs to be replaced.

How to fix an antifreeze leak

However, the most important question that interests car enthusiasts in this regard is how to fix an antifreeze leak? The elimination method directly depends on the reason why coolant is leaking from the cooling system. The first thing you should remember before performing inspections and repairs is that most coolant leaks usually occur when the engine is hot. Therefore, before performing work, you need to warm up the power unit to operating temperature or at least let it run for 3...5 minutes at 2000...3000 rpm. This is usually enough for an antifreeze leak to occur.

Radiator damage

This is one of the most common and easiest problems to diagnose. It can be diagnosed by antifreeze leaks on the radiator housing or by the appearance of antifreeze on the carpet under the front passenger seat when antifreeze leaks from the heater. In the second case, to perform diagnostics, it is necessary to disconnect the inlet and outlet pipes of the heater and connect them to each other (loop them). If after this the drop in the antifreeze level stops, it means that the radiator or heater valve is damaged. You can try to solder the radiator yourself, or contact a specialized workshop. If the radiator is old, it is better to simply replace it with a new one.

This also includes the failure of the tap that supplies coolant to the stove (in cars whose design provides for it, on VAZ cars antifreeze leaks precisely because of this tap). If coolant leaks from it or from its pipes, it must be replaced.

Antifreeze leaking into the engine

When the cylinder head gasket is punctured, an emulsion appears in the reservoir

If antifreeze gets into the engine, the reason for this is a broken cylinder head gasket, a mechanical change in the geometry of the cylinder head due to damage, the appearance of a crack in it or its significant corrosion. When antifreeze gets into the engine cylinders, white smoke comes out of the exhaust pipe, which is the result of combustion of the coolant. Also, this often causes oil from the engine to enter the cooling system, forming a foam-like emulsion in the expansion tank. There may also be a white coating on the spark plugs.

The simplest option that allows you to get by with “little bloodshed” is to break the cylinder head gasket. In this case, you just need to replace it with a new one. The situation is much worse if the cylinder head is damaged. Then it needs to be carefully checked and, if necessary, polished on a special machine. The most expensive option is to replace it completely.

Expansion tank

If the expansion tank body and/or the caps with the gasket on it are old, then there is a high probability that they have microcracks. Another option is to skip the safety valve on said lid. The simplest thing in this case is to replace the cover and install a new gasket. More difficult is to replace the entire tank (including the lid).

Pump failure

If the pump seal loses its tightness or its bearing wears out, then antifreeze begins to flow from the water pump. Usually the gasket fails due to simple old age or due to mechanical damage (for example, due to improper installation of the unit, too much torque, etc.). Fixing this problem is quite simple. To do this, you need to replace the mentioned gasket with a new one. The main thing is to choose a seal of the appropriate size and shape or apply a special sealant. You can do this procedure yourself or delegate this procedure to employees of a car service center or service station. But if there is play in the bearing, there is only one way out - replacing the unit.

Rust, deposits

Symptoms of failure of the VAZ-2110, 2114 or other car models may be different. Upon external inspection of the pump, rust is visible. The most common corrosion is on the impeller blades. This leads to a decrease in the rate of pumping antifreeze into the system. The cause of rust may be contaminated coolant or a compound that is incompatible with the pump. Mixing different antifreezes can also lead to this problem.

Another cause of rust on the pump is damage to the pump cover. In this case, it will not be able to close hermetically. Due to this, air bubbles appear in the composition, which causes oxidation processes.

In this case, the pump will need to be replaced. The cooling system must be thoroughly flushed and new antifreeze added. It is necessary to check the tightness of the cap. You may need to replace it.

The pump should also be replaced if deposits have formed on the inside of the pump. Such signs of a malfunction of a pump 2114, 2110 or another model can only be determined by visual inspection of the system. Deposits of resin, minerals or other substances appear on the internal surfaces of the pump. They clog the pump, preventing the system from working properly.

The cause of this malfunction is contaminated antifreeze or the use of the wrong composition. The system must be thoroughly rinsed with special mixtures. The pump has been replaced and new high-quality antifreeze is added.

Is it possible to drive if the pump is jammed?

Many car owners are concerned about the question: is it even possible to operate the car if the pump does not work? And if so, what is the best way to drive?

It all comes down to the components.

How necessary is it to use the car?

Of course, if the pump is jammed, the circulation of antifreeze in the system will be disrupted. Accordingly, the engine can only be cooled naturally. Therefore, it is better not to start the car, since overheating of the engine brings certain death to your four-wheeled friend. However, it is allowed to drive a faulty car if it is cold outside.

The engine is less susceptible to overheating, but you should avoid traffic lights and forced stops, as the engine heats up faster due to changes in the number of revolutions.

That is, most problems with the pump can be solved on your own. With the affordable cost of this pump, you can change the pump immediately when necessary. However, experienced drivers do not make a replacement until the product begins to act up. Practice shows that the pump's service life is much higher than stated by the manufacturer. Therefore, you don’t have to worry about repairs and replacements if the cooling system is operating normally.

Cavitation, bearing damage

When considering the symptoms of a motor pump failure, you should pay attention to such a negative phenomenon as cavitation. This is the process of formation of air bubbles in antifreeze. They damage the internal surfaces and individual parts of the pump. As a result, scratches remain on them. Then they rust.

Air bubbles appear in the pump inlet. When the pressure in the system increases, they are destroyed. This process causes significant system damage and can cause engine failure. Therefore, it is better not to save money and buy a new pump. It will be much more reliable than a refurbished pump.

It is very important to install it correctly in its original place. Particular attention is paid to seals and proper tightening of fasteners. In some cases, a special sealant is used for joints. Eliminates leakage. However, it is not always possible to use the presented material. This will prevent you from later loosening the engine mounts to secure the timing belt on some car models.

If you know the signs of a bad pump, you can replace it on time. First you need to remove the cover from the timing belt. If necessary, the tensioner will need to be loosened and removed. Then reduce the mounting force on the generator. Its belts and timing belt have been removed. The hose from the pump can be disconnected. Then the antifreeze is drained. After this, you can remove the protective cover and pump.

After installing the new pump in place, align the alignment marks. This is necessary because the crankshaft can move relative to the camshaft.

Shaft defects

Make sure the pump bolts are tightened correctly. They definitely need to fix this element of the system. However, they should not be over-tightened. Otherwise, you can damage the threads and jam the sealant.

When draining antifreeze from the system after finishing work, remove any air pockets. The liquid must be added to the level. After replacing the pump, the engine should be running and the system should be warm. Then it is checked for leaks.

If the car has a 16-valve system, replacing the pump will be a little more difficult. However, doing this procedure yourself is not difficult.

Other verification methods

First you need to remove the plastic cover and the timing belt cover. To remove the upper parts that separate the pulleys from the cylinder block, follow these steps in sequence. This is only possible after removing the camshaft timing belt and pulleys (sprockets and support pulley). Only after this can the pump be disassembled.

To gain access to the bottom cover mounting bolts, remove the right wheel. The pump can then be disassembled. Then follow the same steps as in the previous step. If the pump is installed incorrectly, it will leak. Therefore, it is important to follow the manufacturer's instructions.

Malfunctions in the operation of the pump occur, significant play on its shaft, failure of the seal, wear of the impeller (corrosion or cracking). All these shortcomings lead to the fact that the water pump in the car does not work properly, due to which the engine cooling system does not maintain the required pressure, which in turn leads to an increase in the temperature of the coolant to the boiling point. . You need to buy a new pump and install it in place of the old one.

There are only six main symptoms of a “dying” pump, by which we can say that the pump has partially (or even completely) failed and requires replacement. So, these symptoms include:

Replace or repair?

External noises. A partially faulty cooling system water pump makes an “unhealthy” noise or “howl” during operation. This may be due to significant wear on the bearings and/or the pump impeller contacting the pump body as it rotates. This is also due to partial damage to the bearing.

Pump pulley play. This is due to damage or natural wear to the rotating bearing. In this case, diagnostics can be carried out quite simply, just move the pump shaft from side to side with your fingers. If there is play, it will be felt well to the touch. Please note that the appearance of play causes leakage of the pump seal and leakage of coolant.

The occurrence of leaks. Thus, antifreeze can leak from the gasket, as well as from other places such as the housing and impeller. Including: In this case, antifreeze may be visible on the pump housing, pump mount, some elements of the space under the pump (depending on the design of a particular car), or simply on the ground under the car.

Antifreeze smell appears. In particular, this can be felt not only in the space under the hood (when the hood is opened), but also in the cabin, since its fumes will enter the cabin through the ventilation system. Antifreeze has a sweetish smell, sometimes with a taste of alcohol.

How to find a leak

Leaks in pipes, radiator, and other connections of the cooling system are often detected during the initial inspection. For example, antifreeze may drip or leak, causing wet spots. If a visual check does not allow you to localize the place where the coolant is flowing from, it is necessary to sequentially check all components and connections of the cooling system.

Cooling system radiator . Large temperature changes cause thermal fatigue processes in the main heat exchanger, which leads to the formation of microcracks on its surface. Due to constant contact with liquid media during operation of the radiator, pockets of corrosion appear on its body. In addition, the product receives mechanical damage, for example, as a result of stones falling while the car is moving. All these defects cause antifreeze leakage, which can be seen in streaks on the body or in puddles under the car. If such a breakdown occurs on the road, the best way to fix it is to use a sealant. This material has an emergency purpose and can help out in an emergency. In a car service center, radiators are repaired using soldering or argon-arc welding. If the damage is too deep, it is better to replace the used heat exchanger with a new one.

Expansion tank . Antifreeze can leak from under the cap, through cracks and cracks in the body. Sometimes it happens like this: the surface of the tank is wet, oily, and there is no visual damage. This indicates the presence of microcracks that are invisible to the eye. Therefore, you should replace the housing and/or cover with new, serviceable ones. If you are not sure that it is the expansion tank that is leaking, you should first send the car for diagnostics to a workshop or service center.

Connection points . To check their tightness, drivers often use a simple but quite effective method: a sheet of paper is placed under the car, after which it is left in the parking lot for some time. The appearance of coolant stains indicates the need for a thorough inspection of pipes and hoses, especially their connections to other components of the system. You should also check the thermostat seals, as antifreeze may leak out from under the thermostat gasket or through damage to the housing. In this case, a complete replacement of faulty components and parts is carried out.

Rubber pipes . They operate under a constant temperature difference, which over time leads first to the appearance of microcracks and then to cracking. Such a defect in the pipe does not cause a serious leak; antifreeze leaks out slowly. However, the product must be replaced with a new one. When checking the pipes, they should not only be inspected, but also carefully felt to find subtle cracks. A mirror can be used to visually inspect hard-to-reach areas. It should be remembered: the reason that antifreeze is leaking may not be so much the pipe as a poorly tightened clamp at the junction with the fitting. Often, more tightening is enough to stop the leak.

Pump (cooling system pump) . It is one of the most common places for antifreeze leaks, along with the pipes and expansion tank. Typically, coolant leaks out due to loss of tightness of the stuffing box seal. It is easy to locate the leak: antifreeze flows down the pump rod and then splashes onto nearby parts. If this is the problem, it is recommended to immediately send the car to a workshop, where they will diagnose it and immediately replace the pump. This urgency is due to the fact that on many cars the pump is controlled by a timing belt (gas distribution mechanism). Therefore, unresolved problems with the pump often lead to more serious damage to the car.

Stove (heating) radiator . Clear signs that coolant is leaking from there will be a constant smell of antifreeze in the car interior and heavy fogging of the windshield windows. With more serious radiator leaks, coolant stains appear on the floor (usually in front of the front passenger seat).

You might be interested in: Why does antifreeze “leave” from the expansion tank?

Replacing a pump in an 8-valve system

Installation misalignment. Especially when it comes to gears and pulleys. This can be observed visually or by placing any flat object (for example, a ruler) in the same plane as the shafts and pump. In this case, the strip is often eaten.

The engine temperature rises significantly. And not only the engine, but also the coolant, as evidenced by the indicator light on the dashboard. In critical cases, the antifreeze will simply boil and water vapor will flow out of the cooler. However, the situation is critical and the use of the car is prohibited!

If at least one of the above symptoms of a water pump malfunction occurs, additional diagnostics of both the pump and the cooling system are required. When the first signs of a dying pump appear, you can still ride, but for how long this is unknown, and it is better not to tempt fate. In some cases, a car can run for 500 zlotys. 1000 km, and in other cases not even a hundred. In any case, the cooling system is not to be trifled with and must be promptly and fully diagnosed and repaired.

Depending on the brand and quality of the cooling system water pump, regulations recommend replacing it after approximately 60,000 km. km (depends on the specific case and is recommended by the manufacturer, relevant information can be found in the operating instructions)

Do-it-yourself pump replacement on VAZ cars

As mentioned above, the replacement procedure will look different on different car models. This is due to the location of the unit in the engine compartment and the design of the car itself. The easiest way to perform the replacement is on VAZ cars.

To replace the pump you only need wrenches

The replacement procedure is as follows:

- Wait until the engine cools down. It is prohibited to carry out work immediately after stopping the engine, as you may get burned.

- Prepare a set of wrenches and a container to drain the old coolant. It is necessary to change the pump together with antifreeze (antifreeze), since the old liquid gradually loses its cooling properties during use.

- Unscrew the antifreeze drain plug (the plug is located on the engine block). After this, unscrew the cap on the radiator to quickly get rid of the old fluid. Place containers under the drain points.

- When the antifreeze (antifreeze) stops dripping, loosen the generator belt tension rack. After this, remove the belt, since otherwise it will be impossible to get close to the pump.

- Remove the three pulley bolts. Remove the alternator belt pulley. Unscrew the nuts that secure the part to the motor housing. Take out the pump and along with it the old gasket.

- After this, it is recommended to wipe the seating area with a clean cloth and install a new rubber gasket. To ensure secure fastening, it is better to treat the socket with sealant.

- Install the new pump on a new gasket and then carry out all work in the reverse order. Upon completion of work, fill in new coolant.

Dismantling and installation of the product on VAZ cars takes about an hour. On cars of other brands, the work may take longer due to the fact that you will have to unscrew the engine mounts.

How much does it cost to replace a pump at a service station?

It is necessary to separately say that replacement in itself is not a costly operation. Specialists from service organizations charge from 1,200 to 3,000 rubles for their services, depending on the make of the car.

I changed it myself on a 124 engine, I changed it on an 8-valve engine with a friend on his ten... I still don’t understand what the 1200 came out of... Whatever it was, it took an hour with breaks. I’ll even say more - I recently changed the pump itself on the m50b20 in my BMW, it took about 40 minutes.. The service asked for inadequate money for this work... Although in fact it’s easier to change the pump on a BMW than on the former 21124..

Replacing a pump in a 16-valve system

What are the possible causes of pump failure? This question worries not only beginners, but also quite experienced car enthusiasts. Here are the main reasons, from the most common and widespread to the “exotic”. Among them:

Faulty bearing. This device wears out due to natural reasons. However, accelerated wear is possible due to additional negative factors. For example, incorrect (higher) belt tension results in increased load on the bearing. Another reason for significant wear is the transfer of antifreeze to friction pairs due to leaky seals and coolant leakage.

Damage to the seal. The pump has two seals - a packing and a rubber gasket. Most often the sealant (gasket) is damaged. This happens for two reasons - natural wear and tear (tanning of rubber) and the use of cheap, low-quality antifreeze without appropriate additives or even water. After a longer period of time, these liquids “eat up” the seal, it begins to leak, which leads, firstly, to a decrease in the level of coolant in the system, and secondly, to the entry of antifreeze or water into the bearing, washing out the lubricant and the problems described higher.

Pump malfunctions

Misalignment. This is possible for two reasons - incorrect assembly and manufacturing defects. However, incorrect assembly is a fairly rare occurrence, because the case has ready-made mounting holes that are very difficult to miss. Another reason is uneven seating on the cylinder block (due to dirty, rusty or bent surfaces). And, unfortunately, manufacturing defects, especially in younger pumps, are not so rare. An alignment error causes the pulley to become misaligned, which in turn accelerates wear on the belt and bearings. In the most critical cases, the belt may break and the valves and pistons may collide. Sometimes misalignment is caused by the car being in an accident with a misalignment. Re-pump to a new one, especially if it has been used for a long time. When replacing the pump, the antifreeze is also replaced.