A modern car is literally crammed with complex electronics, which are not so easy to repair. It is for this reason that car owners, at the slightest problem with on-board electrical devices, do not fool themselves, but immediately contact the nearest car service center. However, there are exceptions to this rule. For example, if the diode bridge on a VAZ 2107 is burnt out, then you can completely refrain from visiting a car service center and replace the burnt-out device yourself. Let's figure out how this is done.

- Signs and causes of diode bridge failure

- How to ring a diode bridge on a VAZ 2107

We check the diode bridge with a regular light bulb

- Checking the diode bridge for open circuit

- Checking the diode bridge with a household multimeter

- Sequencing

Examination

It happens that the generator begins to act up ahead of schedule and the battery does not charge properly.

Actually, it serves to ensure the operation of the source of electricity to power all cars - the battery. We advise you to rely not only on our instructions, but also on video lessons that will allow you to carry out repairs and replacements with your own hands, even without much experience.

Troubleshooting

The first step is to determine whether your generator is actually the source of the problem. To check, you need to carry out a series of sequential activities.

- Start the engine and let it warm up to operating temperature.

- Increase the crankshaft speed to approximately 3 thousand rpm.

- Turn on all the headlights, activate the high beams, start the heater, emergency lights, heated glass, and wiper blades. That is, all electricity consumers should be turned on as much as possible.

- Measure the voltage on the battery.

- If the device shows less than 13V, then a short circuit or break has most likely occurred in the generator windings.

- Another option is a breakdown of the voltage regulator, oxidation of the contacts of the excitation winding ring.

You can check for breaks and the condition of other elements of the generator only by dismantling it. But if you don’t have any experience in disassembling a generator, then you shouldn’t try to go there with your own hands. Replace the entire assembly or entrust the repair to professionals.

The most important thing is to understand that the generator, like all components of the car, must be monitored and serviced in a timely manner. Change brushes in a timely manner, do not allow large amounts of dust and dirt to get in, not to mention water. Ensure that the alternator V-belt is properly tensioned so that it is neither loose nor overtightened.

It is recommended to check the technical condition of the generator every 15,000 km. mileage Typically, with proper care of the generator, it can last up to 160,000 km. mileage and repairing the generator with your own hands is simply not necessary, you just replace it and that’s it.

Replacing the roller and brushes

If you hear a rustling noise coming from the tension roller of the Lada Kalina generator belt, then you need to check its serviceability and replace it.

To perform this procedure, you need to use a set of wrenches and a flat-blade screwdriver. Replacing the roller is a very simple procedure. To perform this, you must first loosen the belt tension by unscrewing the rod. Then use a flat-head screwdriver to pry off the protective cap of the roller and unscrew the bolt securing the bearing to the bracket.

The bushing and washer are removed from the old roller, then they are installed on the new roller. The entire assembly assembly is placed in place of the old roller and secured with a bolt. Next, the belt is properly tensioned and the car engine is started to check how the new roller works. After replacing the roller, no extraneous noise should be heard from the Lada generator.

One of the reasons that the battery does not charge well is wear on the generator brushes. To eliminate this malfunction, it is not necessary to replace the entire generator; it is enough to change only the brushes. To check their condition, the brushes must be removed and inspected. This can be done both with the generator installed and with it removed.

To avoid a short circuit when performing this procedure, it is necessary to remove the negative terminal of the battery. After this, remove the protective cover of the device and remove the power plug using a flat-head screwdriver. In this case, you need to make sure that the solder does not come off from the voltage regulator.

Diagnostics

To check, the generator does not need to be removed. The test is carried out using a tester. You can use a cheap Chinese tester. The two probes of the measuring device need to be connected to the battery terminals and the voltage checked.

Analysis of voltage values makes it possible to judge the health of the generator set. What voltage the generator device produces can be found in the manual.

Unit location

Signs of device malfunction:

- The charging indicator light is constantly on or flashes when the engine is running;

- the battery either does not discharge completely or receives an increased charge;

- The headlights do not shine well enough when the engine is running, poor performance of other electricity consumers;

- the headlights are too bright, the electrolyte in the battery boils;

- heats up at high voltage;

- increased noise during engine operation from the generator side.

There may be problems in the brush assembly, which may be due to a malfunction of the brushes, their size, or problems with the three-level regulator. It is impossible to check the size and serviceability of the brushes without removing the generator. But you can change the brushes.

Signs of worn brushes:

- no battery charging;

- Voltage jumps when charging;

- The on-board voltage in the network is below normal.

If the brushes are less than 0.5 cm long, that is, they do not correspond to the required size, they need to be replaced. The condition of the brushes is checked to see how the brushes move in the grooves. After replacing the brushes, the generator restores its operation after a few minutes when the slip rings and brushes grind in.

Three-level voltage regulator

The three-level regulator should be checked along with the brush holders. If the regulator is working properly, the voltage should be 14.7 V. If the voltage is less than 13 V, the regulator must be replaced with a new one, since it maintains the required voltage for devices in the on-board network. If the regulator is faulty, the installation heats up. The procedure for replacing the three-level regulator is similar to replacing the brushes, since the devices are removed together.

Problems are possible not only with the cheeks, but also with the diode bridge.

Signs of a diode bridge malfunction:

- There is no charging at all;

- charging significantly exceeds the permissible values.

Repairing a diode bridge by replacing its spare parts is problematic. Therefore, the problem can be solved by replacing the diode bridge with a new one. When replacing the diode bridge, install the contact bolt, install the leads of the stator windings, and install the brush assembly. After installing the protective casing, the diode bridge is mounted, the power supply is connected and the drive belt is put on the pulley. After installing the belt on the pulley, check the tension of the drive belt.

Removal and installation with a detailed description of all actions

First, before doing all this, you need to remove the generator from your Kalina, as well as the voltage regulator along with the brushes. How this is done is described in the same section; below in the list of recommended topics there are links to these materials, or just go to the “Generator” section and you will find everything there.

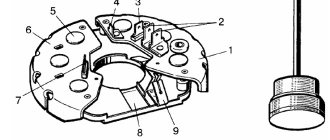

Now that you have already done everything described above, unscrew the upper nut with a 13 mm wrench (it presses the voltage regulator), and then the lower nut securing the bridge:

After this, you need to unscrew all three bolts of the rectifier unit, clearly shown in the picture below:

Now you need to disconnect the windings from the diode contacts with wires. To do this, take a thin screwdriver and insert it into the place as shown below, and turn it a little in that direction to spread the clamp and remove the winding wires.

To release the wire from the left clamp, slightly turn the screwdriver to the left, and to remove the right one, bend the clamps in the opposite direction. And at this time we pull the wire with our hand, disconnecting it from the contacts of the diode bridge:

Then, when all 6 wires are removed from the clamps, you can safely remove the rectifier unit:

If necessary, we replace this part of the generator and install a new block with diodes in its original place, doing everything in the reverse order.

Generator burnout or what is a diode bridge

When they talk about the generator burning out, they mean the diode bridge. It is a mandatory component of the generator.

Diagnosing a car with a burnt-out gene can be done easily. But repairs will require some effort and specific knowledge. It will be necessary to carefully study the design of the generator in order to be able to disassemble it, thereby getting to the diodes.

How to check the diode bridge? First of all, check the readings with the values on the dashboard. There is an icon that resembles a battery. After starting the engine, this icon should go out. Thus, the motorist is informed that the power supply to the main electrical components of the car has been switched from the battery to the generator.

But if the icon does not go out, then this is a cause for concern. The system gives a signal that a breakdown has occurred in the circuit. The reason still needs to be clarified more specifically, because this may also indicate a weak or damaged battery.

The main marks confirming damage to the diode bridge are the following:

- leakage current;

- fast and frequent battery discharge;

- small spark on spark plugs;

- reduction in cooling fan power;

- unstable operation of the air conditioner;

- interruptions in the functioning of the sound system;

- poor lighting of the optics while the engine is running.

Read also: How to connect a receiver for digital television

By looking at the headlights, many experienced motorists will immediately determine the faulty gene, without confusing it with battery problems. If the headlights shine dimly when the engine is off, the battery is to blame; if when the engine is running, it’s the generator.

If the diodes burn out, don't panic. It is better to find out the reason why this happens. Below we will describe instructions that imply autonomous diagnostics of DM.

The generator will need to be disassembled to gain access to the diode bridge.

- the current at the gene outputs is checked (it should not be lower than 13.5 V);

- At the same time, you need to check the instrument readings to see if the indicator continues to light after starting the internal combustion engine (provided that the gene is connected to the car);

- check the diode bridge with a voltmeter (if the meter needle moves into the red zone, the diodes are definitely faulty).

However, these signs, even if they are identified in their entirety, cannot yet prove 100% failure of the diode bridge, since similar symptoms indicate a breakdown of the chocolate bar (regulator).

Experts advise using the exclusion method in this case. That is, check the voltage regulator. If it is working properly, there is definitely a problem with the bridge.

The diode bridge is professionally tested with a multimeter. The device must be set to sound indication mode. If the multimeter does not have this ability, then you will have to measure in 1-kOhm mode.

It is noteworthy that individual measurements are carried out for diodes. In particular, the ends of the diodes should be touched with the probe of the measuring device several times, changing the terminals of the device each time. In one of the cases, the test should show BRS (infinity resistance), in the other - Ohm fluctuations in the range of 500-700.

A diode can be considered damaged if the readings are the same when measured in different directions.

Diodes are also checked using an indicator. This is done like this:

- gene protection is dismantled;

- The DM plate is connected to the negative terminal of the battery;

- The indicator is connected at one end to the positive terminal of the battery, and at the other end it is checked.

If, after touching the second end of the indicator to the diodes, the light bulb lights up, then the element is damaged.

How to check the health of the generator

Generator type 94.3701 alternating current, three-phase, with built-in rectifier unit and electronic voltage regulator, right rotation (drive side).

The generator connection diagram is shown in Figure 1.

The voltage to excite the generator when the ignition is turned on is supplied to terminal “D+” of the regulator (terminal “D” of the generator) through indicator lamp 4 located in the instrument cluster.

After starting the engine, the excitation winding is powered by three additional diodes installed on the generator rectifier block. The “W” output of the generator is not used on vehicles of the VAZ-2115 family.

The operation of the generator is controlled by a warning lamp in the instrument cluster.

When the ignition is turned on, the lamp should be on, and after starting the engine, it should go out if the generator is working.

A brightly burning lamp or glowing at full intensity indicates a malfunction.

The “minus” of the battery should always be connected to ground, and the “plus” should always be connected to the “B+” terminal of the generator.

Failure to turn the battery back on will immediately cause increased current through the generator valves and damage them.

It is not allowed to operate the generator with the battery disconnected. This will cause short-term overvoltages to occur at the “B+” terminal of the generator, which can damage the generator voltage regulator and electronic devices in the vehicle’s on-board network.

It is prohibited to check the functionality of the generator “for spark” even by briefly connecting the “B+” terminal of the generator to ground. In this case, significant current flows through the valves and they are damaged.

The generator can only be checked using an ammeter and voltmeter.

The generator valves are not allowed to be checked with a voltage of more than 12 V or with a megger, since it has a voltage too high for the valves, and they will be broken during testing (a short circuit will occur).

It is prohibited to check the vehicle's electrical wiring with a megger or a lamp powered by a voltage of more than 12 V. If such a check is necessary, you must first disconnect the wires from the generator.

The insulation resistance of the generator stator winding with increased voltage should be checked only on a stand and always with the terminals of the phase windings disconnected from the valves.

When electrically welding components and parts of the car body, you should disconnect the wires from all terminals of the generator and battery.

Rotor and stator repair

First of all, you will need to examine the stator and rotor windings for breaks. To do this, you do not need to remove the generator from the car. It will be necessary to dismantle only its diode bridge. This will require a two- or three-jaw puller, as well as an artificial frame borrowed from a cup puller.

Replacing unit parts

Carefully straighten the wires in the winding and remove the diode bridge. To avoid getting confused during reassembly, you need to mark with a marker the placement points of the front and rear casing of the generator. Using a size 8 socket wrench, unscrew the 4 bolts that hold both trims in place. Carefully remove the front trim using a flathead screwdriver. After this, slide the rear casing and remove the connecting bolt along with the insulating washer, as well as the plastic plug from the bearing.

To check you will need an ohmmeter tester. Having connected its plugs to the rotor rings, check the winding for breaks. In this case, the winding resistance should be 5-10 Ohms. After this, connect the tester plugs to any of the slip rings and to the rotor. Now you need to check the winding for short breaks to ground. If the winding has no breaks and is working correctly, the tester will show the highest resistance value.

In the same way, it is necessary to connect the plugs to the stator and check the winding for breaks. If they are absent and the part is working properly, the tester will show extremely low electrical resistance. When checking for short-term ground breaks, the tester should also show the highest electrical resistance value.

To ensure proper operation of the rectifier unit, its diodes must transmit electric current in only one direction. If they conduct electricity in 2 directions or do not conduct it at all, then the diodes have become unusable and need to be replaced.

Attach the tester plug with a negative value to the diode itself, and the plug with a positive value to the part body or plate in which it is located. A functioning diode will not conduct electric current, and the tester will show the highest resistance value. After this, you will need to swap the plugs and perform the test again. If the diode is working correctly, the tester will show electrical resistance. In the same way, it is necessary to test the remaining diodes in the diode bridge circuit.

Checking with an indicator screwdriver

This is the simplest test option, which will give a general idea of the state of the diode bridge and the entire circuit as a whole.

To operate, you only need an indicator, the entire procedure is performed under voltage, so extreme caution should be used:. Touch the tip of the screwdriver to each AC voltage terminal of the diode bridge in turn.

If the light does not light, this indicates a fault in the circuit up to the diode bridge - a broken winding, a broken charger, etc. If the light is on, then voltage is supplied to the bridge normally.

Touch the tip of the screwdriver to each AC voltage terminal of the diode bridge in turn. If the light does not light, this indicates a fault in the circuit up to the diode bridge - a broken winding, a broken charger, etc. If the light is on, then voltage is supplied to the bridge normally.

Rice. 2. Testing with an indicator screwdriver

- Also touch the positive terminal with a screwdriver - if the light comes on, then the diode bridge normally passes positive half-cycles, respectively, there is potential at this pin. If it does not light, there is damage to the diode bridge.

- Repeat the same procedure with the negative terminal. Be sure to divide the test into both terminals of the rectifier unit, since a fault may be present in any diode and in any branch.

As you can see, in this example an insulated blade screwdriver was used. This is due to the need to perform work under voltage, when you can cover different parts of the electrical installation with a metal part, which will entail extremely unpleasant consequences. A significant disadvantage of the method is its low information content and the limitation on the operating voltage - since the indicator is designed for a nominal value of 220 V, it cannot be used for low-voltage circuits.

Device

The Lada Kalina generator consists of the following parts:

- housing (front and back cover);

- pulley;

- stator windings;

- armatures (rotor);

- voltage regulator relay (charging relay);

- diode bridge (rectifier unit);

- two armature bearings;

- rear plastic casing.

Inside the generator housing, along its walls there is a stator with a winding, and a rotor is located in the center.

At the back of the case there is a diode bridge and a voltage regulator relay; the diode bridge is covered with a plastic casing to prevent dirt and dust from entering.

There is a pulley in front of the housing; it is put on the rotor shaft and secured with a nut.

The generator is driven by a drive belt placed on a pulley.

Why is the battery not charging?

Before writing about the main reasons why the battery may not charge on VAZ 2109-2108 cars, I would like to warn all readers that the list I have given is not complete and is compiled only based on personal operating experience. So, during my short 10 years of driving experience, I had to operate a lot of cars and there were quite a lot of problems with charging the battery, and I will try to write about the main ones here.

It's no secret that the main device that is responsible for the normal operation of electrical appliances in a car is the generator. It is precisely because of the failure of some of its parts that charging may disappear completely or become weak. The main malfunctions of the generator, which entail a decrease in the charge current to the battery:

- Wear of generator brushes. This is a very common and most common reason. If they are worn down to the minimum permissible height, then the charge may disappear gradually, and then disappear altogether. To solve this problem, you just need to replace the brushes with new ones and that’s it.

- Failure of the diode bridge. The most reliable diode bridges are usually installed on VAZ 2109-2108 cars from the factory. And they are the ones who travel the most kilometers! This has already been tested not only by me, and any experienced auto electrician will confirm this. If one of the diodes or the entire rectifier unit burns out, then it also needs to be replaced. The procedure is not very fast and pleasant, but it will not cause much difficulty. Just below I’ll put a link to a page that describes the entire generator repair process.

- A more complex generator breakdown, such as a break in the rotor or stator winding. Of course, this is rare, but it still happens sometimes. The cost of these spare parts is quite low, so it is better to buy new ones and install the burned ones together than to buy a new generator.

- Poor charging may be due to slipping of the alternator belt. This becomes especially noticeable in damp or rainy weather, or when water gets on the belt. It begins to whistle, causing it to slip on the pulley, thereby preventing the generator from gaining sufficient speed to optimally charge the battery.

If you have problems with your car that are described above, then you can read all the maintenance procedures here: Repairing a generator on a VAZ 2109-2108 with your own hands. Everything is described there in quite detail and even for beginners the information will be very useful, and understanding it will not be difficult.

Causes of breakdowns

Common causes of generator malfunctions are simple wear and corrosion. Almost all mechanical failures, be it worn brushes or collapsed bearings, are a consequence of long-term use. Modern generators are equipped with sealed (maintenance-free) bearings, which simply must be replaced after a certain period or mileage of the vehicle. The same applies to the electrical part - often the entire components must be replaced.

Also reasons may be:

- low quality components;

- violation of operating rules or operation outside normal operating conditions;

- external factors (salt, liquids, high temperature, road chemicals, dirt).

Removing the generator on the “eight”

To dismantle the unit for replacement or repair, you will need “17” keys and a mounting blade. Before starting work, be sure to generously treat all threaded connections to facilitate dismantling. The procedure looks like this:

- Disconnect the negative terminal from the battery.

- Unscrew the top nut securing the generator housing to the bracket.

- Unscrew the nut on the lower mounting bolt.

- Slide the generator housing towards the engine block and remove the belt.

- Unscrew the nut from the power contact and move the wires to the side.

- Remove the lower mounting bolt.

After all these manipulations, you can completely dismantle the unit. This can be done either from below, if protection is not installed on the car, or from above.

Checking for serviceability

Repair of the VAZ 2109 or VAZ 21099 generator is carried out in case of failures in the operation of the unit. There are several ways to determine generator malfunctions. The most optimal of these is diagnostics using a multimeter, but you will also need an assistant to carry it out. We will tell you further about how to check the generator on a VAZ 21099 or 2109 using a tester.

So, to determine generator faults with a multimeter, follow these steps:

- First of all, it is necessary to diagnose the VAZ voltage regulator. As practice shows, if the generator on a VAZ 2109 or VAZ 21099 does not work correctly, the problem may lie in the functionality of the three-level voltage regulator. This is especially facilitated by overvoltage in the electrical circuit. To check, you need to set the voltage measurement mode on the tester. So, start the engine and measure the voltage at the battery terminals or at the terminals of the generator unit itself. If everything is normal, then this parameter will fluctuate around 14-14.2 volts. Then press the gas and check the parameter again - it should increase, but no more than 0.5 volts. If the indicators on a VAZ 2109 carburetor or VAZ 21099 injector are different, this indicates that the element is not functioning correctly. Most likely, the VAZ 2109 voltage relay will have to be replaced.

- Next, the diode bridge of the generator is diagnosed. The bridge itself consists of six elements, three of which are considered positive and the remaining three are considered negative. Some diodes have mass at the anode, and the other part at the cathode. To check the diode bridge of the VAZ generator, the tester is switched to sound mode, that is, when the probe outputs are shorted, you can hear a characteristic sound. You are required to test each diode in different directions, and the sound should be heard in only one of them. If during testing the sound is heard in both directions, this indicates that the diode is broken. The best option would be to replace the diode bridge.

- Before disassembling the unit and repairing it, check the functionality of the stator; it is a steel cylinder, inside of which the winding of the mechanism is located. For diagnostics, you need to disconnect the stator leads from the diode bridge. First, inspect the element visually - there should be no signs of damage or burning. The multimeter is set to resistance measurement mode. First, measure the resistance parameter between the winding terminal and the housing (any terminal can be used). The obtained indicators should be high and tend to infinity. If the readings are 50 kOhm, this indicates the need to replace the generator.

- Using a multimeter, you can also check the performance of the rotor - it is a steel rod with a wound winding. At one end of the rod there are rings through which the brushes of the VAZ generator pass. You need to dismantle the rotor and visually inspect the condition of the generator winding and bearing. The integrity of the winding can be checked using a multimeter, after which the resistance parameter between the rings is measured. The results obtained should be no more than a few ohms. Replacing the VAZ 2109 generator brushes is required if they are worn out.

Node diagnostics with a tester

Common battery problems:

- short circuit of battery electrodes/plates;

- mechanical or chemical damage to the battery plates;

- violation of the tightness of battery cans - cracks in the battery case as a result of impacts or improper installation;

- chemical oxidation of the battery terminals. The main causes of these malfunctions are:

- gross violations of operating rules;

- expiration of the product's service life;

- various manufacturing defects.

It is very useful for a motorist to know the main causes of generator malfunctions , how to eliminate them, as well as preventive measures to prevent breakdowns.

All generators are divided into alternating and direct current generators. Modern passenger vehicles are equipped with alternating current generators with a built-in diode bridge (rectifier). The latter is necessary to convert current into direct current, on which the vehicle's electrical consumers operate. The rectifier, as a rule, is located in the cover or housing of the generator and is integral with the latter.

All electrical appliances of the car are designed for a strictly defined operating voltage range. As a rule, operating voltages are in the range of 13.8–14.8 V. Due to the fact that the generator is “tied” with a belt to the engine crankshaft, it will work differently . It is for smoothing and regulating the output current that the relay-voltage regulator is designed, playing the role of a stabilizer and preventing both surges and dips in the operating voltage. Modern generators are equipped with built-in integrated voltage regulators, colloquially referred to as “chocolate” or “tablet”.

It is already clear that any generator is a rather complex unit, extremely important for any car.

No charging VAZ 2109

>When driving a car, you should always pay attention to whether the battery is charging. The VAZ 2109 battery is needed only to start the engine

While the engine is running, all electrical appliances of the VAZ 2109 operate from. Naturally, if the generator stops working, the battery doesn’t last long. How can you tell if the battery has stopped charging? There is a standard voltmeter on the instrument panel. According to its readings, it is very clear whether the generator is working or not. When the VAZ 2109 engine is running, the voltmeter should show a voltage of about 13.5 - 14 V. If you notice that the arrow is always tilted to the right, that is, the on-board voltage is less than 12V, then there is no charging from the generator. It is also very convenient to monitor the voltage of the on-board network of the VAZ 2109 using a digital tachometer. It measures the voltage from the generator with an accuracy of tenths of a volt.

Generator VAZ 2109

I recently had the following situation: I was driving and I saw that the voltage on the instrument panel voltmeter was about 11 Volts. Clearly, there's something wrong with the generator. Well, as usual, there is no time to repair it, it’s dark and cold outside, there is no garage. Well, as always, you need to drive a car every day, you can’t do without it. Therefore, at night every day I put the battery on charge, and in the morning I put the fully charged battery in the car and drove. If you drive only during daylight hours, that is, without headlights, then the battery may last for several days. If, as I did, you have to drive to work in the dark in the morning, then in the evening the battery will run out completely. Of course, it all depends on how often you turn off and start the engine. A lot of battery energy is wasted just for rotating the starter, you can also try to drive without it, then the battery is needed only for the operation of the ignition system and light signaling (stops, turns). Until recently, I believed that no matter how dead the battery was, the VAZ 2109 could always be started from the pushrod. It turned out that this was not true. There is a certain degree of discharge when the starter no longer has enough strength to turn the crankshaft, but it is enough. I pushed it, put it in gear, started up and everything was fine. However, if the battery is completely dead, it does not even have enough power to form a spark. , don’t push, the VAZ 2109 won’t start until you recharge the battery. But still, what to do if the VAZ 2109 battery has lost charging? Of course, not every one of us is an electrician and can check the generator with all its diodes, stabilizers and collectors. The very first thing to do if the VAZ 2109 generator stops working is to check the generator brushes. It’s easy to understand that the VAZ 2109’s brushes are faulty or worn out. Turn on the ignition and look at the instrument panel.

Checking the serviceability of the VAZ 2109 generator brushes

If the brushes are faulty, then the battery charging lamp will not light up when the engine is not running. Or it will glow very dimly. After you start the engine, the light will continue to glow dimly. The dim glow is visible only in the dark; it cannot be seen during daylight hours. If the brushes are in good working order, then when the engine is not running, the battery charging lamp lights up brightly; if it is started, it immediately goes out. It should be noted right away that the VAZ 2109 produced before 1993 has old-style brushes. On the new VAZ 2109, brushes of a new type are installed, immediately with a voltage stabilizer. However, there are both new and old samples of VAZ 2109 brushes on sale. The cost of VAZ 2109 generator brushes is about $3-5. Replacing the VAZ 2109 generator brushes is very simple, the sequence is as follows: 1. Remove the ground from the battery

Removing the mass of the VAZ 2109

2. Disconnect the chip from the generator brush housing and remove the wires from the central stud of the generator.

Disconnect the wires from the VAZ 2109 generator

Wires pulled back

3. Now unscrew the two bolts securing the brushes to the VAZ 2109 generator housing. And slowly remove the brushes from the generator housing.

We unscrew the bolts securing the generator brushes of the VAZ 2109

4. If you want the new brushes to last a long time, you need to clean the generator commutator. To do this, loosen the nut on the generator mounting bracket, loosen the belt and remove it. We take fine sandpaper, press it against the commutator, and we ourselves rotate the generator using the drive wheel. In this way, graphite deposits from previous brushes are removed from the commutator. And the wear of the new brushes will be long. 5. Now we insert new brushes into the housing of the VAZ 2109 generator and clamp them.

Generator brushes VAZ 2109

6. We put back all the chips and wires of the VAZ 2109 generator.

VAZ 2109 generator brushes replaced

We check the functionality of the generator as indicated above.