4/5 — (49 votes)

In this article you will learn about the fan switch sensor 2106, consider a typical connection diagram. The latest versions of VAZ 2106 cars are equipped with an electric fan, which turns on at a certain temperature of the liquid in the cooling system. This is reasonable, since the old “version” of blowing is morally outdated - with constant rotation of the impeller from the crankshaft pulley, the system overcools. Consequently, the temperature becomes too low and the engine operates abnormally. And this has a very bad effect on it when it comes to the cold season. But let's get closer to the topic and talk about how the fan is connected.

Cooling system VAZ 2106

When driving any car, including the VAZ 2106, in operating mode the engine heats up to 85–90˚С. The temperature is recorded by a sensor that transmits signals to the instrument panel. To prevent possible overheating of the power unit, a cooling system filled with coolant (coolant) is designed. Antifreeze (antifreeze) is used as coolant, which circulates through the internal channels of the cylinder block and cools it.

Purpose of the cooling system

Individual engine elements become quite hot during operation, and it becomes necessary to remove excess heat from them. In operating mode, a temperature of about 700–800 ˚C is created in the cylinder. If the heat is not forcibly removed, jamming of the rubbing elements, in particular the crankshaft, may occur. To do this, antifreeze circulates through the engine cooling jacket, the temperature of which decreases in the main radiator. This allows you to operate the engine almost continuously.

The cooling system is designed to remove excess heat from the engine and maintain operating temperature

Cooling system parameters

The main characteristics of the cooling system are the type and amount of coolant required for smooth engine operation, as well as the operating fluid pressure. According to the operating instructions, the cooling system of the VAZ 2106 is designed for 9.85 liters of antifreeze. Therefore, when replacing, you should purchase at least 10 liters of coolant.

Engine operation requires expansion of antifreeze in the cooling system. To normalize the pressure in the radiator cap, there are two valves operating for inlet and outlet. As the pressure increases, the exhaust valve opens and excess coolant enters the expansion tank. As the engine temperature decreases, the volume of antifreeze decreases, a vacuum is created, the intake valve opens and the coolant flows back into the radiator.

The radiator cap contains inlet and outlet valves that ensure normal operation of the cooling system.

This allows you to maintain normal coolant pressure in the system under any engine operating conditions.

Video: pressure in the cooling system

Instructions for removing and replacing the power supply with your own hands

To replace the DTOZH, you need to do the following:

- Open the hood and find the controller. Disconnect the terminals with wires from the battery.

- Antifreeze should be drained from the power unit cylinder block. The liquid is drained until its level is below the sensor installation location.

- Next, you will need to slide the protective cap on the connector and also disconnect the wire connected to the sensor.

- Using a 21mm wrench, you need to unscrew the device and pull it out of the seat. It is more convenient to use a spark plug wrench or socket for this purpose.

- Dismantle the device and replace it with a new one; further assembly is performed in the reverse order.

Loading …

The design of the VAZ 2106 cooling system

The VAZ 2106 cooling system consists of the following elements:

- radiator;

- radiator cap;

- pipes;

- thermostat;

- expansion tank;

- water pump.

Failure of any element leads to a slowdown or cessation of coolant circulation and disruption of the thermal operating conditions of the engine.

Diagram of the VAZ 2106 engine cooling system: 1 - coolant supply hose to the heater radiator; 2 — coolant drain hose from the heater radiator; 3 — heater valve; 4 — heater radiator; 5 — coolant drain pipe; 6 — coolant drain hose from the intake pipe; 7 - expansion tank; 8 — radiator supply hose; 9 — radiator cap; 10 — upper radiator tank; 11 — radiator tube; 12 — electric fan; 13 — lower radiator tank; 14 — radiator outlet hose; 15 - pump; 16 — coolant supply hose to the pump; 17 — thermostat; 18 — thermostat bypass hose

In addition to the listed components and parts, the cooling system includes a heating radiator and a heater valve. The first is intended to heat the interior, and the second is to stop the supply of coolant to the heater radiator during the warm season.

Cooling system radiator

The radiator cools the antifreeze heated by the engine. The manufacturer installed two types of radiators on the VAZ 2106 - copper and aluminum, consisting of the following parts:

- top tank;

- lower tank;

- cooling honeycombs.

The radiator of the cooling system consists of two tanks and honeycombs, with the help of which the liquid is cooled

The upper tank is equipped with a filler neck, in which, during engine operation, hot antifreeze accumulates, having passed through one circulation circle. From the neck, the coolant passes through the radiator honeycomb into the lower tank, cooled by a fan, and then again enters the cooling jacket of the power unit.

At the top and bottom of the device there are outlets for pipes - two large diameters and one small. A narrow hose connects the radiator to the expansion tank. The system uses a thermostat as a valve to regulate the coolant flow, to which the radiator is connected through a wide upper pipe. The thermostat changes the direction of antifreeze circulation - into the radiator or cylinder block.

Forced coolant circulation is carried out using a water pump (pump), which, under pressure, directs antifreeze into channels specially provided in the engine cylinder block housing (cooling jacket).

Radiator malfunctions

Any malfunction of the radiator leads to an increase in coolant temperature and, as a result, to possible engine overheating. The main problems are leakage of antifreeze through cracks and holes resulting from mechanical damage or corrosion, and internal clogging of radiator tubes. In the first case, the copper heat exchanger is restored quite simply. It is much more difficult to repair an aluminum radiator, since an oxide film forms on the surface of the metal, making soldering and other methods of restoring damaged areas difficult. Therefore, when a leak occurs, aluminum heat exchangers are usually immediately replaced with new ones.

One of the common malfunctions of the radiator of the cooling system is the appearance of a leak.

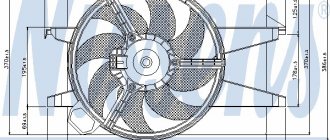

Cooling fan

The VAZ 2106 cooling system fan can be mechanical or electromechanical. The first is mounted on the pump shaft with four bolts through a special flange and is driven by a belt connecting the crankshaft pulley to the pump pulley. The electromechanical fan is turned on and off when the contacts of the temperature sensor are closed or opened. Such a fan is mounted integrally with an electric motor and attached to the radiator using a special frame.

The cooling system of the VAZ 2106 can use a mechanical or electromechanical fan

If previously the fan was powered through a temperature sensor, now it is supplied through the contacts of the sensor-switch. The fan motor is a DC motor with permanent magnet excitation. It is installed in a special casing mounted on the radiator of the cooling system. During operation, the motor does not require any maintenance, and if it fails, it must be replaced.

Fan switch sensor

Failure of the fan switch sensor (FSW) can lead to very serious consequences. When the temperature rises to a critical level, the fan will not turn on, which, in turn, will lead to overheating of the engine. Structurally, the DVV is a thermistor that closes the fan contacts when the coolant temperature rises to 92±2°C and opens them when the temperature drops to 87±2°C.

If the fan switch sensor fails, the engine may overheat.

DVV VAZ 2106 differs from the sensors of the VAZ 2108/09. The latter turn on at a higher temperature. You should pay attention to this when purchasing a new sensor.

The internal combustion engine in a car can be located:

- on the bottom left side of the brass radiator tank;

- in the lower part of the right aluminum radiator tank.

Electrical diagram for turning on the fan

The VAZ 2106 cooling system fan switching circuit consists of:

- electric motor;

- relay;

- fuse;

- sensor;

- power buttons.

The electrical circuit for turning on the fan for cooling the radiator consists of an electric motor, relay, fuse, sensor and button

Output for turning on the fan on a separate button

The advisability of switching on the fan on a separate button in the cabin is due to the following. The DVV can fail at the most inopportune moment (especially in hot weather), and with the help of the new button it will be possible to supply power directly to the fan, bypassing the sensor, and avoid engine overheating. To do this, you need to include an additional relay in the fan power circuit.

The forced fan activation button is installed in the cabin in any convenient place

To complete the work you will need:

- male and female terminals;

- insulating tape;

- wires (7 m);

- pliers;

- screwdrivers.

The fan switch button is installed in the following order:

- Remove the negative terminal from the battery.

- Disconnect and bite off one of the power sensor terminals.

- We clamp the standard and new wire into the new terminal and isolate the connection using electrical tape.

- We lay the wire into the passenger compartment through the engine compartment so that it does not interfere with anything. This can be done either from the dashboard side or by drilling a hole from the glove compartment side.

- We fix the relay near the battery or in another suitable place.

- Prepare a hole for the button. We choose the installation location at our discretion. Convenient to install on the instrument panel.

- We mount and connect the button in accordance with the diagram.

- We connect the terminal to the battery, turn on the ignition and press the button. The fan should start working.

Video: forced activation of the cooling system fan with a button in the cabin

The implementation of such a scheme will allow the cooling system fan to turn on regardless of the coolant temperature.

Water pump

The pump is designed to provide forced circulation of coolant through the cooling system. If it fails, the movement of antifreeze through the cooling jacket will stop and the engine will begin to overheat. The VAZ 2106 pump is a centrifugal pump with a steel or plastic impeller, the rotation of which at high speed causes the coolant to circulate.

The pump is designed for continuous forced circulation of coolant through the cooling system

Pump malfunctions

The pump is considered a fairly reliable unit, but it can also fail. Its service life depends both on the quality of the product itself and on operating conditions. Pump breakdowns may be minor. Sometimes, to restore its functionality, it is enough to replace the oil seal. In other cases, for example, if a bearing fails, the entire pump will need to be replaced. As a result of bearing wear, it may jam and engine cooling will stop. It is not recommended to continue driving in this case.

Most VAZ 2106 owners, if problems arise with the water pump, replace it with a new one. Repairing a faulty pump is usually not practical.

Thermostat

The VAZ 2106 thermostat is designed to regulate the temperature regime of the power unit. On a cold engine, the coolant circulates in a small circle that includes the heater, engine cooling jacket and pump. When the antifreeze temperature rises to 95˚C, the thermostat opens a large circulation circle, which, in addition to the indicated elements, includes a cooling radiator and an expansion tank. This ensures rapid warming up of the engine to operating temperature and extends the service life of its components and parts.

The thermostat is a valve that opens when the antifreeze temperature rises

Thermostat malfunctions

The most common thermostat malfunctions:

- the valve does not open;

- the valve does not close completely.

The first situation is usually caused by a stuck valve. In this case, the temperature gauge enters the red zone, and the radiator of the cooling system remains cold. It is not recommended to continue driving with such a malfunction - overheating can lead to damage to the cylinder head gasket, deformation of the head itself, or the appearance of cracks in it. If it is not possible to replace the thermostat, you should remove it on a cold engine and connect the pipes directly. This will be enough to get to the garage or car service center.

If the thermostat is faulty, the normal operation of the cooling system is disrupted.

If the thermostat valve does not close completely, then most likely debris or some other foreign object has gotten inside the device. In this case, the temperature of the radiator will be the same as the thermostat housing, and the interior will warm up very slowly. As a result, the engine will not be able to reach operating temperature, and the wear of its components will accelerate. The thermostat must be removed and inspected. If it is not clogged, you should replace it with a new one.

Expansion tank

The expansion tank is designed to receive coolant that expands when heated and control its level. The container has min and max marks, by which you can judge the level of antifreeze and the tightness of the system. The amount of coolant in the system is considered optimal if its level in the expansion tank on a cold engine is 30–40 mm above the min mark.

The coolant level in the expansion tank should be 30–40 mm above the min mark

The tank is closed with a lid with a valve, which allows you to equalize the pressure in the cooling system. When the coolant expands, a certain amount of steam escapes from the tank through the valve, and during cooling, air enters through the same valve, preventing vacuum.

Location of the expansion tank VAZ 2106

The expansion tank of the VAZ 2106 is located in the engine compartment on the left side near the container with windshield washer fluid.

The expansion tank on the VAZ 2106 is located on the left side of the engine compartment

The principle of operation of the expansion tank

As the engine warms up, the coolant volume increases. Excess coolant flows into a specially designated container. This allows the expansion of antifreeze to avoid destruction of cooling system elements. The expansion of the fluid can be judged by the marks on the body of the expansion tank - on a hot engine its level will be higher than on a cold one. When the engine cools, on the contrary, the volume of coolant decreases, and antifreeze again begins to flow from the tank to the radiator of the cooling system.

Cooling system pipes

The cooling system pipes are designed for hermetically sealed connections of its individual elements and are large-diameter hoses. On a VAZ 2106, they are used to connect the main radiator with the engine and thermostat and the heater with the cooling system.

Types of pipes

While operating the vehicle, it is necessary to periodically check the hoses for antifreeze leaks. The pipes themselves may be intact, but due to loosening of the clamps, leaks may appear at the joints. All pipes with signs of damage (cracks, ruptures) must be unconditionally replaced. The set of pipes for VAZ 2106 consists of:

- upper inlet pipe;

- outlet pipe;

- couplings connecting the thermostat and pump;

- thermostat bypass hose.

The set of pipes for the VAZ 2106 cooling system consists of four elements

The pipes vary depending on the type of radiator installed. The lower outlets of the copper radiator have a different shape from the aluminum one. The pipes are made of rubber or silicone and are reinforced with metal thread to increase reliability and durability. Unlike rubber ones, silicone ones have several reinforced layers, but their cost is noticeably higher. The choice of type of pipes depends only on the wishes and capabilities of the car owner.

Silicone pipes are more reliable and durable than rubber pipes, but they also cost significantly more.

Replacing pipes

If the pipes are damaged, they must in any case be replaced with new ones. They are also changed during the repair of the cooling system and its elements. Replacing the pipes is quite simple. All work is carried out on a cooled engine with minimum coolant pressure in the system. Use a Phillips or flat-head screwdriver to loosen the fastening clamp and move it to the side. Then, by pulling or twisting from side to side, remove the hose itself.

If there is visible damage to the pipes, they must be replaced with new ones.

Before installing new hoses, clean the seats and the hoses themselves from dust and dirt. If necessary, replace old clamps with new ones. Sealant is applied to the outlet, then a hose is put on it and the clamp is tightened.

Video: replacing cooling system pipes

Coolant for VAZ 2106

The main purpose of antifreeze is engine cooling. In addition, the coolant temperature can be used to judge the condition of the engine. To correctly perform these tasks, antifreeze must be updated in a timely manner.

Antifreeze is used as a liquid for cooling the VAZ 2106 engine

Main functions of coolant:

- maintaining engine operating temperature;

- supply of warm air to the cabin in winter;

- water pump lubrication.

Selection of coolant for VAZ 2106

The cooling system of the VAZ 2106 requires replacing the coolant every 45 thousand kilometers or once every two years. This is necessary, since antifreeze loses its original properties during operation.

When choosing a coolant, you should take into account the year of manufacture of the car.

Table: antifreeze for VAZ 2106

| Year | Type | Color | Lifetime | Recommended Manufacturers |

| 1976 | TL | blue | 2 years | Prompek, Speedol Super Antifreez, Antifreeze-40 |

| 1977 | TL | blue | 2 years | AGA-L40, Speedol Super Antifreeze, Sapfire |

| 1978 | TL | blue | 2 years | Lukoil Super A-40, Tosol-40 |

| 1979 | TL | blue | 2 years | Alaska A-40M, Felix, Speedol Super Antifriz, Antifreeze-40 |

| 1980 | TL | blue | 2 years | Prompek, Speedol Super Antifreez, Antifreeze-40 |

| 1981 | TL | blue | 2 years | Felix, Prompek, Speedol Super Antifreez, Antifreeze-40 |

| 1982 | TL | blue | 2 years | Lukoil Super A-40, Tosol-40 |

| 1983 | TL | blue | 2 years | Alaska A-40M, Sapfire, Anticongelante Gonher HD, Antifreeze-40 |

| 1984 | TL | blue | 2 years | Sapfire, Antifreeze-40, Alaska A-40M, AGA-L40 |

| 1985 | TL | blue | 2 years | Felix, Prompek, Speedol Super Antifreez, Sapfire, Antifreeze-40 |

| 1986 | TL | blue | 2 years | Lukoil Super A-40, AGA-L40, Sapfire, Antifreeze-40 |

| 1987 | TL | blue | 2 years | Alaska A-40M, AGA-L40, Sapfire |

| 1988 | TL | blue | 2 years | Felix, AGA-L40, Speedol Super Antifreeze, Sapfire |

| 1989 | TL | blue | 2 years | Lukoil Super A-40, Tosol-40, Speedol Super Antifriz, Sapfire |

| 1990 | TL | blue | 2 years | Antifreeze-40, AGA-L40, Speedol Super Antifriz, Anticongelante Gonher HD |

| 1991 | G11 | green | 3 years | Glysantin G 48, Lukoil Extra, Aral Extra, Mobil Extra, Zerex G, EVOX Extra, Genantin Super |

| 1992 | G11 | green | 3 years | Lukoil Extra, Zerex G, Castrol NF, AWM, GlycoShell, Genantin Super |

| 1993 | G11 | green | 3 years | Glysantin G 48, Havoline AFC, Nalcool NF 48, Zerex G |

| 1994 | G11 | green | 3 years | Mobil Extra, Aral Extra, Nalcool NF 48, Lukoil Extra, Castrol NF, GlycoShell |

| 1995 | G11 | green | 3 years | AWM, EVOX Extra, GlycoShell, Mobil Extra |

| 1996 | G11 | green | 3 years | Havoline AFC, Aral Extra, Mobil Extra, Castrol NF, AWM |

| 1997 | G11 | green | 3 years | Aral Extra, Genantin Super, G-Energy NF |

| 1998 | G12 | red | 5 years | GlasElf, AWM, MOTUL Ultra, G-Energy, Freecor |

| 1999 | G12 | red | 5 years | Castrol SF, G-Energy, Freecor, Lukoil Ultra, GlasElf |

| 2000 | G12 | red | 5 years | Freecor, AWM, MOTUL Ultra, Lukoil Ultra |

| 2001 | G12 | red | 5 years | Lukoil Ultra, Motorcraft, Chevron, AWM |

| 2002 | G12 | red | 5 years | MOTUL Ultra, MOTUL Ultra, G-Energy |

| 2003 | G12 | red | 5 years | Chevron, AWM, G-Energy, Lukoil Ultra, GlasElf |

| 2004 | G12 | red | 5 years | Chevron, G-Energy, Freecor |

| 2005 | G12 | red | 5 years | Havoline, MOTUL Ultra, Lukoil Ultra, GlasElf |

| 2006 | G12 | red | 5 years | Havoline, AWM, G-Energy |

Coolant drain

Draining the coolant is necessary when replacing it or during some repair work. It's quite easy to do this:

- With the engine cool, open the radiator cap and expansion tank cap.

- We place a suitable container with a volume of about 5 liters under the radiator tap and unscrew the tap.

- To completely drain the coolant from the system, place a container under the drain hole and unscrew the bolt plug on the engine.

If there is no need for a complete drain, then the last step can be omitted.

To drain the liquid from the cooling system, it is necessary to unscrew the radiator valve and the bolt plug on the cylinder block.

Flushing the cooling system

If the stove is working poorly or the entire cooling system is functioning intermittently, you can try flushing it. Some car owners find this procedure very effective. For washing, you can use special cleaning products (MANNOL, HI-GEAR, LIQUI MOLY, etc.) or limit yourself to what is available (for example, citric acid solution, “Mole” plumbing cleaner, etc.).

Before you start flushing with folk remedies, you need to drain the antifreeze from the cooling system and fill it with water. Then you need to start the engine, let it run for a while and drain the fluid again - this will remove debris and impurities. If the system is periodically cleaned and is slightly dirty, then it can be washed with clean water without adding special products.

If dirty water comes out of the cooling system, flushing should be repeated.

It is recommended to wash the radiator and engine cooling jacket separately. When flushing the radiator, the lower pipe is removed and a hose with running water is put on the outlet, which will begin to flow out from above. In the cooling jacket, on the contrary, water is supplied through the upper pipe and discharged through the lower one. Flushing is continued until clean water begins to flow out of the radiator.

To remove accumulated scale from the system, you can use citric acid at the rate of 5 sachets of 30 g for the entire cooling system. The acid dissolves in boiling water, and the solution is diluted in the cooling system. After this, the engine should be allowed to run at higher speeds or simply be driven while monitoring the coolant temperature. After draining the acid solution, the system is washed with clean water and filled with coolant. Despite its cheapness, citric acid cleans the cooling system quite effectively. If the acid fails to remove the stains, you will have to use expensive branded products.

Video: flushing the VAZ 2106 cooling system

Pouring coolant into the system

Before adding antifreeze, you need to close the radiator valve of the cooling system and tighten the bolt plug on the cylinder block. Coolant is poured first into the radiator along the lower edge of the neck, and then into the expansion tank. To prevent air bubbles from forming in the cooling system, the liquid is poured in a thin stream. In this case, it is recommended to raise the expansion tank higher than the engine. During the filling process, you need to make sure that the coolant reaches the edge without air. After this, close the radiator cap and check the fluid level in the tank. Then start the engine, warm it up and check the operation of the stove. If the stove is working normally, then there is no air in the system - the work has been done efficiently.

When pouring antifreeze into the cooling system, it is important to prevent the formation of air locks.

Interior heating system of VAZ 2106

The interior heating system of the VAZ 2106 consists of the following elements:

- stove radiator;

- stove tap;

- heater fan electric motor;

- damper and air duct system.

With the help of a stove, a comfortable microclimate is created and maintained in the car interior in winter. Hot coolant passes through the heater radiator and heats it. The radiator is blown by a fan, the air from the street is heated and enters the cabin through an air duct system. The intensity of the air flow is regulated using dampers and changing the fan speed. The stove can operate in two modes - with maximum and minimum power. In the warm season, you can turn off the coolant supply to the stove radiator using a tap.

Diagram of the VAZ 2106 stove: 1 - deflector; 2 — air duct for heating the windshield; 3 — air supply cover; 4 - radiator; 5 — radiator casing; 6 — heater tap rod; 7 - outlet tube; 8 — underwater tube; 9 — heater valve; 10 — air distribution cover; 11 — electric motor of the heater fan; 12 — fan impeller; 13 - additional resistor; 14 — internal ventilation duct; 15 — lever of the air distribution cover; 16 — bracket for control levers; 17 — air supply cover control handle; 18 — heater tap control handle; 19 — draft of the air supply cover

Coolant temperature gauge

The coolant temperature gauge on the VAZ 2106 receives information from a temperature sensor installed in the cylinder head. The arrow moving into the red zone indicates problems in the cooling system and the need to eliminate these problems. If the instrument needle is constantly in the red zone (for example, when the ignition is on), then the temperature sensor has failed. A malfunction of this sensor can also cause the gauge needle to freeze at the beginning of the scale and not move as the engine heats up. In both cases, the sensor must be replaced.

Using the temperature indicator, you can evaluate the performance of the cooling system

Types, design and principle of operation of the fan switch sensor

Currently, three main types of sensors are used:

- Wax - based on a sealed volume filled with wax (ceresite) or other viscous working fluid with a high expansion coefficient;

- Bimetallic (thermobimetallic) - based on a bimetallic plate;

- Non-contact electronic - based on a thermistor (thermistor).

The first two types of devices are electromechanical contact; they include contact groups (one or two) that close and open the electrical circuit of the fan when the motor temperature changes. The electronic sensor does not have a contact group, it is an absolute temperature sensor, the data from it is sent to the electronic control unit, which, among other things, turns the fan on/off. The design and operation of each sensor is described in detail below.

Contact electromechanical sensors are of two types:

- Single-speed - turn the fan on and off only in one temperature range, have a single contact group;

- Two-speed - they turn the fan on and off, and also change its rotation speed in different temperature ranges, have two contact groups that close/open at different temperatures.

Contacts in DVV can be normally closed and normally open. They can operate in four temperature ranges:

- From 82 to 87 degrees;

- From 87 to 92 degrees;

- From 92 (94) to 99 degrees;

- From 104 to 110 degrees.

In domestic cars, sensors for the first three intervals (up to 99 degrees) are more often used; in foreign cars, higher-temperature devices are often found.

DVV, regardless of type, have a standard design. They are based on a closed housing, inside of which there is a sensitive element (wax, bimetallic plate or thermistor), and on the outer surface there is a thread, a hexagon wrench and an electrical connector. The body is made of brass or bronze (for better thermal conductivity), it has the shape of a plug, which is screwed into the radiator through an o-ring (on the “hot” side - at the pipe from the engine block) and is in direct contact with the coolant flow. In some cars, two sensors are installed at once (at the inlet and outlet of the radiator), which provides better control of the cooling system.

Most sensors have an M22x1.5 thread and a 29 mm hexagon wrench, but there are also other options with smaller threads (M14 and M16). The electrical connector can be either blade or pin, open or with a protective plastic skirt. Usually the connector is located directly on the back of the sensor, but there are also sensors with a remote connector on a short cable.

Tuning the VAZ 2106 cooling system

Some VAZ 2106 owners are attempting to modify the cooling system by making changes to the standard design. So, if the car is equipped with a mechanical fan, during long periods of idle time in city traffic jams the coolant begins to boil. This problem is typical for cars equipped with a conventional mechanical fan. The problem can be solved by installing an impeller with a large number of blades or replacing the fan with an electric one.

To increase the efficiency of the cooling system on the VAZ 2106, an additional electric pump is installed

Another option for increasing the efficiency of the VAZ 2106 cooling system is to install a radiator from the VAZ 2121 with a larger heat exchange area. In addition, you can speed up the coolant circulation in the system by installing an additional electric pump. This will have a positive effect not only on heating the interior in winter, but also on cooling antifreeze on hot summer days.

Thus, the cooling system of the VAZ 2106 is quite simple. Any malfunctions can lead to sad consequences for the owner, including major engine repairs. However, even a novice car enthusiast can perform most of the work on diagnosing, repairing and servicing the cooling system.

Where is the fan relay located?

It is located in an additional block.

4 – electric fan relay;

5 – electric fuel pump;

6 – ignition relay.

Relays and fuses may have a different order. Therefore, you need to focus on the color of the wires. The main relay is always located at the bottom. Find the relay that has a thin pink wire with a black stripe coming from it. It comes from the main relay through pin 85. Be careful! Do not confuse this with the red thin wire, which also has a black stripe and extends from the controller. And find a thick white wire with a black stripe (pin 87). This is where the cooling fan relay is located. There is always a fuse next to it. It is an element of the chain.

Control circuit modernization

The cooling fan on the top ten turns on at a temperature of 100-105°C, while the normal operating temperature of the engine is 85-90°C, so the fan turns on when the engine overheats, which naturally has a negative effect.

This problem can be solved in two ways: adjust the switch-on temperature in the “brains” or make a button. We'll focus on the second one. Turning on the fan from the button is very convenient: if you get into a traffic jam, turn it on, drive out, turn it off, and no overheating occurs.

A button for selecting the fan operating mode was installed in the cabin (always off, constantly on, automatically turned on via a sensor) - this “tuning” is not mandatory, but will be a very useful addition.

There will be a large current at relay contacts 87, 30, on the wire from the battery to the fuse and the fan ground, and therefore we must use wires there with a cross-section of at least 2 mm, otherwise the thinner wire will not withstand it and will burn out.

Fan motor

The electric motor is the main component of the device. The VAZ 2107 used two types of engines: ME-271 and ME-272. In terms of characteristics, they are almost identical, but as for the design, it is somewhat different. The ME-271 engine has a stamped housing, i.e., non-separable. It does not require periodic maintenance, but in case of malfunction, it can only be replaced.

Not every fan motor can be disassembled

Design and characteristics of the fan motor

Structurally, the motor consists of:

- housings;

- four permanent magnets glued around the circumference inside the case;

- armatures with winding and collector;

- brush holder with brushes;

- ball bearing;

- support sleeve;

- back cover.

The ME-272 electric motor also does not require maintenance, but unlike the previous model, if necessary, it can be partially disassembled and attempted to be restored. Disassembly is carried out by unscrewing the tightening bolts and removing the back cover.

ME-272 has a collapsible design

In practice, repairing an electric fan is impractical. Firstly, you can only buy used spare parts for it, and secondly, a new device complete with impeller costs no more than 1,500 rubles.

Table: main technical characteristics of the ME-272 electric motor

| Characteristics | Indicators |

| Rated voltage, V | 12 |

| Rated rotation speed, rpm | 2500 |

| Maximum current, A | 14 |

Possible malfunctions in the operation of the electric fan

When the coolant temperature is within critically high limits and the radiator cooling fan does not turn on, it means that there is a problem somewhere. The task before us is to identify it and correct it. Here are some common reasons for fan failure:

- Electric motor failure;

- Broken fan power supply or power sensor;

- The sensor or motor connection contacts have oxidized;

- The electric fan fuse has blown;

- The fan switch-off relay is broken;

- The power sensor has failed;

- The expansion tank valve is faulty.

Replacing the sensor

Replacing the sensor on an injection model is easier than on a carburetor model, since there is no need to drain the coolant. It is enough to place some rag to absorb the spilled coolant. Using a 19 key, the part is unscrewed, removed and a new one is quickly installed. When installing, it is rational to apply sealant to the threads in advance.

To carry out the replacement procedure on a carburetor car, you must first drain the antifreeze (antifreeze) and only then unscrew the sensor with a 30mm wrench and install a new one.

When purchasing temperature sensors and controllers, try to choose branded parts.

The cooling system fan does not turn on on a fuel-injected car. What is the reason.