Why does P0134 occur?

There are not so many reasons that can lead to error P0134. It specifically indicates an incorrect signal being received from a particular sensor. Based on this, we can conclude that the causes of error P0134 are as follows:

- Failure of the oxygen sensor;

- Short circuit.

Broken wires;

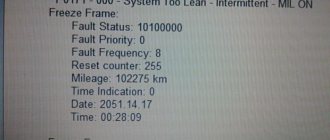

Diagnostic equipment makes it easier to determine the cause of a problem. If, in addition to error P0134, the diagnostic tool reports the presence of error P0171, this indicates that the malfunction is associated with an open or short circuit. As you know, error P0171 indicates a lean mixture in the engine. It occurs together with error P0134 with the above-mentioned malfunctions, since the first oxygen sensor in the exhaust circuit is the control one for supplying the mixture. Accordingly, if it stops transmitting information, the electronic control unit will reduce the amount of fuel supplied, causing the air-fuel mixture to be lean - this is necessary to prevent possible breakdown of the catalyst.

It is worth noting that most often the P0134 problem is directly related to the failure of the sensor itself. In no more than 5% of cases, a malfunction occurs due to a short circuit, open circuit or oxidation of contacts.

On which cars is this problem most common?

The problem with code P0140 can occur on different machines, but there are always statistics on which brands this error occurs more often. Here is a list of some of them:

- Audi (Audi a4)

- BMW

- BYD F3

- Chery

- Chevrolet (Chevrolet Aveo, Captiva, Cruz, Lacetti)

- Chrysler (Chrysler Sebring)

- Citroen (Citroen C3, C4, ds4)

- Daewoo (Daewoo Nexia)

- Dodge (Dodge Stratus)

- Ford (Ford Focus)

- Great Wall (Hover H3, Hover H5)

- Hyundai (Hyundai Santa Fe, Tucson, ix35)

- Kia (Kia Sportage)

- Lifan (Lifan Solano, x60)

- Mazda (Mazda 3, Mazda 5, Mazda 6)

- Mercedes

- Mitsubishi

- Nissan (Nissan Almera, Maxima)

- Opel (Opel Antara, Astra, Zafira, Corsa)

- Peugeot (Peugeot 206, 307, 308, 406)

- Saab

- Skoda (Skoda Octavia)

- Ssangyong

- Subaru (Subaru Forester)

- Suzuki (Suzuki Grand Vitara, sx4)

- Volkswagen (Volkswagen Golf, Passat)

- Volvo

- VAZ 2105, 2107, 2114

- Lada Vesta, Granta, Kalina, Largus, Niva, Priora

- UAZ

Other errors can sometimes be encountered with fault code P0140. The most common ones are: P0036, P0037, P0038, P0133, P0136, P0138, P0141, P0161, P0327, P0420, P0455, P1135, P1138, P2096.

What to do if error P0134 occurs

To resolve error P0134, which reports a loss of signal from the oxygen sensor, you will need to diagnose the sensor's power circuit and test it directly. To do this, the car must be placed on a “pit” or overpass. It is recommended to start the test by diagnosing the wiring. If there are no problems with it, and the contacts are not oxidized, you can proceed directly to checking the serviceability of the sensor.

Before you start diagnosing the sensor with a voltmeter, you need to visually inspect it. If there is a problem with the sensor heater or the mixture is too rich, there will be traces of soot on the sensor, which often clogs the element, causing it to fail. Another common cause of lambda probe failure is damage to it by lead, which is excessively contained in the gasoline used. If there are white deposits on the oxygen sensor, this indicates poor additives in the fuel used.

If an external inspection of the oxygen sensor does not help identify the problem, you can proceed to checking it with a voltmeter. Diagnostics of the oxygen sensor occurs as follows:

- The car engine must be warmed up to operating temperature;

- Next, the probes of the multimeter, switched to voltmeter mode, are connected between the signal wire and the ground wire;

- The car engine speed increases to 2500-3000 per minute.

Common causes of violation

Error P0134 does not occur very often. There are few probable reasons for the occurrence of such a violation, and they all indicate an incorrect signal from a specific sensor. Based on this, you can determine the most popular options for the occurrence of error P0134:

- Presence of a short circuit;

- Oxygen sensor malfunction;

- Broken wires and oxidation of contacts.

During diagnostics using special equipment, the causes of the malfunction are identified quite quickly and accurately. In most cases, this violation is provoked by a breakdown of the oxygen sensor and in 5% of them the malfunction is directly related to a short circuit, an open circuit and the presence of oxidation processes in the contacts.

In situations where, along with the error in question, the presence of errors with code P0171 is also displayed, we can conclude that there is a possibility of a break or short circuit. The second error in most cases appears when the air-fuel mixture entering the engine is too lean. It is often accompanied by error code P0134, since in the exhaust circuit the first oxygen sensor is directly responsible for the supply. When the information supply stops, the ECU spontaneously reduces the fuel consumption. Thus, the air-fuel mixture becomes lean.

Possible reasons

- Lambda probe faulty (bank 1, sensor 2)

- Short circuit or break in oxygen sensor wiring (bank 1, sensor 2)

- Malfunction of the oxygen sensor connector (bank 1, sensor 2)

- Incorrect fuel pressure

- Faulty fuel injectors

- Air leak in the intake manifold

- Exhaust system leaks (“burnt out” exhaust manifold)

Technical Notes

Typically, replacing the secondary oxygen sensor will resolve the P0140 code.

Diagnosis and problem solving

This is a fairly specific problem and shouldn't be too difficult to diagnose.

First start the engine and warm it up. Using a scan tool, monitor the voltage of the O₂ sensor bank 1, sensor 2. Typically the voltage should switch slowly above and below 0.45 volts.

If so, the problem is most likely temporary. You will have to wait until the problem is discovered before you can make an accurate diagnosis. However, if it does not switch or is frozen, do the following.

Turn off the car. Visually check the bank 1 sensor 2 connector and harness for melting or chafing. Repair or replace as necessary.

Turn the ignition on but turn off the engine. Disconnect the O₂ sensor connector and check for 12 volts in the heater power circuit and proper grounding. If there is no 12 V power to the heater, check the fuses for an open circuit.

If the heater circuit fuse has blown, you can assume that a faulty heater in the O₂ sensor is causing the blowout. Replace the sensor and fuse, then repeat the test. If there is no ground, check the circuit and clean or repair the ground circuit.

Next, on the disconnected connector, we check the 5 volt signal coming from the control unit. If not, check for 5 volts at the PCM connector. If 5 volts are present at the PCM connector but not at the sensor harness O₂ connector. This means there is an open or short circuit in the wire between the PCM and the O₂ sensor connector.

If there is no 5 volts at the PCM connector, the PCM is most likely faulty due to an internal short circuit. In this situation, the PCM must be replaced.

If during the test all voltages are present, then it is necessary to replace the oxygen sensor O₂ Bank 1, Sensor 2. After this, we reset the error and re-check with the scanner, error P0140 should disappear.

Description of error P0140

Oxygen sensors monitor the level of oxygen in the exhaust gases before and after the catalyst. For optimal engine performance, the air-fuel mixture (air-fuel ratio) must be maintained near the ideal stoichiometric ratio.

When the oxygen sensor output voltage changes near the stoichiometric ratio, the engine control module (ECM) adjusts the fuel injection so that the air-fuel ratio is near stoichiometric. The oxygen sensor generates a voltage of 0.1 to 0.9 V depending on the oxygen level in the exhaust gases. If the oxygen level in the exhaust gas increases, the air-fuel ratio becomes lean. The engine control unit interprets a "lean mixture" when the lambda probe voltage is less than 0.45 V. If the oxygen level decreases, the air-fuel ratio becomes rich. The control unit considers the mixture “rich” when the oxygen sensor voltage is above 0.45 V.

If the output voltage does not change at all, but remains a constant value (for example, 0.3 V), then error P0140 is recorded.

Reasons for the error

A P0140 code may mean that one or more of the following problems have occurred:

- The oxygen O₂ sensor heater circuit may be shorted. (Usually requires replacing the heater circuit fuse in the fuse box as well)

- Short circuit in the O₂ sensor signal circuit.

- Melting of a harness or wiring connector due to contact with the exhaust system.

- Water has entered the wiring harness connector or PCM connector.

- The engine control unit may be damaged.

Lambda probe on VAZ cars

VAZs use several types of sensors:

1. Bosch No. 0 258 005 133, Euro standard - 2. Installed on outdated models with an engine capacity of 1.5 liters. On later models with Euro 3 standard, this sensor was used as the first one, and was installed before the catalyst.

The second sensor was installed, which has a “return connector”. But you can find two identical sensors installed

2. Bosch No. 0 258 006537 was installed on cars manufactured since October 2004. They have a heating element in their structure.

Lambda probes produced are interchangeable with zirconium sensors of similar structure. Please note that a non-heated sensor can be replaced with a heated sensor. Not the other way around.

Causes of P0132

Depending on the year, make, and model, the P0132 code can have several causes. Here are some of the most common ones.

- Oxygen sensor malfunction. The most common cause is a malfunction of the sensor itself. Constantly exposed to exhaust fumes and temperature, the O2 sensor has a typical service life of less than 5 years.

- Electrical circuit malfunction. As wires are exposed to the environment, harnesses, connectors, and the sensor itself can be physically damaged by external influences. Water and corrosion are also common causes.

Oxygen sensor malfunctions and error codes

Among the possible breakdowns of the lambda probe, the following can be distinguished: loss of sensitivity, non-functional heating. As a rule, the on-board computer will not show you a breakdown if the problem is loss of sensitivity. It’s another matter if the heating circuit breaks, then the malfunction will be recorded.

- Error P1115 - a breakdown has occurred in the heating circuit

- Error P1102 - low resistance on the oxygen heater

- Error P0141 - the heater has broken down on the second sensor

- Error P0140 - sensor number two has broken

- Error P0138 - the second sensor indicates an excessive signal level

- Error P0137 - the second sensor indicates a low signal level

- Error P0136 - there is a short circuit to ground of the second sensor

- Error P0135 - the heater on the first sensor has failed

- Error P0134 - the first sensor has no signal

- Error P0133 - the first sensor responds slowly to the request

- Error P0132 - there is little oxygen in the system, the signal is high at the first sensor

- Error P0131 - too much oxygen in the system, low signal at the first sensor

- Error P0130 - the first sensor sends incorrect signals

Types of sensors and operating principle

The lambda probe is installed in the exhaust system. Sensors are divided into two types: two-point and broadband.

The two-point sensor consists of ceramics, the elements of which are coated with zirconium dioxide on both sides. Installed in front of or behind the catalytic converter.

The principle of operation is to measure the level of oxygen concentration in the environment and exhaust gases. If the level changes and becomes different, a voltage is created at the ends of the sensor elements, from low to high. Low voltage is created if there is excess oxygen in the system.

Otherwise, if the system does not have the required level of oxygen, high voltage will be created. These signals are sent to the engine control unit, which distinguishes them by current strength.

The wideband sensor is a more modern design. It also has two ceramic elements. One of them can be called “pumping”. It is responsible for activating the process of pumping or removing air from the system.

The second element can be conventionally called “two-point”. The principle of operation is based on the fact that as long as there is the required amount of oxygen in the mixture, the current strength on the “pumping” element does not change and is transferred to the “two-point” element.

It, in turn, receiving a constant current from the “pumping” element, maintains a constant voltage between its elements and is inactive.

As soon as the oxygen level changes, the "pumping" element supplies the changed voltage to the "two-point". This, in turn, ensures either pumping air into the system or pumping it back.

Replacing the oxygen sensor

If any damage occurs, the sensor must be replaced. You can try to do this yourself. Let's consider the situation of replacing a lambda probe on a VAZ 2114:

- We put the car on an overpass or drive it into a pit and remove the motor protection (to replace the sensor with the neutralizer).

- We are looking for the wires from the oxygen sensor, and follow them to the sensors themselves, they are located on the catalyst (the first before the converter, the second after).

On other car models, replacing the sensor will be identical.

Replacement problems

When replacing, the old sensor may stick to the pipe. In this case, proceed like this:

- Apply wd-40 generously and try to unscrew

- Turn on the engine, heat the exhaust system and unscrew the sensor

- We try to heat (being careful) the sensor itself and unscrew it

- Tap lightly with a hammer and try to unscrew it again

- If that doesn't help, try thermal shock. Pour cold water onto the well-heated sensor. Try unscrewing it again.

Oxygen sensor price

The price of an oxygen sensor will vary by region and model. It ranges from 1000 to 3000 rubles . Buy a lambda probe in specialized stores and only with a guarantee.

Causes of oxygen sensor failure

- Coolant or brake fluid has come into contact with the sensor housing.

- The fuel used has a high lead content

- Severe overheating of the sensor caused by unclean fuel (clogged cleaning filters)

- The sensor has simply expired

- Mechanical damage to the sensor while the vehicle is moving.

A failed sensor will affect the operation of the vehicle as a whole and lead to additional problems. But using them you can immediately determine a possible breakdown of the sensor and replace it in a timely manner.

Related problems when the oxygen sensor fails

- The car began to consume more fuel than usual

- The car began to move jerkily

- The engine became unstable

- The normal operation of the catalyst is disrupted

- When testing for exhaust gas toxicity, the result gives inflated values.

In conclusion, I would like to give advice: in order to avoid the problems outlined above in the future, monitor the performance of the lambda probe. Check its condition every five to ten thousand kilometers.

Decoding the error codes of the ECU (on-board computer) of the VAZ of the tenth family

As the sad experience of some car owners shows, not everything that comes off the assembly line is gold. In addition to the disappointing statistics of various parts with manufacturing defects, modern realities have added one more item - electronics. Electronic equipment often has imperfections that can make driving a vehicle very difficult. The main blow, as expected, is borne by the control unit. It is about the ECU and how its firmware and flashing is carried out that will be discussed.

- Nuances of preparing for firmware

- Lada Granta as an example of spectacular VAZ tuning

- Suitable equipment

1 Nuances of preparing for firmware

In order to collect bits of information, you will need a lot of time and specific knowledge. At the same time, flashing the VAZ ECU firmware itself, including for Lada Granta cars, does not take much time, since it is work with a computer program and the process is completed in a few mouse clicks.

- Equipment for ECU firmware

- Programs for ECU firmware

- Chip tuning: panacea or unjustified risk?

- Auto scanner for self-diagnosis of any car

This article is an attempt to systematize information about the effective tuning that electronic equipment requires.

Any idea does not come by chance and for a reason. The main reasons why car owners suddenly need ECU firmware are:

- too obvious malfunctions of the factory software;

- low engine power;

- desire to save fuel.

When using liquefied gas as a fuel as an alternative to gasoline, there is also a need to update the control system. Each ECU has its own markings, since they come in different types. Before looking for information about how the firmware is installed, you first need to accurately establish your type of engine and control unit and their designations. Then the appropriate program for updating is selected.

Those who are looking for equipment for flashing a VAZ ECU will definitely be faced with the need to disable the standard immobilizer and replace it with a new, more efficient one. This issue requires mandatory consultation with a specialist, even if you have already sufficiently understood the issue on your own. Otherwise, there is a risk of one day becoming a pedestrian again. The principle of operation of the additional immo on a VAZ car (including the Lada Granta model) most often consists in breaking the most important connection points of electrical circuits (for example, the ignition). Even if your car is broken into, it will not move. There are also alternative systems - the engine is blocked by transmitting a message via a network of ECU controllers to the bus of a VAZ car. It is quite possible to install such an anti-theft system with your own hands; the main thing is to properly think through the placement of the sensors. Removing the car from the alarm system is carried out using a chip key with a special code, which you also program yourself.

To download programs from the on-board computer, a cable is required. With all of the above manipulations, it is important to take into account the fact that not all computers have standard COM ports, and even if they do, it is not a fact that they work. The experience of some experimenters in this case suggests using an old data cable from a cell phone. With its help, you can assemble an adapter based on a microcircuit that suits you. For example, the firmware of the Lada Granta ECU is based on the M74CAN chip.

2 Lada Granta as an example of spectacular VAZ tuning

Reflashing the VAZ ECU changes only the software and does not require major alterations to the electrical network as a whole. You can replace the chip or install additional equipment on the Lada Granta, but this is not a mandatory part of the ECU improvement program. Any modification is primarily designed to ensure maximum comfort in driving VAZ cars:

- no failures during acceleration, increased dynamics;

- starting the engine at any temperature;

- eliminating errors associated, for example, with faulty oxygen sensors, etc.

In modern society, it is common to worry about the harm you cause to the environment. In any case, at least know its scale. For this purpose, various European standards have been developed, including for regulating the content of harmful substances in exhaust gases. These are the so-called Euro-1, Euro-2 and so on. Since 2013, fuel of Euro-2 class and below has been prohibited for use in Russia. Firmware for the VAZ Lada Granta ECU will allow you to switch to Euro-3, which the Startpower firmware corresponds to, without additional costs. The control of harmful emissions is disabled in it, and all errors in the operation of the system due to non-functioning sensors have been studied and eliminated.

3 Suitable equipment

Every motorist should have a universal device for diagnosing his car.

You can read, reset, analyze all sensors and configure the car’s on-board computer yourself using a special scanner...

To check the functionality of the adapter, you will need an ICD. To maintain communication with the on-board computer, you will need special equipment - a cable for flashing the VAZ ECU. The cable comes with a CD with its own drivers. Since the tasks that the cable performs are different, they have corresponding names. For example, USB KKL VAG-COM Scanner tools is a cable for equipment diagnostics, suitable for VAZ Lada Granta cars. Before proceeding with the firmware, the connector itself must be checked for functionality, again, using a special program.

If you care not only about the condition of your car, your own comfort and ergonomics, but also your growth as a specialist in your vehicle, then VAZ ECU firmware is exactly what you need. You will receive incomparable pleasure from independently studying all the intricacies of the process, as well as a satisfied smile from the knowledge that you did not allow yourself to be cheated at the car service. All the processes described in the article are quite capable of anyone, even those who are not very savvy in matters of electronics.

Do you still think that diagnosing a car is difficult?

If you are reading these lines, it means you are interested in doing something in the car yourself and really saving money, because you already know that:

- Service stations charge a lot of money for simple computer diagnostics

- To find out the error you need to go to specialists

- The services use simple impact wrenches, but you can’t find a good specialist

Self-diagnosis of the Kalina/Priora instrument cluster

Decoding error codes in the dashboard:

How to reset errors on Kalina? You can reset the errors yourself using the on-board computer, or contact a service station with special diagnostic equipment.

Let us remind you that you can find detailed photo reports in the Lada Kalina repair category.

Keywords: instrument panel Lada Kalina | dashboard of Lada Priora | on-board computer Lada Kalina | on-board computer Lada Priora | Lada Kalina engine | Lada Priora engine | ECM Lada Kalina | ECM Lada Priora

Share on social networks:

Found an error? Select it and press Ctrl+Enter..

How to diagnose the error?

It is important to know

There are two options for diagnosing a VAZ car - testing using the instrument panel and using a computer. The second option is considered more accurate, but its implementation will require a special program and a cable for connecting to the diagnostic connector.

Checking using a computer is done like this:

- The diagnostic wire is connected to the laptop. Its second end must be connected to the OBD2 connector in the Lada car. The location of this block differs depending on the car model; this nuance must be clarified in the service manual.

- A diagnostic program is launched on the computer, which allows you to decipher error codes. To start the test, press the corresponding button.

- The diagnostic process begins. Depending on the utility, the program can separately check the operation of the engine, transmission or electronics.

- After the test is completed, combinations of faults will appear on the computer screen that need to be deciphered. Depending on the program, a description of the error may also be displayed immediately.

Diagnostics using the dashboard is performed as follows:

- The car owner sits in the driver's seat and presses the daily mileage reset button on the odometer.

- The key is inserted into the lock and scrolled to the “ACC” position.

- The daily mileage reset button is released. The arrows on the speedometer, tachometer, and sensors will begin to quickly move from the minimum position to the maximum.

- The odometer key is pressed and released. An inscription with the software version will be displayed on the instrument cluster screen.

- After the third press of the odometer key, combinations of faults will appear on the screen.

Video: diagnosing a VAZ using the dashboard

The CarFance channel in its video showed in detail the process of testing a Lada car using a control combination.

P0140 error VAZ Kalina

Error 0140 - no activity of the second lambda probe. The error is stored in the EKU memory under the following conditions:

The voltage at the signal terminal of unheated DK2 is 0.45 V, for heated DK-1 when operating in a closed circuit, the voltage is 590-750 mV.

The cause of this error may be a faulty wiring or contacts of the sensor and the “brains”. If error 0036 is still present, then troubleshooting should begin with it.

This code often appears after installing low-quality “bleeders” when replacing the catalyst with a flame arrester. In this case, the sensor simply does not respond to exhaust gases; their quantity is simply not enough.

It is best, when removing the catalyst, not to use decoys for the second diagnostic oxygen sensors; programmatically exclude them from the system using the chip tuning procedure.

— aka lambda probe. A device designed to measure the oxygen level in the exhaust gas mixture.

In a car, it is needed to achieve the correct combination of the proportion of oxygen and fuel in the working mixture. With the correct proportion of oxygen and fuel in the mixture, the engine operates as efficiently as possible and, importantly, the consumption of the fuel itself is reduced.