Progress does not stand still. Every year, more advanced high-tech technologies appear that are designed to make human life easier. The automotive industry is no exception in this case. Modern cars are equipped with all kinds of systems that greatly facilitate their operation.

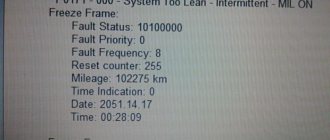

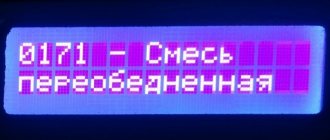

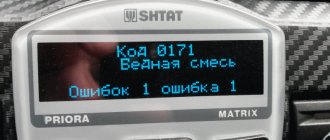

However, due to his incompetence, it can be difficult for a vehicle owner to determine the cause of a particular malfunction, especially when a variety of factors can be the reason for its occurrence. One of these faults is a lean air-fuel mixture, which is displayed on the instrument panel as code P0171.

It happens that a warning light comes on, indicating a malfunction in the engine. After connecting the scanning device, it often turns out that behind all this lies the same error. Let's try to figure out what's hidden behind these encrypted symbols and try on our own to restore the car to full functionality.

Why does error P0171 occur?

What is the primary source of the presented error? It is not possible to answer this question unambiguously. The fact is that this error can be caused by a variety of malfunctions in the operation of various related devices.

This encoding allows us to conclude that the mixture entering the car engine cylinders is poor. The power system of a working passenger car provides the optimal proportion of the air-fuel mixture, where 1 part gasoline accounts for 14 parts air. In our case, there is a deviation from the specified parameters.

Injector problems

You don't have to be an expert to understand that the problem here lies in the operation of the injector. And first of all, before we start studying lean mixture, let’s try to find out what it even is. This is important only because such a reason can lead to expensive repairs to the car.

Why do jerks happen?

The presence of jerks while the car is moving is a problem that directly or indirectly indicates the presence of problems with the engine, or more precisely, a loss of power. In total, there are two features that affect the development of power in the engine - fuel supply and the ignition system.

If with the ignition, everything is more or less clear, due to the inspection of the generator, spark plugs, ignition wires for faults, and the battery for charge, then in the case of the ignition system everything looks much more complicated.

High voltage wires are marked with arrows

Inspecting the condition of the spark plugs

To ensure a successful engine start, it is necessary to mix the fuel and air mixture in ideal proportions; this is what the injector is responsible for.

It happens that when mixing these proportions, a malfunction occurs, and the mixture turns out to be rich or lean.

A clear example of the air-fuel mixture ratio.

In order for the car to obtain maximum power when burning fuel in the cylinders, it is necessary to bring its indicator to the level of 0.85 - 0.9, when excess oxygen = > 1 (at this indicator, gasoline burns completely without residue - approx.), and when there is a lack of oxygen, and the readings are equal. The main reasons for a lean mixture

The main and most important symptom that the system has a lean mixture is a stalling or unstable engine. And if the mixture is very poor, then it is possible that it will not start at all.

The cause of these problems is most often a clogged air filter (see “replacing the air filter”), clogged injectors, wear in the fuel pump, and there may also be air leaks into the system. All these reasons are, one way or another, related to the stable operation of the engine.

What do spark plugs tell us?

One of the fundamental checks for the condition of the mixture will be to assess the condition of the spark plug.

So, a light brown tint will indicate that the system is operating normally, a too dark tint will indicate a lack of (enriched mixture - approx.), too light, an excess (depleted - approx.) mixture.

Symptoms of malfunction

A car can be compared to a living organism. It is especially appropriate to make such a comparison when it comes to identifying the symptoms of a particular malfunction. Almost any, even the most minor malfunction in the operation of an individual component or element of the system has a number of characteristic signs that manifest themselves in various engine operating modes.

So, we managed to make sure that a lean working mixture, as evidenced by error code P0171, can be caused by a variety of reasons. It's time to consider the so-called symptoms for each of the malfunctions noted above.

Let's start with the flow meter . During operation, the so-called DRMV requires systematic diagnostics. Otherwise, sooner or later it may cause various types of engine malfunctions.

With a high degree of probability, we can talk about a malfunction of this device if the following symptoms occur:

- reduction in engine response;

- uneven engine operation in different modes;

- problems starting the engine;

- loss of engine power.

Next on the list is the EGR valve . Often, they find out about its failure only when a comprehensive diagnosis of the engine control unit is carried out.

For your information: What is a timing belt, after how many kilometers does it need to be changed and what happens if it breaks

In most cases, this applies to cars before 2000. In other cases, valve malfunctions are easily detected by a number of signs of engine operation.

The most common of them:

- unstable engine operation;

- reduction in the dynamic characteristics of the car;

- Unstable engine operation in idling mode.

Let's talk about undesirable symptoms in engine operation, the culprit of which is the fuel pump .

These include:

- Difficulty starting the engine;

- increased engine noise;

- deterioration of engine performance in various modes.

Now it's time for the injectors . Before covering all the possible symptoms of their malfunctions, it is worth noting some nuances of their diagnosis. The fact is that the injector is one of the key elements of the fuel system.

Their diagnosis should not be limited only to visual inspection. All of them must undergo a special test on a so-called stand, where the spray angle is set, filling capacity and other operating parameters are checked.

The following undesirable symptoms can indicate malfunctions of the injectors:

- failures in engine operation;

- problems when starting the engine;

- interruptions when increasing engine speed;

- uneven engine operation in idle mode.

How does a faulty fuel pressure regulator ?

Most often, signs indicating its failure are associated with:

- unstable engine operation at idle;

- a sharp decrease in vehicle acceleration dynamics;

- pops and dips while gaining speed.

Causes of error P0171

If a lean mixture enters the combustion chamber of a car engine, there can be two reasons for this: too much air is supplied or too little fuel is supplied. Each of these reasons can arise due to a number of problems.

Why does a lot of air enter the combustion chamber:

- Malfunction of the air flow sensor. This may be due to contamination, which prevents precise control of air flow;

- Additional air enters the intake manifold through the exhaust gas recirculation (EGR) valve. This reason is most often due to the fact that the valve does not close well, thereby allowing exhaust gases to be directed into the intake manifold;

- Increased air flow through the EGR valve due to improper operation of the EGR differential pressure sensor;

- Presence of a vacuum leak.

Why is there little fuel entering the combustion chamber:

- The fuel pump is not doing its job;

- Fuel injectors are damaged or dirty, causing them to not deliver enough fuel in the allotted time;

- The supply of the required amount of fuel is hindered by resistance from the fuel filter;

- Fuel partially leaks out of the pressure regulator without entering the combustion chamber in full.

As you can see, there are many reasons for error P0171. To find the engine element that is causing a lean fuel mixture in the combustion chamber, you will need to check sensors, injectors, filters and a number of other components.

How to find and fix problem areas in a car

At this stage, it is advisable to first conduct a visual inspection of all the above components and devices. It often happens that the problem of this type of error may be associated with a violation of the integrity of the supply wires or loosening of the fastening.

If a visual inspection does not reveal a malfunction, it is necessary to conduct a comprehensive check of the functionality of each of the presented devices.

First, let's evaluate the condition of the flow meter . After dismantling it, you should pay attention to the presence of deposits and contamination. The sensor should be washed using special washes, which are available in a wide range of auto stores.

If there is no spray nearby, you can wash the flow meter with alcohol or a solution of gasoline and kerosene in equal parts. It is worth noting that this sensor cannot be blown out with compressed air using a compressor. Such a procedure can simply disable it.

This is interesting: What is a diesel intercooler: principle of operation and causes of device failure

If the warning lamp still indicates an error, you need to check the functionality of another component. Next up is the EGR valve . An external inspection of this device includes checking the tightness of the underwater pipes of the valve and its body for mechanical damage.

In order to ensure that the valve is working properly, you must adhere to the following sequence of actions:

- Remove the valve underwater pipes;

- Blow out the valve cavity with compressed air;

- Remove underwater contacts;

- Apply current to the valve from the battery;

- Purge the valve again.

If the valve is in good working order, at the time of the first purge, the valve should not be purged, but the second time, vice versa.

At the next stage, we will evaluate the condition of the fuel pump . First of all, you need to make sure whether it shows signs of life at all, which is expressed in the characteristic “rumbling”. The overwhelming majority of modern cars are equipped with submersible fuel pumps.

The operating pressure of such pumps ranges from 3 to 4.5 bar. Therefore, it is enough to connect a pressure gauge to the fuel line and see for yourself that it is working.

It's time to look at the injectors . Of course, visual control of their condition is exclusively subjective, but, nevertheless, it does not hurt to look at them, especially if you only had to remember about their existence just now. If the working part of the nozzle with calibrated holes is covered with soot, then there is no need to talk about its effective operation.

the fuel pressure regulator is working properly . This procedure will not take much time if you have a multimeter at hand.

The verification algorithm looks like this:

- remove the chip from the pressure regulator;

- We attach the negative wire to the “-” terminal of the battery;

- positive wire to the signal terminal of the regulator (the one in the middle);

- start the engine;

- gradually increase the speed up to the maximum value.

When the engine is running at idle, a working regulator consumes about 1.5 V. As the speed increases, the operating voltage should increase to 4.8 - 5 V. If the multimeter needle remains stationary, despite the increase in engine speed, the regulator must be replaced .

Checking the sensors

The complete verification of the presented error includes checking all kinds of sensors. First on the list is the mass air flow sensor, the so-called air meter. One of the testing methods is to simply turn off this sensor and evaluate the dynamic characteristics of the car without its participation. If improvements are evident, it is highly likely that it is malfunctioning.

When this error appears, it is advisable to check the oxygen metering sensor, the so-called lambda probe. If an external inspection did not reveal obvious deposits on the surface of the sensor, a more thorough check should be started. To do this, we will use a tester in voltmeter mode.

So, 4 wires go to the sensor. One of them (black), the so-called “+ signal,” is connected to the + of the voltmeter, and the negative terminal to the mass end of the sensor.

If the sensor is working properly, the voltmeter reading on a cold engine should be about 0.2 V. On one warmed up to operating temperature - up to 0.3 - 0.9 V. In this case, it is important to measure the signal voltage of the sensor.

On the subject: What is a Thermostat: principle of operation, testing and troubleshooting

As soon as the engine starts, a working sensor will operate in open-loop mode, and the voltage will be stable around 0.1 - 0.2 V. As the engine warms up, the sensor will switch to closed-loop mode, with the voltage varying from 0. 2 to 1 V up to 10 times per second.

If no oscillations are observed, which indicates that the sensor does not go into closed-loop mode, we can assume that the lambda probe has given up its life.

Checking the fuel system

Checking the fuel system involves diagnosing all elements of the fuel equipment and fuel lines.

An inspection of the vehicle's power system in the event of this error involves checking the functionality of the following components:

- submersible fuel pump;

- fuel pressure regulator;

- nozzles;

- fuel lines.

It is important to remember that a condition for the efficient operation of the power system of any injection engine is the presence of a given operating fuel pressure. This factor should serve as a starting point in identifying all kinds of malfunctions in the vehicle’s fuel system.

How to diagnose the fuel system?

The most common cause of breakdown is the presence of air leaks. First, check the tightness of the system. If the seal is broken, the damaged part is replaced. Next, make sure the fuel system is working properly. You need to check the pressure in the fuel supply system and check whether the injectors are clogged. If the pressure is insufficient, you need to disassemble and check the fuel pump.

When idling, the pressure in the fuel rail should be from 2.8 to 3.2 kgf/cm²,

Having found out the reasons for the lean mixture on the VAZ 2114, you need to move on to eliminating them.

On which cars is this problem most common?

The problem with code P2187 can occur on different machines, but there are always statistics on which brands this error occurs more often. Here is a list of some of them:

- Audi (Audi a4, Audi A5, Audi a6, Audi q3, Audi q5)

- BMW

- Chery (Chery Tiggo)

- Chevrolet (Chevrolet Cruze)

- Ford (Ford Mondeo)

- Geely (Emgrand)

- Hyundai (Hyundai Santa Fe, Solaris, Sonata, Elantra)

- Kia (Kia Magentis, Rio, Sid, Sorento, Cerato)

- Lifan (Lifan x60)

- Mazda (Mazda 2, Mazda 3, Mazda 5, Mazda 6, Mazda cx7, Demio)

- Mercedes

- Mini (Mini Cooper)

- Opel (Opel Corsa)

- Porsche

- Saab

- Volkswagen (Volkswagen Passat)

- Volvo (Volvo s80, xc90)

- Vortex (Estina's Vortex)

- VAZ 2107, 2114, 2115

- Lada Vesta, Granta, Kalina, Niva, Priora

- UAZ Loaf, Patriot, Farmer, Hunter

With fault code P2187, you can sometimes encounter other errors. The most common ones are: P0022, P0026, P0133, P0171, P0174, P0420, P0441, P0507, P2177, P2192, P2279.

Causes of excess air

If, after carrying out this work, instability is also observed in the operation of the system, pay attention to possible places where excess air occurs, since it also affects the leanness of the mixture and the main reasons lie in the following:

- Presence of dirt or marks on the mass air flow sensor.

And in order to eliminate the above reasons, it is necessary to conduct a thorough diagnosis.

Troubleshooting

Mass air flow sensor - the air flow sensor can become clogged due to natural reasons, as well as from vapors that come from the throttle valve while the car is not running. And then, over time, accumulating in a thick layer on the thin thread of the sensor, forcing it to send inaccurate data to the ECU, which in turn negatively affects the parameters of air flow and flow into the system.

When diagnosing its malfunction, it is best not to rush into purchasing, since it costs a lot of money, but it is best to check its performance on a known working device. And when it is established that the reason lies in it, then you can try to clean it, or then replace it with a new one.

Vacuum leak

Vacuum leak - these words mean any form of air leaks, i.e. suction into the system, primarily through the manifold gasket or hoses.

The vacuum pump and return hose may cause

Pay attention to the condition of the pipe leading from the air filter to the throttle valve, and the hoses that go to the crankcase ventilation. There should be no visible damage to them, as well as large cracks through which excess air could enter.

In addition to all of the above, you can check the engine oil dipstick and the oil filler cap on the neck, because if these connections are not completely closed, they can cause the appearance of that same excess air.

Error "Lean mixture"

In this case, the amount of fuel in the working mixture is too low, while too much air is supplied there.

A similar problem appears in a situation where the engine takes in a significant portion of air from the atmosphere for one of many reasons. Also, the problem may lie in insufficient fuel injection due to clogging or other problems.

Symptoms and behavior of the car with such an error

This phenomenon can lead to misfires, as well as delays that occur in the car’s response to pressing the gas pedal. The car may start to stall or stall at stops (idling).

In addition, when accelerating, a noticeable twitching is felt, and dips are observed during idle.

Well, the engine itself changes its sound, starting to work extremely unstable. In those engine monitoring and control systems that support Euro 2 and higher standards, there is a lambda probe. It is he who is responsible for controlling the quality of the mixture. It is optimal if there are about 14.7 parts of ordinary atmospheric air per part of fuel.

If there is a shift from this value by more than a quarter, the system will generate error message P0171.

How does a car behave with a similar problem?

If the engine receives too lean a mixture, this can cause the car to begin to “chop” at idle, and also overheat, since the rate of combustion of the mixture becomes much lower. If you listen closely, you may hear popping noises in the intake manifold. The revs pick up extremely slowly under load.

A lean mixture can be recognized by deposits on the spark plugs.

Burnout of valves and piston system

In the most difficult situations, if the engine overheats very much, this can lead to burnout of the valves and piston system , which entails serious costs for further maintenance and repairs.

A burnt valve will require serious financial investment in car repairs.

Strong vibration, the engine began to shake violently - symptoms of burnt valves

Still the same Avensis, general view of the head The owner was lucky that the broken piece of the valve did not lead to a major overhaul of the engine. It feels like someone just bit off an even piece of the valve

High fuel consumption

If a car is used for a long time with such a problem, this can lead to very high fuel consumption, which occurs due to a slow increase in speed. So, drivers have to operate their car in lower gears more often. A lean mixture can occur when the supply balance of its components is upset.

Causes of a lean mixture

There are several main reasons why the mixture is supplied to the car lean. But, they are all divided into two main groups: a large amount of air and a small amount of fuel.

A lean mixture error can occur in the case of excessive air supply, then the problem lies in the incorrect operation of the fuel flow sensor. This can happen when the channels become dirty.

The second reason can be called the problem of vacuum leakage. And reason number three talks about the problem of air intake through the EGR valve when it is broken or does not close tightly enough.

In order to eliminate the EGR valve, it is necessary to remove it from the car and check its operation. The test is carried out with compressed air. Compressed air can be taken from a compressor, a tire pump, or, in extreme cases, from the tire itself. Learn more about video verification.

Carrying out an inspection

Speaking about the lack of fuel, there are also three main reasons.

- The first includes problematic operation of the fuel pump, when it does not have enough power or it does not work as it should.

- Next comes the non-optimal resistance of the fuel filter.

- Well, the third reason will be a leak that may occur in the pressure regulator . Also, the breakdown may consist of simple contamination of the fuel injectors.

Sometimes we may need to check almost all possible causes in order to find exactly the one that is typical for our case.

Therefore, the first thing you need to do is check the sensors. As you may know, one of the most common problems is a clogged sensor, which is responsible for controlling air flow . If too much dirt has accumulated on its wire, this may cause the response to changes in air flow to become too slow.

It can also be contaminated by fuel vapors that pass through the intake manifold and through the throttle body when the engine is not running. These pairs can deposit a special layer of paraffin on the sensor wire, which will send data to the system about the incorrect proportion of the mixture.

What happens next is that the engine control unit cannot add fuel when the amount of air is too high. And after that, an error code will appear on the sensor screen indicating a lean mixture.

False errors P0100 and P0102

It also happens that along with the indicated error, other codes appear, like p0100 or p0102, by which you should definitely know that the problem lies in the sensor. To solve this problem, you need to clean the sensor.

To do this, use specialized means for cleaning electrical appliances or the so-called carb cleaner, which is evenly sprayed onto the element that needs to be cleaned.

But, still, the best option would be to install a new sensor.

In the video, craftsmen made a simple smoke generator from a bottle and a cigarette.

Also, be sure to check the system for vacuum leaks. Depressurization can occur in any part of the inlet pipeline.

But this can also happen at the outlet of the throttle body, namely at the place where the vacuum-type hoses and the intake manifold are connected.

In addition, depressurization can even appear in places such as the throttle body gasket and the intake manifold.

And, of course, it wouldn’t hurt to check the fuel system. First of all, it is necessary to monitor the performance of the injectors, which is carried out exclusively on a special stand. Most problems with injectors occur due to low-quality fuel; in this case, flushing the injectors will help.

Next, you need to check the fuel pressure, as well as the performance of the gasoline pump, if present. You also need to check the voltage on it. Among other things, pay attention to the fuel pressure regulator and the fuel filter, as they must be in good working order so as not to cause a lean mixture.

Lean mixture codes

But you should not think that for all reasons there is only one code, as for all cars. For example, the P0171 code in question is standard.

But, in Ford cars, this code will indicate problems in the first cylinder block, while the P0174 code will indicate shortcomings in the second cylinder block.

But on some Honda car models, code P0172 (45) may appear, which also indicates a lean mixture error, which turns out to be incorrectly prepared.

On the popular Chevrolet Captiva car in our country, a similar problem will be indicated within its own diagnostic system with code (DTC) P2177. But, the methods for eliminating this code are exactly the same as for other cars. In the Mazda 6, code 2178 may appear, which is exactly the same as what the previously mentioned codes indicate.

Technical description and interpretation of error P2187

This diagnostic trouble code (DTC) is a generic powertrain code. Trouble code P2187 is considered a common code because it applies to all makes and models of vehicles. Although the specific repair steps may vary slightly depending on the model.

This code is ambiguous; it is not always possible to notice it, since the Check engine indicator may not be displayed. Therefore, if you do not have a diagnostic scanner, you may not know about it. This code is difficult to crack without a diagnostic strategy. A problem with the idle fuel mixture is usually determined when other errors are read by the scanner.

The error code means that the fuel mixture is too lean (too much air and not enough fuel) at idle. If you have a 4 cylinder engine, the "Bank 1" information is meaningless to you. However, if you have a 6 or 8 cylinder engine, then Bank 1 indicates a problem on the number one cylinder side. Code P2189 is the same code, but for bank 2.

There is an extensive list of components that can cause this error scenario. But moreover, the diagnostic procedure is not complicated, but simply takes a lot of time. A bug-hunting strategy requires that problems be observed and noted. The check then starts with the most frequently occurring ones and moves forward.