ADJUSTING THE AIR DAMPER. Adjusting the carburetor choke drive

Air damper adjustment

The carburetor air damper drive in the car's engine power system is adjusted if the mechanical drive rod has been replaced, or the carburetor has been removed from the car for repair or replacement. Adjustment may be required if the engine does not start well when cold, or if the air damper does not open completely after the engine warms up. Incomplete opening of the air damper leads to unstable operation of a warm engine and increased fuel consumption. Incomplete closing results in poor starting of a cold engine.

Was there an automatic choke?

Of course he was. As for domestic cars, he first used it on the Solex 21083 carburetor, but it was installed only on export VAZ 2110. The essence of its work was as follows - a special spring controlling the damper was connected to the coolant. The bimetal changed its properties as it warmed up, and, accordingly, opened or closed the damper depending on the temperature of the antifreeze.

There have also been developments for our country - this is an electronic suction control system. Instead of a cable, an electric drive was installed, and there was a programming button and a control unit in the cabin. First, the operation of the choke was programmed, and then it closed the damper based on the program. But each season had to be reprogrammed anew, because what worked in the summer, in the winter already required a different open time.

Damage to the carburetor air damper

For the carburetor to function properly, the choke valve must operate without any malfunctions. Any jamming of the carburetor air damper leads to increased fuel consumption and difficulty starting a cold engine.

Read also: What to wear to a summer wedding. (21 photos)

One of the reasons for the damper sticking is the incorrect operation of the return mechanism; in such a situation, it does not return to its position. In addition, the lever or damper axis may be the reason for the choke to not work properly. In this situation, you should check the correct operation of the damper in the engine compartment of the car and eliminate any detected problems.

Another failure of the damper is hidden in the damage to the cable. Often the cable breaks, as a result of which there is no reaction to changing the position of the handle. In this situation, you should replace the damaged cable with a new one. The cable could also stretch, as a result of which the damper will also not respond to the movement of the handle. To solve this problem, unscrew the bolt on the handle that clamps the cable. Then pull the cable to the required length and tighten the fastener. Then check the correct operation of the damper.

When automatically controlling the air damper, the spring most often fails. There is only one solution in this case - replacing the spring. It is also necessary to check the serviceability of the damper axis and control lever.

Replacing the carburetor

The reasons for removing a unit can be different: replacement with a product of a different modification, repair, cleaning. In any case, you must first remove the air filter. To carry out the replacement work you will need the following tools:

- open-end wrench 13;

- crosshead screwdriver;

- heads for 8 and 10;

- knob;

- small extension cord.

How to remove

After the preparatory activities, you can begin dismantling:

- Unscrew the 4 nuts securing the air filter housing and remove the plate.

After dismantling the device, procedures are carried out to replace or repair the unit.

Video: how to remove a carburetor using the example of a VAZ 2107

How to put

Installation of the product is carried out in reverse order. When tightening the nuts, do not use much force. The fasteners are tightened to a torque of 0.7–1.6 kgf. m. The fact is that the carburetor mating plane is made of soft metal and can be damaged. Before installing the unit, the gasket is replaced with a new one.

Today, carburetor engines are no longer produced, but there are a lot of cars with such units. In Russia, the most common are “Zhiguli” classic models. If the carburetor is properly and promptly serviced, the device will work without any complaints. If breakdowns occur, you should not delay their elimination, since engine operation is destabilized, fuel consumption increases, and dynamic characteristics deteriorate.

The role of the throttle valve in the operation of the carburetor

The amount of fuel mixture that enters the cylinders depends on the position of the throttle valve, which, in turn, is connected to the gas pedal.

In addition, in the interior of some carburetor cars there is a special lever on the dashboard that can also be used to control the throttle. It is commonly referred to as a "choke", although technically it is a "cold start device". By pulling its handle towards himself, the driver closes the air damper, limiting the access of air and increasing the vacuum in the carburetor mixing chamber. As a result, gasoline is sucked out of the float chamber more intensively and, with a lack of air, prepares an enriched combustible mixture for the engine, which is necessary to start a cold engine.

In order for the engine to idle, the carburetor has special additional calibrated air jets, through which a strictly defined amount of air enters under the throttle valve and mixes with the fuel, even if you take your foot off the gas pedal.

How to check Solex

To ensure high-quality work on adjusting and tuning the carburetor, you should ensure that sand particles, etc. do not get on the throttle valves. If solid particles get into the carburetor, this can lead to an expensive overhaul of the internal combustion engine (due to some small thing).

After you have adjusted the carburetor correctly, you need to check the accelerator pump. When the throttle valve is opened slightly, the nozzle should spray gasoline. Here is the answer to the question: why does the car jerk when driving? If a stream of gasoline from the sprayer appears late, then this precisely leads to braking when you press on the gas and the car jerking.

To clean the carburetor, it must be disassembled. First, we unscrew the fuel and air jets, as well as the emulsion tubes. If it is difficult to remember what is where in the carburetor device, then it is most convenient to photograph each step.

To determine whether the diaphragm is intact, unscrew the cap of the power mode economizer.

Signs of a broken carburetor diaphragm:

- The internal combustion engine does not stall when the screw is tightened.

- If you turn off the ignition, the engine continues to run for some time, that is, self-ignition occurs.

- Unstable operation of the internal combustion engine.

- Increased gas mileage during normal, moderate driving.

ECTO or EURO? What brand of fuel is best to fill in? ECTO fuel is not recommended for use in cars with high mileage.

After checking the integrity of the diaphragm, we clean the SOLEKS. For cleaning we use air pressure (a compressor or pump is needed). If the dirt is hard and does not fly off with a stream of air, then carefully clean the stuck dirt with copper wire. I use air pressure cleaning without damaging the surfaces of carburetor parts. After this, close the lid and now you need to lubricate all the rubbing surfaces of the carburetor parts. It should be lubricated after washing the outer part.

When is it time to clean your throttle body?

If you notice the signs described below on your car, then you need to visit a service station soon and clean the throttle.

- The idle speed began to float, the engine runs unevenly

- It's hard to start the car (especially when it's hot)

- Noticeable increase in fuel consumption

- Deterioration in dynamics (it feels like someone is holding the car from behind when accelerating)

- Jerking at the beginning of movement at low speeds

You can see the condition of the damper yourself; to do this, you need to remove the air filter pipe and look into the throttle. If you see carbon deposits on the walls, and the flap tongue is black and not golden, then there is only one conclusion that needs to be cleaned.

Setting the air damper of the Solex and Ozone carburetors

In order for the engine to start confidently and continue to operate normally, it is necessary to correctly adjust the carburetor air damper mover. If the damper is incorrectly adjusted, for example, it does not completely close the air supply, a cold engine may simply not start. If the air damper does not open completely, fuel consumption increases and idle speed adjustment becomes almost impossible.

To adjust the carburetor air damper, we need two 8-mm open-end wrenches.

Checking the operation of the damper:

- First, you need to unfasten the air filter cover (so that you can see the damper);

- Then close the air damper completely (there should be no gaps between the damper and the carburetor air chamber);

- Then open the damper completely. When operating correctly, it should be in a vertical position and completely open the carburetor air chamber;

- If the air damper closes or does not open completely, it needs to be adjusted.

Adjusting the carburetor air damper drive:

- First you need to remove the air filter from the carburetor;

- Open the carburetor air damper, completely recessing the choke lever;

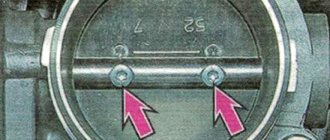

- Loosen the screw on the damper control lever (which clamps the cable);

- Loosen the screw that secures the suction cable casing;

- We check that the choke handle is completely recessed;

- Turn the damper adjustment handle all the way and, leaving 1 cm to the choke cable casing, clamp it;

- Then open the air damper completely, and in this position tighten the screw that holds the choke cable.

By pulling the choke handle several times, we make sure that it opens and closes completely. The air damper setting is complete.

Adjusting the idle speed on a VAZ 2106

First you need to prepare the car. We warm up the engine to a temperature of 900 degrees. We ensure that the engine operates stably at idle speed.

Let's watch a video in which everything is shown in an accessible and understandable way:

The text instructions are as follows:

- Using the quantity screw, we achieve a crankshaft speed of 820 to 900 rpm.

- Using the quality screw, we bring the unit into stable and uniform operation. Then, by tightening the screw, we destabilize the operation of the motor and unscrew it again to restore it. Our task is thus to achieve the most stable engine operation with the leanest possible mixture.

- Using the quantity screw, we again bring the speed to the desired value.

- It is best to carry out the operation two or three times.

What role does the air damper play in a carburetor?

The air damper is installed at the top of the carburetor and is a round or oval metal sheet. Its task is to limit or allow a large amount of air entering the carburetor. The principle of operation of the damper is approximately the same as that of the gas pedal. The only difference is that it works independently of the accelerator.

The air damper is used to facilitate starting an engine that has not been warmed up. That is, in the morning, when the engine is cold, part of the gasoline condenses and does not reach the combustion chamber. The other, remaining part is in too small an amount and is not enough to ignite. When the damper is closed, the volume of air entering the carburetor is limited and the amount of gasoline increases. Thus, the engine starts and the throttle opens to reduce fuel consumption and increase air volume.

To control the damper, both manual and automatic choke are used. Earlier cars used manual throttle control. A cable was attached to it and pulled into the cabin to the control handle. To close the damper, you need to pull the damper towards you until it stops. During the warming up process, it is gradually retracted to its original position and as soon as the engine begins to stably maintain idle speed with the throttle open, you can start driving.

The automatic “choke” has the simplest design and is a spring that controls the damper drive. Spring stretch directly depends on engine temperature. During the warming up process, the spring independently opens the damper and regulates the air supply level.

How to adjust idle speed on a Solex carburetor

Just as in the case of “Ozone”, before adjusting the idle speed, the car’s internal combustion engine must be warmed up to operating condition, and both the engine itself and the spark plugs, fuel pump, high-voltage wires must be in good working order, and the air and fuel filters must not be dirty. The air damper should be opened all the way (recess the choke handle all the way), then proceed to adjust the XX using the quantity and quality screws:

- using a large screw (quantity), turning it in, we increase the speed;

- We tighten the quality screw until the engine starts to slow down and work intermittently, then we unscrew it until the engine starts to operate stable;

- Using both screws, we achieve the most optimal mode by setting the idle speed to 850-950 rpm.

After the adjustment operation, you should check the dynamics and stability of the engine while driving: the engine should not stall when the gas is suddenly released, and there should be no dips, jerks or jolts when driving.

Diffuser capacity

The diffuser is one of the main elements of the carburetor. The defining parameters of a diffuser include its diameter. The choice of diameter strictly depends on the requirements for the engine. The numerical values of the diffuser diameter and other important parameters are initially determined based on engineering practice and experience in designing various motorcycles and engines for them. The final selection of diameter is carried out during testing on the engine. For example, small-capacity two-stroke engines used on mopeds and scooters are equipped with carburetors with a diffuser diameter of 12 to 14 mm. 125 cc sports engines use diffusers with a diameter of 36 to 40 mm. On racing engines with spool valve timing, you can find carburetors with an even larger diffuser. This trend is due to the fact that the diameter of the diffuser determines the maximum throughput of the main air channel, i.e. — maximum filling of the cylinder. The more power it is expected to develop, the larger the diffuser should be, since it will provide less resistance to the flow of the mixture.

However, the large diameter of the diffuser makes the engine less responsive, as it impairs fuel atomization in low and medium load modes. For engines operating over a wide rpm range, throttle response is more important than maximum power. In this case, carburetors with a diffuser of small cross-section are used, which improves the flow of fuel due to greater vacuum.

To increase the throughput without changing the diameter of the diffuser, special inserts are used to eliminate stepwise changes in the cross-section along the air flow path, thereby reducing parasitic turbulence.

Parasitic effects

Four-stroke engine carburetors may experience a stick-close effect due to the very strong low-pressure clamping action in the intake tract. To reduce this effect, as well as prevent rapid wear leading to parasitic air leaks, the surface is coated with chrome to increase hardness and smoothness (picture below under letter a

).

The same effect forces the use of very stiff return springs to ensure the throttle valve closes. However, since spring stiffness determines the driver's throttle force, efforts should be made to minimize friction between the throttle and the housing. For example, in the picture below under the letter b

presents a chrome-plated throttle body with a return spring for a sports carburetor of the VHSD line. It can be seen that the spring used is of a very modest size, but its force is quite sufficient to close the throttle, since the chrome coating of the damper significantly reduces friction on the body.

a - chrome throttle valves, b - spring return throttle valve

We previously noted the advantages of a flat throttle valve, but it is not without its disadvantages. A flat throttle valve makes it difficult to place the idle air passage. This hole(s) is necessary to supply fuel at a time when the low idle speed hole can no longer supply the required amount of fuel and the main metering system has not yet come into operation. In the technological cycle of carburetor manufacturing, these holes are drilled after processing the main fuel well and, for proper functioning, are located slightly further than the edge of the throttle valve. With a flat choke, the holes are located very close to the atomizer, which complicates the layout. But despite this, flat choke carburetors are the most advanced in their design.

To be continued…

Prevent sticky suffocation

BEGINNER'S CORNER

John Gunnell

The automatic choke found on most American collector cars is a simple choke in the "throat" of the carburetor. When you close the throttle, less air enters the engine. More gas is supplied, which is what is needed for a cold start.

As the engine warms up, the choke opens, allowing the engine to breathe in more air. If the choke is stuck, the mixture will remain rich. Your warm car will be difficult to start, perform poorly and waste precious gas.

A bimetallic spring in the choke body on the carburetor is connected to the shaft on which the choke rotates. This spring compresses when cold, causing the shaft to rotate and close the valve. Because the shaft is slightly off center, the valve does not close completely.

A small hole allows just enough air to flow to create the correct starting mixture. There may also be a choke piston, controlled by manifold vacuum, that is tensioned by a spring and partially opens the choke.

The tube - or throttle body - will flow to the throttle body. When the engine reaches operating temperature, heat moves up the pipe to the bimetallic spring. As the spring heats up, it opens the choke even wider, creating a leaner mixture for better hot starts, good fuel mileage and proper performance.

Many automatic throttle bodies have rods connecting the throttle body to the throttle body. The rod controls the fast idle cam, which keeps the throttle body from closing tightly. Increasing the idle speed prevents a cold engine from stalling. As the engine warms up, the choke opens wider, the cam comes out of fast idle, and the idle speed drops.

The cam also helps start a flooded engine. There is too much gas in a flooded engine - the mixture is too rich - the throttle is closed tightly. But when you press the gas pedal all the way down, the cam forces the "unloader" mechanism to open the choke to remove excess gas from the carburetor. When the car starts, you release the pedal and the choke starts working again.

Automatic throttles seem complicated. They are designed with special bimetal spring rates, special cam designs and precise spring tension. They also require set clearances and adjustments. However, in most cases, caring for them comes down to cleaning only. It's rare that parts break or adjustments fail. Choke problems are usually caused by sticky gasoline or carbon deposits. These are maintenance items that any hobbyist can take care of with regular household tools and chemical cleaners.

This cutaway drawing of a Carter WCD two-barrel carburetor shows some of the choke system parts that you will clean as part of your spring car maintenance.

Let's get started

Place the newspaper on a clean surface or floor. You will need a screwdriver, pliers, an adjustable crescent wrench, cleaning solvent, a parts cleaning brush, several clean rags, several clear plastic bags for storing food, index cards, and a coffee can or container to drain the oil. For personal protection, wear safety glasses , respirator and latex-free surgical gloves.

Remove the air filter. Use an adjustable wrench to loosen the clamp bolts and place them in a plastic bag. Describe or draw (take a photo?) how the clips fit together on an index card and seal it in a bag with the parts. Write #1 on this card. If your car has an oil bath air cleaner, don't tip it over or you'll end up with an oily mess.

Hold it straight and carefully set it aside for now.

Next, turn off the throttle valve. Place it in a second bag with the description of your index card #2. Use pliers to remove the tiny rod clips (place them in the third bag so you don't lose them). Disconnect the rods at their upper ends. Loosen the screws holding the choke body to the carburetor. As with other parts, place the screws in the bag with the card description.

Remove the choke housing cover and do the pouch trick again. If it has a thin metal gasket or small clock-shaped tabs, put them in the same bag. The throttle body itself can be placed on newspaper. Using a parts cleaning brush, apply solvent to the choke body. In the past, many mechanics used lacquer thinner or spray gun cleaner as a solvent. Very effective aerosol carburetor cleaners are available today. Use a coffee or tuna can to catch the solvent you wash off.

Apply solvent to all areas. Go through the cleaning procedure twice, each time using clean solvent. This will prevent contaminated fluid from forming sticky fuel deposits around the throttle shaft and exhaust piston. Move the piston by hand to force fluid out of the cylinder. Carbon deposits on the choke body are a sign that the engine is burning oil. Regular carbon deposits in the carburetor air passages can be removed with a toothpick or drill.

Since the air cleaner has been removed from the car, now is the time to clean it. In fact, if it is scratched or pitted, you can sand it down and repaint it. On an oil bath air cleaner, check the oil level. There will be a mark inside the base part indicating how high the oil level should be.

Starting with the highest numbered plastic bag, begin assembling the pieces together. By following the number sequence and following the parts descriptions you wrote on each index card, you should have no problem reinstalling the clean throttle body and inserting the parts into it correctly.

Make sure that the housing cover "catches" the bimetallic spring and moves the valve flap as the temperature changes.

Experts recommended cleaning the automatic choke housings every 5,000 miles. In the good old days, this meant about twice a year - usually in the spring and fall. Although hobbyists put fewer miles a year on their older cars, there's no excuse for not taking care of that vehicle at least every spring. By avoiding sticky throttles, you can save a lot of gas, which is more important today than when these cars were new.

data-matched-content-ui-type = "image_card_stacked" data-matched-content-rows-num = "3" data-matched-content-columns-num = "1" data-ad-format = "autorelaxed">

Signs of a carburetor malfunction

As you use a car with a carburetor, certain problems may arise that require cleaning, adjusting the unit, or replacing any of its parts. Let's look at the most common problems with the mechanism and methods for eliminating them.

Stalls at idle

One of the most common malfunctions of carburetors of the VAZ 2106 and other “classics” is problems with idle speed. In this situation, the following happens: when you press the gas pedal, the engine normally picks up speed, and when you release it, the engine stalls, i.e., when the transition to idle mode (idle) occurs. There may be several reasons for this phenomenon:

- clogged jets and channels of the XX system;

- solenoid valve malfunction;

- problems with the forced stroke economizer;

- failure of the quality screw seal;

- the need to adjust the unit.

The design of the carburetor is made with a combination of the XX system and the primary chamber. As a result, problems may occur that lead not only to failures, but also to a complete stop of the motor. The solution to these problems is quite simple: replacing faulty elements, if necessary, cleaning and blowing the channels with compressed air.

Dips during acceleration

When accelerating a car, dips may appear, which represent a drop in acceleration or a complete stop of the car.

Dips can vary in duration - from 2 to 10 seconds; jerking, twitching, and swaying are also possible.

The main cause of this problem is a lean or rich fuel mixture entering the cylinders of the power unit when the gas pedal is pressed.

First of all, it is worth noting that failures can be caused not only by carburetor problems, but also by clogging or malfunction of the fuel system, as well as the ignition system. Therefore, you first need to check them and only after that start repairing the carburetor. The most likely cause of VAZ 2106 failures may be a clogged hole in the main fuel jet (GFJ). When the engine operates under low loads or in idle mode, a small amount of fuel is consumed. When you press the gas pedal, high loads occur, resulting in a sharp increase in fuel consumption. If the GTZ is clogged, the passage hole will become smaller, which will lead to a lack of fuel and failures in engine operation. In this case, the nozzle must be cleaned.

The appearance of dips can also be caused by clogged fuel filters or loose fuel pump valves. If there is an air leak in the power system, then the problem in question is also quite likely. If the filters become clogged, they can simply be replaced or cleaned (the mesh at the inlet to the carburetor). If the problem is caused by the fuel pump, the mechanism will need to be repaired or replaced with a new one.

As for air leaks, this usually happens through the intake manifold. It is necessary to check the tightness of the connection between the carburetor and the manifold. To do this, with the engine running, spray WD-40 on the connections between the manifold, gaskets and carburetor on all sides. If the fluid leaves too quickly, it means there is a leak in that place. Next, you need to remove the carburetor and eliminate the malfunction (align it under a press or resort to improvised means).

Video: eliminating air leaks

Pouring candles

The problem with flooded spark plugs is familiar to almost every owner of a car with a carburetor engine. In this situation, starting the unit is quite difficult. When you turn the spark plug out, you can see that the part is wet, that is, it is filled with fuel. This indicates that the carburetor supplies a rich fuel mixture at the time of start-up. In such a situation, it is impossible for a normal spark to appear.

The problem with flooded spark plugs can occur both during a cold and hot start of the engine.

Since there may be several reasons for this phenomenon, it is worth considering them in more detail:

- Starting the engine with the choke pulled out. If you close the air damper on a warm engine, an over-enriched mixture will be supplied to the cylinders, which will lead to flooding of the spark plugs.

- The starter is faulty or needs adjustment. The problem in this case usually manifests itself when it is cold. In order for the starting device to be properly adjusted, the starting gaps must be set properly. The trigger device itself must have a complete diaphragm and a sealed housing. Otherwise, when starting a cold unit, the air damper will not open slightly to the required angle, thereby depleting the fuel mixture by mixing in air. If there is no such opening, the mixture will become enriched when starting cold. As a result, the candles will be wet.

- Faulty spark plugs. If the spark plug has black soot, an incorrectly set gap between the electrodes, or is completely broken, then the part will not be able to ignite the fuel-air mixture and will be flooded with gasoline when the engine starts. This indicates the need to have a set of spark plugs in stock so that replacement can be carried out if necessary. With such a malfunction, the part will be wet both cold and hot.

- Needle valve malfunction. If the carburetor needle valve in the float chamber has lost its tightness and allows more fuel to pass through than it should, the fuel mixture becomes rich during start-up mode. If this part fails, the problem can occur during cold and hot starts. Valve leakage can often be determined by the smell of gasoline in the engine compartment, as well as by fuel leaks on the carburetor. In this case, the needle must be checked and, if necessary, replaced.

- The fuel pump is overfilling. If the fuel pump drive is not adjusted correctly, the pump itself may pump fuel. As a result, excess gasoline pressure is created on the needle valve, which leads to an increase in fuel in the float chamber and an enrichment of the fuel mixture. To fix the problem, you need to adjust the drive.

- Clogged air jets of the main dosing system (GDS). GDS air jets are necessary to supply air to the fuel mixture so that it has the necessary proportions of gasoline and air for normal engine starting. Lack of air or its complete absence due to clogged nozzles leads to the preparation of an enriched combustible mixture and flooding of the candles.

Smell of gasoline in the cabin

Owners of the VAZ 2106 and other “classics” sometimes encounter such a nuisance as the appearance of the smell of gasoline in the cabin. The situation requires urgent search and elimination of the problem, since fuel vapors are harmful to human health and are explosive. There may be several reasons for this smell. One of them is damage to the fuel tank, for example due to a crack. Therefore, the container must be checked for leaks and, if a damaged area is detected, repairs must be made.