Many motorists remember how a problem arose on carburetor engines when a lean mixture appeared due to the carburetor or filters, which not only slowed down the engine, but also increased consumption (consumption rates). With the development of the automotive industry, the reasons for the effect have become more numerous, since many new details have been added that regulate this indicator. No, all motorists know why a lean mixture can appear on a VAZ-2112, and even more so, how to solve this problem.

Symptoms of malfunction

Engine operation with a mixture that is too lean is manifested by the following symptoms:

- significant loss of power;

- The Check Engine light is on on the instrument panel;

- engine throbbing or throbbing (unstable idling);

- problems starting the engine;

- motor overheating.

If the problem with a lean mixture is not addressed, fuel consumption increases, as the driver is forced to press harder on the gas and drive at higher speeds. Damage to the catalytic converter can also occur over time.

Self-adjustment

Most drivers are very glad that they know how to adjust the throttle angle, as they are completely confident that this will help regulate fuel consumption. In addition, some resort to flashing the vehicle's electronic control unit. In order not to damage some units or ECUs, it is worth seeking help from qualified technicians who can, using special programs, without affecting the quality of the mixture, improve some of the car’s performance. Otherwise, the risk of “killing” the engine of your vehicle increases. Thus, a lean mixture is formed on the injector, the reasons (2114 is no exception) for which lie in the independent adjustment of the angles or the intervention of an inexperienced car owner in the operation of the engine system.

Causes of DTC P0171

Since the mixture can be lean due to too much air or not enough fuel, we will look at these two problems separately. Reasons for the increase in air quantity:

- Vacuum leak (air leak) through lines, intake manifold gaskets, throttle valve, mass air flow sensor, EGR valve, idle air control, vacuum brake booster, etc.;

- malfunction of the mass air flow sensor (MAF);

- oxygen sensor malfunction.

Fuel shortage can be caused by the following factors:

- decreased fuel pump performance;

- dirty fuel pump screen;

- clogged fuel filter and injectors;

- Fuel pressure regulator malfunction.

Carrying out an inspection

Speaking about the lack of fuel, there are also three main reasons.

- The first includes problematic operation of the fuel pump, when it does not have enough power or it does not work as it should.

- Next comes the non-optimal resistance of the fuel filter.

- Well, the third reason will be a leak that may occur in the pressure regulator. Also, the breakdown may consist of simple contamination of the fuel injectors.

Sometimes we may need to check almost all possible causes in order to find exactly the one that is typical for our case.

Checking the MAF sensor using a multimeter (video)

Therefore, the first thing you need to do is check the sensors. As you may know, one of the most common problems is a clogged sensor, which is responsible for controlling air flow. If too much dirt has accumulated on its wire, this may cause the response to changes in air flow to become too slow.

It can also be contaminated by fuel vapors that pass through the intake manifold and through the throttle body when the engine is not running. These pairs can deposit a special layer of paraffin on the sensor wire, which will send data to the system about the incorrect proportion of the mixture.

What happens next is that the engine control unit cannot add fuel when the amount of air is too high. And after that, an error code will appear on the sensor screen indicating a lean mixture.

False errors P0100 and P0102

It also happens that along with the indicated error, other codes appear, like p0100 or p0102, by which you should definitely know that the problem lies in the sensor. To solve this problem, you need to clean the sensor. To do this, use specialized means for cleaning electrical appliances or the so-called carb cleaner, which is evenly sprayed onto the element that needs to be cleaned. But, still, the best option would be to install a new sensor.

“Vacuum” leak (video about checking for air leaks)

Also, be sure to check the system for vacuum leaks. Depressurization can occur in any part of the inlet pipeline. But this can also happen at the outlet of the throttle body, namely at the place where the vacuum-type hoses and the intake manifold are connected. In addition, depressurization can even appear in places such as the throttle body gasket and the intake manifold.

Checking the fuel system (video)

And, of course, it wouldn’t hurt to check the fuel system. First of all, it is necessary to monitor the performance of the injectors, which is carried out exclusively on a special stand. Most problems with injectors occur due to low-quality fuel; in this case, flushing the injectors will help.

Next, you need to check the fuel pressure, as well as the performance of the gasoline pump, if present. You also need to check the voltage on it.

Among other things, pay attention to the fuel pressure regulator and the fuel filter, as they must be in good working order so as not to cause a lean mixture.

How to tell if a mixture is rich

Several characteristic features:

- Pops, explosions in the muffler. Excess fuel, unburned as a result of an incorrect ratio, explodes in the hot exhaust pipe;

- Black exhaust and carbon deposits on the exhaust pipe;

- Loss of dynamics. The driver feels as if the car is being held by the bumper;

- Increased consumption. The car tries to compensate for the excess air by adding fuel;

- Rich mixture error "P0172". Read by the scanner when CHECK ENGINE lights up on the panel:

How to diagnose trouble code P0172?

- Checking the fuel pressure in the fuel rail

- Using indicator lights, the voltage pulses of the fuel injectors are checked.

- Vacuum hoses are checked for leaks

- The serviceability of the mass air flow sensor and oxygen sensors is checked

- Checking the patency of the exhaust system

This is interesting: Scheduled maintenance for Mitsubishi Lancer X: regulations, cost, maintenance schedule

Fuel system diagnostics

The “lean mixture” error often occurs for reasons related to improper operation of the fuel supply system. Diagnostics of this system is carried out as follows:

- check the power of the fuel pump (using a pressure gauge);

- conduct a performance test of fuel injectors on a special stand;

- check the fuel filter;

- check the fuel pressure regulator;

- Check the power supply to the fuel pump.

If fuel is supplied without failure, there is only one reason left - air leaks.

How to resolve the error

Regardless of the cause of error P0172, you should not delay repairs; a rich mixture will shorten the life of the catalyst. The most likely sources of problems are checked and eliminated first:

- Examine the candles. Check by the presence of black soot that the mixture is over-rich.

- On vehicles with a return line, remove the hose from the regulator and try to bleed it to ensure it is not pinched anywhere along the way to the gas tank.

- Find out the correct fuel pressure values for your car. For a VAZ with a drain ramp it is 3 bar, with a drainless one - 4. Please note that the pressure on the drain ramp is measured with the vacuum pipe removed from the regulator, otherwise the readings at idle will be 0.6-0.5 bar lower! The pressure gauge itself for measurement can be inexpensively purchased or borrowed.

- Connect the tester to the signal wire of the lambda probe in voltage measurement mode. It is more convenient to use pointer instruments - they do not have the same inertia as digital ones; on a working lambda probe, you can see the needle oscillate from 0.25 to 0.75 V.

- Measure the voltage at the output of the mass air flow sensor with the engine turned off, comparing it with the standard one, if it is possible to find it out. For example, for VAZ sensors it should not be higher than 1.03 V (Bosch) and 0.04 V (Siemens).

- Check the level and condition of the engine oil.

- Without “catching” the source of the problem, contact the service - for a qualified diagnostician there will be no problems here.

New Lada: How to connect a radio so that it works without ignition

Injector problems

You don't have to be an expert to understand that the problem here lies in the operation of the injector. And first of all, before we start studying lean mixture, let’s try to find out what it even is. This is important only because such a reason can lead to expensive repairs to the car.

Why do jerks happen?

The presence of jerks while the car is moving is a problem that directly or indirectly indicates the presence of problems with the engine, or more precisely, a loss of power. In total, there are two features that affect the development of power in the engine - fuel supply and the ignition system.

If with the ignition, everything is more or less clear, due to the inspection of the generator, spark plugs, ignition wires for faults, and the battery for charge, then in the case of the ignition system everything looks much more complicated.

High voltage wires are marked with arrows

Inspecting the condition of the spark plugs

To ensure a successful engine start, it is necessary to mix the fuel and air mixture in ideal proportions; this is what the injector is responsible for.

It happens that when mixing these proportions, a malfunction occurs, and the mixture turns out to be rich or lean.

A clear example of the air-fuel mixture ratio.

In order for the car to obtain maximum power when burning fuel in the cylinders, it is necessary to bring its indicator to the level of 0.85 - 0.9, when excess oxygen = > 1 (at this indicator, gasoline burns completely without residue - approx.), and when there is a lack of oxygen, and the readings are equal. The main reasons for a lean mixture

The main and most important symptom that the system has a lean mixture is a stalling or unstable engine. And if the mixture is very poor, then it is possible that it will not start at all.

The cause of these problems is most often a clogged air filter (see “replacing the air filter”), clogged injectors, wear in the fuel pump, and there may also be air leaks into the system. All these reasons are, one way or another, related to the stable operation of the engine.

Don't put it off until later, fix it as quickly as possible

But, in any case, you need to remember that long-term operation of a car with such a problem can lead to premature failure of many components and assemblies. As a result, the bill for repairing your car will be much higher than in the case of a simple check, which we described in the previous sections of this article.

Many motorists remember how a problem arose on carburetor engines when a lean mixture appeared due to the carburetor or filters, which not only slowed down the engine, but also increased consumption (consumption rates). With the development of the automotive industry, the reasons for the effect have become more numerous, since many new details have been added that regulate this indicator. No, all motorists know why a lean mixture can appear on a VAZ-2112, and even more so, how to solve this problem.

conclusions

It is quite easy to establish the cause of a lean mixture on a VAZ-2112, and knowing it, you can eliminate it. Of course, not all motorists are able to make repairs themselves. Therefore, if you are not sure that you can handle it, we recommend that you contact a car service, where they will do everything efficiently and quickly. Not always true!

We had such a problem on our 12. They suspected that fuel consumption had increased significantly. Unfortunately, we couldn’t handle it on our own and had to go to a service station.

For no apparent reason, the consumption increased greatly, I came to the guys for service, they established the reason, the air flow sensor was covered, well, they changed the filter to catch up.

Maybe someone knows (or has encountered) a problem like mine (VAZ-21103, 2001 year old, mileage 91,000 + km, one owner, no major problems have arisen over the entire period. Due to circumstances, the last three -four years, rarely used, annual mileage does not exceed 3,000 km, only gasoline). From time to time, the following situation began to appear: The car drives as usual, and then it stops moving, but does not stall, but simply does not pull. In this case (but not always), error 0171 appears (the system is too lean). Then, after several kilometers of torment, the car starts driving again, as if nothing had happened. I also noticed that when you press the gas to the floor, you get the feeling that the car doesn’t understand what they want from it. You start to take off the gas, she (!) suddenly begins to accelerate confidently! I have already adapted to the fact that in order to accelerate it, I look for the point of travel of the gas pedal at the very beginning, at which it begins to accelerate. If you press the gas a little, that's it, it starts to go dull! Sometimes it helps to remove the terminal for 10-15 minutes, after which everything returns to normal again. I went to diagnosticians (different ones), connected the scanner - no errors were visible, everything worked fine, the idle values were also normal. I arrived with error 0171, they say that the system is too poor and they say that there could be a lot of things. It’s possible to drive as you are, but it’s not entirely normal—there’s no certainty that while overtaking, the car might suddenly, for no apparent reason, become dull. Yes, such jambs, it gives out both in a straight line and on the rise...

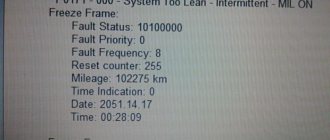

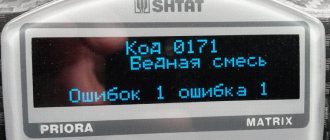

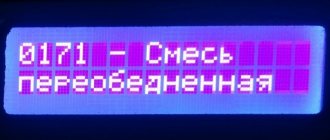

What does error P0171 (“fuel supply system too lean”) look like?

At some point, a car owner may discover that a message with code P0171 appears on the dashboard of his car. This message can appear on any car if the engine management system in it is made according to the Euro-2 standard. In such systems, so-called lambda probes are installed, whose task is to monitor the chemical composition of the fuel mixture.

The probe monitors that there are 14 parts of air to 1 part gasoline. The amount of air can deviate from this number in any direction, but no more than 30%. As soon as this threshold is exceeded, the driver sees error P0171 on the dashboard.

Search for air leaks from a smoke generator

For a smoke generator from a cigarette we will need:

- empty 1.5-2 liter bottle

- bottom from the same bottle

- knife

- drill with 5-6mm drill bit

- a couple of cigarettes

- old bicycle camera

- hose from the brake booster (or similar).

- pump or compressor

I explain in detail how to assemble all this into a finished structure in the video below. We connect a ready-made smoke generator instead of a vacuum amplifier and begin to pump smoke into the intake manifold, simultaneously checking all the connections and hoses to see if smoke is coming out of them. The appearance of smoke indicates a leaky connection and, accordingly, a possible air leak.

Also, separately from the intake manifold, you should check the vacuum brake booster and the adsorber valve. It is quite easy to check the vacuum seal - just disconnect it from the intake manifold, install a plug and see if there are any changes in the operation of the engine. If it starts to work smoothly and well, then the problem is in the vacuum seal - you need to check the hose itself; if it is intact, we buy a new vacuum seal.

The adsorber valve can be checked just as easily - we disconnect the hose from the throttle assembly and blow into it - it should not blow, i.e. the valve should be closed.

If it blows, the valve must be replaced. We figured out the main reasons for air leaks. Now the second point - LOW fuel.

The first thing to check here is the pressure in the fuel rail. It should not be lower than 3.8 kg/cm2 at XX.

Common mistakes when diagnosing code P0172

The most common mistake when diagnosing a P0172 code is not checking the coolant temperature sensor and cooling system. If the engine is cold, more fuel is added to the fuel mixture so that the engine can warm up to the required temperature. If the coolant temperature sensor is not working properly, it sends an erroneous signal to the vehicle's ECM, which in turn may assume that the engine is constantly cold. This may result in the mixture becoming too rich.

Tightness

If the previous point did not help in solving the problem, you need to check the fuel system for leaks. First of all, the throttle valve is checked for depressurization. Next, all places where the vacuum hoses connect to the exhaust manifold are checked.

The hoses are also inspected for mechanical damage, and this applies not only to the intake manifold. It is necessary to inspect the hoses of the fuel vapor trap and crankcase ventilation. The rule is simple: at least within a radius of half a meter from the oxygen sensor, the system must be absolutely sealed.