21.06.2017

Using a gearbox, torque is transmitted from the engine to the wheels. The gearbox is a set of gears and includes two main blocks: a cross-axle differential and a main gear. When replacing or repairing this module, the question may arise as to how the VAZ 2103 gearbox differs from the 2106, which do not look identical in appearance.

Features of using gearboxes on all-wheel drive vehicles

For all-wheel drive vehicles, the front and rear axle ratios must be the same.

In everyday practice of car maintenance, quite often there are cases of installing gearboxes with different gear ratios on an all-wheel drive vehicle (Niva, Taiga). Most often this happens due to the lack of appropriate knowledge among those people who repair the car. These can be both car owners who repair the car themselves, and unskilled car service workers who provide services to the population to replace units.

When installing a gearbox with a gear ratio different from the required one on an all-wheel drive vehicle, the owner will not notice any disturbances in the operation of the transmission. The car will drive normally until the owner tries to engage the center differential lock. The fact is that this differential “works out” the difference in gear ratios of the gearboxes while driving.

A simple, but quite dangerous for transmission units, method of checking for differences in gear ratios in gearboxes is as follows:

- Place the vehicle on a dry, level road with a slight slope to move forward.

- Check the vehicle's ability to roll freely downhill when releasing the brakes in neutral. The slope should be small, but sufficient for the car to move on its own.

- Engage the center differential lock (transfer case) and allow the vehicle to roll downhill.

If the car rolls as freely as in the test according to point No. 2, the gear ratios are the same. If, with the center differential locked, the car is unable to roll in neutral, the gear ratios are different.

Operating a vehicle with different gear ratios is unacceptable. Therefore, before installing a new unit on a car, you should ask what models of gearboxes are installed on the car. KEMP specialists will help you evaluate them without disassembling the car.

Rear axle

How much does the engine from a VAZ 2109 weigh?

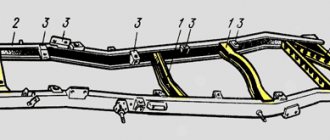

Rear axle in section

Description of design

The rear axle of the car is made in the form of a hollow beam, to the ends of which flanges with seats for axle shaft bearings and holes for attaching brake shields are welded. In the middle, a main gear reducer with a differential is bolted to the beam, and on the flange side, two axle shafts are inserted into the beam, transmitting torque from the gearbox to the rear wheels. The rear axle of all “classic” VAZ cars (except all-wheel drive models) is unified and, depending on the model, can be equipped with a gearbox with a gear ratio of 3.9 or 4.1.

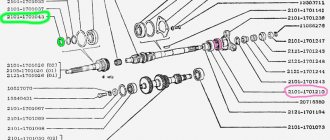

| The location of the gear ratio marking on the driven gear. |

The drive and driven gears of the gearbox are selected in pairs and if at least one of them is damaged, they are replaced as a set. The drive gear is mounted on two tapered roller bearings, and an elastic spacer sleeve is inserted between their inner rings. When the nut on the pinion shank is tightened, this bushing is deformed, providing preload to the bearings. An adjusting ring is installed between the drive gear and its bearing, which determines the axial position of the drive gear. The final drive gear is bolted to the differential housing, which is mounted on two tapered roller bearings. The preload in these bearings, as well as the amount of clearance between the teeth of the drive and driven gears, are adjusted by ring nuts screwed into split bearing beds. Inside the differential housing, two satellite gears sit freely on the axle and mesh with the semi-axial gears. The axle shaft with its inner end enters the splined hole of the semi-axial gear, and with its outer end it rests on a ball bearing, which fits into the flange of the beam and is locked there by a plate. The plate, together with the oil deflector and the brake shield, is secured with four bolts to the beam flange. A cuff is installed in the bridge beam socket. The bearing is secured against axial displacement on the axle shaft by a locking ring. Do you think you know everything about sex? Prostitutes of Krasnoyarsk will be able to pleasantly dissuade you of this. Sex can be absolutely amazing when you leave it in the hands of a professional! The prostitute will be as you wish - obedient or daring, domineering, shameless, but in any case, a very sexy prostitute in Krasnoyarsk. Choose a girl in the catalog of prostitutes, because the most beautiful and exciting whores of Krasnoyarsk are collected here. All photographs and descriptions are real - the site administration checks the content before posting and periodically after posting. The brake pads, the brake cylinder with the brake fluid supply tube and the parking brake cable sheath are attached to the brake shield. The brake drum is attached to the axle flange with two guide pins. For filling and draining oil, two plugs with conical threads are installed.

| previous page10.2.4. Replacing the flexible coupling | next page 11.1. Checking the serviceability of the rear axle |

Features of using gearboxes on rear-wheel drive vehicles

Cars with rear-wheel drive, as already noted, are equipped with gearboxes with different gear ratios. The transmission configuration of modern cars is difficult to predict.

So, for example, during the years of production of the VAZ 2102* car, one could say with confidence that it had a gearbox with a gear ratio of 4.44. The modern generation of “twos” - VAZ 2104 * - is usually equipped with a gearbox with diametrically opposite parameters - VAZ 2106, 3.9. This is very unusual for a utility vehicle, but the manufacturer is guided by its own considerations. The situation is also the same with the equipment of other models of the classic Zhiguli. In this matter, judging by experience, there are certain patterns, but there are no hard and fast rules. Therefore, in general terms, we can assume that the “classic” can have any kind of gearbox.

VAZ gearbox device

gear ratio of main gears of VAZ gearboxes

You can install any one in the rear axle gearbox of VAZ rear-wheel drive vehicles, regardless of the car model.

The only exceptions are all-wheel drive VAZ models (“Niva” and its modifications). Regarding the latter, the rule is true: when repairing a gearbox (front or rear separately), it is necessary to ensure that the gear ratios of the main gears of both gearboxes match. Failure to comply with this rule will inevitably lead to breakage of the main gear teeth of one or both gearboxes immediately after the start of movement. Currently, main pairs with the following gear ratios are on sale: 3.9; 4.1; 4.3. The greater the gear ratio of the main pair, the correspondingly greater the power of the gearbox. On the contrary, the lower the gear ratio of the main pair, the faster the gearbox. The gearbox of the VAZ 2102 car had the best power characteristics, but with the departure of this model from the assembly line, the main pair with a gear ratio of 4.44 also fell into oblivion.

If you are just preparing to repair a gearbox and you are faced with the task of purchasing a main pair, but you do not know which main pair and with what gear ratio is installed in the gearbox of your car, you can use the following method to obtain the data necessary for purchasing (it is better to perform the operation described below with an assistant):

We hang up one rear wheel of the car and place it (the car) on reliable stands. Set the gear shift lever to the neutral position and completely release the handbrake, thereby ensuring free rotation of the wheel.

We rotate the raised wheel, while counting its revolutions and the revolutions of the propeller shaft. To obtain the most accurate data, you need to make 10 revolutions of the wheel.

By counting the revolutions of the wheel and driveshaft using the table below, we determine the gear ratio and, accordingly, the model of the main pair. If during repairs a non-original main pair is installed in the gearbox, with a different gear ratio, then the speedometer readings (speed and distance traveled by the car) will change when driving.

| main couple | number of teeth on gears | number of revolutions of the propeller shaft per 10 wheel revolutions | gear ratio | |

| on the slave | on the leading | |||

| 2102 | 40 | 9 | 22,2 | 4,44 |

| 2101 | 43 | 10 | 21,5 | 4,3 |

| 2103 | 41 | 10 | 20,5 | 4,1 |

| 2106 | 43 | 11 | 19,5 | 3,9 |

And the last thing I wanted to especially note when concluding the chapter on main gears: hypoid gearing has large longitudinal slip, which significantly worsens the lubrication conditions during operation of the gearbox. These circumstances, in turn, put forward corresponding requirements for the strength of the created oil film, and therefore a more serious approach when choosing a particular brand of transmission oil for filling into the gearbox. Currently, during their manufacture, main gears are subjected to a special chemical treatment - phosphating. This allows the use of less viscous oil for operation, while avoiding sticking and, possibly, welding of gear teeth. This is especially true during the most dangerous period, when their mutual grinding and running-in occurs.

With a lot of their advantages, hypoid gears (main pairs) require special attention with regard to heating. The normal operating temperature of the main pair fluctuates during gear operation in the range of 90-95 degrees. Of course, the temperature range shown is typical for average driving conditions. During a long trip and, especially, in hot weather, the temperature of the main transmission can significantly overcome the barrier of 100 degrees.

Based on the above, the following rule follows: after repairing the VAZ gearbox, it is necessary to monitor the heating of the unit. To do this, drive at a speed of 60-70 km/h for 20-30 minutes. You should check the heating of the gearbox in the area of the neck of its crankcase, which, in turn, should not exceed 90-95 degrees. The heating of the gearbox is checked like the heating of an iron: the water entering the test zone should not boil.

Signs of gearbox problems

The rear gearbox is one of the reliable mechanisms of classic Zhiguli cars and breakdowns rarely occur with it. However, like any other unit, it may have its own malfunctions, which are determined by characteristic symptoms. They are worth dwelling on in more detail.

Noise when accelerating

If during acceleration there is an extraneous sound from the gearbox installation site, then it can be caused by:

- worn out or incorrectly adjusted differential bearings. It will require dismantling, disassembling and diagnosing parts with subsequent adjustment;

- Incorrect meshing of the teeth of the main pair gears. Eliminated by proper adjustment;

- lack of lubrication in the gearbox. The lack of oil in the crankcase is restored, after which it is checked for leaks at the places where the sealing elements are installed.

Axle bearings are not a structural element of the gearbox, but if the part fails, then an extraneous sound may also be observed during acceleration.

Noise when accelerating and braking the engine

If noise occurs both during acceleration and during braking by the power unit, there may not be many reasons:

- deterioration or failure of the bevel gear bearings of the main pair. Eliminated by replacing failed elements;

- Incorrect adjustment of the gap between the tip and the planetary gear. The mechanism needs to be diagnosed and replaced with damaged parts, as well as setting the required gap between the gear teeth.

Video: how to determine the source of noise in the rear axle

Knocking, crunching noise when moving

If the gearbox begins to make sounds uncharacteristic of its normal operation, then it will be possible to accurately diagnose the breakdown only after disassembling the unit. The most likely causes of a crunching or knocking sound may be:

- tooth breakage on the gears of the main pair;

- great wear of the main pair;

- Problems or incorrect adjustment of the bevel gear bearings.

Noises when turning

Noise in the gearbox is also possible when turning the car. The main reasons for this phenomenon may be:

- tight rotation of the satellites or the appearance of scratches on their surface. Eliminated by replacing damaged parts or treating roughness with sandpaper. If the defect cannot be removed, the failed parts must be replaced;

- jamming of side gears. If the gears have barely noticeable damage, clean them with sandpaper. Elements with signs of heavy wear are replaced with new ones;

- The gap between the differential gears is set incorrectly. It is necessary to set the correct gap between the gears;

- defective semi-axial bearings. The ball bearings need to be replaced with new ones.

Knock when starting to move

The appearance of a knock in the rear gearbox of a VAZ 2106 at the beginning of movement may be accompanied by:

- large gap between the splines of the bevel gear shaft and the flange. It is necessary to inspect the condition of both parts. If significant wear is detected on the splines, the elements are replaced;

- increased gap between the teeth of the main pair gears. The problem is “cured” by adjusting the gap;

- large amount of space for the pinion axle in the differential box. The box needs replacing;

- The fastening of the reaction rods of the rear beam has become loose. It is necessary to inspect and tighten the fastening.

Gearbox jammed

Sometimes the REM may jam, i.e. torque will not be transmitted to the drive wheels. The reasons that can lead to such a malfunction are as follows:

- lack of lubricant in the mechanism, which could leak due to leakage of the unit;

- failure of satellites;

- damage to the bearing on the bevel gear of the main pair.

Lack of lubrication in the gearbox leads to increased production and jamming of the mechanism

If one wheel is stuck, the problem may be related to the brake mechanism or axle bearing.

Oil leakage can be determined without disassembling the gearbox, but other faults cannot be identified without this procedure. If, after disassembly, scuffs, broken teeth or visible damage to the bearing are found on the gears, then the parts need to be replaced.

Oil leak

Lubricant leakage from the “six” gearbox is possible for two reasons:

- failure of the shank oil seal;

- damage to the gasket between the gearbox and the rear axle stocking.

To accurately determine where the oil is leaking from, you need to wipe off the lubricant with a rag and after a while inspect the gearbox: the location of the leak will be noticeable. After this, you can take further actions - remove the entire gearbox to replace the gasket, or dismantle only the cardan and flange to replace the lip seal.

An oil leak is indicated by a wet gearbox in the lower part.

This is interesting: How a car hydraulic brake works