VAZ 2106 gearbox repair

| Having installed the gearbox on the workbench, use a 10mm wrench to unscrew the two bolts securing the locking plates of the differential bearing nuts and remove the plates. |

| We use a core to make marks on the bed and the corresponding bearing cover so that during assembly we can install the covers in their places. |

| Using a 14mm wrench, unscrew the bolts securing the bearing caps. |

| Remove the outer bearing rings and adjusting nuts from the differential housing. |

If we do not change the bearings, then we mark the outer rings so as not to mix them up during installation, because The bearings are individually worn in and it is not advisable to disassemble them.

| We check the absence of radial play in the axle gears. |

| Use a puller to compress the inner rings of the tapered bearings. |

| Using a 17mm wrench, unscrew the eight bolts securing the driven gear to the differential housing and remove it. |

| We use a beard to knock out the satellite axis. |

| We turn the axle gears and remove the satellite gears. |

| We take out the axle gears with adjusting washers, marking their position. |

| We remove the drive gear and the deformed spacer from the crankcase. When assembling the gearbox, we replace it with a new one. |

| Using a soft metal drift, knock the inner ring of the tapered bearing off the drive gear shaft. |

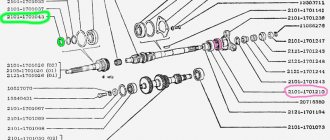

| An adjusting ring is installed under the bearing to ensure the correct relative position of the main gear gears. |

| Use a suitable tool to knock out the outer rings of the tapered bearings from the crankcase. |

We thoroughly wash the gearbox parts in kerosene and carefully inspect them. If at least one tooth is damaged (chipping, waves, scratches, scuffs on the working surfaces), we replace the gears with new ones.

The edges between the tops and working surfaces of the driven gear teeth must be sharp. If the slightest nicks or roundings are visible, replace the main pair with a new one. Minor damage to the satellite axle, axle pinion journals and their mounting holes can be eliminated with fine sandpaper followed by polishing. When assembling, replace the cuff, flange nut and spacer with new ones. If the gearbox is assembled in the same crankcase, then the change in the thickness of the drive gear adjusting ring can be calculated as the difference in deviations in the manufacturing dimensions of the old and new gears. The deviation in size with a “ ” or “–” sign in hundredths of a millimeter is engraved on the drive gear shaft. For example, the old gear is engraved with –12, and the new gear is 4. The difference between the two corrections will be 4–(–12)=16. This means that the new adjusting ring should be 0.16 mm thinner than the old one. With the opposite ratio of corrections (4 on the old one, and 12 on the new one), the ring should be 0.16 mm thicker than the old one. To more accurately determine the thickness of the adjusting ring, we make a device from the old drive gear.

| We weld a plate 80 mm long and trim it to a size of 50–0.02 mm relative to the plane for the bearing. The serial number and size deviation are engraved on the conical part of the shaft. |

We grind the seats under the bearings (can be treated with fine sandpaper) until they fit smoothly. We press the outer rings of the front and rear bearings into the crankcase. We install the inner ring of the rear bearing on the manufactured device and insert the device into the crankcase. We install the inner ring of the front bearing, the flange of the drive gear and tighten the nut with a torque of 0.8–1.0 kgf.m.

| We set the crankcase to a horizontal position and level. |

| We place a round, even rod (an extension from a set of socket heads) in the bearing bed and use a flat feeler gauge to determine the size of the gap between it and the device plate. |

The thickness of the adjusting ring is determined as the difference between the gap size and the deviation in the size of the new gear (taking into account the sign). For example, the gap value is 2.8 mm, and the gear size deviation is 15. This means that it is necessary to install an adjusting ring with a thickness of 2.8–(–0.15)=2.95 mm.

| We install an adjusting ring of the required thickness on the shaft and, using a piece of pipe of a suitable size, press on the inner ring of the bearing. |

We insert the shaft into the crankcase. We install a new spacer, front bearing inner race, collar and drive gear flange.

| Gradually tighten the nut with a torque wrench to a torque of 12 kgf.m. |

| We determine the moment of rotation of the drive gear shaft. |

To do this, tightly wrap a strong thread around the neck of the flange in several turns and attach a dynamometer to it. The force at which the flange begins to rotate evenly should be 7.6–9.5 kgf (which corresponds to a torque of 16–20 kgf.cm) (for new bearings). If the force is not enough, tighten the flange nut. In this case, the tightening torque should not exceed 26 kgf.m. If, when tightening the nut, the turning torque exceeds 20 kgf.cm (9.5 kgf), disassemble the gearbox and replace the spacer sleeve.

| We install the differential housing together with the bearings into the crankcase and tighten the bolts of the bearing caps. |

If axial play is detected in the axle gears, then during assembly we install new, thicker support adjusting rings. The side gears should fit tightly into the differential housing, but can be turned by hand.

| We make a wrench from a steel sheet 2.5–3 mm thick for tightening the adjusting nuts. |

We adjust the gap in the main pair and preload the differential bearings simultaneously, in several stages: tighten the nut on the side of the driven gear until the gap in the mesh is completely eliminated;

| Using a caliper we measure the distance between the covers; |

screw the second nut until it stops and tighten it by 1-2 teeth of the nut. The distance between the covers should increase by approximately 0.1 mm; By rotating the first nut, we set the required gap in engagement of 0.08–0.13 mm. This is minimally noticeable play in the engagement, accompanied by a slight knock of tooth against tooth; We control the constancy of the gap in the engagement with our hands and gradually tighten both nuts until the distance between the covers increases by 0.2 mm. This will ensure the necessary bearing tension.

How to make repairs

To begin, remove the gearbox from the machine, and then clamp it into a clamp. Unscrew both bolts for the locking plates and remove them.

Next, the bearing caps are marked for their future assembly. To do this, you will need a center punch and use a hammer to make marks. Use wrench No. 14 to unscrew the bolts and remove the covers.

It is important to note that the covers are removed together with the adjustment nuts. You must also remember to remove the roller bearing races.

It is important to immediately inspect the bearings for wear and serviceability. The outer races of each bearing are marked, since they are selected in pairs and cannot be disassembled.

The radial play located on the axle gears is checked. If its size exceeds 0.5 mm, then the box is replaced. In normal condition, the bearing is removed and the planetary gear is unscrewed.

Next, you need to knock out the satellite axis using the adapter and pull them out.

You need to remove the drive shaft and gear from the gearbox housing. A soft metal punch is perfect for this. The inner wheel of the roller bearing is knocked out.

It is also necessary to replace the adjusting sleeve with a new one.

After knocking down the bearing, you need to remove the adjustment ring.

Next, use a drift to knock out the outer rings of the bearings.

Now you can wash all parts in kerosene or diesel fuel. After the washing is done, all parts are diagnosed. There should be no chips or cracks. If these defects are present, it is important to replace the parts. In case of small scuffs, they can be polished with sandpaper.

Device

In order for the car to move, it is necessary to transfer the rotation of the engine to the wheels. But the engine speed is too high, and in order to correctly distribute the torque, a mechanism is needed that changes the gear ratio. Due to the gearbox and different engine speeds, the speed of movement changes, and the main pair of the rear axle takes over the rotation and transmits it to the wheels through gears.

- flange, it is fixed on the drive gear (shank) of the RZM, and is an intermediate link between the driveshaft and this gear;

- the shank of the main pair, at one end of which there are splines for pressing the flange, at the other end there is a bevel gear with a small number of teeth;

- driven gear (planet gear), it is in mesh with the drive gear, and it is with it that it forms the main gear;

- center differential, allowing the rear wheels to spin at different angular speeds.

The differential design is very simple - the mechanism consists of two axle gears, two satellites and a satellite pin. From the gearbox, the movement is transmitted to the axle shafts, on which the wheels are mounted.

Why did it happen so?

Perhaps the automatic requests do not belong to you, but to another user accessing the network from the same IP address as you. You need to enter the characters into the form once, after which we will remember you and be able to distinguish you from other users exiting from this IP. In this case, the page with the captcha will not bother you for quite a long time.

You may have add-ons installed in your browser that can make automatic search requests. In this case, we recommend that you disable them.

It is also possible that your computer is infected with a virus program that is using it to collect information. Maybe you should check your system for viruses.

If you have any problems or would like our support team, please use the feedback form.

The front suspension and rear axle assembly are called the main elements on which the so-called “wheel drive” of the vehicle rests. If these units are in working order, the machine will function well.

Differences in VAZ rear axle gearboxes

RZMs differ in the gear ratio of the main pair; in total, there are four types of gearboxes on the VAZ classic:

The slowest one is the RZM 2102, its drive gear has 9 teeth, and the driven gear has 40 teeth. To calculate the gear ratio, you need to divide the number of planetary gear teeth by the number of teeth on the drive shaft; for the VAZ 2102 the drive gear is equal to 4.44.

The “penny” gearbox (2101) accordingly has the number of teeth on the gears 10/43, so its IF is 4.3. The next, faster one is RZM 2103 - it has a ratio of 1041, which means the gear ratio is 4.1. And finally, the “fastest” will be the 2106 gearbox, with the number of teeth 11/43 and an inverter frequency of 3.9, respectively.

Many VAZ 2101-07 owners strive to install the fastest gearbox, but this is not always necessary. If the car often carries cargo, that is, the car is a “workhorse”, high speed is of no use, but high-torque power will be very useful. It should be noted that RZM 2102 was not supplied as spare parts; it was installed only on station wagons.

↑ Diagnostics of gearbox parts

We thoroughly wash the gearbox parts in kerosene and carefully inspect them. If at least one tooth is damaged (chipping, waves, scratches, scuffs on the working surfaces), we replace the gears with new ones.

The edges between the tops and working surfaces of the driven gear teeth must be sharp. If the slightest nicks or roundings are visible, replace the main pair with a new one.

Minor damage to the satellite axle, axle pinion journals and their mounting holes can be eliminated with fine sandpaper followed by polishing.

Replacing the rear axle gearbox of VAZ 2106, 2107

The main disease of REM is increased noise (hum), and the gearbox can hum for various reasons:

- there is insufficient oil in the bridge, or it is completely missing;

- the gap between the gears of the main pair is not adjusted;

- the gears are worn out, they have chips and other damage;

- the main pair has a manufacturing defect, the gears are not ground in from the factory;

- the shank nut has become unscrewed or loosened;

- bearings are worn out.

The main malfunction of the center differential is the wear of the gears of the axle shafts and satellites, when the surfaces of the parts are heavily worn, play forms between the differential gears, but the rear axle usually does not make noise due to wear of the differential gears.

ZM gearboxes on VAZ classics can be repaired, but only if there is no wear on the gears. If the mechanism can no longer be repaired, it needs to be replaced. We replace the rear axle gearbox of a VAZ 2106 on a “seven” as follows:

- we install the car on a pit or a car lift; changing the gearbox on the ground is extremely inconvenient;

- if the car is installed on a pit, it is necessary to jack up both sides; in any case, the rear wheels must be removed. If the work is not done on a lift, you should install stops under each side of the car (in the rear);

- unscrew the drain plug in the REM, drain the transmission oil, having previously prepared a container for it;

- remove the rear brake drums (two guide bolts on each side), after first removing the car from the handbrake. The drums can be difficult to remove; they are dismantled by tapping them from behind with a hammer through a wooden block. You cannot hit the drum with a metal hammer; the drum may break;

- remove the brake pads;

- unscrew the fastenings of the rear axle axle shafts on each side, each axle shaft is secured with four nuts;

- we press out the axle shafts, for this you will need a special puller, you can also make a homemade device;

- remove the driveshaft by unscrewing the four bolts and nuts. If the same REM is installed, the cardan with the shank must be marked; this is done in order to put the shaft back in the same position. If you install the cardan incorrectly according to the marks, the shaft may begin to vibrate;

- unscrew the eight bolts securing the rear gearbox (key 13), remove the assembly.

Malfunctions

Causes of malfunctions

The rear axle gearbox is a complex mechanism consisting of a large number of elements. Failure of any one of them can lead to failure of the entire system.

- System overload. One of the most common reasons for failure of the rear axle gearbox is the frequent excess of the required load on the vehicle. For example, when towing heavy vehicles or other loads. During towing, the load on all elements of the system increases significantly.

- Play in crosspieces. Many motorists note that after 5-6 years of using the car, play appears in the crosspieces. This occurs due to increased engine detonation, unregulated ignition and the resulting shocks and shocks. Therefore, during repairs, they carry out diagnostics of all elements of the chassis and do not limit themselves to replacing the transmission mechanism.

- Lack of lubrication. If there is no oil in the rear axle gearbox, it may jam due to overheating. Steel parts may burst or teeth on gears may break. To avoid such problems, it is necessary to keep the lubricant level under control.

- Production of bearings located in “stockings”. This malfunction appears after many years of using the car. It can cause bending of shafts and destruction of gears. As a result, the rear axle gearbox will not be suitable for repair.

Signs of trouble

You will recognize problems associated with the operation of the rear axle gearbox by the characteristic noise:

- Increased bridge noise. The beam may be deformed, the gears and axle shafts may be worn out, the oil level may be low, or there may be a leak. Noise that appears immediately after repair is a consequence of incorrect adjustment.

- Noise during acceleration. If noise appears when the car accelerates, it means the differential or axle bearings are worn out or damaged. Another possible reason is a lack of lubrication in the gearbox.

- Noise during acceleration and braking. If noise appears not only during acceleration, but also when braking the car, it means that the drive gear bearings are worn out or damaged. It is possible that the clearances in the final drive gears are incorrect.

- Noise when cornering. If you notice noise when turning, it means that the axle bearings in the car are faulty. Possible reasons are scoring on the surface of the satellites or their rotation being too tight.

- Knocks when starting to move. Most likely, the gap between the splined connection of the drive gear shaft and the flange has increased. It is also likely that the pinion pin hole located in the differential is worn out.

Vehicle testing

Test 1. Start driving on the highway at 20 km/h, then gradually increase the speed to 90 km/h. At the same time, listen to the sounds the car makes at different speeds. Release the throttle pedal and, without braking, reduce engine speed. Watch for changes in noise.

Test 2: While driving at 100 km/h, shift the lever to neutral, turn off the ignition and roll freely until it comes to a complete stop. Watch the noise change at different deceleration rates.

Test 3. The car is stationary, with the hand brake on. Start the car engine and, gradually increasing the speed, listen to the noise that arises. If you hear the same noise as during test No. 1, then the source is not the gearbox, but other components of the car.

Test 4. If the noise detected in test No. 1 was not repeated in tests No. 2 and No. 3, then it comes from the gearbox. To finally verify this, lift the rear wheels of the car, start the engine and shift into fourth gear. This will allow you to make sure that the source of the noise is the gearbox, and not the suspension or body.

How to avoid premature failure of the axle gearbox? You need to monitor the oil level, listen to noises and knocks in the car, visually inspect the bridge for leaks and external damage to the beam.

Defects in the gearbox

Increased play in the RZM can be formed due to wear of the differential pinion pin - if you grab the driveshaft and rotate it clockwise and counterclockwise, this play can be felt. Also, increased clearance can be formed due to wear of the splines inside the differential housing itself.

If the gaps in the main pair of gearboxes are not adjusted, a characteristic noise occurs when the car moves:

- when the load increases (sharp acceleration), a characteristic howl is heard in the bridge;

- When I let off the gas the noise goes away.

The engine can hum in a different way, but the characteristic feature described above can most often be heard on VAZ classic cars. Worn teeth of the main pair are clearly visible on the planetary gear - they become rounded, and they often show traces of rust.

Main characteristics of the gearbox

The most significant technical and operational parameters of the gearbox include the following:

- Gear ratio. Reflects the ratio of the number of gear teeth to the number of gear teeth in the gear. The calculations can also take into account the number of passes to the worm gear and the ratio of the diameter of the larger pulley to the thickness of the smaller pulley in the belt drive.

- Reliability. It does not affect the performance qualities, but expresses the service life of both individual elements and the system as a whole. By the way, changes in structural parameters due to wear can also affect the quality of the main functions of the mechanism, which is also reflected in adjacent units. For example, an axle gearbox may well affect the performance of the axles through a forced reduction in torque.

- Efficiency. Characterizes the performance and efficiency of the device in terms of the quality of energy transmission. To determine efficiency, the ratio of energy used to energy expended is used.

- Protective and insulating qualities. Determined by the IP protection class system. For example, standard mechanisms today are provided with IP 55 housings capable of withstanding temperatures ranging from -15 to 40 °C. The insulation also prevents dust particles, dirt and water from entering the housing.

Adjusting the VAZ rear axle gearbox

If the main pair in the gearbox is worn out, it must be replaced. But you can’t just put the gears back in place; the gaps in them must be adjusted. In total, two types of basic adjustments are made:

- The thickness of the adjusting sleeve (washer) is selected for the shank (drive gear). The washer can have a thickness from 2.6 mm to 3.5 mm;

- The gap between the gears of the main pair is adjusted using two adjusting nuts of the differential housing.

The washer for the shank is selected in such a way that the shaft with the drive bevel gear rotates in the gearbox housing without backlash with a force by hand (0.3-0.4 kg). In this case, the shank nut should be tightened with a force of 12 to 26 kg, usually 18-19 kg are tightened.

After installing the shank, the differential housing with the planetary gear attached to it is put in place. The housing is secured with two covers (4 bolts, a knob with a 17mm head). The adjusting nuts are tightened from the sides of the bearings, the differential is installed so that there is play between the gears of the main pair, and the planetary gear should not be clamped. By moving the adjusting nuts to the right and left, the shank gear is brought to the planetary gear. By adjusting, you select the moment when the gap between the gears practically disappears.

The last stage is to adjust the preload of the differential bearings; the adjusting nuts are tightened from the sides. This work must be done with an indicator; the device should show from 0.14 to 0.18 mm, the gap between the gears should be within 0.08-0.13 mm. After the operation, the adjusting nuts are fixed with plates so that they do not turn.

It should be noted that adjusting the VAZ rear axle gearbox is a very difficult matter, and it is better to trust it to professionals.

↑ Adjusting the gaps

We adjust the gap in the main pair and preload the differential bearings simultaneously, in several stages:

- tighten the nut from the side of the driven gear until the gap in the mesh is completely eliminated;

- Using a caliper we measure the distance between the covers;

- screw the second nut until it stops and tighten it by 1-2 teeth of the nut. The distance between the covers should increase by approximately 0.1 mm;

- By rotating the first nut, we set the required gap in engagement of 0.08–0.13 mm. This is minimally noticeable play in the engagement, accompanied by a slight knock of tooth against tooth;

- We control the constancy of the gap in the engagement with our hands and gradually tighten both nuts until the distance between the covers increases by 0.2 mm. This will ensure the necessary bearing tension.

Slowly turn the driven gear three turns and at the same time feel the play in the meshing of each pair of teeth.

If it is uniform in all gear positions, then install locking plates.

A decrease (increase) in play in any sector indicates deformation of the differential housing and the need to replace it or trim it on a lathe.

There are two types of locking plates: single-claw or double-claw.

Depending on the position of the nut slot, we install one of them.

Repair or replacement, which is better?

Car owners of VAZ classics often cannot decide what is best to do - buy a complete ready-made REM assembled or purchase individual parts and repair the gearbox. It’s really difficult to decide here - the price of a new gearbox, of course, is higher, but the owner of the car is freed from the headache of adjustment. The thing is that it’s not so easy to find a good specialist in VAZ gearboxes, and there is no guarantee that the new main pair will not hum.

If a car owner buys a new gearbox, but it hums, the part can be exchanged under warranty, but the car owner loses money on removing and installing the gearbox. If you purchase a defective main pair, the repair itself will be more expensive - you will have to pay a technician for a secondary overhaul of the gearbox.

VAZ rear axle gearbox locking

On VAZ 2101-07 vehicles, the factory does not provide locking of the center differential, but the industry already produces both differentials with locks and fully assembled 3M gearboxes. The most common today are REMs with screw locking; in them, the differential gears are locked depending on the load. In such rear axle gearboxes, a preload clutch is installed, it connects the wheel axle shafts with a certain force, and acts as a blocker.

Locking the VAZ rear axle gearbox provides the following advantages:

- increases cross-country ability, allows the vehicle to avoid slipping on difficult road sections;

- allows the car to accelerate faster at the start;

- The car corners more confidently.

But ZM gearboxes with screw locking also have their disadvantages:

- Fuel consumption increases slightly;

- when accelerating, the car handles worse;

- The differential and assembled gearbox with locking are much more expensive than standard parts (the price is approximately 2-2.5 times higher).

VAZ 2101-07 car owners should know that after installing the RZM with blocking, the car will not become an SUV, and it will not be able to move on severe off-road conditions.

Failure of the steering mechanism

When the gearbox finally fails, the ability to drive the vehicle is completely or significantly lost. How to timely determine the “quick end” of the steering mechanism of a VAZ 2106 car, so as not to encounter this at the most inopportune moment? There are several “warning lights” that indicate that the mechanism in question needs replacement.

| Problem | Causes and consequences |

| 1. Extraneous squeaks are heard when turning the steering wheel | This may indicate that a foreign substance of an abrasive type has entered the gearbox, or an internal breakage of the worm or gear. Possible jamming of the unit, loss of control over vehicle control functions |

| 2. Significant play in the steering wheel | In most cases, play is caused by loosening the adjustment bolt and is eliminated by tightening it. If such a measure does not produce results, therefore, the gearbox of the VAZ 2106 car must be replaced |

| 3. Oil leak | This may mean either a rupture of the sealing gasket or a crack or hole in the housing. This is fraught with high oil consumption, insufficient lubrication of the steering mechanism and acceleration of its inevitable failure. |

| 4. Difficulty turning the steering wheel | The reason is insufficient lubrication, displacement of the engagement angle of the worm and gears, partial jamming of moving parts and mechanisms. It is fraught with increased driver fatigue during a long trip, complete jamming of the unit, loss of control over vehicle control functions |

| 5. Knocks and vibrations in the gearbox, which are felt through the steering wheel | The reasons may be: a loose adjustment bolt, failure of sealing couplings and gaskets, or wear and tear of mechanisms moving in mesh. Possible jamming of the unit, loss of control over vehicle control functions |

Is it necessary to change it?

Of course, there are other ways to solve the problem. Instead of buying a new part, you can repair the VAZ 2106 gearbox. However, doing this in a garage is highly not recommended, since you simply will not be able to set the gap in the gear meshing correctly. That is why the most reliable solution would be to purchase a new element. Fortunately, its cost is not that high (about 4 thousand rubles), so from a financial point of view, your costs will be minimal.

How is a gearbox different from a differential?

How to check the thermostat at home video

This unit is often confused with a gearbox, which is not entirely correct, although there are good reasons for this. Indeed, both units are part of the same structural system, which is responsible for the transmission and distribution of torque. What is a gearbox in this infrastructure? This is a mechanism that lowers or increases the rotation speed by transmitting movement to the differential. The latter, in turn, does not affect the dynamics of the torque, but only distributes the force between the axles. For this reason, the differential is called an interaxle differential. However, there is also a type of inter-wheel units that can also change the proportions of torque, transmitting it to the wheels when cornering.

Let's get started

To begin dismantling the bridge, you must first drive the car onto an inspection pit or overpass. Then you need to drain the oil and disconnect the driveshaft from the gear shank flange.

After this, the axle shafts are removed from the machine and, using an end prick, the 8 mounting bolts that connect the gearbox to the beam are unscrewed. Then you can safely remove the rear axle (gearbox) from the VAZ 2106. At this stage, you can go in two ways - install a new element or try to dig deeper into the old one. In the first moment, the elements are assembled in the reverse order, but we will tell you how to proceed in the second case in the following sections.

Replacement procedure

Before proceeding with dismantling the gearbox, drain all oil from it.

Remember - never reuse old grease. In order to free the rear axle, put the car in neutral.

- raise the rear with a jack;

- The cardan joint, carefully held with a pry bar (so that it does not turn during the process), is disconnected from the drive gear;

- unscrew the 4 nuts securing it;

- taking a flat screwdriver, disconnect the flange;

- the cardan is suspended on a rope, secured to the bottom of the car;

- twist the nut that secures the drive gear;

- remove the washer;

- the flange itself is dismantled;

- turn off the brakes and unscrew the wheels.

Since it is impossible to replace the gearbox without removing the axle shafts, dismantle them too.

After this, all that remains is to remove the gearbox itself. It is disconnected from the beam by unscrewing 8 bolts.

Whatever the reason forces you to disassemble the rear axle, always check the condition of other moving elements along the way. As previously noted, oil seals most often become unusable.

The main bearings also often wear out due to high loads. If visible defects are found on these elements, they must be replaced. By the way, this element is designed to ensure the correct gear ratio of the power unit. For those who intend to start tuning their “seven”, it is useful to know that installing a superior gear directly into the gearbox allows you to lower the above-mentioned indicator and, therefore, increase the speed. For 2107, the highest allowed number is 4.4.

About sealing elements and their replacement

Note that on the first Six models, the connection between the bridge and flanges was sealed with a special gasket. A few years later, an oil-resistant sealing agent began to be tried on the assembly line instead. Therefore, in any case, it is necessary to update this seal during reassembly.

What needs to be done next? At the next stage, you need to thoroughly clean the surface of the gearbox connectors from the sealing substance, and then use a rag pre-moistened in gasoline to degrease this surface. If you use white spirit, take extra precautions to protect your respiratory tract. The threads of the mounting bolts and the holes for them located in the can must also be degreased.

All these surfaces are then treated with a new oil-resistant sealant. The threads of the fixing bolts are lubricated with a special fixing compound.

Then the axle gearbox is mounted into the beam and tightened evenly (crosswise) with bolts. Installation of the remaining elements is carried out in reverse order. Finally, you need to pour new oil into the rear axle.

DIY repair

Boring brake drums at home

Repairing the rear axle gearbox Repairing the rear axle gearbox is not very complicated and does not require specialized knowledge, but before disassembling and reassembling it is better to familiarize yourself with the technical documentation. Before starting all work, it is necessary to raise the rear of the car so that the wheels are free and the gear is in neutral. Next, you need to unscrew the plug to drain the lubricant, and while it flows out, proceed to remove the cardan. When raised, you can freely scroll it in order to unscrew the 4 bolts that secure the shank. But before disconnecting, it is necessary to put a mark on the shank of the transmission mechanism and on the cardan, because it is screwed in only one of 4 positions.

Repairing leaks

If the shank is always wet from grease, then the gearbox seal most likely needs to be replaced. To do this, just disconnect the cardan. Next, you need to unscrew the drive gear nut and remove the flange from its shaft. Under it there is an oil seal, which can be removed using a thin but hard tool, slightly picking. Then use a clean rag to remove all the old grease and evenly press in the new oil seal and put on the flange. The hook must be clamped with the required force, which should be 1 Newton.

If the shank is dry, and the source of the leak is the junction of the transmission unit with the bridge, then it is necessary to replace the cardboard gasket; for this it is necessary and sufficient to unscrew the gearbox itself. Here a 12mm socket wrench will help you, with which you need to unscrew 8 bolts. After removing the mechanism, it is necessary to thoroughly clean the contacting surfaces of dirt and old gasket and carefully put on a new one, lubricated with sealant. The bolts are tightened thoroughly, but not to the point of stripping the threads. A new lubricant TAD-17, GL-5 or TM5-18 is poured.

Next, align the driveshaft shank with the flange at the mark and tighten it using new nuts, because they have plastic retaining rings that are disposable.

The entire repair of the rear axle gearbox usually takes little time, because there is nothing complicated.

How to fill the oil?

Before revealing the specifics of the replacement, we note that this instruction can be used not only for cars of model 2106. A similar algorithm for changing the oil can be observed in VAZ cars of models 2101, 2102, 2104, 2105, as well as model 2107.

So what do we need to do to change the oil? First you need to unscrew the drain plug with a hex key. Next, put some container and unscrew the filler element. After the oil has drained well, we screw the plug back in and use a special oil pump (or a large syringe) to pump transmission oil into it. Pour to the level of the bottom edge of the hole. Next, tighten the plug, and now you can safely start operating the car.

Sometimes the substance in the gearbox can be heavily contaminated. In this case, before adding new fluid, thoroughly rinse the gearbox or gearbox housing with a mixture of diesel fuel and oil (not necessarily transmission oil). The proportion is about 300 milliliters of diesel fuel per liter of oil.

Where are worm gearboxes used?

Worm gearboxes are most often used in mechanisms that require the transmission of low power with a large conversion ratio. For example, devices with weak high-speed engines that provide a small number of strokes or revolutions of the executive body.

Many mechanisms may require a low angular speed of rotation of the output shaft. In this case, a worm gearbox will be ideal. It guarantees significant output torque, and thanks to the huge gear ratio, the output speed is very low. These can be gate drives, various lifts of a lever design.

To solve some problems, a feature of worm gearboxes may be useful, which consists of changing the direction of the output shaft relative to the input shaft by 90 degrees. This indicator never changes.

Separately, it is worth noting the combined gear reducers. They carry out a double conversion: preliminary using a cylindrical circuit and final - using a worm gear. This achieves an even higher conversion factor for the lowest angular velocity of the output shaft.