water pump

, also known as a car engine water pump, is a pump that creates forced circulation of coolant in the internal combustion engine cooling system.

The water pump

is intended to organize the circulation of antifreeze or other composition in the cooling system.

A malfunction of the pump leads to a serious disruption of the internal thermal regime of the engine, which is why it “boils” quite quickly. photo gallery:

This cannot be allowed to happen, so to make sure that the engine pump is working, you need to periodically listen and inspect the motor in order to repair or replace the failed unit in time.

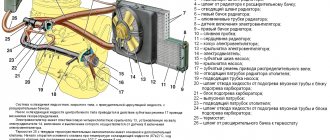

Water pump design

Pump device

in most cars it is very similar, especially for domestic cars. And you won’t have to search for long to find where the pump is located either, since it is driven by the timing belt and is located near the radiator.

Structurally, the pump looks like this: a shaft is mounted in the cover. An impeller is mounted on it, the movement of which initiates the movement of liquid in the system. A drive pulley is mounted on the other side of the shaft, and in some car models there is also a fan. Through the timing belt and drive pulley, the rotational energy of the engine is transmitted to the shaft, the shaft drives the impeller and the entire system operates.

Pump device.

An oil seal is mounted between the housing and the impeller, the wear of which is associated with many pump problems. If this seal is bad, antifreeze or antifreeze gradually seeps into the cavity towards the bearings, washing away their lubricant. Because of this, the bearings begin to work much louder and wear out quickly, which leads to the pump jamming.

Possible malfunctions of the cooling system pump

A failure of the coolant pump can lead to the shutdown of the entire system. This can seriously affect the condition of the engine. The most common pump problems are:

- Wear of the seal (oil seal). In this case, a coolant leak occurs.

- Impeller failure. When the impeller is destroyed, fluid injection becomes worse (pressure drops) or stops altogether.

- Bearing jamming. If the pump's lubrication deteriorates, which can also be a consequence of leaking coolant, the pump begins to operate intermittently.

- Increased play between the impeller and the pump shaft. During operation, the impeller attached to the shaft may become loose, which leads to unstable operation of the pump and other breakdowns.

- Chemical corrosion. Most often, this problem affects the pump impeller and occurs if low-quality fluids are used.

- Destruction due to cavitation. Air bubbles that may arise during operation of the pump intensively destroy it from the inside, which leads to fragility of parts and their damage by corrosion.

- System contamination. Chemical deposits and simply dirt that gets inside the pump over time form a hard coating on its parts, which makes it difficult for the impeller to rotate and the passage of liquid.

- Bearing destruction. In this case, a characteristic whistle appears when the pump operates. It is difficult to replace such bearings, and therefore in this case the pump is simply replaced.

- Broken drive belt. If a low-quality belt is used or is not replaced in a timely manner, rupture or slippage may occur.

If the engine cooling system is stopped for just 5-6 minutes, the engine may overheat. The action of high temperatures disrupts the geometry of the cylinder head and leads to damage to the crank mechanism. You should not ignore minor malfunctions of the cooling system, as they can lead to serious repairs in the future.

Causes and consequences of water pump failure

Since the car pump is a fairly simple mechanism, it does not break down too often, especially with normal engine care. However, even the most reliable pump can fail. There may be several reasons for the breakdown, including:

- wear of device components, including aging of the oil seal;

- initially low quality pump;

- unprofessional repairs.

If the system remains sealed, but the pump does not initiate fluid circulation through it, this will lead to an increase in engine temperature, as indicated by the gauge on the dashboard. Driving for a short time in this mode will cause the radiator to boil or the engine to seize.

If a pump leak occurs, you need to take action to eliminate it as quickly as possible.

Another sign of a pump failure is an antifreeze leak in the area where it is installed. If the leak is not very severe, this is not so scary, since the liquid circulating in the system will still perform its functions normally, it just needs to be topped up regularly. But still, if such a breakdown is detected, it is best to eliminate it immediately, because leaks tend to increase in intensively used engines.

Antifreeze leaking through the pump body.

Sometimes antifreeze leaks along the back wall of the pump at the junction with the back cover of the pump (Fig. 5 and Fig. 6). Basically, this malfunction occurs immediately after installing the pump. The cause of this breakdown is a leaky connection between the pump body and the back cover. This can be caused by foreign particles entering the joint, uneven (with gaps) application of sealant to the mounting surfaces, insufficient or uneven tightening of the mounting bolts, or the use of sealant simultaneously with a rubber O-ring.

To prevent this type of breakdown, you need to carry out vehicle maintenance only by qualified specialists.

Fig.5

Fig.6

Common water pump failures

There are not very many types of failures due to which a water pump can fail, which is due to the relative simplicity of its design. The most common are:

- Problems with the impeller are the most common, but wedge bearings also happen.

- impeller failure;

- deterioration of fastening of the impeller to the shaft;

- bearing jamming;

- deterioration of joint tightness due to engine vibrations, leading to coolant leakage.

Types and their structure

Strange shift lock release button: why is it needed in a car?

Pumps operating in SMA are divided into two types, each of which has its own filter and its own “snail” structure.

Drain

The drain pump is an attribute of washing machines in the lower and middle price ranges. They are equipped with a regular pump that drains wastewater from the machine into the sewer. Most likely, it will not be possible to repair such a pump - the damaged pump is completely replaced with a new one. The power consumption of a conventional pump does not exceed 40 watts. Fastening to the cochlear canal - with screws or using latches. The electric motor contacts are located separately or together. The disadvantage of a simple pump is that the filter often gets clogged, which is why the drain is not completely drained; the waste water stagnates inside the channel and a corresponding smell appears from the drain pump. A simple pump requires regular monitoring of the filter condition.

The operation of a simple SMA pump is not that complicated. The fact is that the pump rotor is a permanent cylindrical magnet located in a plastic housing. When the drainage system starts, the rotor itself starts up first, followed by the impeller, located on the shaft at an angle of 180 degrees. The impeller should not deviate significantly from its position aligned with the anchor - such a small stroke allows the motor to start at high speeds without much effort, since the water also resists the propeller itself. On the magnetic core there are two coils connected at the ends. In other words, the drive of a simple pump is a small asynchronous motor, which has a rotor and a stator. The stator contains a magnetic stationary part of the rotator with windings, and the rotor contains a magnetic core.

Circulating

A circular (booster) pump can be used in conjunction with a simple (drainage) pump. Such a system for pumping and pumping liquid is used in SMAs of the middle and upper price ranges. Advantages: water is supplied directly to the drum, circulation is possible (this allows you to reduce water costs for washing clothes). The operating principle of a circular pump is that water flows only in one direction along a closed path.

Thus, Samsung uses a seal in a circular system - it prevents water from leaving the contour. Bearings remain dry. This mechanism has a shaft on the rotor that passes through a sealing sleeve that operates with a spring-loaded ferrule. To lubricate such a mechanism, a special thickened composition is used that penetrates into all rubbing areas.

Water pump repair

The engine pump is a repairable, dismountable unit. Here it is possible to replace both the entire mechanism and its individual elements, such as bearings. The fact that a car pump does not have to be completely replaced is good news, since this can significantly reduce the cost of repairs. True, access to this unit for partial or complete disassembly can be difficult. So, in some car models, this requires partially unscrewing the engine mounts, working from below from the inspection hole. Very often, the pump is replaced every second time the timing belt/chain is replaced, but if symptoms of a malfunction occur, the water pump is replaced even earlier, it all depends on the quality of the part and the level of work performed during the previous change of the timing drive and the part itself.

Checking the pump's health

It should be noted right away that in order to identify many problems with the water pump, this device will have to be removed from the engine and disassembled. This is the only way to see dirt, corrosion and traces of cavitation.

Water pump impeller heavily damaged by corrosion

But there are a number of signs by which you can determine if the pump is faulty without removing it. Here they are:

- a thin continuous whistle coming from under the engine camshaft pulley. This whistle indicates a faulty bearing.

- coolant leaks, which are visible both on the engine itself and on the asphalt under the car;

- play in the pump, which can be detected by simply holding the pulley and moving the pump up and down with your hand.

Let's look at these faults in more detail.

Pump whistle

The reason for the pump whistling is a partially or completely destroyed ball bearing on the main shaft of the device. Moreover, the pump bearing, as a rule, produces a very high-pitched, piercing whistle, while the whistle of a faulty generator is significantly lower and sometimes turns into a grinding sound. This is affected by the difference in the size of the bearings: the ball bearing on the pump is small, so it whistles very thinly. The generator bearing is twice as large, so the sound comes from it accordingly. So it is almost impossible to confuse the sound of a broken pump and a broken generator.

The central ball bearing of the pump has completely collapsed

The problem is solved by replacing the central bearing of the pump. However, there is one caveat: these bearings are practically not sold separately anywhere. And they can only be purchased in conjunction with a new pump. Therefore, the driver, having heard a characteristic thin whistle coming from under the hood, must be prepared to fork out the cash: a new water pump can cost from 2 to 10 thousand rubles (depending on the make of the car).

This is interesting: A couple of emergency braking techniques

Coolant leak

Liquid begins to flow from under the pump in two cases:

- the mounting bolts have become loose;

- The sealing gasket under the pump is damaged.

The first problem can be solved by simply tightening the bolts. But a damaged sealing gasket will have to be replaced. Fortunately, it is easier to find a gasket for a pump on sale than a central bearing (and in especially difficult cases, car enthusiasts even order seals via the Internet, from the Chinese on Aliexpress, for example).

Water pump is leaking due to over-tightening

It should be noted here that even a new gasket can easily be cut by a pump if the mounting bolts are not tightened correctly. The pump is one of those devices where it is very important not to over tighten it. It is necessary to tighten the bolts in a cross pattern: first tighten the upper right, then the lower left, then the upper left, lower left, etc. Only this tightening pattern can guarantee maximum tightness and tightness of the connection.

Finally, we must not forget about sealants. There are situations when neither a new gasket nor the correct tightening pattern helps get rid of a leak. Then there is only one option left: to use a sealant, and its composition must be very resistant to high temperatures.

The sealant is applied to the pump gasket in a very thin layer.

The best option here is a professional sealant from ABRO, which has proven itself on all brands of cars.

ABRO professional sealant, resistant to high temperatures

Coolant leak after replacing heat exchanger

In the vast majority of cases, after replacing the heat exchanger, antifreeze begins to flow not from under the pump, but from under the clamps of the pipe connected to the pump. On most modern cars, pump pipes are made of plastic, and very fragile plastic. Any careless movement when replacing the heat exchanger, if it does not break such a pipe, will at least break the tightness of its connection to the pump. After this, the antifreeze will definitely begin to leak. There are two options to solve this problem:

- if there are no cracks in the pipe, then you can simply tighten its clamps with a flat screwdriver, then let the engine idle for a few minutes, and then check the connection for leaks;

- If the pipe is broken after replacing the heat exchanger, there is only one way out: going to the nearest auto store and replacing it. This part cannot be restored.

The pipes on water pumps are made of very fragile plastic.

FAQ

Where is the pump located in the car?

The pump is mounted on the engine housing because its shaft is driven by a timing belt or an attachment belt (very rarely). Moreover, it is located on the side of the engine that is closer to the radiator. This makes it possible to reduce the length of the pipes, because the coolant must pass through the radiator, give off heat and flow further into the pump, already cooled.

Where does the pump go?

The pump always pumps away from itself, that is, it pushes, but does not suck. This is ensured by the fact that the rotating impeller creates a centrifugal force, which pushes the antifreeze further. The purpose of the pump is to ensure the movement and pressure of the fluid from the radiator to the engine, so it pumps coolant into the engine. Structurally, the impeller can rotate both clockwise and counterclockwise.

What is a pump in a car and its purpose?

The liquid cannot move through the cooling system on its own, so the design of the liquid system includes a water pump, also known as a pump. Its main task is to ensure the circulation of coolant through the system, which ensures heat intake and removal.

The pump does nothing else, but the normal functioning of the motor depends on its operation. Without it, the power plant will overheat very quickly, since heat removal will not be provided.

Video: Why does a car need a water pump?

Cars currently use a centrifugal type water pump. This type of pump has become widespread due to its simplicity of design, and it copes with the task quite well. To drive it, the force obtained from the crankshaft is used, which is transmitted through a belt drive.

Liquid circulation throughout the system is ensured by an impeller. To ensure the movement of liquid in the cooling jacket, the pump is included in the design of the power unit. Moreover, its main part is located on its outer side, and only the impeller is located inside the jacket.

Fluid leaking from the drain hole or from under the seating surface

There may be various symptoms of pump failure for VAZ-2109, 2107, 2114 and other car models. So if the coolant was of poor quality, there may be a leak in the drain hole area. In this case, leakage occurs, the formation of drops after the car is broken in. This can be determined by looking at the surface of the drain hole. Please note that a small leak in a new pump is normal. This happens during the first 10 minutes of engine operation. This is because the mechanical seal moves to the correct position.

If a new pump has a break-in period. If the pump is not operating properly but fluid continues to flow from the drain port, the pump is damaged. It is necessary to thoroughly flush the cooling system and install a new pump. Then you need to fill in the required amount of new antifreeze of acceptable quality.

If there is leakage from under the seating surface, this also indicates a malfunction. In this case, a sign of failure of the VAZ-2107, 2110, 2109 or other models is humidity, the appearance of drops, drops on the body or around a certain area. The cause of such a breakdown is incorrect installation of the pump or incorrect use of sealants and gaskets.

If the pump is new, remove it and check that it is installed correctly. It is especially important to pay attention to the tightening torques. If the pump is already old, it needs to be replaced.

Water pump device

The pump consists of the following main components:

- Housings;

- Electric motor;

- Discharge pipe;

- Suction pipe;

- Impeller (rotor);

- Working shaft;

- Salnikov;

- Bearings;

- Guide device;

- Casing.

The bowl body is made of steel or cast iron, and there is an impeller inside it. The housing design has a hole located at the bottom for suction of liquids and an outlet located on the side edge of the housing.

The housing can be a separate element to which the pipes are connected, or it can be cast, representing a single structure. The housing has brackets for mounting the pump. A receiving pipe is screwed into the hole where liquid is sucked into the working chamber. Using it, a pipeline is connected to the pump, which is located in the liquid source. The design allows for a pipe as part of the housing and as a separate element, depending on the operating principle of the pump.

A discharge pipe is connected to the outlet on the side of the housing, through which water is transferred from the working chamber to the consumer using a pressure pipeline connected to this pipe. The pipe is part of the cast housing.