Functions and principle of operation

The rear axle reducer (RAG) is part of the vehicle transmission. This unit changes the direction and increases the value of torque, which is transmitted from the driveshaft to the axle shafts of the drive wheels. The engine rotates at high speed (from 500 to 5 thousand revolutions per minute), and the task of all transmission elements is to transform the direction and angular speed of the rotational movement of the motor and ensure the efficient operation of the drive wheels.

Technical characteristics of the gearbox

The VAZ 2103 gearbox is suitable for any “classic” VAZ model, but engine performance may change after installing a “non-original” gearbox. This is due to the design features of such a gearbox.

Gear ratio

Each type of REM installed on the VAZ 2101–2107 is characterized by its own gear ratio. The lower the value of this indicator, the more “speedy” the gearbox is. For example, the gear ratio of a “penny” RZM is 4.3; a gearbox with a gear ratio of 4.44 is installed on a “two”, i.e. the VAZ 2102 is a slower car compared to the VAZ 2101. The VAZ 2103 gearbox has a gear ratio of 4, 1, i.e. the speed indicators of this model are higher than those of the “kopek” and “two”. The fastest of the “classic” REMs is the unit for the VAZ 2106: its gear ratio is 3.9.

Number of teeth

The gear ratio of the RZM is related to the number of teeth on the gears of the main pair. On a “three-piece” RZM, the drive shaft has 10 teeth, the driven one - 41. The gear ratio is calculated by dividing the second indicator by the first, i.e. 41/10 = 4.1.

The number of teeth can be determined by the gearbox markings. For example, in the inscription “VAZ 2103 1041 4537”:

- VAZ 2103 - gearbox type;

- 10 and 41 - the number of teeth of the drive and driven shafts, respectively;

- 4537 — number of the final drive gear set.

Consequences of installing a non-standard gearbox

You should know that installing a “faster” REM does not mean an automatic increase in vehicle speed. For example, if on a VAZ 2103, instead of the “native” gearbox with a gear ratio of 4.1, you use a VAZ 2106 unit with a gear ratio of 3.9, then the car will become 5% “faster” and the same 5% “weaker”. It means that:

- effective torque will decrease by 5%;

- to accelerate to a certain speed, fewer engine revolutions will be required, i.e., to accelerate, for example, to 120 km/h, 3900 rpm will be enough, instead of 4400. The problem is that now the engine may not have enough power to spin up to 3900 rpm.

Thus, if you installed a non-standard RZM with a different gear ratio on a VAZ 2103, then in order to maintain the dynamic performance of the car, a proportional change in engine power will be required.

genchik64

https://vaz-2106.ru/forum/lofiversion/index.php/t5261–600.html

Defects in the gearbox

Increased play in the RZM can be formed due to wear of the differential pinion pin - if you grab the driveshaft and rotate it clockwise and counterclockwise, this play can be felt. Also, increased clearance can be formed due to wear of the splines inside the differential housing itself.

If the gaps in the main pair of gearboxes are not adjusted, a characteristic noise occurs when the car moves:

- when the load increases (sharp acceleration), a characteristic howl is heard in the bridge;

- When I let off the gas the noise goes away.

Malfunctions and repairs of the VAZ 2106 gearbox

If the gearbox is properly adjusted, it will serve for a very long time.

A gearbox made according to technology and properly adjusted can serve for decades without reminding itself of anything at all. No noise, no hum, no ringing. This was the case until recently, but two popular products appeared on the market - fake gear oil, and a few years later, fake VAZ rear gearboxes. In most cases, everything that is sold in car dealerships and looks like a gearbox is actually just a pile of metal, unsuitable for use. The fact is that for high-quality adjustment of the gearbox, which is necessary, serious skills and sophisticated measuring equipment are needed. There can be no talk of any adjustment by eye here. And most service stations do just that, without realizing that they are simply killing a healthy gearbox. After replacement, you can check the performance of such a unit only on the go. Therefore, they are washed, painted with beautiful paint and placed on store shelves next to counterfeit lubricants. We will talk about lubrication separately, but now a little about the main malfunctions of the VAZ 2106 gearbox.

As with all units that have a closed lubricated volume, the shank oil seal can leak in the gearbox. This is noticeable right away, because after parking, drops of the transmission under the rear axle will speak volumes about it. It may also be that the oil leak is not caused by the oil seal, but by loose bolts securing the gearbox to the rear axle housing. But the most common symptom of gearbox failure is noise. The unit can make noise in different ways and in different modes, so no specialist can give any specific recommendations without listening to it personally. Nevertheless, there are the most common noise manifestations, which we will briefly discuss.

The main source of noise is a worn main pair. This sound cannot be confused with anything else, but it appears under load. As soon as you let off the gas, the noise disappears, and the active phase begins again after pressing the gas pedal. This malfunction can only be cured by replacing the main pair. Those who like to experiment can add magical additives to the lubricant, but, as a rule, these dubious means do not restore the main pair, cannot adjust the gaps, and do not change the bearings.

Gearbox bearing noise is quite easy to identify. They hum under any load, and in the most advanced cases they can even crunch at low speeds.

There are no options other than replacement to fix the problem. Except in cases where the noise was caused by improper tightening of the shank nut after replacing the oil seal. Incorrect adjustment of the gearbox can also cause a hum, but it is almost impossible to describe this noise, because it manifests itself differently in each gearbox. Gear adjustment is carried out only if you have measuring instruments, torque wrenches, the necessary probes and, most importantly, experience in this matter. An incorrect adjustment can ruin a good gearbox literally a thousand kilometers away.

A common sign of a gearbox malfunction is unit noise.

Removing the rear axle gearbox of VAZ 2107

Before removing the gearbox, it is necessary to drain the transmission oil that is poured into the rear axle of the VAZ 2107. To do this, place an oil container under the drain hole of the axle and unscrew the drain plug.

Important: after repair, new transmission oil should be poured into the gearbox.

The next procedure is as follows:

- Unscrew the bolts securing the cardan to the gearbox flange;

- Uncouple the rear part of the cardan and lower it down;

- jack up the car (if it is not on a lift) and remove the rear wheels;

- Unscrew the guide screws of the brake drums;

- remove the brake drums;

- unscrew the 4 bolts securing the axle shafts;

- pull out the axle shafts, freeing the gearbox;

- unscrew the 8 gearbox mounting bolts;

- remove the gearbox.

How to replace a VAZ 2106 gearbox with your own hands

The task of steering is to ensure that the rotation of the steering wheel is converted into turning the wheels of the car. The more synchronously this process occurs, the smoother the car will be.

On the VAZ 2106 model, the rotation converter is the gearbox. The main element through which the work is performed is the worm gear. If it fails, the best solution is to replace it. Repairing is not the best solution; this can lead to the steering wheel sticking or being difficult to rotate.

Gearbox VAZ 2106

- How to reduce backlash?

- How to replace the gearbox?

- How to replace the swing arm?

Problems when paying with bank cards

Sometimes difficulties may arise when paying with Visa/MasterCard bank cards. The most common of them:

- There is a restriction on the card for paying for online purchases

- A plastic card is not intended for making payments online.

- The plastic card is not activated for making payments online.

- There are not enough funds on the plastic card.

In order to solve these problems, you need to call or write to the technical support of the bank where you are served. Bank specialists will help you resolve them and make payments.

That's basically it. The entire process of paying for a book in PDF format on car repair on our website takes 1-2 minutes.

Steering gearbox - repair, replacement, adjustment

The steering gearbox is a rather old mechanical device that is now used mainly on cars of the classic LADA family. Today you will learn what a steering gearbox is - repair, replacement, adjustment with your own hands.

The steering gearbox is a small mechanism designed to transfer rotational motion to translational motion. This means that the gearbox converts the rotation of the steering wheel into a force that moves the steering rods in the right directions, causing the wheels to turn and change the direction of movement of the car.

The gear used in the gearbox is a reduction gear and consists of two elements - a worm and a gear. In addition, the mechanism has a special lever that moves the steering rods in the right directions.

The steering gearbox of the VAZ 2107 is sealed and filled with oil, which significantly increases its service life and makes it easier to turn the steering wheel, reducing the effort exerted by the driver.

Video - Steering gear repair

https://youtube.com/watch?v=_iGPcODrMRc

In most cases, this unit is not repairable, since it is relatively inexpensive and consists of only two main parts. However, the manufacturer left the option for car technicians to purchase a repair kit.

Before repairing the steering gear, let's determine the malfunctions.

- Firstly, it can be repaired if the steering wheel rotates but the wheels do not. This means that there are defects on the threaded part of its shafts that prevent the two interacting parts from touching.

- The second type of fault is oil seals. If they have reached critical wear, then the oil from the gearbox will certainly leak, which already leads to its accelerated wear. If there are other mechanical damages, the gearbox must be replaced.

First, remove the faulty unit from the car. After this, press the bipod off its shaft using two hammers. Drain the oil from the gearbox through any technological hole. Now unscrew the four bolts that secure the cover and remove it. To access the worm shaft, you need to unscrew a similar cover on the other side of the mechanism. Pull out the remaining parts and replace the faulty ones. These may include oil seals and damaged shafts. After this, reassemble the gearbox in the reverse order. Don't forget to add oil!

How to change the steering gear on a VAZ 2107

If there is more serious damage, the steering gear must only be replaced. To do this, you need to purchase a new VAZ 2107 gearbox and immediately fill it with transmission oil. Now you need to remove the faulty gearbox from the car.

- Disconnect the tie rod ends from the tie rods. To do this, first unscrew them, and then unscrew the fastening nuts using a 22mm wrench. To pull them out, you need to use a special puller, which is available in any auto parts store.

- Go inside the car and loosen the clamp that secures the steering shaft to the steering gear. Pull the shaft out of engagement with the gearbox.

- All that remains is to unscrew the three bolts that secure the mechanism to the engine compartment of the car.

- Install the new gearbox in reverse order. Before you start operating the car, do not forget to adjust it.

Adjusting the VAZ gearbox

Adjustment of the steering gear is carried out to get rid of play in the steering wheel, as well as all kinds of discrepancies when it rotates with the position of the wheels. The car wheels must first be aligned.

To adjust the steering gear, you need to unscrew the lock nut on its cover from above and loosen the special adjusting screw. Ask your partner to sit behind the wheel and rotate the steering wheel in different directions with energetic, but not wide movements, while you gradually tighten the adjusting screw. As soon as the steering wheel begins to rotate tightly and the wheels move with the slightest movement, the locknut is tightened.

This completes the adjustment of the steering gear. As you can see, this procedure is not long at all and can be performed with just a 19-mm wrench and a regular flat-head screwdriver.

Typical gearbox failures and their causes

The rear gearbox of the VAZ 2107 is a reliable device that is very resistant to mechanical wear. However, over time, parts gradually wear out even in the gearbox. And then the driver begins to hear a characteristic crunch or howl heard in the area of the rear axle or in the area of one of the rear wheels. Here's why this happens:

- one of the wheels jammed because one of the rear axle shafts was deformed. This happens extremely rarely, usually after a strong blow to one of the wheels. In this case, the axle shaft is so deformed that the wheel cannot rotate normally. If the deformation is insignificant, the wheel will rotate, but when rotating, a characteristic howl will be heard coming from behind the damaged wheel. It is not possible to fix such a breakdown on your own . To straighten the axle shaft, the driver will have to contact specialists;

- crunching sound in the gearbox when the car is moving. This is a more common problem that every driver of an old “seven” will face sooner or later. The gearbox begins to crunch after several teeth and splines on the axle shafts wear out in the main gear. If the wear is very severe, the teeth may break. This happens both due to metal fatigue and due to poor lubrication of the gearbox (this is the most likely reason, since the lubricant in the “seven” gearbox often escapes through the breather and through the shank flange, which have never been leak-tight). In any case, such a breakdown cannot be repaired, and gears with broken teeth will have to be replaced;

- bearing wear on the axle shaft. This is another reason for the characteristic grinding noise behind the wheel. If the bearing has collapsed, then you cannot drive such a car, since the wheel may simply fall off while driving. The only solution is to call a tow truck and then replace the worn bearing. You can do this either on your own or at a service center.

VAZ 2109,2108,2107,2106,2105,2104,2103,2102,2101, 2170, Tavria, Chevrolet Niva

VAZ-2101 » Transmission » Monitoring, adjustment and maintenance of the rear axle

The main gear and differential, located in the rear axle housing, are a complex gearbox with hypoid gears that transmits significant torques.

To protect the working surfaces of gears and bearings from wear, a special transmission oil TAD-17 is used with special additives that help maintain a durable layer of oil film on the rubbing surfaces.

The use of oils not recommended by the factory instructions is unacceptable, as it can lead to premature failure of the unit.

The total capacity of the rear axle oil bath is 1.5 liters; in this case, the oil level should be close to the lower edge of the oil filler hole 1 (Fig. 1). The lubricant level should be checked after 10,000 km of vehicle mileage, and replaced after 30,000 km.

When replacing the lubricant or if it is necessary to drain it for inspection or disassembling the axle, it is drained through an oil drain hole located near the lowest point of the axle housing and closed with plug 2.

If it is necessary to perform complex adjustment or repair work, such as adjusting the relative position of the main gear gears, adjusting the preload of bearings, replacing axle bearings, you should use the techniques and methods described in the specialized literature, or resort to the services of a specialized service station.

It should be remembered that the drive and driven gears of the main gear are selected in pairs at the factory for correct engagement. noise level, therefore, if it is necessary to replace the gears, it is best to replace them only in pairs, having first checked the identity of the serial numbers on them.

The main signs of correct engagement of the main gear gears are the shape, area and location of the contact patch on the working surface of the driven gear tooth.

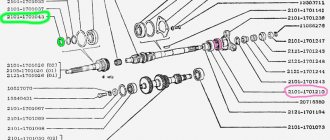

In Fig. 2 shows various cases of the location of the clear spot depending on the relative position of the gears.

The left side corresponds to the shape of the spots that are observed when the gears rotate under load when the car is moving forward, and the right side corresponds to the location of the spots on the back side of the gear when the car is moving backwards.

With spots corresponding to images a, b, c and d, the main gear needs to be adjusted, but with spots shown below (o), the engagement is normal.

In cases a and b, to obtain correct engagement, the drive gear should be moved away from the driven gear by reducing the thickness of the adjusting shim 31 (see Fig. 4-21) installed under the head of the drive gear.

In cases c and d, to obtain correct engagement, the drive gear of the main gear must be brought closer to the driven gear by installing an adjusting shim 31, which has an increased thickness.

To perform adjustment along the contact patch, the gearbox must be disassembled, so it is strongly not recommended to do this work on your own without special tools and the necessary set of shims.

To eliminate leaks, it is recommended to first clean the breather from contamination to ensure communication between the internal cavity of the bridge and the atmosphere, and then check the tightness of the oil filler and oil drain plugs and the gearbox housing mounting bolts.

To identify cracks, the suspected location of their occurrence should be wiped dry and then tightly shaded with chalk, on the surface of which they can be easily detected in the event of an oil leak.

The appearance of an oil leak through the oil seals of the shank of the drive gear of the gearbox or axle shafts is an alarming signal that requires checking the serviceability of not only the oil seals, but also the corresponding bearings and axle shafts.

Despite the fact that the rear axle housing is a rigid and durable part, it can be deformed when the vehicle is operated in difficult road conditions or in accidents.

To check the rear axle housing, the axle must be completely disassembled and the housing checked according to the instructions in the repair manual.

The transmission components and assemblies of the Zhiguli car are distinguished by their well-thought-out design, high production standards and low maintenance labor intensity.

If you follow the recommendations given in the operating instructions and in this manual, the transmission of a Zhiguli car is a reliable and durable set of mechanisms.

Bottom line

Adjusting gearboxes is a troublesome and time-consuming task, but if you have the appropriate equipment (even homemade), you can perform precision work with high accuracy. Basic measurements are carried out with a micrometer or dynamometer. Adjustment “by eye” is possible, but experienced craftsmen still recommend having precision tools in the garage.

Over-tightening the gearbox accelerates wear of parts, and excessive free play leads to backlash and noise.

If you have any questions, leave them in the comments below the article. We or our visitors will be happy to answer them

How bridge malfunctions manifest themselves

The rear axle of the VAZ “six” is endowed with its own characteristic problems, which manifest themselves in one way or another.

Excessive noise from rear wheels

There may not be many reasons for the appearance of large noise from the wheels of the rear axle:

- The wheel has become loose. In this case, it is necessary to check and tighten the fasteners;

- semi-axial bearing failure. The axle bearing wears out over time, resulting in a characteristic noise. The axle shaft needs to be inspected and the faulty element replaced.

Constant noise from the rear axle while driving

Sounds unusual for the normal operation of the device in most cases indicate problems. The main causes of malfunctions include:

- stocking deformation. If the case is deformed, you can try to restore it, but it is better to replace it with a serviceable one;

- bent axle shafts and excessive runout. In this case, the part must be replaced;

- increased wear on splines. It is necessary to inspect the gears and splines of the axle shafts, and then replace the damaged elements;

- the gearbox is incorrectly adjusted, gears or bearings are worn or broken. Complete disassembly, defect detection and repair of the mechanism is required;

- low oil level. You need to check the level, bring it to normal and make sure that there are no leaks through the lip seals and gaskets.

Noise when accelerating the car

The appearance of noise when accelerating a vehicle may be associated with the following reasons:

- Worn or incorrectly adjusted differential bearings. The gearbox needs to be dismantled, inspected and repaired;

- The gearing between the teeth of the bevel and planetary gears is incorrectly set. The problem is solved by proper adjustment;

- wear of semi-axial bearings. It is necessary to remove the faulty axle shaft and replace the bearing;

- little lubrication. The problem is resolved in the same way as with constant noise.

Noise when accelerating and braking the engine

If noise from the motor side is present when the motor accelerates and decelerates, then the reason is possible in the following:

- Excessive wear or damage to the shank bearings. Requires disassembly and diagnostics of the gearbox;

- Incorrect alignment of the teeth of the bevel and planetary gears. Eliminated by checking the integrity of the parts and setting the correct gap.

Video: identifying the cause of noise in the rear axle

Noises when cornering

Extraneous noise can appear not only when driving straight, but also when cornering. This may be due to the following reasons:

- Difficulty turning the satellites on the axis. Requires disassembly, inspection of serviceability and replacement of elements whose condition does not allow them to be used further;

- jamming of side gears. If the gears and the surfaces with which they come into contact have minor damage, then they are cleaned with sandpaper. Otherwise, failed elements must be replaced;

- Incorrect alignment of the differential gears. Diagnostics and correct adjustment of the gap are required;

- failure of semi-axial bearings. Defective elements must be replaced.

Knock when starting to move

If the “six” rear axle gearbox (RAZ) makes a knocking sound as soon as the car starts moving, then this may indicate the following:

- Excessive clearance between flange and tip. Inspection of the spline connection and replacement of worn parts is required;

- increased gap between the shank and the planetary gear. Eliminated by setting a gap;

- increased wear of the landing site under the satellite axis. If such a breakdown occurs, the box must be replaced;

- The rear suspension rod fasteners have dropped. The bolts need to be checked and, if necessary, tightened.

Oil leak

Lubricant may leak from the gearbox for the following reasons:

- wear of the bevel gear cuff. If a leak appears from the shank side, the oil seal must be replaced;

- Damage to the axle seal. If traces of grease appear on the brake flaps, this indicates wear of the axle shaft seal, which requires its replacement;

- The fastening of the gearbox to the stocking has become loose or the gasket has been damaged. In such a situation, it is necessary to tighten the fasteners or replace the seal.

When oil leaks, gear wear accelerates.

Where is the gearbox located?

On the "sevens", as on all representatives of the rear-wheel drive family, the gearbox is located at the rear, under the bottom of the car. It connects the cardan to the VAZ 2107 axle and causes the wheels of the car to rotate. Rotation occurs thanks to axle shafts engaged in the gearbox, which, due to the technical features of the rear axle of the VAZ 2107, will have to be removed later. If the car is lifted, or when viewed from a garage pit, the gearbox is simply impossible not to notice.

Signs and malfunctions of the classic rear axle gearbox

Replacing a gearbox with your own hands is a labor-intensive process, which includes not only the purchase of a new unit (quite expensive), but also time costs. Therefore, before you start, you need to make sure that the gearbox is faulty. You can define the signs like this:

- gradually accelerating the car, listen carefully and remember at what moment the noise appears;

- while driving, start engine braking (remove your foot from the gas pedal at speed), at this time listen to the gearbox and note the moment the noise appears;

- accelerate the "seven" to hundreds, switch to neutral and turn off the engine - listen to how the gearbox behaves while coasting.

“If the bridge is noisy both in neutral and at speeds, the gearbox has nothing to do with it. If the hum occurs only at speed (regardless of the number), repairs, or, as a last resort, replacement of the gearbox are inevitable.”

When the signs are identified, it is necessary to carry out another check:

- park the car, secure the front wheels with shoes;

- jack up the rear so that the bridge hangs over (it is necessary that the wheels come off the surface);

- start the engine and accelerate the “seven” to the point at which noise occurs, while the wheels should spin without load.

If the noise has not changed, then the gearbox is clearly in good working order and it is not the cause of the trouble. Here other drive units are checked. Well, if there is no noise when driving without a load, then we are talking about worn gears of the gearbox, which make noise only when driving with a load.

The “seven” gearbox itself is a fairly reliable unit that can withstand a period of 100 to 300 thousand mileage, and there is no need to even look into it. Gears, gear spacer, differential adjustment - all these problems arise during improper operation:

- the use of oil with a low viscosity level, as well as failure to comply with the terms of its replacement;

- operating the “seven” with an amount of oil insufficient for this;

- During movement, the bridge is subject to extreme loads (frequent and unsuccessful slips).

Gearbox removal process

In order to repair or replace the rear axle gearbox of a VAZ 2107, you first need to remove it from the car:

- Drain the oil. This, by the way, may be a reason to replace it.

- Separate the flanges of the cardan and gearbox. To do this, you need to unscrew four bolts and nuts. At this time, it is necessary to fix and immobilize the cardan with a screwdriver or by holding the brake pedal. After unscrewing the nuts, you need to tie the cardan to the muffler. You can simply hang it, but this can also lead to negative consequences for the cardan.

- Remove the axle shafts, because without this the gearbox cannot be removed. At the same time, you can inspect the seals, and if they are worn out, replace them. This will save time and prevent possible malfunctions.

- Separate the beam and gearbox by unscrewing all eight bolts that secure it. When unscrewing the latter, it is necessary to hold the gearbox so that it does not fall. The bolts are unscrewed - carefully remove the gearbox.

Repair and adjustment of the VAZ 2107 gearbox

Before you start repairing the gearbox and its subsequent adjustment, you need to have certain skills, backed up by skills, observe all the nuances and subtleties of this process, and also strictly follow the technological nuances of the process. Therefore, if a person starts work for the first time, then it is better to abandon this idea. In addition, you must have all the necessary tools:

- pullers;

- stands;

- a set of keys, screwdrivers and other accessories.

Failure of the steering mechanism

When the gearbox finally fails, the ability to drive the vehicle is completely or significantly lost. How to timely determine the “quick end” of the steering mechanism of a VAZ 2106 car, so as not to encounter this at the most inopportune moment? There are several “warning lights” that indicate that the mechanism in question needs replacement.

| Problem | Causes and consequences |

| 1. Extraneous squeaks are heard when turning the steering wheel | This may indicate that a foreign substance of an abrasive type has entered the gearbox, or an internal breakage of the worm or gear. Possible jamming of the unit, loss of control over vehicle control functions |

| 2. Significant play in the steering wheel | In most cases, play is caused by loosening the adjustment bolt and is eliminated by tightening it. If such a measure does not produce results, therefore, the gearbox of the VAZ 2106 car must be replaced |

| 3. Oil leak | This may mean either a rupture of the sealing gasket or a crack or hole in the housing. This is fraught with high oil consumption, insufficient lubrication of the steering mechanism and acceleration of its inevitable failure. |

| 4. Difficulty turning the steering wheel | The reason is insufficient lubrication, displacement of the engagement angle of the worm and gears, partial jamming of moving parts and mechanisms. It is fraught with increased driver fatigue during a long trip, complete jamming of the unit, loss of control over vehicle control functions |

| 5. Knocks and vibrations in the gearbox, which are felt through the steering wheel | The reasons may be: a loose adjustment bolt, failure of sealing couplings and gaskets, or wear and tear of mechanisms moving in mesh. Possible jamming of the unit, loss of control over vehicle control functions |