Malfunctions of the starter and generator often cause a lot of trouble for motorists. After all, as often happens, during operation we do not pay much attention to the loads that the car has to withstand. However, this continues only until our car suddenly stops starting and requires repair.

Below we will talk about the most common causes of faulty starters and generators, as well as ways to eliminate them.

At the end of the article, watch detailed video instructions for finding the causes of a car starter malfunction.

You may also be interested in the following materials:

- Self-check and repair of the generator.

- DIY Bendix starter repair.

The understanding that any thing breaks if left without proper care comes too late, and the only way out of the situation is often an urgent repair of the starter or generator. To avoid breakdowns, you need to know and be able to recognize the first signs of impending malfunctions, and listen carefully to your car.

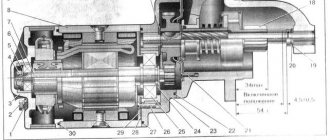

The principle of operation of the starter and its design

A starter is an electric motor with a drive that provides its connection to the engine rotor. Through it, the device spins the internal combustion engine.

The piston group begins to move, compression and ignition of the fuel mixture in the combustion chamber occurs. After this, the engine begins to work independently.

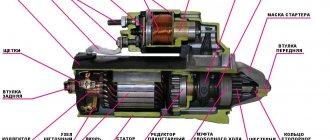

Modern starters are quite simple in design.

They consist of several parts:

- Housing with stator windings.

- Case toe (not on all models).

- Bendix.

- Rotor.

- Solenoid relay.

- Brush unit.

- Back cover.

- Fork.

- Some models also have a gearbox that increases the speed of rotation of the Bendix gear.

Starter device.

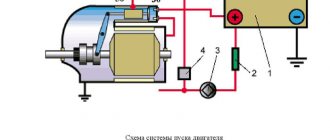

To start the engine, the driver first turns on the starter by turning the key in the ignition, starting the following chain of processes:

- When the contacts on the lock close, current is supplied to the starter solenoid relay.

- A magnetic field is excited in the relay, which draws the rod into the housing, compressing the spring.

- At the end of the rod there is a contact plate made of copper, which presses forcefully against the copper contacts, one of which is connected to the windings of the starter motor, and the second directly to the positive terminal of the battery.

- When the contacts are closed, current is supplied to the windings and the starter rotor is rotated.

- Simultaneously with the closure of the contacts, the retractor relay, using a fork, pushes the bendix forward, the gear of which engages with the teeth on the flywheel crown. The flywheel spins, the pistons begin to rotate and the engine starts.

- To prevent the starter from starting to slow down the engine after the engine starts, Bendix has a device that allows it to rotate only in one direction, slipping in the other. This allows the flywheel to spin freely, overtaking the rotation of the bendix.

- After turning off the starter by turning the key, the current supply to the relay windings is interrupted and the magnetic force disappears. The rod returns to its normal position under the influence of the return spring, which leads to the opening of the starter supply contacts and the removal of the Bendix gear from engagement with the flywheel ring.

Anchor diagnostics

The armature is the stator and rotor. The first is the external winding in which magnetic voltage is created. The second is the internal winding, which rotates under the influence of vibrations.

In this case, the unit will also need to be removed from the car and disassembled. Next, you should inspect the winding for damage. This could be “smoked” varnish, visible tears, or a characteristic burnt smell.

If everything is fine, the problem may be internal. Then you will need to know how to check the starter winding with a multimeter:

- Set the multimeter to resistance measurement mode.

- Hang the red crocodile on the winding, and the black one on the body.

- If there are more than a million ohms on the screen, everything is fine. If it is not there at all or is minimal, it means there is an internal breakdown.

These are the most unpleasant starter malfunctions and there is no way to eliminate them - only replacement.

If everything is fine with the anchor, you can finally check the brushes:

- Take a 12 volt light bulb with 2 wires.

- Place the minus on ground, and the plus on the plus of the brush holder.

- Connect the unit to the ABC.

- If the lamp lights up, it’s time to change the brushes.

Electrical causes of failure

Failures of this type indicate that the starter either does not rotate at all or rotates reluctantly.

The first thing you need to check is the following:

- The battery is fully charged.

- The contacts from the battery and to ground are well tightened.

- All wires coming from the starter are not broken, there is no short circuit on them.

- The pull-down relay receives voltage and is grounded.

If you do not hear a click from the solenoid relay when you turn the key, then there is no voltage going to it, there is no ground, or the relay has failed.

If there is a click, but the starter does not spin or does it slowly, and the battery is well charged, then the part will have to be removed for inspection and disassembly.

The most common electrical faults:

- Worn brushes that do not fit tightly to the commutator ring.

- Burnt out collector.

- Solenoid relay malfunction.

- Short circuit or break in the stator or rotor windings.

Worn brushes in need of replacement.

Electrical problems are solved by replacing the broken unit. It is possible to repair the windings, relays, and rotor, but it will cost much more than replacement.

Problems with the solenoid relay

Sometimes, when the ignition is turned on, only this relay is immediately activated, and accordingly, the circuit remains open. You can try closing the traction contacts, but this does not help in all cases. The appearance of extraneous crunching noise in the engine compartment area is evidence of a malfunction of the Bendix. This element is made in the form of a small gear and is located on the rotor shaft. The solenoid relay is activated when voltage is applied to it, controlling the movement of the bendix, causing it to engage the flywheel. Wear of this part makes it impossible to perform this procedure, since its worn out parts cannot be aggregated with the teeth of the flywheel, and this causes a strong crunch.

Mechanical problems

Basically, mechanical problems manifest themselves in the fact that the starter works, but the crankshaft does not rotate.

However, there is one exception - worn out bearing shells.

In this case, the gap between the rotor and the stator winding may disappear and the starter will stop rotating altogether.

This failure is determined after removing the unit - just try to see if the rotor shaft moves in the sock.

If there is rotation, but it is not converted to the crankshaft, the following parts may be to blame:

- The rollers in the bendix clamping device were worn out.

- Bendix gear teeth are worn out.

- The feed fork is broken.

- Several teeth broke off on the engine flywheel crown.

A problem with the flywheel is identified by a grinding noise when starting up. It is especially typical when the flywheel begins to rotate and immediately stops spinning with a grinding noise.

Often the problem is a worn-out fork that has jumped out of place and does not push the bendix forward.

A powerful current is supplied to the starter, so the contact pins are exposed to significant spark corrosion.

After some time, their surface burns out, eventually leading to a lack of contact.

Burnt nickels of contacts.

Burnt contacts are the most common reason that the starter stops turning or sometimes rotates, sometimes not, but the relay operates properly.

For repair you need:

- Remove the relay cover; to do this, you need to unscrew the fasteners, remove the nuts on the copper bolts, you will also need to unsolder the contacts and flare the housing with a screwdriver.

- Using sandpaper, thoroughly clean the burnt contacts.

- In case of severe corrosion, the contacts are cleaned with an emery wheel or need to be completely replaced.

- It is enough to turn the contact plate on the rod with the smooth back side.

Sometimes a situation occurs when the starter does not turn off, but continues to work despite the open contacts in the ignition switch.

This is due to:

- The solenoid relay is stuck.

- Sticky contacts on the relay.

- Drive lever (stuck, falling off its mounts).

- The return spring has weakened or broken.

To repair it, you will have to turn off the engine and remove the unit for disassembly.

Usually you can find out about imminent problems with the starter in advance if you are careful.

The following symptoms may indicate a future breakdown:

- It is possible to turn on the starter only after several turns of the key. In this case, the sound of the solenoid relay is heard. It's time to clean the burnt contacts.

- The starter turns the flywheel with difficulty, but the battery is serviceable and well charged. Most likely, the brushes have worn out, the commutator unit has burned out, or the rotor has started to run out due to worn-out bearings.

- When the starter is turned off, it does not immediately disengage from the flywheel. The causes may be worn-out flywheel or bendix gear teeth, as well as a weakened return spring.

When can you move the starter from one car to another?

If the starter manufacturer switched to producing geared models, then direct drive starters can be replaced with geared ones, and vice versa. In this case, it is possible to select even several replacement options for European foreign cars. Starters from different manufacturers that are installed on the same car model can also be considered analogues.

Today there is a very wide variety of starters produced, and they differ significantly, even though they are outwardly similar. So, they differ in the offset of the bendix, the seating dimensions, the number of teeth on the gears, the size of the teeth, and so on.

How to determine if the starter is faulty

Most starter breakdowns are quite easily identified by characteristic signs.

For convenience, the most common unit malfunctions and their symptoms are summarized in the table:

| Symptoms of malfunction | The essence of the problem | Reason for appearance |

| The starter turns properly, but the flywheel stays in place | Bendix planetary gear broke | Mechanism bushings are worn out |

| Spring doesn't work | The spring has weakened | |

| Gear teeth and flywheel ring do not mesh | The teeth are worn out | |

| The starter clicks but doesn't turn over | No mass | The ground cable is broken or the contact is oxidized |

| Insufficient current | The battery is not charged or does not gain capacity | |

| No contact between rotor ring and brushes | Brush wear | |

| Solenoid relay does not work | Burnt contacts or burnt winding | |

| The anchor is not working | Short circuit in the winding, the contact ring is worn out or burnt out, the lamins pass current | |

| Starter barely turns | There is wear on the bushings | Deterioration from time or dirt |

| Short circuit in the brush assembly | The part is covered with graphite dust from brushes | |

| The turns of the stator winding are punched to ground | Corrosion, the rotor rubs against the winding | |

| Interturn closure of the winding on the armature | The insulation is damaged due to corrosion or the armature touching the stator winding | |

| A sharp grinding noise when trying to turn on the starter | Scored flywheel ring or broken teeth | Natural wear, abrasive material on the gears, corrosion, defective part |

| Bendix bushing worn out | ||

| The starter works on a cold engine, but after warming up you can hear clicks. | Solenoid relay is faulty | Relay core stuck |

| Sagging of the springs pressing the brushes | Natural fatigue or overheating of the starter when starting | |

| Development on bushings | Natural wear or contact with sand or other abrasives on the walls | |

| Burnt nickels of contacts | Natural wear and tear, the starter takes too long to start | |

| There is no minus on the brush assembly | Contact oxidation |

Parameters and differences between crankshafts of classic vases.

So, “Zhiguli” crankshafts have several parameters that may vary. 1. The crankshaft stroke is the distance between the axes of the connecting rod journal at bottom dead center (BDC) and top dead center (TDC). Crankshafts with a stroke of 66 mm, 80 mm and 84 mm were installed at the factory on classic VAZ engines. In addition to them, there are sport variants of crankshafts with a piston stroke of 86 mm, 88 mm and even 90 mm. But still, you shouldn’t think that by installing a crankshaft with a stroke of 90 mm in the block, the engine will immediately become much more powerful. The behavior of the engine is greatly influenced by the ratio of the length of the connecting rod and the stroke of the crankshaft - the so-called R/S (from the English “rod to stroke ratio”). Many people believe that the “golden mean” of a cylinder block is the R/S value, which is equal to 1.75. If R/S is large, then the piston remains at TDC for a longer time, so more complete combustion of the air-fuel mixture occurs, therefore, greater pressure on piston after passing TDC. The result is good torque at medium and high speeds. Also, a longer connecting rod reduces its friction on the crankshaft. However, there are also disadvantages - with a long connecting rod and a short stroke, due to a decrease in air flow speed (again due to the lower piston speed after TDC), good filling of the cylinders at low and medium crankshaft speeds is not ensured. There is also a high probability of detonation due to the high temperature in the combustion chamber and the long time the piston remains at TDC. If R/S is small, then a very good cylinder filling rate is ensured at low and medium crankshaft speeds, as well as With a short time spent at TDC (and therefore a higher piston speed at the beginning of the stroke), the mixture becomes more homogeneous, which contributes to better combustion. But there are also disadvantages here - a small R/S value means a larger angle of inclination of the connecting rod. Therefore, a large force will push the piston in a horizontal plane. Therefore, the load on the connecting rod, on the walls of the cylinder block, and the pistons of the ring increases, the operating temperature increases due to increased friction, and lubrication deteriorates. Well, due to the increased piston speed, the engine life is also reduced. Another common problem when installing a crankshaft with a long stroke is the connecting rod touching the block wall. In this case, you need to refine the wall using a grinder or grinder.

2. Size of the connecting rod journal The crankshaft journal is the support with which the shaft is connected to the connecting rods. The standard diameter of the connecting rod journal in a “classic” engine is 47.8 mm. The rolling bearings and connecting rods are also made to this size, however, on “sports” crankshafts with a stroke of 86 mm, 88 mm and 90 mm, the diameter of the connecting rod journal can be 43 mm. It requires special liners, as well as connecting rods, don’t forget about it! 3. Number of counterweights Counterweights provide unloading of the main bearings from the centrifugal forces of inertia of the unbalanced masses of the crank and the lower part of the connecting rod. On standard crankshafts 2101, 2103 there are only 4 counterweights, essentially on one side on the cheek (the main and connecting rod journals are connected) from the main support. On the remaining crankshafts 21213 and with a stroke of 86 mm, 88 mm, 90 mm there are already 8 of them, which ensures a more balanced unloading of the main bearings from inertial forces.

FAQ

What problems could the starter have?

Answer: All breakdowns are divided into electrical and mechanical. Electrical problems are associated with oxidation and burning of contacts, short circuits in windings, and broken cables.

The main 5 mechanical ones are as follows:

- Brush wear.

- Worn bearing bushings.

- Bendix failure.

- Bendix jamming in the screw thread on the anchor.

- A weak return spring or a slipped Bendix feed fork.

When to change the starter?

Answer: The starter is a unit that can be easily restored. They usually change it when repairs have already been carried out more than once, and the number of breakdowns becomes too frequent.

It's also time to buy a new one if:

- Cracks or chips have appeared on the body or covers.

- The rotor is jammed.

- The stator winding burned out.

Why doesn't the starter turn?

Answer: First of all, you need to check the battery - it is often to blame due to undercharging, insufficient electrolyte density, its leakage, and aging of the plates.

In the starter itself, the most common causes are:

- Oxidized terminals on the battery and connection to the starter.

- Short circuits in the stator or rotor windings.

- Damage to the solenoid relay.

- Jammed rotor.

- Excessive bushing wear.

- Critical brush wear.

How can you tell if the brushes are worn out?

Answer: Usually, when the brushes are worn out, the starter begins to work unstably, turning on after several attempts, and even after it starts working, it may suddenly stop working.

Sometimes you hear a crackling or slight knocking sound, and the starter smells a little like burning. The relay is activated, which is determined by a characteristic click, but the starter remains motionless.

How can you tell if the bushings are worn out?

Answer: With the starter removed, try moving the shaft on the toe. If there is wear, the shaft will move slightly from side to side.

Traces of the rotor touching the starter windings also appear. In particularly advanced cases, the stator and armature may burn out.

Sometimes the anchor jams and does not turn at all, or this can only be done with considerable effort.

Do not try to change the bushings yourself, this requires experience. Even the slightest misalignment will lead to the rotor being difficult to rotate and the starter will quickly burn out after repair.

The starter either turns or doesn't. Why is this happening?

Answer: Usually this behavior is associated with a malfunction of the solenoid relay, or more precisely, burnt contact brushes.

This is very easy to check. It is enough to close the starter contacts directly, for example, with a screwdriver.

Just remember to put the car in neutral, otherwise the car will move. The second possible reason is severe wear of the brushes.

Conclusion

The starter, depending on the model, has a resource of 70-200 thousand kilometers of the total mileage of the car, it depends on the condition of the engine and electrical system.

The resource can be significantly extended subject to periodic preventive maintenance and immediate servicing of the unit when the first signs of malfunction or abnormal operation appear.

Expert recommendations

If you have no experience in repair work, then you can contact a specialist who will tell you how to check the removed starter from the battery; the video can also help with this. If you carry out a comprehensive diagnosis and repair of the starting unit (replacing bushings, brushes, forks, bendix if necessary, cleaning internal surfaces), then it will last without repair for 3-4 years.

To extend the service life of the starter, you must adhere to the following rules:

- do not force the starter to operate continuously for 15 seconds,

- if extraneous noise is heard or the device periodically fails, you must immediately look for the cause of the malfunction and eliminate it,

- monitor the condition of the traction relay contacts; sparking and overheating of the contacts can destroy the part.

A working starter will ensure a comfortable trip and will not fail at the right time. It is better to correct minor problems in a timely manner than to make major repairs. The given tips on how to check the operation of a starter from a battery, the videos posted in the article will help to carry out a set of routine maintenance to restore the starter’s functionality.

Grinding noise from under the hood

In this case, the engine may or may not start. When you hear grinding noise, it means that the metal parts are not contacting each other the way the manufacturer intended. The problem may be a worn starter bendix that does not align with the engine flywheel.

If you continue to start the car, the Bendix gear will soon fail and the engine flywheel may also be damaged. Also, the starter may simply jam. So be sure to have your starter repaired as soon as possible after you hear the grinding noise.