The question of where the cooling fan relay is located on a VAZ 2114 confuses many car owners. Those who like to tinker under the hood of their own vehicle believe that if there is a fuse in the mounting block, then it must correspond to a contact relay. But, as it turns out, this cooling device has two fuses, and both of them are located in different parts of the car. In this article, the reader will learn how to find the fan relay, where its first and second fuses are located, for what reasons the engine cooling device does not work, how to troubleshoot some problems in its electrical circuit, and in the cooling mechanism itself.

Where is the cooling fan relay on a VAZ 2114

A common problem on the VAZ 2114 is a breakdown of the cooling fan relay. From the very beginning of production, the model suffered from frankly “weak” relays, which often did not live out their warranty period. Therefore, it is important for every driver to know where it is and how to replace it.

Please note that the instructions are for models 2113 and 2115.

Cooling system design features

Depending on the design features, the fan can be turned on in 3 ways:

- using a power sensor for activation of the VSO. This sensor is also called a fan temperature relay, since the power contacts of the electric motor pass directly through the sensor. With this scheme, the load on the thermal relay increases significantly, which reduces its service life;

- using the fan switch sensor, but now closing the contacts in the temperature switch triggers the relay, through which the power contacts of the cooling fan are connected. This connection method is much more reliable than the previous option;

- using an electronic engine control unit. The ECU, focusing on the coolant temperature sensor installed in the engine cooling radiator, supplies power to the VCO through a relay. A resistive temperature sensor is used as a meter. It is this switching circuit that is used on the vast majority of modern cars. On cars equipped with air conditioning, one of the electric fans will be controlled by the comfort unit. This is necessary for forced cooling of the condenser when the interior air conditioning system is activated.

Operating modes

When understanding the operating principle and connection diagram of a radiator fan, you should remember that electric motors often have two speed modes. This is implemented in 2 ways:

- by adding a resistor to the circuit, which increases the resistance and, as a result, reduces the current. The design uses a two-contact sensor, which, depending on the temperature, powers the electric motor directly or through resistors;

- a combination of parallel and series connection. The circuit is used on a car with two fans. They can be connected in series, in which case, according to Ohm's law, they will operate from 6 V, or in series, when 12 V is supplied to each of the VSOs. The modes correspond to low and high speed rotation of the propeller.

Relay block location

First you need to determine where the cooling fan relay is located. It is located in an additional mounting block. In the photo you can see its location.

Please note that in some cases the position and order may change slightly, so it is recommended to rely on indirect signs:

- First, find the main relay. It is always placed at the very bottom.

- Now examine it and find a thin pink wire with a black stripe. It goes through pin 85.

- “Walking” along it, you will find the fan relay at 2114. There is also a cooling fan fuse on the VAZ.

Be careful, because... Through pin 87 there is a pale red wire with a black stripe and they are easy to confuse.

The wiring you need is marked in the photo.

Connection diagram

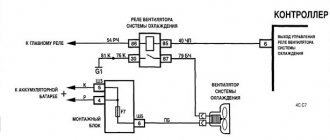

In the event of a breakdown, the fan relay on the VAZ 2114 will need to be replaced. A detailed diagram will help you with this.

If nothing is clear, here is a short explanatory “note”:

- As you can see, there are 2 wires coming from the fan (indicated by number 1).

- The first goes to the mounting block and is connected through fuse No. 5.

- The second wiring goes through the harness block to the relay block (namely to relay 87).

- From there, through relay 85, the wire goes to the injection controller.

Why is this necessary to know? The breakdown can occur in any of these nodes. When repairing, it is recommended to diagnose this entire circuit. Often little things become unusable, such as a harness block or a connecting busbar in the mounting block.

Scheme options

Schematic diagram of VSO connection on VAZ 2108, 2109, 21099 (until 1998).

As we can see, the sensor controls the fan relay, which is located in the fuse box. When a certain temperature is reached, the contacts of the temperature switch close, which leads to the flow of current in the electric motor circuit.

Above is a diagram for VAZ 2108, 2109, 21099 cars, but after 1998. As we can see, the power sensor now functions as a relay.

Let's consider a circuit using a resistor to implement two propeller rotation speeds using the VW Passat as an example. The two-position fan power sensor S23, depending on the coolant temperature, closes the contacts directly or through an additional resistance.

DIY connection

Some drivers, warning the engine against overheating due to improper operation of the radiator fan power supply thermal relay, make an external button to force the electric motor to turn on. To do this, it is enough to connect a fixed button in parallel to the control output of the relay coming from the sensor, which, when pressed, will close the contact to ground, thereby provoking the operation of the relay. If the car's design does not provide a fan relay, you will have to install it yourself to force cool the radiator.

Under no circumstances should you connect the electric motor directly through the button in the cabin! We also do not recommend connecting the circuit so that after turning on the ignition the electric fan constantly rotates, as this significantly reduces its service life.

To connect, you only need to understand the operating principle of a 4-pin relay and minimal knowledge in installing additional equipment. Be sure to include a fuse of the correct rating in the power circuit and place it as close to the power source as possible (read more about how to choose the correct fuse rating).

If desired, you can replace the single-position sensor with a two-position one, which, paired with a selected resistor, will allow you to realize a low speed of operation of the VSO. If you have a sufficient level of knowledge in electrical engineering, then you can build a PWM controller to adjust the speed of rotation of the propeller. Controlling the electric fan using a PWM signal will allow you to smoothly regulate and arbitrarily select the rotation speed depending on the temperature load on the engine. There is enough material on the Internet on how to make a PWM controller with your own hands.

How to check fuse and relay

So, a characteristic icon appeared on the dashboard, indicating overheating of the car’s interior. In this case, diagnostics is necessary, because Relay failure is the simplest of malfunctions.

The main sign of a breakdown is a gradually rising engine temperature that does not subside. If this happens, immediately turn off the engine. You will have to move slowly to the garage so that the engine does not smoke.

The easiest way to check a relay is to connect it directly to the battery.

It runs on the same 12 volts, so there will be no problems. If the fan motor starts, then the problem is somewhere else. If no movement is noticed, replacement is necessary.

You can immediately check the fuse on the relay. It is also responsible for the horn, so if the car does not “beep”, it means it is also burned out. In this case, replacement is also necessary.

Here it is worth knowing that both the relay and the cooling fuse on the VAZ 2114 injector burn out separately. Therefore, it is worth checking the safety block first.

- Check contacts 85/86/30. In some cases, if they do not open, pin 87 of the fan control may suffer. They are checked by regular dialing. If they ring when they are off, replace the relay.

- Clean the harness block. Due to short-term excess current, the contacts may melt or become covered with soot. In this case, current cannot move between the relay and the fan, which prevents the cooling from working. To begin with, the pad can be cleaned using a stiff brush and alcohol/solvent.

Also, do not forget that the car, depending on the revision, may have 2 fan control relays, as in the picture. In this case, it also needs to be checked using the methods described above.

How to check the fan

If everything is fine with the circuit, the problem is in the fan. Here the situation is aggravated by the fact that this is the most expensive part of the cooling system, so it is recommended to repair it.

Most often the problem manifests itself in the electric motor, i.e. in the heart of the fan. To check, connect it directly to the battery: plus to plus, and minus to minus. If it doesn't work, it's a wake-up call. First, inspect the brushes. They must be intact and not erased.

Next comes the bearings. If you hear a crunch or crack when turning, they need to be disassembled, cleaned and lubricated. Then inspect the contact group. If there is black carbon deposits, clean it with sandpaper and a brush soaked in alcohol.

If these actions do not lead to the desired result, the only option left is to completely replace the fan. It is also recommended to replace all components of the circuit, including fuses and relays.

Source

Where is the fan relay located on the VAZ 2114 (connection diagram, testing methods)

The question of where the cooling fan relay is located on a VAZ 2114 confuses many car owners. Those who like to tinker under the hood of their own vehicle believe that if there is a fuse in the mounting block, then it must correspond to a contact relay. But, as it turns out, this cooling device has two fuses, and both of them are located in different parts of the car. In this article, the reader will learn how to find the fan relay, where its first and second fuses are located, for what reasons the engine cooling device does not work, how to troubleshoot some problems in its electrical circuit, and in the cooling mechanism itself.

How to properly replace the fan switch sensor?

Typical set of tools and accessories for replacement:

- set of heads;

- extension cord with ratchet;

- pliers;

- flat blade screwdriver;

- sealant;

- a socket for removing the sensor or a suitable wrench;

- container for draining liquid (5-6 l);

- coolant for topping up (0.4-0.5 l).

Sequence of steps for replacement:

- Cool the engine to a comfortable temperature.

- Place a container and drain the coolant from the radiator. To access the drain valve, you may need to remove the engine crankcase protection or plastic mud flaps. Some vehicles require removal of the heating system pipe.

- Disconnect the wiring plug from the sensor. Inspect the terminals, clean them from dirt and traces of oxidation. Check the condition of the wires going to the plug. If the insulation becomes cracked or otherwise defective, the worn area must be replaced. Connecting new wires must be carried out in compliance with polarity.

- Unscrew the faulty sensor. It is not recommended to apply a lot of force, as there is a risk of breaking the radiator. To facilitate the process, the use of liquids such as WD40 is allowed. To access the sensor installation location, it may be necessary to remove the battery, its platform, or engine air ducts.

- Lubricate the threads of the new sensor with sealant designed for use in elevated temperatures.

- Install a new O-ring on the sensor. Reusing gaskets is not recommended since the joint is not sealed.

- Screw the sensor into place and tighten to the required torque.

- Install the wiring plug onto the sensor.

- Restore the coolant level in accordance with the vehicle service instructions.

- Warm up the engine to operating temperature and check the operation of the new device. During the first days of operation, carefully monitor the coolant temperature. This applies mainly to domestically produced cars, since the sensors are often defective or set to the wrong response temperature.

On some cars, after turning on the ignition, a new sensor is diagnosed, which consists of turning on the cooling fan for 15-20 seconds (on a cold engine).

How to choose a new sensor?

When purchasing a new sensor, it is recommended to purchase a device of the same type and range as the one you had previously. However, it is possible to replace the device with a similar one, similar in characteristics.

Where is the fan relay located on the VAZ 2114

There are 2 relays installed in a VAZ 2114 car. The first is located in the main mounting block, which is located in the engine compartment. Fuse F5 with a current of 20A, in addition to the sound signal, is connected to the fan relay.

The figure shows a new type of mounting block. On the cover there is a clear electrical diagram of the unit. There are symbols next to each device. The letters K indicate relays, the letters F indicate fuses. The device that protects the engine cooling fan is marked with the letter F5 . This fuse is located in the right row, third from top to bottom.

Helpful : Cooling fan does not turn on (7 possible reasons)

There is one small nuance. In cars of the Samara family there are 2 types of mounting blocks. Below is a diagram of the old mounting block:

To open the mounting block to replace a blown fuse, you must release the two latches holding the cover in place and remove it. A special clothespin is attached to the box of the unit, which can be used to safely remove the fusible protective device. A blown fuse will be indicated by a silent beep, since this protective device also supports its operation.

The engine cooling fan relay on the VAZ 2114 is located in a small relay and fuse box in the passenger compartment under the dashboard on the passenger seat side. To get to this block, you need to unscrew the screws and move the partition.

This block has a built-in ignition relay, which is called the main one. The second is the cooling fan relay and the third is the fuel pump relay. Moreover, if the main relay has a constant location, the next 2 relays, depending on the assembly diagram of the electrical circuit, change places. More precisely, in some cars they are second, in others they are third. A fuse is built into each switching device. Their location also depends on the assembly scheme. Therefore, the required relay should be found using symbols. The figure offers 2 assembly options.

And now that you know where the cooling fan relay is located on the VAZ 2114, you can always check its operation, remove it if necessary and replace it with a new one. The fact is that four-pin relays, like fuses, are not repairable. They can only be replaced. They are relatively inexpensive - in the range of 100-200 rubles.

Intelligent Engine Cooling Fan Control Relay

After reading mrsom’s post about transplanting microcontroller filling into a retrotachometer from a Zhiguli, I decided to talk about one of my long-standing microcontroller developments (2006), made for smooth control of the electric cooling fan of the engines of front-wheel drive VAZ models.

It must be said that at that time there were already a lot of different solutions - from purely analogue to microcontroller-based, performing the required function with varying degrees of perfection. One of them was a fan controller from the Silych company (what now looks like this, known among those interested in its automatic ignition timing regulator, which software detects engine knocks. I spent some time following the forum of the manufacturer of these devices, trying to determine what turned out well in the device, but not so much, and as a result I decided to develop my own.

As planned, in contrast to existing solutions at that time, the new device was supposed to a) be placed in the housing of a regular automotive relay; b) do not require changes in the standard vehicle wiring; c) have no adjustment elements; d) operate reliably and stably under real operating conditions.

The history of the device and the operating algorithm of the first version was discussed here - for those who do not want to click, I will describe the key things online:

-1. The operating algorithm of the device was assumed to be as follows: the voltage at the standard engine temperature sensor was measured; upon reaching the lower threshold temperature, the fan began to spin at minimum speed, and if it increased further, it linearly increased the rotation speed up to 100% at the moment when, according to the ECM (engine control controller), it was time to turn on the fan at full power. That is, the temperature value corresponding to 100% switching on could be obtained when the device was turned on for the first time, because it has an input corresponding to the output of the standard relay winding. The lower threshold in the first version had to be set somehow, thus drawing a linear control characteristic through two points.

0. At currents of the order of 20A, it is obvious that PWM is used for smooth regulation, and a powerful field switch is used as a key element.

1. Placing the device in a conventional relay housing means there is virtually no heat sink. And this, in turn, imposes strict requirements on the power dissipated by the key element in static (channel resistance) and dynamic (switching speed) modes - based on the thermal resistance of the crystal-case, it should not exceed 1 W under any conditions

2. The solution to point 1 can be either the use of a field driver or operation at a low PWM frequency. Unlike analogues, for reasons of compactness and noise immunity, an option with a low PWM frequency was chosen - only 200 Hz.

3. Operation of the device with standard wiring and temperature sensor inevitably leads to PIC, because The TCR of a standard temperature sensor is negative, and when the fan is turned on, due to the resistance of the common wire and the 'sagging' of the on-board network, the voltage measured on the sensor inevitably drops. It is impossible to stabilize or use a four-wire switching circuit - changes in the standard wiring are prohibited. It was decided to deal with this programmatically - by measuring the voltage on the sensor only at the moment when the PWM switch is turned off - that is, there is no parasitic voltage drop. Fortunately, the low PWM frequency left enough time for this.

4. Programming the device's activation threshold should either be very simple or completely automatic. Initially, the device was equipped with a reed switch, by bringing a magnet to it through the housing, the lower threshold was programmed (the value, of course, was stored in the EEPROM). The upper threshold was set itself at the moment of the first pulse from the ECM. Subsequently, I came up with and implemented an algorithm for fully automatic setting of thresholds, based on finding the thermostable point of the engine (thermostat response point) in the absence of saturation in radiator-to-air heat transfer.

5. The device must provide diagnostics to the user. For this, an LED was added that blinked two bytes in binary code - the current ADC code and the word of status flags.

The device was assembled partly by overhead mounting directly on the terminals of the former relay, partly on a printed circuit board that had turned up from somewhere. The power MOSFET drain output was soldered directly to the relay output lamella, which increased the power dissipation margin. The device worked without glitches on a VAZ-2112 from 2006 to 2010, when I removed it before selling it, and was used not only in the cold climate of St. Petersburg, but also on the Crimean mountain roads (and even on a car in a supercharged version - it was standing on my inlet drive compressor), despite the installation of the prototype level and the controller in the socket.

Here is the original diagram (drew only on paper):

And this is a view of the device from the inside:

The device was repeated by several people, one of them (off-roader Gennady Olomutsky from Kyiv) used it on a UAZ, drawing a circuit in sPlan and laying out a printed circuit board - in his version it looks like this:

- the diagram, signet and the latest version of the code are here: https://code.google.com/p/mc-based-radiator-cooling-fan-control-relay

But here is a piece from a correspondence with one of those who repeated this device - in it, for the first time, the algorithm was written out in detail (!) - before that he wrote directly from the brain into the assembler: Now the idea and implementation of the auto-installation algorithm itself (all steps below correspond to unspecified thresholds):

1. We are waiting for the signal to turn on the fan from the ECM (or from the temperature sensor in the radiator in Gennady’s version) 2. We remember the temperature at the moment the signal appears as T1 (we actually remember the ADC channel code for digitizing the sensor signal - let’s call it C1) 3. Turn on the fan at 100% . Set the flag “auto-installation mode is active (bit 3)” 4. After 3 seconds, read the ADC code (let’s call it C1′). This action is necessary in order to determine the amount of compensation for the temperature value due to the influence of the current flowing through the fan and the resulting voltage drop in the measuring circuit on the digitized temperature value. In reality, in 3 seconds the motor does not have time to cool down, but the fan starts and reaches the rated current. 5. Calculate the ADC correction for 100% fan power (let's call it K100 = C1 - C1′). Remember K100. 6. We are waiting for the signal to turn on the fan to be removed from the ECM (or the sensor in the radiator is turned off). 7. Smoothly reduce the power from 75% to 12% by about 1.5% per second. 8. Turn off the fan and wait 60 seconds. 9. We remember the temperature as T2 (ADC code C2). 10. We adjust the lower threshold (increase by 1/8 of the difference between the upper and lower) so that it is above the thermostable point of the thermostat. T2 = T2 + (T1 - T2) / 8. In ADC codes this is C2 = C2 - (C2 - C1) / 8, because The voltage at the sensor drops with increasing temperature. 11. Save C1, C2, K100 in the internal EEPROM of the relay. 12. Set the flag “thresholds are set” (bit 5), remove the flag “auto-setting mode is active”, exit the auto-setting mode to the operating mode

The idea of the algorithm is that it blows through the radiator to the thermostable point of the thermostat, but does not blow strongly so as not to cool the engine by directly cooling the block and head. Then the fan turns off and the relay allows the motor to warm up a little - this way we automatically get the point for the fan to start operating.

During auto-installation, the relay receives a signal from the reed switch during steps 7 and 8 - bringing the magnet to the relay at these moments causes a sequence of steps 9, 11, 12. The threshold is not adjusted in step 10).

If during auto-installation some conditions expected by the relay are violated, the “auto-configuration error (bit 4)” flag is set and the relay exits auto-installation mode. In order for the relay to be able to enter this mode again according to the conditions of step 1, it is necessary to turn off and turn on the power of the relay.

The errors that are caught are as follows: Step 2 - the ADC value is out of range (too low or high). Autoconfiguration range according to ADC code 248..24 (11111000…00011000). In this case, the relay simply does not enter auto-configuration mode without setting the error flag. Step 4 - During the 3 second wait time, the external fan signal is detected to be removed. Step 7 - during a decrease in speed, an active external signal to turn on the fan is detected. Step 8 - while waiting, an active external signal to turn on the fan is detected. Step 11 - the set thresholds are outside the range of 248..24, or the difference C2 - C1 < 4 (that is, they are too close to each other, or for some reason C2 > C1 - for example, when the fan does not actually work and the temperature continues to rise)

Now working mode:

Calculation of the required power (Preq) 1. If the external signal is active - Preq = 100% 2. If inactive, then the current ADC code © and the corresponding temperature T are looked at: T < T2 (C > C2): Preq = 0% T > T1 (C < C1): Preq = 100% T2 <= T <= T1 (C2 >= C >= C1): Preq = Pstart + (100% - Pstart) * (C2 - C) / (C2 - C1), where Pstart = initial power (12%)

At the same time, the required power is not immediately supplied to the fan, but goes through a smooth acceleration algorithm and limiting the fan start/stop frequency. This algorithm works only in operating mode and in the absence of an external turn-on signal: Let Pcurr be the current power of fan 1. If Pcurr > 0 and Preq = 0, or Pcurr = 0 and Preq > 0, that is, it requires starting a stopped or stopping a running fan, then: — The time the fan has been in this state (started or stopped) is shown. If the time is less than the threshold, the fan state does not change. — In this case, if Pcurr > Pstart and Preq = 0, then for the remainder of the running state time Pcurr = Pstart is set (that is, the fan rotates at minimum speed) 2. If step 1 is not fulfilled, or the time spent in the state has passed, then: — If Preq < Pcurr, then Pcurr = Preq is set (then the rotation speed changes downward immediately as the new value is calculated) — If Preq > Pcurr, then the increase in rotation speed is limited from above by approximately 1.5% per second (except for the case when turning on the fan is requested by an external signal) - that is, if Preq - Pcurr > Pdelta, then Pcurr = Pcurr + Pdelta, otherwise Pcurr = Preq

Now about the algorithm for digitizing the ADC value of the sensor and compensating for parasitic feedback during fan operation:

When calculating power, the average value of the current temperature code C is used (see Calculation of the required power), obtained by the arithmetic average of the last 8 values Cm1, Cm2, Cm3... Cm8. Averaging occurs using the “sliding window” method - that is, placing a new value in a buffer of 8 values pushes out the oldest one and causes recalculation of the arithmetic mean C. The ADC cycle (and recalculation of the average) occurs every 640 ms. The “raw” (read from the ADC) Cadc value, before entering the counting buffer, is involved in the following algorithm: 1. It is checked that Cadc > Cdisc, where Cdics is the max. ADC value for an unconnected measurement pin. 2. If Cadc > Cdisc, then the “sensor not connected (bit 6)” flag is set, the value does not fall into the buffer of the last 8 values, and the average is not recalculated. 3. If Cadc >= Cdisc - that is, the sensor is connected, then Cadc is adjusted by a certain amount depending on the current fan power and the correction value for 100% power (see step 4 of the auto-setting algorithm): Cadc = Cadc + Kcurr, where Kcurr = K100 * (Pcurr / 100%). If Kcurr > 0, then the flag “ADC value adjusted (bit 7)” is set. The correction algorithm works only in operating mode and does not work in autoconfiguration mode. 4. The negative dynamics of Cadc are limited in order to suppress sharp decreases in C due to pulse load in the vehicle power circuits common with the temperature sensor: If C - Cadc > Cdelta, then Cadc = C - Cdelta. The limitation does not work during the first 15 seconds after turning on the ignition, so that the correct values Cm1, Cm2…Cm8 are quickly formed in the value buffer. 5. The power and dynamics corrected Cadc value is pushed into the value buffer for averaging as Cm1..Cm8 depending on the current value of the buffer head pointer (the buffer is cyclic, the head pointer takes values from 1 to 8).

Now about LED diagnostics:

The first byte is the “raw” ADC code (in earlier versions the average C value was displayed here). The second byte is the status word. There is a pause of about 1.5 seconds between the first and second bytes. There is a pause of 3-4 seconds between indication cycles. Bytes are displayed bit by bit, starting with the most significant (bit 7, bit 6,... bit 0). A long flash corresponds to a bit set to “1”, a short flash to “0”.

Explanation of the status word: Bit 7 - ADC value is adjusted according to the current fan power Bit 6 - temperature sensor is not connected Bit 5 - thresholds are set Bit 4 - threshold setting error Bit 3 - auto-configuration mode is active Bit 2 - internal processor reset due to freezing - abnormal situation Bit 1 - external signal to turn on the fan is active Bit 0 - purge mode when the engine stops is active

When I described the algorithm, I was surprised how it was possible to cram it into 1024 words of tiny15 program memory. However, with a creak, it fit! EMNIP, there were only a couple of dozen free cells left. That's the power of assembler

UPD: Many people ask for a link to download the code - here is a link to a page where you can click on Download and get the archive: https://code.google.com/archive/p/mc-based-radiator-cooling-fan-control- relay/source/default/source

Connection diagram

Knowing the electrical diagram for turning on the radiator fan, it will be easier to find problems in its electrical circuit.

The cooling fan has 2 inputs: the first input leads to the generator through fuse F5 and the connection busbars in the mounting block (2). The harness block (3), nicknamed the chip by drivers, connects the electric fan via a relay to the injection controller connected to the ignition relay. From the wire coming from the controller, a branch leads to an auxiliary relay with a fuse.

How to check the cooling fan?

If the cooling fan does not work, you will have to find the cause of its failure. First, let's check the temperature sensor using the method used on injection engines, to which the VAZ 2114 belongs. To do this, you need to start the engine and warm it up to the temperature at which it usually operates. Then you should remove the temperature sensor connector, thereby disconnecting it from the machine’s power supply. This is done so that the controller starts the fan in emergency, constant mode. If the drive starts working, this indicates a faulty temperature sensor (thermostat), while the relays, fuses, wires and the turntable itself are in working order.

If there is a problem with the electrical circuit of the cooling system, the fan will not start. There are several reasons why it does not turn on:

- Electric drive malfunctions;

- One or both fuses have blown;

- The cooling fan relay has failed;

- There is a break in the electrical wiring;

- The expansion tank plug is damaged.

Electric drive elements include an electric motor. This is the main fan assembly. It is checked by direct connection to the battery. If it does not work, you should check the motor brush mechanism, bearings, and contacts. These items can be replaced or repaired. If the problem is in the winding, then the entire motor, or even the fan itself, should be replaced. The drive belt often breaks and requires replacement. If it turns out that the motor and drive system are in order, we continue to check further.

Another element that affects the operation of the engine cooling system is the temperature sensor. If the sensor gives incorrect readings, this may cause the fan to turn on earlier or later. A delay in turning it on leads to overheating of the engine. One of the reasons may be that the sensor does not match the climate in which it is used. Then it is advisable to replace it.

Fan problems also include reverse rotation, when the blades drive air inward. This happens if the motor poles are connected in reverse. Video: the cooling radiator on a VAZ 2114 does not turn on - what to do?

Where is the sensor located and how does it work?

Fan switching sensors are located on the cooling system elements. The installation point is located in the path of the fluid flow supplied from the engine jacket to the radiator. This is due to the fact that the liquid in this line will have the highest temperature.

VAZ car sensor installed at the bottom of the radiator

Possible installation locations:

- thermostat housing outside the valve;

- cylinder head;

- lower radiator hose;

- side of the radiator.

On some vehicles, the sensor is combined with a coolant thermometer. The fans are turned on by the control unit based on temperature data. In this case, there is an additional sensor on the radiator that is used to operate the climate control or air conditioning. Triggering of any of the devices turns on both fans (on the engine and air conditioner radiators). A similar solution is found on Japanese cars.

On cars, two fan switching sensors can be used, located at the inlet and outlet of the radiator pipes. This scheme allows you to maintain the temperature in a narrow range.

Varieties

On cars, the following types of sensors are used to turn on the fan:

- bimetallic;

- waxy;

- thermistor;

- a sensor that operates on a circuit break or short circuit.

The first two types of sensors have an electromechanical operating circuit and can be of two varieties:

- single-speed, equipped with a single contact group that controls the fan in one temperature range;

- two-speed, equipped with a pair of contact groups configured to operate at different temperature ranges.

Regardless of the type, the sensors are a metal housing equipped with a thread. The body material used is non-ferrous metals based on copper (bronze or brass), which provide increased thermal conductivity. There is a hex key on the body that is used for installing the part. The wiring connector is located on the top of the sensor.

Bimetallic sensor

A bimetallic sensor contains a metal plate. In normal condition the contacts are open. As the plate heats up, it deforms and closes the circuit, supplying a control signal to the impeller motor turn-on relay. There are sensors that activate the fan motor directly without a relay. When the liquid cools, the plate returns to its original shape and the current supply to the motor stops.

The principle of operation of the sensor on a carburetor engine

Wax sensor

Sensors were produced for which wax or ceresite (or another substance with a significant coefficient of thermal expansion) was used as a working substance. As it warmed up, it expanded and shifted the metal membrane associated with the contacts. As it cooled, the volume of the wax decreased, and under the action of the spring the contacts opened.

What to do if the fan on the VAZ 2114 (2115,2113) does not work?

Overheating of the engine leads to serious problems: the pistons may jam, the cylinder block gasket may break, which leads to the need to overhaul the engine. To protect the power unit from overheating, it is important to maintain stable operation of the cooling fan. In this article we will discuss the operating principle of the device, its connection diagram, independent diagnostics and repair, as well as modernization of the control circuit. The instructions are fully suitable for VAZ 2115 and VAZ 2113 cars.

How to choose a new sensor

To select the right sensor, you need to know the optimal coolant temperature at which it should turn on and off. For a VAZ 2110 car this is 92 and 87 degrees. The optimal sensor response temperature for another car is indicated in the repair and operating instructions for the car. Buy a sensor only in large stores and be sure to take a receipt. Before installing the sensor on the vehicle, check it as described above. If the difference between the temperature indicated on the sensor body and the temperature at which it actually operates exceeds 5%, replace it. Operating the motor at a temperature different from the optimal one greatly reduces its service life.

Operating principle

A fan is a device that allows you to increase the efficiency of a cooling radiator. The radiator takes heat from the engine and releases it into the air. This process is accelerated by blowing through the blades of an electric fan.

The coolant flows through a closed, sealed system. Its task is to remove excess heat from overheated engine parts. Hot antifreeze flows into the radiator, is cooled here and returns back. While in the radiator, the coolant passes through a system of thin tubes. The incoming air flow while the car is moving helps to quickly remove excess heat from the engine compartment.

But when the car is stuck in traffic or idling, the air flow stops cooling it. In this case, the cooling system may not cope with its task. An electric radiator fan is designed to create air flow artificially. The temperature for turning on the fan on a VAZ 2114 is 85 degrees Celsius.

Having received a signal that the permissible temperature value has been exceeded, the sensor starts the device’s operating mechanism. An artificial air flow is created that removes heat from the radiator. The mechanism operates until the temperature level drops to an optimal state.

The thermal switch then receives a signal that the normal temperature has been reached and turns off the fan.

The device consists of four plastic blades that are mounted on the EDF shaft. A special controller regulates the automatic operating mode. The thermostat is equipped with a solid filler that is sensitive to temperature changes.

There are main and additional valves. When the temperature reaches 85 degrees Celsius, the main valve opens.

Where is the fan relay located?

It is located in an additional block.

4 – electric fan relay;

5 – electric fuel pump;

Relays and fuses may have a different order. Therefore, you need to focus on the color of the wires. The main relay is always located at the bottom. Find the relay that has a thin pink wire with a black stripe coming from it. It comes from the main relay through pin 85. Be careful! Do not confuse this with the red thin wire, which also has a black stripe and extends from the controller. And find a thick white wire with a black stripe (pin 87). This is where the cooling fan relay is located. There is always a fuse next to it. It is an element of the chain.

Cooling fan diagnostics

If signals appear on the dashboard indicating that the permissible temperature level in the cooling system has been exceeded, this may indicate that the fan on the VAZ 2114 is not working. The main symptom of the malfunction is that the mechanism does not start even with a significant increase in temperature. It is urgent to turn off the engine to prevent its elements from overheating.

The engine should not be operated with a faulty electric cooling fan. This may damage the cylinder head.

If the cooling fan on a VAZ 2114 does not work, the following malfunctions may be the cause of the breakdown:

- The fan switch sensor on a VAZ 2114 has failed.

- Lack of contact at the sensor connector.

- The wiring has broken.

- Electric fan relay faulty.

- The fuse has blown.

- Damage to the device's electric motor drive.

Unplug the device. Connect it to the battery terminal. Maintaining polarity. If a direct connection to an energy source starts the electric motor, then the drive is working. There may be problems with the wiring, the fuse, or the temperature sensor.

Semiconductor Applications

Instead of an electromagnetic relay, you can use a thyristor switch, or a design based on field-effect transistors. The essence is the same, only there are no moving contacts; their functions are performed by electrons and holes in the semiconductor crystal. But do not forget about cooling the thyristors and transistors, install radiators that will be able to provide the necessary heat transfer.

Soft engine start is a very useful function for engine control. This innovation will ensure a gradual increase in the load on the electric motor. This idea is accomplished by using PWM modulation. But along with all the innovations, you can use a second temperature sensor in the cooling system, whose response temperature is 5 degrees lower than the main one.

If, when the main sensor is triggered, the fan turns on at full power, then when the second sensor is triggered, its speed should be half as much. To do this, you will have to use a resistor when connecting. The one installed on the stove fan is perfect. This will prevent the temperature in the system from reaching extreme values.

This solution allows you to get rid of frequent switching on of the cooling fan , there are no voltage drops (although I didn’t have any due to a good generator and an automatic LV at 14.5V), and the idle speed does not drop when the fan is turned on. And there is no vibration in the body with the original 4-blade fan. The normal operation of the cooling fan remained in place.

The cooling fan now turns on at half power at a temperature of 92 degrees, and the maximum speed will be when it reaches 96 degrees.

This is what happened:

For this we needed the following components:

1…

Tee for a cooling sensor from a gazelle, costing 150 rubles.

Sawed by a Bulgarian's wife and rolled with a hammer and filed. 2... DTOZH from the classics 92/87 degrees. 100 rubles. 3... 2 clamps for the pipe. What size - I don't know. Just fit this pipe and that’s it... 4... 4-pin relay for 70 A + connector. Cost 160 rubles with chip. 5... 30 A remote fuse. I installed a 30 pin relay in the power circuit. 6... Crimping chips + crimping (can be done with narrow pliers) and heat shrinking. 7... Miscellaneous wires 4 meters. 8... Mom/Dad chips for the fan, because I didn’t want to cut the insulation. The “original” fan chip is disconnected, our purchased one is connected to each other, the positive contact is isolated, and the negative contact is used to connect the signal from the relay to it. 9... Resistance from a classic stove is 1.5 ohms.

You can put a resistance of 2-2.5 Ohms, but I couldn’t find the resistance from the UAZ stove in my city. So we are content with what we have. The fan is supplied with 6.6 V according to the tester. The lower radiator pipe is cut if your radiator is a new model without a plug for the DTOZH. Place the tee so that the sensor contacts are at 90 degrees, and not as in my photo (I almost missed this point, the stove body does not sit properly). But this will be corrected when replacing the coolant. If you have an old-style radiator, or a Luzarovsky universal one, then you do not need to cut the pipe. These radiators have a plug for the DTOZH.

How to make a replacement

If you are convinced that the cause of the malfunction lies in the fan motor, then the easiest way to carry out repairs is to completely replace the device. In this case, there is no point in spending money on a new casing. It will be cheaper to just buy a new electric motor.

Necessary tool

No special tool is needed. The work is carried out simply using 8 and 10 socket wrenches and a Phillips screwdriver.

Step-by-step algorithm of work

You can replace the cooling fan motor without removing the radiator.

- Disconnect the connector and device wiring harness from the casing.

- Unscrew the mounting bolts using a 10mm wrench.

- Unscrew the lower fastening nut.

- Using a 10 mm socket wrench, unscrew the mounting nut from the radiator.

- Using a size 8 socket wrench, unscrew the two pressure plate nuts.

- Remove the plate.

- Remove the electric fan along with the casing.

- Let's start dismantling the electric motor. Using a 10 mm wrench, unscrew the three mounting nuts and remove the engine along with the blades.

- Using a screwdriver, pry up the lock washer.

- And take it off.

- Remove the impeller.

- Put the impeller on the new motor. Make sure that the shaft pin fits into the impeller groove.

- Reassemble in reverse order.