The reasons for this error are in many ways a mirror image of the reasons for the appearance of error P0172 in the controller memory.

A lambda probe that degrades over time may physically stop working - that is, deviations in the oxygen balance “from different sides” of the sensitive element will no longer lead to a change in voltage at its terminals (here we are talking about the classic version of a platinum oxygen sensor, which is precisely the source of voltage). For the ECU, this is equivalent to a constantly lean mixture; accordingly, the “fuel supply correction” parameter will begin to constantly go positive.

Causes of error P0171

The most common causes of P0171 are:

- Fuel pressure regulator malfunction

- Damage to the fuel pump

- Fuel filter clogged

- PCM (Powertrain control module) malfunction

- Vacuum leak

- Malfunction of one or more fuel injectors

- Malfunction of one or more oxygen sensors

- Malfunction of the mass air flow sensor

Elimination method

It usually consists of three large stages:

- Checking fuel sensors.

- Checking the fuel system and injectors.

- Check the tightness of all hoses and manifolds.

Sensors

A clogged MAF (mass air flow sensor, mass air flow sensor) is the most common cause of error P0171. Dust and dirt accumulate on its wires over time. As a result, it does not immediately respond to changed air flow. It's not just dirt that can get into this sensor. Combustion products may be deposited on it, which come out of the throttle valve and from the intake manifold with vapors after the engine stops. Because of these vapors, a thin layer of paraffin appears on the wires, after which the sensor begins to send a signal to the system that there is little air in the fuel mixture. Something similar can happen with other sensors. All of them are thoroughly cleaned using a special spray for cleaning electrical appliances. The second solution to the problem is to completely replace all “suspicious” sensors with new ones. We should not forget about the service life of the sensors. They can simply serve their purpose. Example: it is recommended to change the differential pressure sensor every 80,000 km.

How does a mechanic diagnose a P0171 code?

- First, the mechanic will check the engine for vacuum leaks using a vacuum gauge. If there is a leak, a hissing sound will be heard. It can usually be heard clearly when the engine is turned off.

- He will then check the fuel pressure sensor and mass air flow sensor using the fuel pressure gauge.

- To maintain the correct air-fuel mixture ratio, the vacuum pressure and fuel pressure in the engine must correspond to the values specified in the manufacturer's specifications.

- If no fault is found after performing the above checks, the problem is most likely a fault with one or more of the oxygen sensors.

- The mechanic will check the operation of the oxygen sensors following the procedure set forth by the vehicle manufacturer.

- If no problem is found, the mechanic will check the PCM (Powertrain control module).

How to find an air leak

First method. It is the simplest, it allows you to find out whether there are any air leaks at all and does not require absolutely any equipment. All we need is just the key for “10”. You need to unscrew the mass air flow sensor from the air filter and pull it out together into the corrugation.

Now we start the engine and, using the palm of our hand, completely block the air inlet into the intake manifold through the mass air flow sensor. The corrugation should shrink from the vacuum and after a couple of seconds the engine will stall. We don’t let go of our hand and listen for where things hiss—this is an extra air leak (more details in the video below).

Second way. Here we need some kind of flammable liquid - gasoline, ether, WD-40, carburetor cleaning fluid, etc. It is best, of course, to use gasoline or ether, they are more natural for engine operation. We fill a syringe with gasoline or take a can of any of the above liquids and spray all the connections of the intake manifold. If any of the connections are not sealed, then the liquid will definitely get inside the manifold and the engine speed, at the same time, should change (either decrease or increase). If the engine does not react in any way, then the connection is sealed, there are no problems with it and you need to look further. Well, if the engine starts to react, consider half the job done. We change the gasket or hose and rejoice that error P0171 has disappeared.

The third method is to use a smoke generator. If you don’t have such a thing in your garage, you can ask your friends for it or make it yourself. There are many options for making smoke generators on the Internet. I chose the simplest and fastest - a smoke generator made from a regular cigarette.

Common mistakes when diagnosing code P0171

The most common mistake made when diagnosing a P0171 code is that mechanics do not consult the vehicle manufacturer's technical service bulletin for common troubleshooting tips before diagnosing the error.

Although recommendations may not be provided for all error codes, it is important to review the Technical Service Bulletin as in some cases this will save time and make it easier to diagnose and resolve the error.

Search for air leaks from a smoke generator

For a smoke generator from a cigarette we will need:

- empty 1.5-2 liter bottle

- bottom from the same bottle

- knife

- drill with 5-6mm drill bit

- a couple of cigarettes

- old bicycle camera

- hose from the brake booster (or similar).

- pump or compressor

I explain in detail how to assemble all this into a finished structure in the video below. We connect a ready-made smoke generator instead of a vacuum amplifier and begin to pump smoke into the intake manifold, simultaneously checking all the connections and hoses to see if smoke is coming out of them. The appearance of smoke indicates a leaky connection and, accordingly, a possible air leak.

Also, separately from the intake manifold, you should check the vacuum brake booster and the adsorber valve. It is quite easy to check the vacuum seal - just disconnect it from the intake manifold, install a plug and see if there are any changes in the operation of the engine. If it starts to work smoothly and well, then the problem is in the vacuum seal - you need to check the hose itself; if it is intact, we buy a new vacuum seal.

The adsorber valve can be checked just as easily - we disconnect the hose from the throttle assembly and blow into it - it should not blow, i.e. the valve should be closed. If it blows, the valve must be replaced.

How to diagnose the fuel system?

The most common cause of breakdown is the presence of air leaks. First, check the tightness of the system. If the seal is broken, the damaged part is replaced. Next, make sure the fuel system is working properly. You need to check the pressure in the fuel supply system and check whether the injectors are clogged. If the pressure is insufficient, you need to disassemble and check the fuel pump.

When idling, the pressure in the fuel rail should be from 2.8 to 3.2 kgf/cm²,

Having found out the reasons for the lean mixture on the VAZ 2114, you need to move on to eliminating them.

Carrying out an inspection

Speaking about the lack of fuel, there are also three main reasons.

- The first includes problematic operation of the fuel pump, when it does not have enough power or it does not work as it should.

- Next comes the non-optimal resistance of the fuel filter.

- Well, the third reason will be a leak that may occur in the pressure regulator. Also, the breakdown may consist of simple contamination of the fuel injectors.

Sometimes we may need to check almost all possible causes in order to find exactly the one that is typical for our case.

Checking the MAF sensor using a multimeter (video)

Therefore, the first thing you need to do is check the sensors. As you may know, one of the most common problems is a clogged sensor, which is responsible for controlling air flow. If too much dirt has accumulated on its wire, this may cause the response to changes in air flow to become too slow.

It can also be contaminated by fuel vapors that pass through the intake manifold and through the throttle body when the engine is not running. These pairs can deposit a special layer of paraffin on the sensor wire, which will send data to the system about the incorrect proportion of the mixture.

What happens next is that the engine control unit cannot add fuel when the amount of air is too high. And after that, an error code will appear on the sensor screen indicating a lean mixture.

False errors P0100 and P0102

It also happens that along with the indicated error, other codes appear, like p0100 or p0102, by which you should definitely know that the problem lies in the sensor. To solve this problem, you need to clean the sensor. To do this, use specialized means for cleaning electrical appliances or the so-called carb cleaner, which is evenly sprayed onto the element that needs to be cleaned. But, still, the best option would be to install a new sensor.

“Vacuum” leak (video about checking for air leaks)

Also, be sure to check the system for vacuum leaks. Depressurization can occur in any part of the inlet pipeline. But this can also happen at the outlet of the throttle body, namely at the place where the vacuum-type hoses and the intake manifold are connected. In addition, depressurization can even appear in places such as the throttle body gasket and the intake manifold.

Checking the fuel system (video)

And, of course, it wouldn’t hurt to check the fuel system. First of all, it is necessary to monitor the performance of the injectors, which is carried out exclusively on a special stand. Most problems with injectors occur due to low-quality fuel; in this case, flushing the injectors will help.

Next, you need to check the fuel pressure, as well as the performance of the gasoline pump, if present. You also need to check the voltage on it.

Among other things, pay attention to the fuel pressure regulator and the fuel filter, as they must be in good working order so as not to cause a lean mixture.

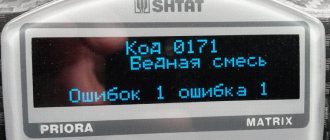

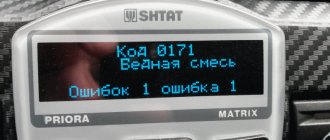

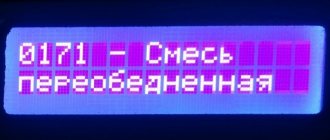

What does error P0171 (“fuel supply system too lean”) look like?

Error P0171 on Priora At some point, the car owner may discover that a message with code P0171 has appeared on the dashboard of his car. This message can appear on any car if the engine management system in it is made according to the Euro-2 standard. In such systems, so-called lambda probes are installed, whose task is to monitor the chemical composition of the fuel mixture. The probe monitors that there are 14 parts of air to 1 part gasoline. The amount of air can deviate from this number in any direction, but no more than 30%. As soon as this threshold is exceeded, the driver sees error P0171 on the dashboard.

Signs of error and diagnostic methods

The error is diagnosed after the Check Engine warning light appears on the vehicle's dashboard. The error is read using diagnostic equipment: a scanner, a laptop with a program installed, etc. The error is often accompanied by signs that may indicate problems with the car’s engine.

- The engine does not start or starts with difficulty - you have to turn the starter longer to start.

- The engine shakes during operation - the speed fluctuates, the engine runs unevenly, especially at idle. Incomplete combustion of the fuel-air mixture is felt, accompanied by popping noises in the exhaust system.

- There is a noticeable loss of engine power, especially as the vehicle load increases.

The symptoms are felt especially strongly in transitional modes - when accelerating and decelerating, as well as at idle. As the engine warms up and when driving smoothly, the manifestations of a lean fuel-air mixture subside, and the engine begins to operate almost in standard mode.

How does a car behave on a lean mixture?

When operating on a lean mixture, the car engine idles unevenly, overheats due to the lower combustion rate of such a mixture, and popping noises are heard in the intake pipe. The car itself can slow down and slowly gain momentum under load.

When the mixture is lean, the temperature of the engine increases, which leads to overheating, burnout of the valves and piston.

During long-term operation with a lean mixture, excessive fuel consumption occurs due to a slow increase in speed, as a result of which you have to operate the car in low gears. A lean mixture appears as a result of an imbalance in the supply of air and fuel for mixing with a large amount of air.

Let's sum it up

Taking into account the above information, it becomes clear that error P0171 can occur either separately or in combination with other errors recorded in the ECU memory. In any case, you first need computer diagnostics of the engine and decoding of all errors.

If no causes are found or the P0171 error is the only one on the list of problems after diagnosis, then it is necessary to check the systems and elements discussed in this article.

We also recommend reading the article on how to clean injection nozzles. In this article, you will learn about the available methods for cleaning injectors, as well as what you need to consider when choosing a cleaning method.

As a summary, we note that a lean mixture is dangerous for a car engine, that is, the problem cannot be ignored. Otherwise, further operation of the vehicle will lead to the fact that the power unit itself, as well as other elements and systems, may require repair.

To avoid possible consequences, it is necessary to regularly clean and check the EGR system (if equipped), as well as read and decipher errors in the ECU memory at certain intervals (even if the “check” is not lit). This approach will make it possible to timely identify failures and malfunctions at the initial stage, which eliminates prolonged operation of the internal combustion engine on a lean mixture.

Injector problems

You don't have to be an expert to understand that the problem here lies in the operation of the injector. And first of all, before we start studying lean mixture, let’s try to find out what it even is. This is important only because such a reason can lead to expensive repairs to the car.

Why do jerks happen?

The presence of jerks while the car is moving is a problem that directly or indirectly indicates the presence of problems with the engine, or more precisely, a loss of power. In total, there are two features that affect the development of power in the engine - fuel supply and the ignition system.

If with the ignition, everything is more or less clear, due to the inspection of the generator, spark plugs, ignition wires for faults, and the battery for charge, then in the case of the ignition system everything looks much more complicated.

High voltage wires are marked with arrows

Inspecting the condition of the spark plugs

To ensure a successful engine start, it is necessary to mix the fuel and air mixture in ideal proportions; this is what the injector is responsible for.

It happens that when mixing these proportions, a malfunction occurs, and the mixture turns out to be rich or lean.

A clear example of the air-fuel mixture ratio.

In order for the car to obtain maximum power when burning fuel in the cylinders, it is necessary to bring its indicator to the level of 0.85 - 0.9, when excess oxygen = > 1 (at this indicator, gasoline burns completely without residue - approx.), and when there is a lack of oxygen and the reading is < 1.

The main reasons for a lean mixture

The main and most important symptom that the system has a lean mixture is a stalling or unstable engine. And if the mixture is very poor, then it is possible that it will not start at all.

The cause of these problems is most often a clogged air filter (see “replacing the air filter”), clogged injectors, wear in the fuel pump, and there may also be air leaks into the system. All these reasons are, one way or another, related to the stable operation of the engine.

What do spark plugs tell us?

One of the fundamental checks for the condition of the mixture will be to assess the condition of the spark plug.

So, a light brown tint will indicate that the system is operating normally, a too dark tint will indicate a lack of (enriched mixture - approx.), too light, an excess (depleted - approx.) mixture.

Candles with different types of soot

Please pay attention to the fact that if, in the presence of such malfunctions, the throughput decreases by at least 10-15% , this may lead to further failure of the oxygen sensor (lambda probe, if equipped - approx.), or worse, lead to increased detonation.

And this, as you can already understand, will directly affect the performance of the motor. You can change the engine performance readings by cleaning the injector (nozzles), provided the ignition elements are working correctly.

Stable washing every 20-30 thousand kilometers can keep it in close to ideal condition.

Diagnostics of the throttle valve block on a VAZ-2114

If you have never performed such a procedure, then first of all you can be advised to inspect the condition of the throttle valve for carbon deposits and other deposits, because fuel vapors coming from the intake manifold settle precisely in this place, accumulating over time.

And the already deposited carbon deposits prevent the damper from closing completely, allowing more air into the system, thereby changing the composition of the mixture - making it leaner. Since large traces of carbon deposits can be detected visually, cleaning should be done with a regular carburetor cleaner, sold in cylinders of different capacities.

We dismantle the throttle assembly

How to clean the injector yourself!

If you do not want to take your car to a specialized workshop to clean the injector, then you can handle this on your own. This work can be carried out both on the removed mechanism and directly on it.

In order to clean the injector (nozzles - approx.) on a VAZ-2114, you need to read this article and do everything as stated in the detailed instructions.

How to reset a check on Kalina yourself

It is not recommended to reset errors yourself if the Lada Kalina check engine light is on. The error information will disappear. In a car service, if something happens to the engine after the reset, they will not be able to determine what kind of malfunction caused the engine to stop working. This means that you will have to completely disassemble the motor. It's an expensive endeavor.

However, if the car owner is sure that the wires were simply shorted after washing the car (this happens), then he can do the following at his own peril and risk:

The check lamp should disappear from the panel.

How to regulate fuel consumption on a VAZ 2112

We have already considered the factors and reasons that affect the use of gasoline in the VAZ 2112. Now you need to know what needs to be done to prevent gasoline consumption from increasing or how to reduce it. The main points to prevent increased fuel consumption are:

- constantly change the fuel filter;

- monitor the operation of the engine system;

- change candles that become black and oily over the years - non-functional;

- watch the condition of the fuel pump mesh so that it does not fall into the glass;

- The catalyst and exhaust must function.

By adhering to these rules, you can save on fuel costs for the VAZ 2112 by 7.5 liters.

Basic rules for reducing gasoline consumption

An attentive driver must constantly monitor all indicators of the car. Monitor the oil level, monitor engine operation, and monitor all filters and strainers. If you bought a car that has already traveled a certain number of kilometers and its fuel consumption exceeds 10 liters, then you should immediately take the following actions:

- change oil (adjust level);

- replace the filter;

- check the quality of gasoline;

- observe the performance of the fuel pump;

- regulate driving maneuverability.

If all this does not lead to the desired result, then you need to do computer diagnostics of the car.

Error 0171 “lean mixture”

With this error, the check engine icon does not light up. It can only be detected through diagnostics, for example, through ELM327 . This error directly indicates a malfunction in the ignition system.

But it can also appear as a result of using low-quality fuel. If, when you reset it, it appears in the future, after refueling at a good pump, then be prepared to look for the faults that we wrote about above.

Source

Causes of excess air

If, after carrying out this work, instability is also observed in the operation of the system, pay attention to possible places where excess air occurs, since it also affects the leanness of the mixture and the main reasons lie in the following:

And in order to eliminate the above reasons, it is necessary to conduct a thorough diagnosis.

Troubleshooting

Mass air flow sensor - the air flow sensor can become clogged due to natural reasons, as well as from vapors that come from the throttle valve while the car is not running. And then, over time, accumulating in a thick layer on the thin thread of the sensor, forcing it to send inaccurate data to the ECU, which in turn negatively affects the parameters of air flow and flow into the system.

When diagnosing its malfunction, it is best not to rush into purchasing, since it costs a lot of money, but it is best to check its performance on a known working device. And when it is established that the reason lies in it, then you can try to clean it, or then replace it with a new one.

Vacuum leak

Vacuum leak - these words mean any form of air leaks, that is, suction into the system, primarily through the manifold gasket or hoses.

The vacuum pump and return hose may cause

Pay attention to the condition of the pipe leading from the air filter to the throttle valve, and the hoses that go to the crankcase ventilation. There should be no visible damage to them, as well as large cracks through which excess air could enter.

In addition to all of the above, you can check the engine oil dipstick and the oil filler cap on the neck, because if these connections are not completely closed, they can cause the appearance of that same excess air.

Rich fuel assembly: concepts

Thus, the composition of the fuel mixture is determined by the ratio of air to fuel. This ratio depends on the volume of liquid fuel supplied to the cylinders. When acceleration occurs, the liquid fuel is intensively saturated with air mass. When this ratio is disrupted, the air/fuel mixture is either rich or lean.

Preparing the fuel-air mixture is a process for which the car's injector is responsible. The injection system prepares mixtures with different oxygen contents, and this is what provides a variety of operating modes for the internal combustion engine. It is the composition of the fuel mixture that allows the car to sharply increase speed while overtaking or overcome an incline.

A rich mixture is a mixture that contains less air than required and more gasoline than required. The burning rate of the rich mixture is reduced, and therefore it burns out already in the muffler. Sometimes such a mixture is symbolically called high-calorie.

There is a mathematical formula that determines at what ratio of atmospheric air to fuel the fuel mixture will be normal, rich or lean. It is believed that the normal ratio is a mixture of 14.7 kg of air and 1 kg of liquid fuel. If the ratio of 14:1 is increased in favor of the air mixture, the fuel mixture will be lean. And, on the contrary, when the ratio is 14:1 in favor of liquid fuel, the mixture will be rich.

Artificial boosting of engine power is ensured by adjusting the fuel supply when the amount of supplied oxygen increases. The car owner’s desire to save on fuel consumption is achieved by supplying more atmospheric air.