In this article we will talk about the power steering system and structure, discuss the issue of replacing the power steering pump and modernization.

Those car enthusiasts who have driven a car for a long time without this device, and then switched to a foreign car with this function, will immediately notice a significant difference in control. Power steering helps solve several problems at once: the steering process no longer requires much effort, maneuverability increases and the turning trajectory is reduced.

As it turned out, the presence of a hydraulic booster in a car is a very positive thing, however, like other functions, there comes a time when the amplifier fails. The most common problems are: unpleasant noise when turning the steering wheel, leakage of hydraulic fluid, problems with the amplitude of the steering wheel and a significant deterioration in controllability.

Actions to replace and repair the pump

You can change this unit yourself. It is even possible to replace a failed bearing. In this case, a power steering pump repair kit will come in handy, which can be purchased at any car store.

Before making a decision to carry out repair work, you need to check the presence of fluid in the tank, as well as its compliance with the brand approved for use on this machine. Often, the cause of signs of malfunction is the appearance of air locks in the system. Therefore, if you suspect this, you need to bleed the hydraulics, removing all air pockets. In this case, the performance of the power steering can be completely restored. If, when checking the quality of the working fluid, it is discovered that it does not meet the standard, it must be replaced with a fluid of the required brand. If you decide to repair the power steering pump, you need to prepare a workplace and the necessary tools, as well as materials for the work:

- you need a key for “12”, as well as heads for “14” and “24”;

- you will need a snap ring remover;

- prepare in advance two copper washers, a gasket for the rear casing, two O-rings and an oil seal; they can be replaced by a power steering pump repair kit;

- It is necessary to have a bearing marked “6202” and an outer diameter of 35 mm;

- To pump oil out of the tank you need a large syringe and container;

- clean the workbench and cover it with clean cardboard for disassembling the pump;

- Prepare fine sandpaper and rags for wiping.

How to remove the power steering pump

In order to remove the power steering pump and repair it yourself, you need to perform the following steps.

- Lightly loosen the axle bolt that secures the pump unit to the bracket using the hole provided in the pulley. Completely unscrew the tensioner lock nut and remove the belt.

- Using a syringe, pump out the hydraulic fluid from the reservoir. Turn the steering wheel left and right until it stops so that the oil completely leaves the system, do this several times to completely clean the pipelines.

- Loosen the clamp on the hose that comes from the expansion tank and remove this pipeline.

- Unscrew the bolt that secures the high pressure hose coming from the pump to the system.

- Remove the axial bolt securing the pump to the bracket and insert a screwdriver or a metal rod of suitable diameter in its place to lock the pulley. After this, unscrew the nut that secures the pump pulley.

- Pull the released power steering pump unit up and place it in a specially prepared place. Remove dirt and oil from the unit body.

- Using a puller, remove the bearing retaining ring.

- Unscrew the bolts securing the rear cover. Carefully pry it up with a small screwdriver and remove it, making sure that the rotor blades do not fall out of the housing.

Pull out the blades and place them on pre-prepared numbered pieces of paper so as not to mix anything up during assembly. Attention! Remember the position of the blades when assembled. When installed in the housing, the rounded part of these blades should be turned outward.

Remove the plate and all parts underneath it. Knock out the shaft while gently tapping it with a screwdriver.

- Press the bearing off the pump shaft.

- Replace the unusable bearing with a previously prepared one.

- Check the parts of the pump unit for defects and wear. Clean surfaces from dirt and roughness. Experts say that simple cleaning of internal parts reduces gaps and allows you to extend the operation of this unit without replacing any parts.

Assembly

Reassemble in reverse order. Be sure to replace the oil seal, O-rings and washers with new ones prepared in advance.

If it is difficult for you to repair the power steering pump yourself or you don’t have time for it, then it is possible to replace the power steering pump with a new one. This will significantly reduce repair time.

Also watch the video on the topic:

Part selection

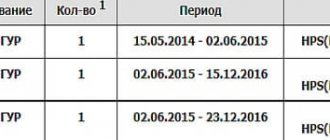

The original catalog number of the power steering pump for Chevrolet Aveo is 96535224. The cost of such a part is 5,000 rubles.

The main signs of a faulty power steering pump

Now you need to find out what are the signs of malfunction and failure of the power steering pump:

- Return forces are necessary for turning, which means the power steering pump does not pump fluid.

- The steering wheel does not return to its normal original position after turning.

- Heavy turning of the steering wheel along with violins at low speed.

- Liquid leakage through the pump itself, if there are cracks.

Purpose and design features of power steering

Oil for power steering

Power steering is designed not only to make it easier for the driver to control the car when maneuvering on the road, but also to soften impacts from unevenness and damaged road surfaces

It is especially important that the hydraulic booster significantly reduces the likelihood of an accident when a tire breaks, primarily on the front wheels. Power steering is a closed hydraulic system, which includes:

- a tank into which hydraulic fluid is filled;

- pressure regulator;

- control spool;

- pump;

- power cylinder.

The main unit of the power steering design is the pump. It ensures the pumping of liquid from the tank into pipelines and its further movement under high pressure along the ring. The type of mechanisms used is gate or plate units. They have a sufficient level of efficiency and little wear on the working surfaces. At the same time, they have a weak link; the bearing may fail, which requires repair of the power steering pump. The operating pressure in pumps of this type, intended for the power steering system, is high, up to a maximum of 150 bar. Such a unit is driven by a belt that simultaneously turns the generator and the pump. The gaps that are set at the factory during assembly must be maintained in the range of 0.005-0.01 mm. If the gap increases and exceeds the permissible value by 0.01 mm, then a drop in pressure in the system at low speeds is possible; this is felt on the steering wheel as an increase in load, or in the language of professionals - a “tight” steering wheel.

Diagnostics

Schematic design of the power steering system

Repair of the power steering begins with its testing. When checking the system, the quality and level of lubricant in the reservoir under the hood are first tested. If the oil has not reached the end of its service life, it will not have a waste smell, and dark shades of the liquid are not allowed. Ideally, the power steering lubricant should be transparent, and if its color is gray or brown, then the fluid must be replaced. Service manuals for modern cars indicate that oil is filled once, but in practice, lack of maintenance will lead to pump failure.

To diagnose the operability of the system, the power unit is started. It is necessary to determine by ear the presence of noise in the area where the pumping device is located. If the mechanism functions without interruption, there will be no extraneous sounds. The pump itself is used to pump working fluid into the mechanism.

Further verification steps are performed as follows:

- The steering wheel turns to the right and left until the end. If the steering wheel turns and this is accompanied by a howling or buzzing sound in the pump area, the sound intensifies as the angle of rotation increases, the mechanism is broken. These signs may indicate wear on the shaft bearing device. If this part breaks, this leads to a violation of the tightness of the amplifier system, then foam forms in the expansion tank. The liquid may bubble and overflow from the reservoir; if this problem occurs, it will usually have a brown tint.

- When turning the steering wheel, pay attention to the idle speed of the engine. If the pump unit fails, then when you turn the steering wheel, the engine speed will drop. If additional effort is required, the problem may be wear of the ball joints or failure of the rotary bearing elements. We are talking about parts located on the front pillars. Failure of the pumping mechanism can be indicated by a change in the forces on the steering wheel with increasing engine speed.

- If vibration or wobbling occurs when you turn the steering wheel, the problem may be that the pump drive belt is slipping. In particular, if it increases when the steering wheel is rotated to a greater angle. Perhaps the strap itself is worn out or the bearing element is defective. With such a problem, a squeal will appear.

- The lubricant in the reservoir may be of high quality, and the fluid level may be within normal limits. At the same time, no extraneous sounds appear in the pump area. With such symptoms, the steering wheel could become stiff if the bypass valve is jammed or sticks.

- Diagnostics of the pressure switching mechanism is performed in the case when there is a difference in the applied force when turning the steering wheel. In particular, when the steering wheel is turned in different directions. The pressure switch mechanism may be worn. The presence of defects can lead to the appearance of intermittent forces.

After installing new wide tires on a vehicle, stress may be placed on the steering wheel.

The VseSam channel spoke in detail about the procedure for diagnosing the hydraulic power steering system on a car.

Warning

Audi S8 Logbook AUDI and Ceramic brakes

I must say that power steering repair is a very responsible matter. After all, your life and the lives of your passengers may depend on the quality of the steering. Therefore, at the beginning of this article we would like to advise you to carry out repairs from a competent specialist. Self-repair is allowed only if you have extensive experience. The recommendations in this article are of a general nature and should not be taken as a strict guide to action. Power steering models for cars and trucks are different. And each driver is personally responsible for their own repairs.

The first stage of repair is diagnostics.

First, it would be a good idea to inspect the hoses (the tubes that connect the parts of the power steering system). If the hoses leak, you need to have them repaired by specialists. It is extremely difficult to restore them with your own hands.

To inspect the power steering pump, we need to remove it.

Power steering pump

KIA Ceed SW Black mother of pearl Logbook Steering rack bulkhead Kia Sid 2008

We can say that the power steering pump is its heart. After all, it is he who pumps the fluid, with the help of which the steering is facilitated. The pump contains rubber gaskets, seals, bearings and balls and much more. All this can become unusable over time.

More serious damage may be associated with pistons that may not work correctly. There may be various reasons for this. From the usual play of some parts to the entry of air into the power steering system. As with hydraulic brakes, air causes the system to malfunction. In this case, bleeding the system will help.

If you suspect that it is necessary to change gaskets and other consumables, then it is advisable to find out the number of the repair kit you need.

Some car enthusiasts prefer to purchase a hydraulic booster from a disassembly site and use parts from it. This option sometimes pays off in case of serious breakdowns.

Power Steering Removal Procedure

- Clear the pump and hoses of debris. This must be done to prevent dirt from getting into the cavities of the system when disconnecting the hoses.

- Drain the fluid from the power steering reservoir. This can be done using a special syringe.

- Take a strong 6mm hexagon and unscrew the screws of the steering shaft coupling. Don't forget to mark its position in relation to the power steering shaft. We use a pry bar to move the coupling from the splines of the power steering shaft to the steering shaft.

- We remove the steering rods using pullers from the bipod.

- Remove the left wheel (after jacking it up).

- Find the pump mounting bolt. For example, on Audi cars it is located under the radiator fan. There is an adjusting bolt under the mounting bolt. It performs the same role as the alternator belt tension adjustment bolt. Only in this case the tension of the power steering belt is adjusted. So if you need to tighten this belt, use this bolt. Also on some cars there is another bolt that secures the power steering pump to the side member. Be careful not to drop the gearbox on your foot when removing the bolts.

- Now you can disconnect the hoses (pipes). Place some kind of container under the fittings that secure them. Because liquid will pour out of the hoses.

- Let's seal the hose fittings.

- Wash and clean the power steering again before disassembling it.

So, you have removed the power steering pump

On some vehicles, the pump can be removed without removing the pipes.

Pump disassembly

Before disassembling the power steering pump, try to find its diagram and disassembly and repair instructions. Since different pumps have different designs. Some are almost completely understandable. It’s better not to disassemble others.

Let's look at an example of disassembling a pump from an old Audi 80 (1988). In this case, the list of actions below is carried out in order to change the rubber seals and seals.

It is advisable to put each of the parts on a separate A4 sheet, putting down a serial number. This will help us later put everything in the right order.

- After we have washed the pump, we remove its pulley, which is secured with 3 bolts.

- The pump is made of two halves, which are attached to each other with 4 bolts. Unscrew the bolts. Thus, we disassemble the pump into two halves.

- We inspect the “halves” for wear on the rubber seals. All worn rubber parts must be replaced. 026 198 049 A is the repair kit number for the pump in question.

- We remove the plate, which in appearance resembles a fungus.

- We remove the retaining ring and then the rotor. At the same time, be careful that the vanes (they look like plates) do not fall out of the rotor.

- Now you can remove the pump shaft.

- We have an oil seal in front of us. Let's take it off.

- Washing pump parts.

- New spare parts (including oil seals and rubber bands) that will be installed must first be lubricated with new power steering fluid.

We assemble everything in reverse order. We connect the pipes.

Bleeding the system. We pour new fluid into the reservoir and turn the pump by the pulley by hand without putting on the belt. The goal is to fill the system with new fluid and expel air.

Experts say that replacing oil seals does not always solve the problem. If the rotor parts are worn out, then more serious professional repairs are required. In some cases, you simply need to replace the pump.

This article provided general information with some examples. Power steering breakdowns can be very different and it is almost impossible to cover them in one article. We hope these recommendations help some of you!

After the repair, we advise you to undergo diagnostics from a specialist, since the steering is not a car system that you can joke with...

Power steering repair at Riotechservice

Before starting power steering restoration work, it is necessary to accurately determine the cause of the problem. The correct diagnosis of the system will be carried out by our specialist, who has been working with Mercedes steering systems for many years now. For example, the symptoms of a faulty rack and a faulty pump are similar; it is possible to determine exactly what can be repaired by a qualified specialist who has diagnostic equipment at his disposal.

Further, if we are talking about repairing the rack, then the rack is disassembled, damaged, washed, and a repair kit is installed. If the pump is being repaired, the procedure is similar: disassembly, cleaning, replacement, assembly. In case of leaking pipes and hoses, the damaged element is replaced.

Next, new fluid is poured in, the system is pumped, and a comprehensive check of the performance of the power steering on the car is carried out.

What does power steering consist of?

In new cars, power steering is gradually losing competition to more modern electric power steering.

However, it continues to be installed, including in many fairly modern car models, so it is important to know the rules for operating power steering and its main components

The main components of power steering are: pump, distributor, reservoir, hoses, drive belt and hydraulic cylinder. The tank contains liquid, which can also be considered one of the main components of the system.

Please note: Recently, it has become increasingly rare to come across designs where the drive belt is a separate component of the power steering system. Nowadays, more and more often, the power steering pump is activated by one of the service belts of the outboard equipment.

Replacing the power steering pump

First you need to remove the air filter with the box. When the replacement is not carried out indoors, it is better to temporarily close the air suction pipe. Then you need to remove the belt from the power steering. Before doing this, it is important to remember the tension of the belt or even mark it. When removing the belt, you need to release the tension roller, and then use it to loosen the belt. Afterwards, one protective bolt is removed, and the other is released to move the protection to the side. At the same time, you can change the tension rollers themselves. Next, we de-energize the car and remove the terminals from the battery. Then remove the sensor terminals from the power steering and unscrew the return hoses. It is worth preparing dishes in advance for the oil that will flow from the pipes. Now, we move from the pump along the high pressure pipe. We remove the bolt at 10. We shake it from side to side, you should do this carefully, because the tip of the tube is aluminum and can deteriorate. We take a pre-prepared container to drain the old power steering fluid. We remove the hidden bolts behind the belt pulley by turning the pulley one at a time. We remove the pump.

Pump replacement process

You need to put the pump in place in the same sequence, but there are some features:

Place a sock over the high-pressure tube so that it fits well and does not come into contact with anything. Remember that the low pressure inlet must be sealed with a transport cap at this time. Next, lightly bolt the pump onto the exhaust manifold side. Mark the location of the pipe relative to the body. Reinstall the pump. Fill it with power steering fluid. Insert all tubes back and press them with clamps, check for any contact. We fasten the belt and set the tension according to the markings. We are bleeding the system. The main thing is not to start the engine, as during the process the fluid will fly out of the power steering. You should start by lightly warming up the tank and channels with a technical hair dryer. You can also slightly warm up the transmission fluid itself. Lower the return hose into the container. We pour the liquid into the tank and turn the starter, which turns the pump itself, and it is already pumping the liquid. Then through the return pipe, it goes into the container. When to stop pumping can be determined by the color of the drained liquid. Then we connect the hose to the reservoir and again turn the starter, simultaneously turning the steering wheel in different directions by 25% of the revolution. Then again add power steering fluid to the reservoir to the required “MAX” level. We are in no hurry to start the engine. Turn the steering wheel 5 times all the way left and right. We make sure that there is no air leakage and pour the liquid in time. Open the air intake pipe and start the car. We determine by ear whether there are any extraneous noises or beats. At the same time, turn the steering wheel and hold the extreme points on the stop for several seconds. Again add liquid to the desired level. We attach back the manifold protective clamp and the box with the air filter, and the replacement of the power steering pump is complete.

Checking the power steering pump

The first step is to identify by external signs what the breakdown of the pump is. Here are some common problems:

When the seals are worn out, there should be a fluid leak and its level in the tank will be reduced. It is worth paying attention to the pipes connected to the pump: their fittings must be dry. If you notice the steering wheel sticking or erratic forces appear, air may have entered the device, which ultimately created air locks. To correct the situation, you need to pump the unit by repeatedly rotating the steering wheel all the way in both directions. It is important that the engine is turned off at this point. Traffic jams can also occur due to clogged distributor valves. It is necessary to wash all parts of the pump assembly. There is noise, which means the issue is worn out bearings, but it is better to make sure by pulling the pump drive pulley and the shaft in opposite directions, while removing the belt. The play can be easily felt by touch. Also, the appearance of noise may be due to scuffing of the ends of the elements and plates of the pump stator. When the bearings are worn out, the seals will not work for long and will quickly fail. Bearings can wear out not only due to dirty fluid, but also due to an overtightened pulley drive belt.

If a malfunction is identified, then do not put off repairing or replacing the pump until later. Changing the entire hydraulic booster is difficult, because you need to remove the engine and disassemble the front chassis of the car. Therefore, in order to avoid mistakes, let’s consider how to replace the power steering pump?

Leaks on the power steering

In foreign cars, replacing the power steering pump is more difficult, since the mechanisms are more complicated with new elements. In this case, it would be appropriate to visit a service station.

What usually breaks

Although the hydraulic booster of such a reliable car as a Mercedes is a durable system, it can also fail due to improper operation or lack of proper maintenance.

The majority of problems are associated with loss of system tightness. The steering rack itself, as well as the pipes, hoses and the power steering pump itself can leak. Depressurization can occur due to corrosion of metal lines, or as a result of mechanical impact on them (for example, during unqualified repairs or an accident). As for the rack, over time its seals wear out and begin to leak oil.

The second most frequently reported problem with our service is the problem with the power steering pump. If you operate it for a long time without oil or with the wrong type of fluid, then repair is guaranteed. In some particularly advanced cases, the pump will have to be changed altogether. Therefore, when the power steering fluid level drops, you need to find the leak as quickly as possible and restore the tightness of the system. It will be much cheaper than replacing the pump.