3.8/5 — (42 votes)

The cooling system of the VAZ 2107 allows the engine to operate at normal temperature conditions. Without it, the metal around the combustion chambers would overheat greatly. The consequence of this is early ignition of the mixture and the appearance of detonation. In addition, it is even possible to destroy the metal. The sevens have a dual-circuit system, it is called that because it has two cooling circles - large and small. And during engine operation, liquid circulates through them.

Heater device VAZ 2107

The design of the VAZ-2107 stove includes the following components:

- a housing with dampers installed in it;

- stove radiator;

- fan with electric motor;

- air ducts;

- damper control mechanism.

The interior heating system does not use electronic components or complex components, so the stove is reliable and easy to operate and maintain.

The source of heat in the heating system of the VAZ-2107 interior is the liquid from the power plant cooling system. Heat transfer is carried out thanks to a heat exchanger - a radiator, which is installed in the stove body under the front panel and connected to the cooling system. The design provides for shutting off the supply of heated antifreeze to the heater radiator by means of a special tap cut into the coolant supply pipe.

From the body, the air flow is distributed in several directions - to the windshield, to the center of the cabin, to the side windows and to the footwell area. To supply air flow to the windshield, there is an air duct with an outlet at the top of the front panel. Air is supplied to the side windows through air ducts running inside the panel. Deflectors with dampers are installed at their ends, which more effectively directs the air flow. The same deflectors are located on the front panel in the central part, through which air is supplied to the center of the cabin. Heated air enters the leg area directly from the body.

The VAZ-2107 stove provides for the forced creation of air flow. And it is done using a fan driven by an electric motor, located in the stove housing under the radiator. The electric motor operates in two modes - with different rotation speeds.

The heater is equipped with three dampers to distribute air flows. The first of them is the air supply damper. With its help, the air supply into the cabin from the environment is regulated. The second damper distributes the air flow along the necessary air ducts - either to the windshield area, or to the central and side deflectors. The third damper regulates the air supply to the leg area. The first two dampers are controlled using the sliders of the control mechanism, the third is controlled by a separate lever located on the side of the center console near the pedal assembly.

Air is supplied into the cabin from the street through air intakes on the hood. To prevent water from entering the cabin (when driving in the rain), the air flow that has passed through the air intakes first enters a special box where the water is separated. And only after that it goes to the air supply damper.

Cooling design of car drive

The hydraulic cooling system of a car is a group of devices and pipelines connecting them, as well as channels in the internal combustion engine block, which allow the heat received from the parts to be removed from the parts during the operation of the mechanisms. Structure of the cooling system in the VAZ-2107:

- radiator;

- expansion tank;

- water pump;

- thermostat;

- fan.

The main task of the cooling structure is to maintain the optimal temperature when the engine is running, regardless of operating conditions, by removing part of the heat produced in it through the coolant. Cars use an intermediate cooling layout:

- heat from the engine;

- coolant;

- heat exchanger, such as a radiator.

Consequently, the cooling design prevents overheating of the engine and a decrease in temperature below the optimal value, which ensures stable operation of the motor, good lubrication of rubbing parts, and reduction of gaps when parts come into contact. In the 2107 car model with an injector, a heated throttle body is installed.

Engine cooling system. Design and principle of operation

The heat received from the engine can be used to heat the car. This task is implemented by a second heat exchanger of similar design, in which the process opposite to the cooling radiator occurs. Heated air from the heat exchanger is supplied to the vehicle interior. The structure of the VAZ-2107 carburetor engine cooling system consists of two circuits:

- circulation of coolant in a small circle inside the engine;

- the contour of a large circle, which includes the radiator and expansion tank.

Thermal comfort of a modern engine requires cooling consisting of two independent circuits - for the block and the cylinder head. This allows the cylinders to reach high temperatures to improve their lubrication, since the oil viscosity is lower and frictional resistance is also reduced. The temperature of the block head also decreases, which protects the engine from detonation combustion of fuel.

A modern view of regulating the temperature conditions of the engine using the so-called smart cooling system 21074 with an injector includes:

- Radiator for the cooling system of a carburetor engine VAZ 2108, 2109, 21099

- electronic control of the pump regardless of engine operation;

- fan with adjustable variable speed;

- temperature sensors placed in the cylinder head gasket to monitor engine operating conditions;

- multifunctional valve instead of a traditional thermostat.

Such a device quickly and flexibly regulates the fluid temperature in the current operating mode of the engine. Its maintenance consists of the following operations:

- control and periodic replenishment of the amount of refrigerant;

- checking the tightness of the hydraulic system;

- coolant suitability test;

- periodic replacement of antifreeze;

- monitoring the operation of sensors and indicators.

DESCRIPTION OF PIPES VAZ 21073

What a set of pipes for a VAZ 2107 with an injection engine looks like is shown in the figure below:

RICE. 1. A set of rubber pipes for the VAZ 21073 “injector”.

- Outlet pipe

- Inlet pipe,

- Water pump coupling,

- Bypass pipe.

1. Outlet pipe - popularly called the lower radiator pipe. Catalog number 2105-1303010.

The lower pipe is designed to connect the lower part of the cooling radiator to the thermostat. The pipe removes liquid from the radiator and supplies it to the thermostat. It is also used on VAZ “classic” cars with carburetor engines.

2. Inlet pipe – popularly called the upper radiator pipe. Catalog number 2123-1303025. It supplies coolant to the upper part of the radiator of the engine cooling system. It can also be used as an outlet pipe on a Niva - Chevrolet.

3.Water pump coupling - installed between the thermostat and the pump. Its catalog number is 2103 - 1803092. It supplies coolant from the thermostat to the water pump. It is also used in all VAZ “classic” engines. People also call him “shorty”.

4. Bypass pipe - connects the top of the thermostat and the exhaust pipe of the engine cooling jacket. Catalog number 2101 – 1303090. It is also called “corner”.

LOCATION OF PIPES VAZ 2107

Next, we will look at where and how all these pipes are located using the example of a fragment of a VAZ 2107 engine:

RICE. 2. VAZ 2107 engine cooling system.

1. Outlet pipe. 2. Supply pipe. 3. Water pump coupling 4. Overflow pipe. 5. Hose for supplying hot fluid to the heater radiator. 6. Expansion tank. 7. Engine cooling jacket. 8. Radiator cap. 9. Engine cooling radiator. 10. Fan casing (diffuser). 11. Radiator cooling fan. 12. Lower radiator support. 13. Water pump pulley. 14. Liquid outlet pipe from the heater radiator. 15. Water pump belt. 16. Water pump. 17. Exhaust pipe, engine cooling jackets. 18. Thermostat. The arrows here indicate the direction of movement of the coolant.

REASONS FOR MALFUNCTION OF RADIATOR PIPES IN VAZ 2107

The cooling system pipes are replaced when it is discovered that the coolant level is decreasing over time. If you find this in your car, then carefully inspect all the pipes. Sometimes it happens that one of the clamps is loose, and simply tightening it is enough. In some cases, the leak appears in the cooling radiator itself.

Then you will have to change it if you have an aluminum radiator, and if you have a copper radiator, then soldering the radiator will save the situation. But, since we have a different topic today, we will consider the case when liquid leaks due to a defect in the rubber pipes of the cooling system.

Most often, cracks appear on the rubber at the places where they are secured with clamps. This can be detected when leaks appear. It is necessary to slightly bend the pipe in this place and then this crack will immediately become visible. As an example, I will give you the photo below:

RICE. 3. A crack in the pipe where it is secured with a clamp.

Sometimes they install pipes that are not quite suitable in shape and bends. Then either stress or deformation occurs in the material. It is in places of deformation that cracks most often form (or even the rubber breaks off completely) and liquid begins to flow out through them.

It also happens that the pipes burst altogether, as shown in the figure below:

RICE. 4. Broken main radiator pipe.

REPLACING RADIATOR PIPES VAZ 21073

Before replacing the VAZ 21073 pipes, you need to remove the plugs from the radiator and expansion tank. Let's prepare a hose of a suitable diameter and some kind of container, maybe an old canister, but not less than 10 liters. According to the passport, the cooling system of the VAZ 2107 contains 9 liters of liquid.

Then we find the engine drain valve. It is located at the bottom of the block. We put one end of the hose on the fitting of this tap. We insert the other end into a container, which we prudently placed below the engine level. If we install it anywhere, it may turn out to be higher than the engine level. In this case, the cooling system fluid will not leak from the engine.

Replacing the water pump

The pump (water pump) of the VAZ 21014 ensures the circulation of fluid throughout the system, and it is this that most often fails. A faulty water pump is indicated by traces of coolant leakage, as well as a characteristic hum when the engine is running. If the unit is faulty, it will need to be replaced.

Replacing the pump on a VAZ 21074 yourself will require the following tools:

- ratchet, large and small;

- open-end wrench 13;

- extension;

- socket heads for 10 and 13;

- container for draining liquid;

- flat screwdriver.

The procedure for replacing the pump in the VAZ 2107 injector engine cooling system will be as follows:

- The plug on the left side of the engine block is unscrewed and the coolant is drained into a specially prepared container. If you need to completely replace the coolant, then the drain plug is unscrewed on the cooling radiator too.

- The generator belt is removed by unscrewing the tension nut.

- Using a screwdriver, loosen the hose clamp that fits the pump. After this, the pipe is removed with little effort.

- Next, use a ratchet handle with a 10mm socket to unscrew and remove the thin coolant supply tube. You should act carefully so as not to accidentally damage the tube.

- The longest bolt securing the pump body, located on top, is unscrewed. After unscrewing, the bolt must be removed, sometimes you have to use penetrating lubricant to do this.

- The two remaining bolts at the bottom are unscrewed. An open-end wrench is best suited for this.

- The pump along with the housing is carefully removed and pulled out. The seat needs to be thoroughly cleaned.

- The new pump is put into place in the reverse order. In this case, it is advisable to replace all gaskets. After the pump has been successfully replaced, coolant is poured into the system.

- At the end of the work, you will need to bleed the system. To do this, disconnect the hose from the intake manifold.

Replacing a pump on a VAZ 2107 injector usually takes no more than an hour.

Movement is life, but movement is warmth. Try rubbing your palms together and see for yourself. Heat is the final transformation of all energies into each other. In the human body, mutual transformations of proteins, fats, and carbohydrates occur, which as a result decompose through multi-stage enzymatic oxidation with the release of heat. In the heart of a car engine, chemical transformations of fuel into exhaust gases and water also occur, releasing a large amount of energy, which is converted into mechanical energy, and some is dissipated as heat. Moreover, this heat must be purposefully collected and removed, no matter how much of it is generated. This is precisely what the cooling system of the VAZ 2107 serves for.

If we remember that the efficiency of a gasoline engine is ideally 25%, and in city traffic jams - about 7%, this means that out of a 40 liters of a fully filled VAZ 2107 tank in city conditions, you spent only three liters on moving the car! How many? We repeat, three liters, we were not mistaken. Where did the other thirty-seven go? That's right, they burned in a useless fire, polluting the air and wearing out the car. The carburetor and injector improve efficiency, but not much. The cooling system of the VAZ 2107 is responsible for removing this heat.

The engine cooling system diagram is as follows:

Structure of the main parts of the system: (in the picture there is a VAZ 2106 engine on which a carburetor is installed).

- The actual jacket of the engine cooling system (7), passages and holes in the cylinder block, with its exhaust pipe (4).

- The cooling system pump, or pump (16), during the operation of which coolant (antifreeze, antifreeze) circulates. Its structure is similar to an impeller. It is in a single connection with the generator, a single belt (15).

- Thermostat (18) separates the small (when the engine is cold) and large (when the engine is hot) fluid circulation circles. The thermostat device is simple; its task is to open or close the liquid bypass valve.

- Cooling system hoses (discharging cooled liquid from the radiator and supplying hot liquid to the radiator, thermostat hoses, hoses to the pump, etc.).

- The radiator is the main heat exchanger with a cooling function. The design of the radiator can be different; now aluminum is used, but a copper radiator is much more efficient, but less resistant.

- Radiator fan, commonly known as “Carlson” (11), which turns on if necessary when the engine temperature rises.

- Expansion tank available for visual control of fluid quality and topping up. A durable hose runs from the expansion tank to the radiator neck. Some people think it's a coolant hose, but that's wrong. Its function is simply to keep the radiator filled.

Read also: Jaguar alarm valet mode

The complete cooling system circuit includes additional parts such as drain plugs, fan switch, fan fuse and others. Let us remind you that on the VAZ 2107 the electrical circuit is such that the fan and sound signal fuse are one common, 10 A. This means that if you beep too much when the fan is running (and this can be easily noticed by the slight noise and increased charge consumption) , then you risk being left with an overheated engine.

The total volume of the cooling system on the VAZ 2107 is 9.85 liters. Inexperienced drivers sometimes find it impossible to fill more than 3-5 liters; this is hampered by air pockets that need to be removed. The volume of plugs can be half the volume of the entire system! The container is designed for a completely filled jacket, hoses, radiator, and expansion tank.

In the cooling system, the freezing point of antifreeze should not be higher than -40 degrees Celsius.

People often ask: injector and carburetor - is there a difference in the cooling system? Yes, there is, but it is insignificant.

The top picture is the carburetor, the bottom picture is the engine on which the injector is installed. The difference is in the installation of the coolant temperature control system sensor (5) if an injector is installed, as well as the presence of a throttle body heating unit (4), in the figure on the right (injector). The engine on which the carburetor is installed has a simpler cooling system.

Flushing the cooling system is recommended with special liquids, but you can prepare them yourself using the example of a mixture for the YaMZ 236 engine (the YaMZ 236 diesel engine is installed on domestic KAMAZ and Ural trucks).

It contains technical hydrochloric acid 30%, PB-5 inhibitor, technical methenamine, defoamer, water. Since the YaMZ 236 engine is a diesel engine that works well at low speeds, these components flush the system well.

Simplified flushing of the cooling system includes clean water with the addition of phosphoric acid, which effectively removes scale both in YaMZ 236 and in “classic” engines.

On a Zhiguli you can buy 10 liters of Coca-Cola and clean the cooling system until the engine is completely warmed up, the main thing is to release the gas from the drink. Since the volume of the YaMZ-236 cooling system is much larger, a lot of Coca-Cola will also be consumed

The operation of the internal combustion engine of any car is associated with high temperatures. The internal combustion engine heats up during the combustion of the fuel-air mixture in the cylinders and as a result of friction of its elements. The cooling system helps to avoid overheating of the power unit.

VAZ 2107 fan sensor malfunctions and performance check

It is easy to find out whether the VAZ 2107 fan switch sensor is working properly. The fan motor is quite noisy; you can hear it turning on even from inside the cabin. If the temperature gauge shows more than 90 degrees, but the fan does not turn on, you should check the sensor.

First you need to localize the source of the problem. If the antifreeze is hotter than 90 degrees, but the bottom of the radiator remains cold, the problem is the thermostat, not the fan. It is not possible to replace the thermostat on the road. To get out of the situation, you can increase the cooling by fully opening the heater damper and turning on its fan. Of course, such a solution will be extremely uncomfortable in the warm season, but, if you’re lucky, it will make it possible to get to the repair site without stopping. If this is not enough, you will have to make stops along the way to allow the engine to cool.

Another reason for overheating is low coolant level. In this case, it is necessary to quickly find and eliminate the leak and add antifreeze to the system. If it is not there, you can add water to the system. But then, as soon as possible, it is necessary to drain the liquid from the cooling system and add antifreeze.

If the radiator is hot and the fan does not start, you need to try to start the fan by short-circuiting the two wires going to the sensor contacts. If the cause of the breakdown is the latter, the fan should start working.

If the sensor is not installed on the car, you can check it using a thermometer and ohmmeter. You need to place the part of the sensor that is inserted into the radiator into water and heat it to about 90 degrees. The sensor should turn on when the water heats up to no more than 92 degrees. The switching on (closure of the sensor contacts) is indicated by the absence of resistance between the sensor terminals.

Cooling radiator and heaters

Two more elements that make up the cooling system of the VAZ-2107. Injector or carburetor - it doesn’t matter what is in the fuel supply system. The difference between these two radiators is only in size and shape. There is also one small detail - a pipe coming from the expansion tank is connected to the main radiator. Consequently, it has two pipes at the inlet. Both radiators have fans. One helps heat the interior, and the second allows for additional airflow for effective cooling.

From this we can conclude that if the fan on the main radiator fails, you need to open the heater tap and turn on the interior airflow. In the summer, of course, it is not very convenient; the effectiveness of this action is much lower, but it allows you to avoid boiling of the liquid in the system. Therefore, the likelihood of engine damage is extremely low.

Signs of air in the cooling system

The presence of an air lock in the engine cooling system causes serious consequences, including overheating of the engine and its failure. The presence of a plug will immediately manifest itself in the form of uneven heating of the engine. The air in the system restricts the passage of coolant in a large or small circle. The fact that the plug is present helps reduce the heat exchange between the engine and the antifreeze, so there will be an increase in temperature above the maximum level, which is unacceptable.

The plug can also prevent the passage of fluid to the heater core, so driving the car in winter will be cold. Heated antifreeze does not pass to the heater radiator through the cooling system of the VAZ 2107, so when it is turned on, a stream of cold air will blow into the cabin.

It is contraindicated to operate the machine in this condition until air has been removed from the system. To remove it, several different methods are known, which are described in detail in the material.

Reasons for the formation of air pockets

The formation of a plug in the cooling system is also called airing. This phenomenon occurs in the pipes and hoses, whereby their throughput capacity is lost, thereby causing overheating of the engine and boiling of the coolant. Before you remove the plug from the system, you will need to understand the reasons for its occurrence.

It is necessary to identify the causes of airing in order to prevent its reoccurrence. So, let's look at the reasons for airing the cooling system of the VAZ 2107 injector:

- Incorrect coolant replacement. This is a common reason why a vehicle owner is faced with the problem of a traffic jam in the system. If the reason is improper replacement of the coolant, then after releasing the air from the system, the problem will be solved.

- Air jams also form due to depressurization of the system. You can detect such defects yourself by checking each pipe connection. If there are coolant leaks, the clamps or pipes should be replaced if there are signs of wear. Removing the plug is possible only after the causes have been eliminated, that is, you first need to tighten all connections or replace the pipes.

Purpose of the thermostat on the VAZ 2106

The thermostat must control the degree of heating of the coolant and react in a timely manner when the antifreeze temperature becomes too high or, conversely, too low.

The thermostat maintains the temperature of the coolant in the engine cooling system in the desired range

The device can direct coolant through either a small or large cooling circle, thereby preventing the engine from overheating, or, conversely, helping it quickly warm up after a long period of inactivity. All this makes the thermostat the most important element of the VAZ 2106 cooling system.

Thermostat location

The thermostat in the VAZ 2106 is located to the right of the engine, where the pipes for discharging coolant from the main radiator are located. To see the thermostat, simply open the hood of the car. The convenient location of this part is a big plus when it becomes necessary to replace it.

To gain access to the VAZ 2106 thermostat, simply open the hood

Principle of operation

As mentioned above, the main task of the thermostat is to maintain the engine temperature within specified limits. When the engine needs to warm up, the thermostat blocks the main radiator until the engine reaches the optimal temperature. This simple measure can significantly extend the life of the engine and reduce wear on its components. The thermostat has a master valve. When the coolant reaches a temperature of 70 °C, the valve opens (it should be noted here that the opening temperature of the main valve can be higher - up to 90 °C, and this depends both on the design of the thermostat and on the thermal filler that is in it used).

Essentially, a thermostat is a regular valve that responds to changes in antifreeze temperature

The second important element of the thermostat is a special compression cylinder made of brass, inside of which there is a small piece of technical wax. When the antifreeze in the system reaches 80 °C, the wax in the cylinder melts. As it expands, it presses on the long rod connected to the main thermostat valve. The rod extends from the cylinder and opens the valve. And when the antifreeze cools, the wax in the cylinder begins to harden, and its expansion coefficient decreases. As a result, the pressure on the rod weakens and the thermostatic valve closes.

By opening the valve here we mean moving its leaf by only 0.1 mm. This is the initial opening value, which consistently increases by 0.1 mm as the antifreeze temperature rises by two to three degrees. When the coolant temperature rises by 20 °C, the thermostat valve opens fully. The full opening temperature can vary from 90 to 102 °C depending on the manufacturer and design of the thermostat.

Method two - electric

If you have a new car, an injector and an electric fan are installed, is it worth spoiling it with a forced impeller? It would be somewhat more reasonable to leave the electric fan, but make a backup way to turn it on using a button. Purchase several items and materials from the store:

- New sensor (if the old one has become unusable).

- Electromagnetic relay with normally open contacts.

- Red wire with a cross section of 0.75 square meters. mm.

- A button for installation in the dashboard of a VAZ 2107 (preferably backlit).

- Heat shrink insulation.

- Female connectors and relay socket.

The connection diagram is shown in the photo. First of all, turn off the fan and change the sensor for turning it on. Then you assemble the circuit.

Please note that newer vehicles use sensors that can handle very high currents. But despite this, they still burn

Sudden loads still quickly damage it. What to do? There is only one way out - to reduce the current at the sensor terminals. To do this, introduce an electromagnetic relay into the circuit. Now the chance of sensor failure is reduced. But the chance of relay failure becomes higher. True, it will be easier to change it.

Install a button to force the fan on in the dashboard and stretch two wires from it - one can be connected directly to ground, and the second to the sensor output. It turns out that your button and sensor contacts are connected in parallel. Therefore, if the sensor fails, you can turn on the electromagnetic relay with a button.

System connections

These are pipes made of durable rubber. There is reinforcement inside, which improves their parameters. They serve to circulate fluid along the circuits. The pipes are fastened using worm-type metal clamps. But this type of fastener has a big drawback. If you tighten it loosely, the liquid will gradually come out of the pipes and a leak will appear. If you tighten too much, the clamp or pipe may break.

Therefore, when tightening, attention should be paid to physical force. And do not forget that the service life of the pipes with a mileage of 30,000 kilometers per year is not very long

There is a need for replacement once every 2-2.5 years. By this time, temperature changes and exposure to moisture and dust lead to the surface of the pipes becoming covered with microcracks and becoming brittle. Rubber, no matter how high quality it is, wears out and breaks down. In addition, a leak may occur and, as a result, insufficient engine cooling.

Lack of fluid and consequences

The disadvantage of antifreeze is rapid evaporation; you also have to solve the problem of leakage. It happens that liquid can be seen leaking under the car. There are also cases when it goes into the car interior, this indicates a breakdown of the heater taps, they need to be replaced.

In addition, smoke may be emitted from the exhaust pipe. This occurs due to a faulty cylinder head gasket. When antifreeze boils, you need to fix the problem in time ; you need to drain it and change it.

If you do not give significance to the signs that appear and continue to move on, then the consequences can be very sad. If the fluid disappears from the tank, the motor may overheat when the mark reaches the minimum value.

Radiator fan device

A car fan for an internal combustion engine cooling system has at least four blades, which are mounted on a single common pulley. The blades are located at a certain angle relative to the plane of rotation. This is done for the most efficient intake and subsequent supply of air. There are no strictly established patterns in the design of the fan, although the most common design has become one that includes an impeller with 8 blades.

Drive types

The radiator fan may differ in drive design. Existing types are divided into:

- mechanical;

- hydromechanical;

- electric;

Mechanical drive

Such a drive is a design that is essentially a permanent drive from the crankshaft of the power plant. This drive is the simplest and is implemented using a belt drive. The main disadvantage of a mechanical drive is the power taken from the unit, which is spent to ensure constant rotation of the fan. Today, mechanical drives are practically not used in cooling systems on civilian cars.

Hydromechanical drive

This type of drive is a solution that is implemented by installing a viscous coupling (viscous coupling) or a hydraulic coupling. These couplings are constantly driven by the engine crankshaft. In order to keep the fan blades intact when the internal combustion engine is operating at maximum speed and high crankshaft rotation speed, the fan impeller is connected to the pulley via a hydraulic or viscous coupling. There is also a definition of a thermal coupling, which depends on the design features.

The clutch may become partially or completely blocked due to the increasing temperature of the fluid with which it is filled. Silicone is such a filling fluid. The increase in temperature occurs as a result of increased crankshaft speed and increased load on the engine. The clutch is blocked and the cooling fan begins to rotate. A hydraulic coupling differs in design from a viscous coupling and is blocked depending on the amount of oil in the coupling.

It turns out that the viscous coupling is often filled with silicone gel, which has the ability to change its properties under the influence of temperature. Silicone oil is poured into the coupling in an amount of about 30 or 50 ml. Clutch blocking affects the fan rotation speed regardless of the engine crankshaft speed. If the power unit reaches high speed mode, then the clutch slows down the rotation of the impeller, thereby protecting the fan from destruction at high rotation speeds. The main task of all types of couplings, which differ in operating principles and design features, is to maintain the fan rotation speed within strictly limited limits. The viscous coupling provides the speed range that the impeller needs for the most efficient cooling.

As already mentioned, mechanically driven fans have become rare, but have not completely disappeared. Such a device can still be found on some car models that have a longitudinally located power unit. Another segment of cars in which the installation of a fan with a similar type of drive is widespread and justified is powerful SUVs. Such machines are able to overcome water obstacles and are prepared for operation in conditions of extremely high humidity. The fact is that any electronics fails after contact with water, and viscous couplings are completely sealed devices and are not afraid of moisture.

Electric drive

The active development and implementation of electronic control and monitoring devices for various systems during engine operation has led to the emergence of an electrically driven radiator fan. This drive has a separate electric motor and its own control system. The controller allows you to set the intensity of the impeller operation and flexibly change the speed and duration of fan rotation based on the readings of the temperature sensor. The sensor measures the temperature of the coolant in the internal combustion engine. This solution not only increased efficiency, but also made it possible to achieve improved uniformity of engine cooling compared to systems that are based on the use of a viscous coupling.

Reasons for antifreeze boiling in the expansion tank

So, the easiest and most quickly solved problem for the driver is the insufficient level of antifreeze in the expansion tank. If it is not enough, then the heating of the coolant in the system increases, the antifreeze overheats and boils.

In this case, the antifreeze either has not been changed for a long time and has lost its properties, or it was not completely filled to begin with. In this case, you need to add the required amount of coolant to the level between o and “max” on the expansion tank body.

If the antifreeze level continues to drop, it means that the seal of the expansion tank or cooling system is broken and the liquid is leaking. In this case, it is necessary to check the tank, pipes and hoses, and look for a leak. If the problem cannot be resolved, it is necessary to check the tightness of the cooling system at a service station.

Also, the cause of bubbling in the expansion tank may be a malfunction of the thermostat. It maintains the optimal engine temperature, regulates the temperature of the antifreeze circulating through the large and small circuits of the cooling system.

When 90°C is reached, a special valve between the circuits opens, the coolant flows from the small circle to the large one, then cools as it passes through the radiator. If the thermostat breaks down, this valve jams, the antifreeze does not cool down and bubbles in the expansion tank.

To check the serviceability of the thermostat, you need to turn off the engine, open the hood, inspect the pipes and compare their temperature. If one of them is cold and the other (attached to the radiator) is hot, this means that the problem is in the thermostat. In this case, you need to change the thermostat.

If, while driving, the coolant temperature indicator located in the car interior shows normal, but the antifreeze still boils, then the problem is in the pressure, since as the temperature rises, the pressure on the liquid also increases, causing it to also boil.

Another reason for antifreeze boiling may lie in the insufficiently efficient operation of the cooling radiator. One way or another, the radiator is not able to provide sufficient cooling of the coolant and protect the engine from overheating, especially in the heat of a traffic jam. Then just turn off the engine to let the car cool down.

As for clogging of radiator tubes, in this case their thermal conductivity decreases. As a result, the cooling capacity of the radiator is reduced. The reason is the accumulation of deposits in the pipes (often after using low-quality antifreeze).

Often scale forms in the radiator, as a result the circulation of the coolant deteriorates and it boils. A dirty radiator needs to be immediately flushed at a service station or replaced.

Also, the problem of insufficient coolant cooling in the radiator is solved with the help of a fan mounted on the radiator. It turns on automatically when the antifreeze temperature rises above 90°C and blows cold air over the engine to prevent overheating.

However, the fan itself often fails. If the engine temperature is 100°C, steam is flowing, and the fan does not rotate, this means that the cause of overheating and boiling of antifreeze is in the fan. Its breakdown can also be determined by ear: when the cooling fan is not working, the hot engine runs relatively quietly.

Even after replacing the antifreeze in the cooling system or when air leaks, air pockets sometimes appear, impeding coolant circulation. You can get rid of them if, with an assistant, you drive up a hill in front so that the radiator is at the highest point. Next, you need to unscrew the radiator cap, start the engine, press on the cooling system pipes until the air pockets are eliminated. At the same time, the assistant should accelerate intensively. Then screw the radiator cap back and add the missing amount of antifreeze.

Low-quality antifreeze is the shortest route to engine problems. Such coolants are cheap, but they clog individual elements (the radiator) and contaminate the water pump that circulates the antifreeze. Low performance of the water pump leads to boiling of the coolant, and the pump itself quickly rusts.

It is important to remember that operating a machine with a damaged pump will lead to engine damage. In this situation, the car must be delivered to the service station using a tow truck or towed by another car

Let us add that a burnt cylinder block gasket causes antifreeze to boil. In this case, the tightness of the cooling system is compromised. The coolant may end up in the exhaust, bubbles appear in the tank, and the coolant level decreases. In this case, the gasket must be replaced.

Advantages of an aluminum radiator

To find out which heater radiator is better to install on the seven, let’s make a comparative comparison. To do this, you need to find out all the advantages and disadvantages of the two types of stove heat exchangers. First, let's figure out what the pros and cons of aluminum units that are installed on classics from the factory.

The advantages of aluminum devices include the following factors:

- Cost is one of the main advantages of such devices, since it is precisely because of the low price that many choose models made of aluminum alloy. The price difference between copper (brass) and aluminum devices can be up to two times.

- Large selection - these models are more popular, despite some of their disadvantages. The reason for this popularity is their price, but you often have to make sure that it is better to buy a copper unit for the stove.

Among the advantages, heat transfer should also be noted, however, practice shows that heat transfer rates are significantly inferior to brass devices. For the seven, manufacturers do not produce three-row heat exchangers made of aluminum, which actually causes low heat transfer. Only two-row ones are produced.

Before buying copper heater radiators for the seven, you need to find out the disadvantages of aluminum units. These include:

- Thermal conductivity - the heat conductivity indicators of the models under consideration are low, so if the owner does not want to have problems with heating the interior, then heat exchangers made of aluminum alloy are not worth buying.

- Unsuitable for repair - some craftsmen, if the device is damaged, try to solder it, but soldering aluminum can cost almost the same as a new radiator. Considering the difficulty of replacing it, then if the aluminum heat exchanger of the stove on the seven leaks, it is better to immediately replace it with a new one.

- Corrosive effects - aluminum alloy is also not resistant to rust formation, so it is possible that the device will not last long if water gets into the system.

The presence of so many shortcomings leads to the fact that owners of sevens are increasingly inclined to switch to brass units. However, there is no need to rush, and first let’s find out all the advantages and disadvantages of our main competitors.

Advantages of copper stove radiators

Now let’s find out why a copper stove radiator is better than an aluminum one. The advantages of these units include:

- Thermal conductivity - even if we take into account the fact that copper ones are only called such, since they contain much more brass than copper, they have high thermal conductivity. It is this indicator that is fundamental when choosing a heat exchanger from which you can get more heat to heat the interior.

- Easy to repair - even the slightest mechanical damage can be repaired at home. Moreover, after soldering work, the unit can last a long period of time (which also depends on the quality of the soldering).

- The entire radiator is made entirely of plastic without the use of plastic. Not only are the plates made of copper, or rather a brass alloy, but the body itself is also made of a similar material. This is a big advantage, because due to this design, operational parameters are increased.

- Three-row versions of radiators are produced. This brings more heat into the cabin.

With so many advantages, one wonders if these devices have any disadvantages.

What is better to put on a VAZ 2107

Having made a comparative analysis, we can summarize which heater radiator to choose for the interior of a VAZ 2107 car. Practical experience and reviews from car owners indicate that aluminum devices cope with their task perfectly. However, this is appropriate when operating a car in urban conditions. As soon as you leave the city at temperatures below -10 degrees, you immediately realize that the stove is not up to the task. The problem is in the double-row heat exchanger, which does not have time to heat the interior even when the heater fan is switched to maximum speed.

If you install a three-row copper radiator, then it copes with its task much better, as evidenced not only by the reviews of the owners, but also by the advantages of these units. Therefore, if you often have to travel outside the city in winter, then it is better to install a copper three-row radiator instead of an aluminum two-row one, with which you can forget about the discomfort and chilliness in the cabin of the 7 when the heater is running.

About antifreeze and antifreeze

It should be said right away that dividing coolants into antifreeze and antifreeze is accepted only in Russia. To understand why this happened, you need to answer the question: what is coolant anyway?

As a rule, the base for the coolant is ethylene glycol (in rare cases, propylene glycol), to which water and a set of special additives are added to prevent corrosion. Different manufacturers have different sets of additives. And all coolants on the market today are classified according to the technologies for producing these additives. There are three technologies:

- traditional. Additives are made from salts of inorganic acids (silicates, nitrites, amines or phosphates);

- carboxylate. Additives in carboxylate fluids are obtained only from organic carbonates;

- hybrid. In this technology, manufacturers add a small percentage of inorganic salts (most often phosphates or silicates) to organic carbonate additives.

Coolant made using traditional technology is called antifreeze, and liquid made using carboxylate technology is called antifreeze. Let's take a closer look at these liquids.

Antifreeze

Antifreeze has several advantages. Let's list them:

- protective film. The inorganic salts contained in antifreeze form a thin chemical film on the surface of the cooled parts, which reliably protects the parts from corrosion. Film thickness can reach 0.5 mm;

- color change. Even if the driver forgot to change the coolant, he will easily understand that it is time to do it simply by looking into the car's expansion tank. The fact is that antifreeze becomes darker as it ages. Very old antifreeze resembles tar in color;

- price; Antifreeze produced using traditional technology is about a third cheaper than antifreeze.

Of course, antifreeze also has disadvantages. Here they are:

- small resource. Antifreeze quickly becomes unusable. It needs to be changed every 40–60 thousand kilometers;

- effect on aluminum parts. The additives contained in antifreeze negatively affect the aluminum surfaces in the main radiator. In addition, antifreeze can form condensation. These factors significantly reduce the service life of aluminum radiators;

- influence on the water pump; The tendency to form condensation can also have a detrimental effect on the VAZ 2107 water pump, leading to premature wear of its impeller.

Antifreeze

Now let's look at the pros and cons of antifreeze. Let's start with the pros:

- long service life. On average, six liters of antifreeze are enough for 150 thousand kilometers;

- temperature selectivity. Thanks to carbonate additives, antifreeze can more actively protect the engine surface that is hottest than others;

- long engine operation. The above temperature selectivity leads to the fact that an engine cooled by antifreeze does not overheat much longer than an engine cooled by antifreeze;

- no condensation. Antifreeze, unlike antifreeze, never forms condensation, and therefore cannot damage the radiator and water pump of the car.

And antifreeze has only one disadvantage: high cost. A canister of high-quality antifreeze can cost two or even three times more than a canister of good antifreeze.

Taking into account all the above advantages, the vast majority of VAZ 2107 owners opt for antifreeze, since saving on coolant has never led to anything good. Almost any antifreeze, both domestic and Western, is suitable for the VAZ 2107. Most often, car owners prefer to use Lukoil G12 RED antifreeze.

Lukoil G12 RED is the most popular brand of antifreeze among VAZ 2107 owners

Other, less well-known brands of antifreeze are Felix, Aral Extra, Glysantin G48, Zerex G, etc.

Possibility of tuning the VAZ 2107 cooling system

You can increase the efficiency of the VAZ 2107 cooling system in various ways. Someone installs a fan from a Kalina or Priora on the radiator, someone tries to better heat the interior by adding an electric pump from a Gazelle to the system, and someone installs silicone pipes, believing that with them the engine will warm up faster and cool down. However, the feasibility of such tuning is highly questionable. The cooling system of the VAZ 2107 itself is quite well thought out. If all its elements are in good working order, the engine will never overheat in the summer, and in winter the cabin will be warm even without turning on the heater fan

To do this, you only need to periodically pay attention to system maintenance, namely:

- fill only high-quality coolant into the engine;

- change the coolant every 50 thousand km with a complete drain and flushing of the system;

- monitor the coolant level and add it if necessary;

- When topping up, never mix antifreeze with antifreeze;

- When replacing faulty elements, use only high-quality certified parts.

Thus, the cooling system of the VAZ 2107 is quite reliable and simple. However, it also needs periodic maintenance, which even an inexperienced car enthusiast can perform.

Source

Periodic replacement of refrigerant

The period for replacing the fluid is indicated by the manufacturer in the operating instructions. In older engines, the replacement interval is usually 2 years or 60 thousand km of the vehicle. In new engines, this period is increased to 5 years or up to 120 thousand kilometers of total mileage.

To replace the cooler, it is necessary to drain the used one. To drain, you need to perform the following operations:

- wait until the engine cools down, otherwise there is a risk of burns;

- open the radiator cap;

- install a wide vessel under the radiator;

- Unscrew the drain plugs in the radiator and engine block.

When replacing coolant, and especially when changing its type, it is necessary to flush the hydraulic system. Flushing involves supplying water with a hose to the radiator filler neck and passing it through the entire hydraulic system. During the procedure, you can start the engine so that the running pump participates in the flushing process.

After emptying and flushing, the drain plug must be tightened. Slowly fill the radiator, block jacket and pump to the maximum level. When the radiator cap is open, you must start the engine to remove air from the pipeline. Only when you are sure that the air has been removed can you tighten the plug tightly.

After filling with antifreeze, you must leave the engine running for another 10 minutes to check the tightness, as well as the time it takes to reach the desired temperature (signaled by turning on the radiator fan).

Fan motor

The electric motor is the main component of the device. The VAZ 2107 used two types of engines: ME-271 and ME-272. In terms of characteristics, they are almost identical, but as for the design, it is somewhat different. The ME-271 engine has a stamped housing, i.e., non-separable. It does not require periodic maintenance, but in case of malfunction, it can only be replaced.

Design and characteristics of the fan motor

Structurally, the motor consists of:

- housings;

- four permanent magnets glued around the circumference inside the case;

- armatures with winding and collector;

- brush holder with brushes;

- ball bearing;

- support sleeve;

- back cover.

The ME-272 electric motor also does not require maintenance, but unlike the previous model, if necessary, it can be partially disassembled and attempted to be restored. Disassembly is carried out by unscrewing the tightening bolts and removing the back cover.

In practice, repairing an electric fan is impractical. Firstly, you can only buy used spare parts for it, and secondly, a new device complete with impeller costs no more than 1,500 rubles.

Table: main technical characteristics of the ME-272 electric motor

| Characteristics | Indicators |

| Rated voltage, V | 12 |

| Rated rotation speed, rpm | 2500 |

| Maximum current, A | 14 |

Which pump to choose

Unlike the standard VAZ and GAZ pump, which has a mechanical belt or chain drive, an electric pump is used as an additional driving force. Most often, motorists use an electric pump, which is standard equipment on the Gazelle car.

The unit has high performance, but the quality of its manufacture leaves much to be desired. Therefore, before installing such a pump, it is recommended to disassemble it, coat all seals with automotive sealant, reassemble it and let it dry for 24 hours.

An alternative to GAZ products is to install an additional pump manufactured by Bosh. These units have high build quality and a different operating principle. The blade rotates under the action of a magnetic coupling, and not an electric motor, as in the first case. » alt=»»> By using such a scheme, the manufacturer was able to abandon sealing connections and almost completely eliminate the possibility of leakage. The disadvantages of the imported unit include its high cost and relatively low productivity (700 liters versus 1200 liters per hour for the GAZ unit).

Coolant suitability

The refrigerant is checked based on monitoring its freezing point. This temperature increases over time as the glycol content in the liquid decreases, which evaporates faster than water. Control can be carried out by measuring the density of the liquid with a hydrometer.

Measuring the density of antifreeze can also be done using an optical disc tester - a refractometer. This instrument uses the relationship between the concentration of glycol in a liquid and the refractive index of light. A drop of the material under study is applied to the prism of the device, and it is observed where the boundary between the white and blue fields lies. Two scales are used for two grades of glycols.

Diagnostics

Before trying to determine why cooling system fans may turn on when the engine is cold in cars, it is recommended that you understand the operation of this unit.

The fan is turned on due to the operation of a special sensor, which activates the rotation of the blades. This controller is located at the bottom of the cooling radiator.

There are some modern cars where the engine control unit is responsible for starting, although this is rather a rarity and the exception and the rule.

When the cooling liquid (coolant) reaches the required temperature, which is usually in the range of 100-105 degrees Celsius, the sensor closes the electrical circuit, and this allows the fan to turn on. It starts blowing on the radiator. This achieves a better cooling effect, since the air and liquid systems are combined.

At the same time, there are situations when the engine is still absolutely cold, it does not require any additional cooling, but the fan still turns on. This is not a normal condition. It is necessary to look for the reason for this behavior of the cooling system and eliminate any malfunctions that have arisen.

If you continue to ignore the constantly running fan, the initially simple discomfort will give way to more serious problems.

But here it is important to note that the constant operation of the blades is not as dangerous as a complete failure of the device. Although this fact is absolutely not a reason to do nothing

It all starts with diagnosis. The simplest and most convenient in this regard are injection engines. To detect a malfunction, it is enough to conduct computer diagnostics. This is done both in a car service center and in the garage with your own hands.

Connecting to an electronic control unit makes it possible to obtain error codes that are not difficult to decipher and understand the true reasons for this behavior of the cooling system fan.

There are situations when the ECU detects a malfunction in the cooling system and causes the fan to spin constantly, even when the engine is cold. This is a kind of protective function aimed at preventing possible overheating of the internal combustion engine. Therefore, when errors are detected and after troubleshooting, a reset is required. To erase errors, you should look at the owner's manual for your car. On some cars, it is enough to remove the terminal from the battery, and the errors will be erased. On other cars, errors are erased using connected diagnostic equipment.

If the option of computer diagnostics does not suit you or it cannot be used for one reason or another, you will have to use the method of elimination to check all potential sources of trouble.

Cooling fan VAZ 2107

In the power plants of the first "sevens" the radiator fan was installed directly on the water pump shaft. Like the pump, it was driven by a belt drive from the crankshaft pulley. This design was also used on other cars at that time. It almost never failed, and it was impossible to overheat the engine with it. However, she had one drawback. The constantly cooled power unit warmed up very slowly. That is why AvtoVAZ designers changed the principle of forced airflow, replacing the mechanical fan with an electric one, and with automatic activation.

Early modifications of the VAZ 2107 had a mechanically driven fan

Why do you need an electric fan?

The fan is designed for forced airflow of the cooling radiator. During operation of the power plant, liquid coolant enters the radiator through the opened thermostat. Passing through its tubes equipped with thin plates (lamellas), the refrigerant cools due to the heat exchange process.

Later modifications of the Sevens were equipped with electric cooling fans

When a car moves at speed, heat transfer is facilitated by the oncoming air flow, but if the car sits for a long time or drives slowly, the coolant does not have time to cool. At such moments, it is the electric fan that saves the engine from overheating.

Device design

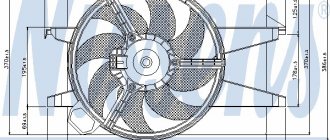

The radiator fan consists of three main elements:

- DC motor;

- impellers;

- framework.

The electric motor rotor is equipped with a plastic impeller. It is she who, rotating, creates a directed air flow. The engine of the device is installed in a metal frame, with which it is attached to the radiator housing.

We independently change the thermostat on a VAZ 2106

Before starting work, you should select tools and consumables. To replace the thermostat we will need:

- new thermostat;

- coolant (5 liters);

- basin for draining old antifreeze;

- flat screwdriver.

It should be noted here that the thermostat cannot be repaired. The reason is simple: inside it has a thermoelement with liquid or solid filler. It is the one that fails most often. But such elements are not sold separately, so the car owner has only one option - replacing the entire thermostat.

Sequence of work

Before performing any manipulations with the thermostat, you need to drain the coolant. Without this operation, further work is impossible. It is convenient to drain antifreeze by placing the car on an inspection hole and unscrewing the cap of the main radiator.

- After draining the antifreeze, the car hood opens. The thermostat is located to the right of the engine. Three hoses come to it.

- The hoses are attached to the thermostat pipes using steel clamps, which are loosened using a flat-head screwdriver.

- After loosening the clamps, the hoses are removed from the pipes manually, the old thermostat is removed and replaced with a new one. The hoses are returned to their place, the clamps are tightened, and new coolant is poured into the radiator. The thermostat replacement procedure can be considered complete.